Preparation method of in situ double-tilt electronic microscope sample rod

A technology of electron microscope samples and sample rods, which is applied in the direction of circuits, discharge tubes, electrical components, etc., can solve the problems of expensive, difficult to modify, and immature products, etc., and achieve low manufacturing costs, mature equipment, and fill the gaps in the market Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

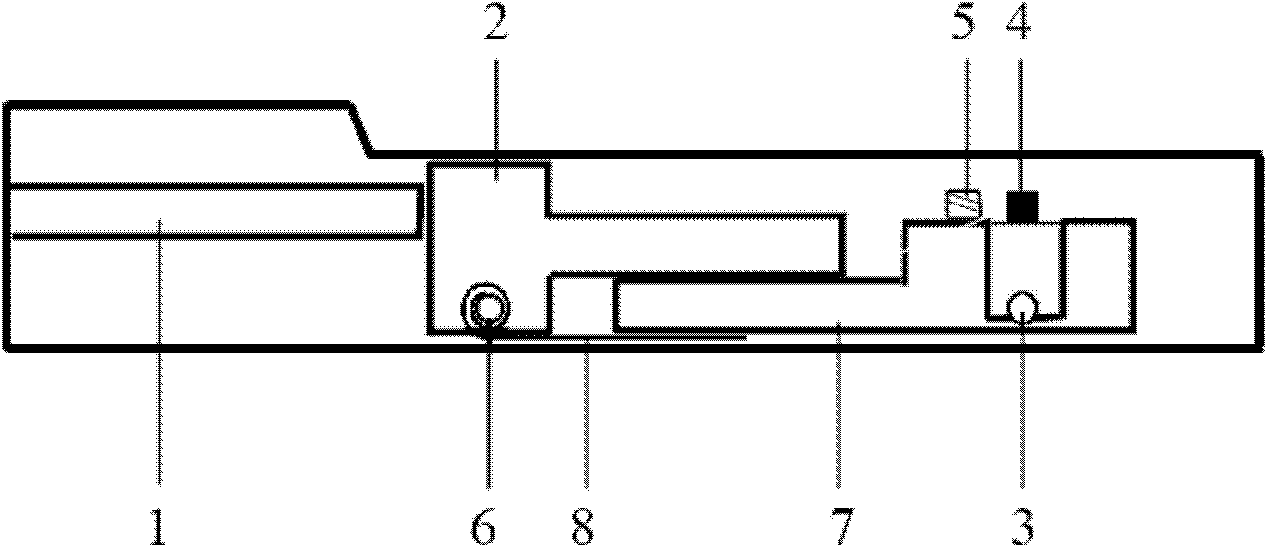

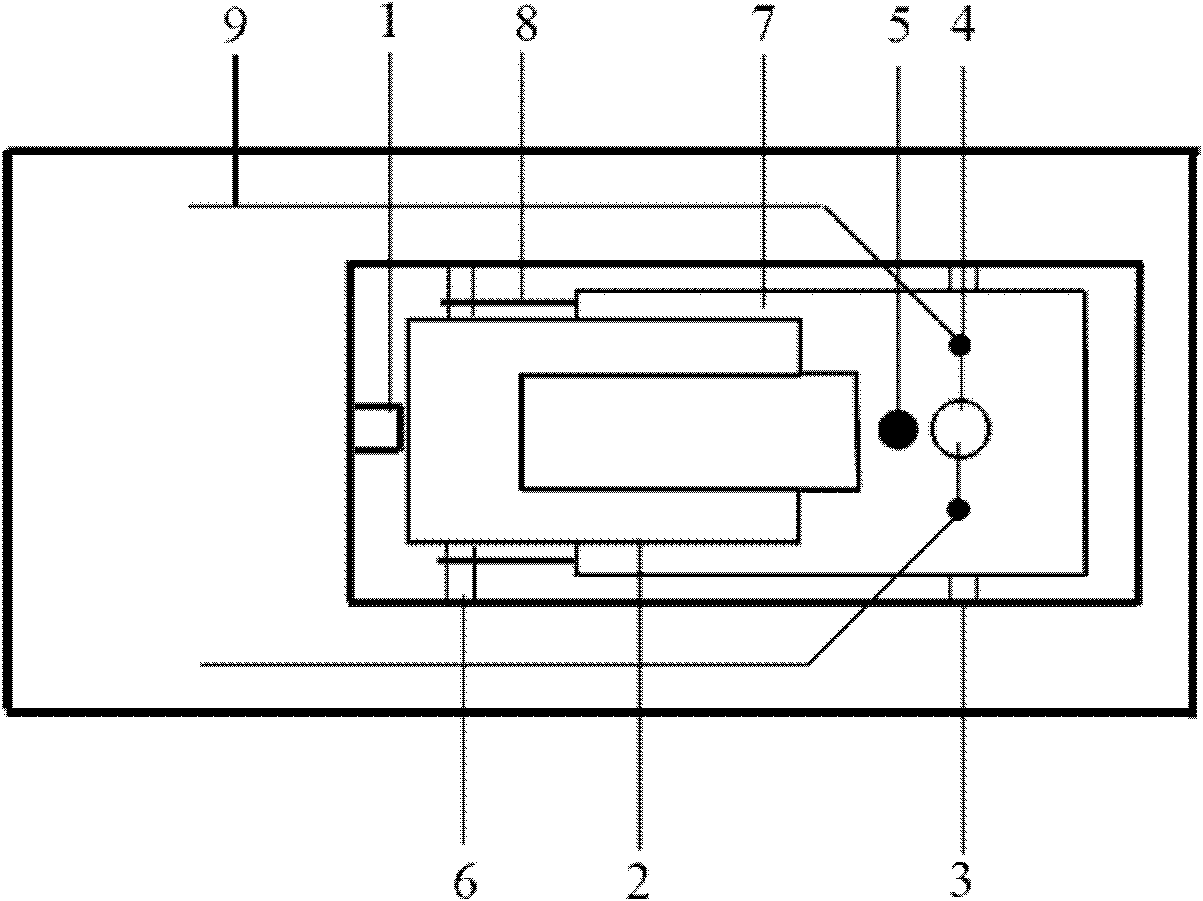

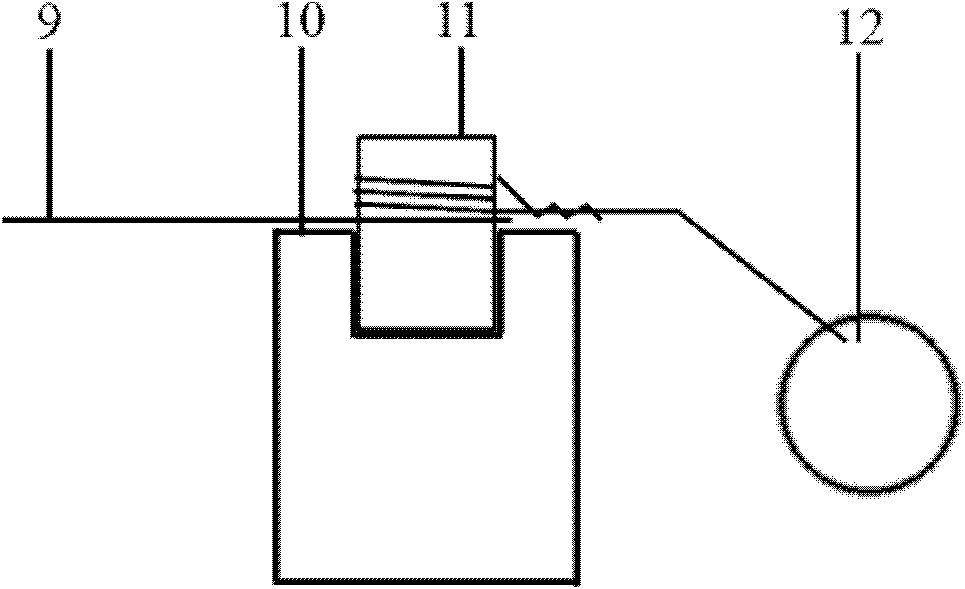

[0014] The process steps of this embodiment include in-situ double-tilt sample rod design, electric field component installation and optical fiber access, wherein the in-situ double-tilt sample rod design is based on the existing single-tilt electron microscope sample rod, and the hollow copper of the sample rod Open up three independent sealing passages in the rod, which are respectively assigned to the horizontal transmission rod 1, the wire 9 and the optical fiber, and respectively seal the horizontal transmission rod 1 with a special sealing ring for transmission electron microscopy, and seal the optical fiber and the wire 9 with epoxy resin. The side view and top view of the front end of the in-situ double-tilt sample rod are shown in Fig. figure 1 and figure 2 As shown; the X-axis tilt of the sample rod is realized by the goniometer of the electron microscope itself; the Y-axis tilt drives the horizontal transmission rod 1 to move in the horizontal direction through a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com