Continuous tea twisting machine

A kneading machine and tea technology, which is applied in tea treatment before extraction, etc., can solve the problems that a single leaf cannot be fully kneaded, insufficient kneading, short tea kneading time, etc., and achieves simple structure, uniform kneading quality, The effect of continuous kneading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

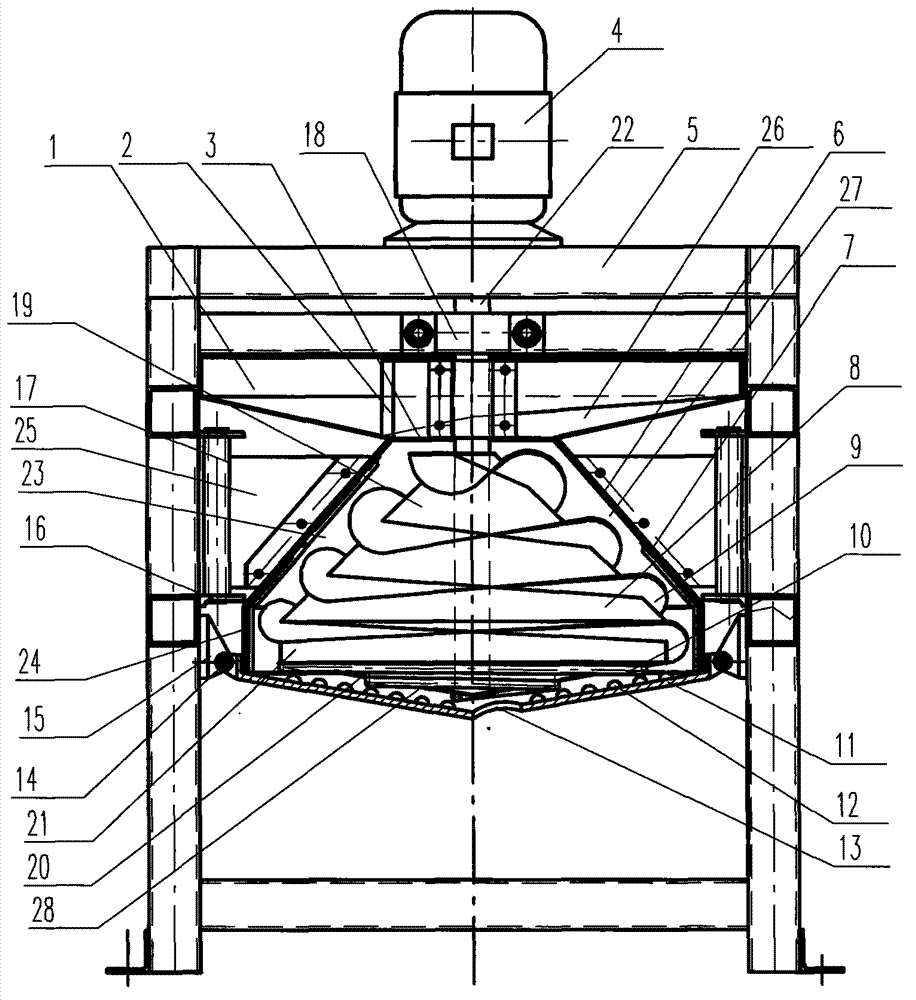

[0021] refer to figure 1 , a continuous rolling machine for tea, comprising a frame 5, a rolling device and a transmission mechanism 4, the rolling device comprising a feed hopper 1, a sweeper 2, a shell 6, a rolling core 8 and a kneading disc 11, the feeding hopper 1 and the sweeper 2 are located above the kneading core 8, the kneading core 8 is installed in the space formed by the shell 6 and the kneading disc 11, the kneading disc 11 is located below the kneading core 8, the discharge port 13 is located at the bottom of the kneading disc 11, and the output The center of the mouth deviates from the center of the kneading pan;

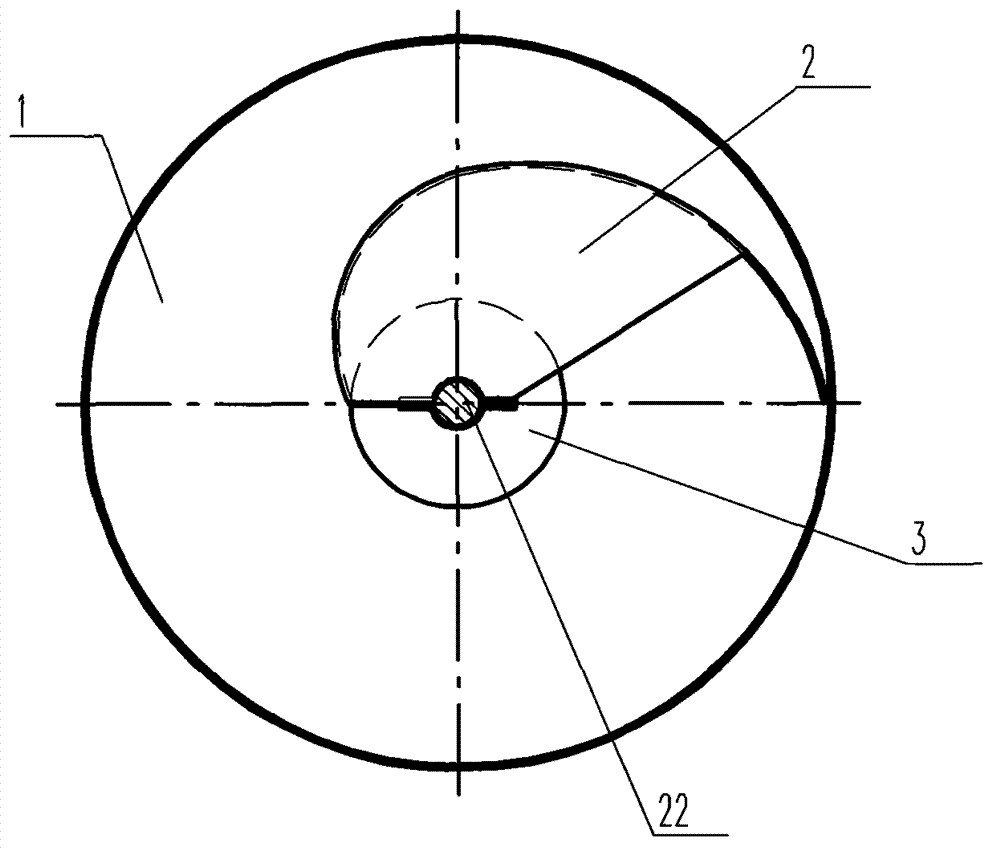

[0022] refer to figure 2 , the sweeper 2 is installed in the feed hopper 1, fixed on the transmission shaft 22, the feed port 3 is at the bottom of the feed hopper 1,

[0023] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com