Nut rotating ball screw pair transmission unit

A ball screw pair and nut rotation technology, which is applied in the field of ball screws, can solve the problems of high noise in the transmission process, difficulty in installing the rack, and the length of the screw can not be too long, so as to ensure positioning accuracy, simple and compact structure, and design The effect of novel ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

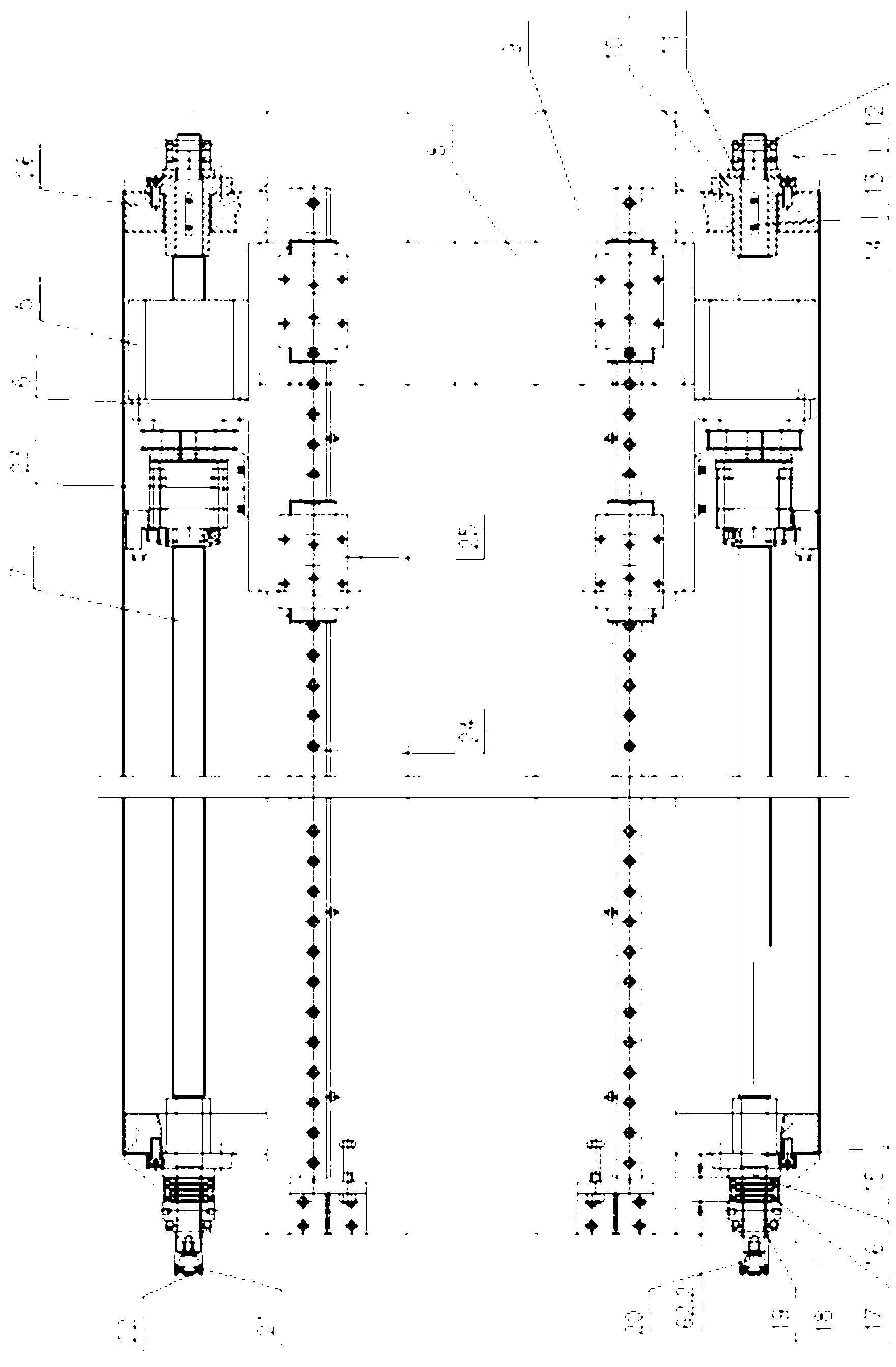

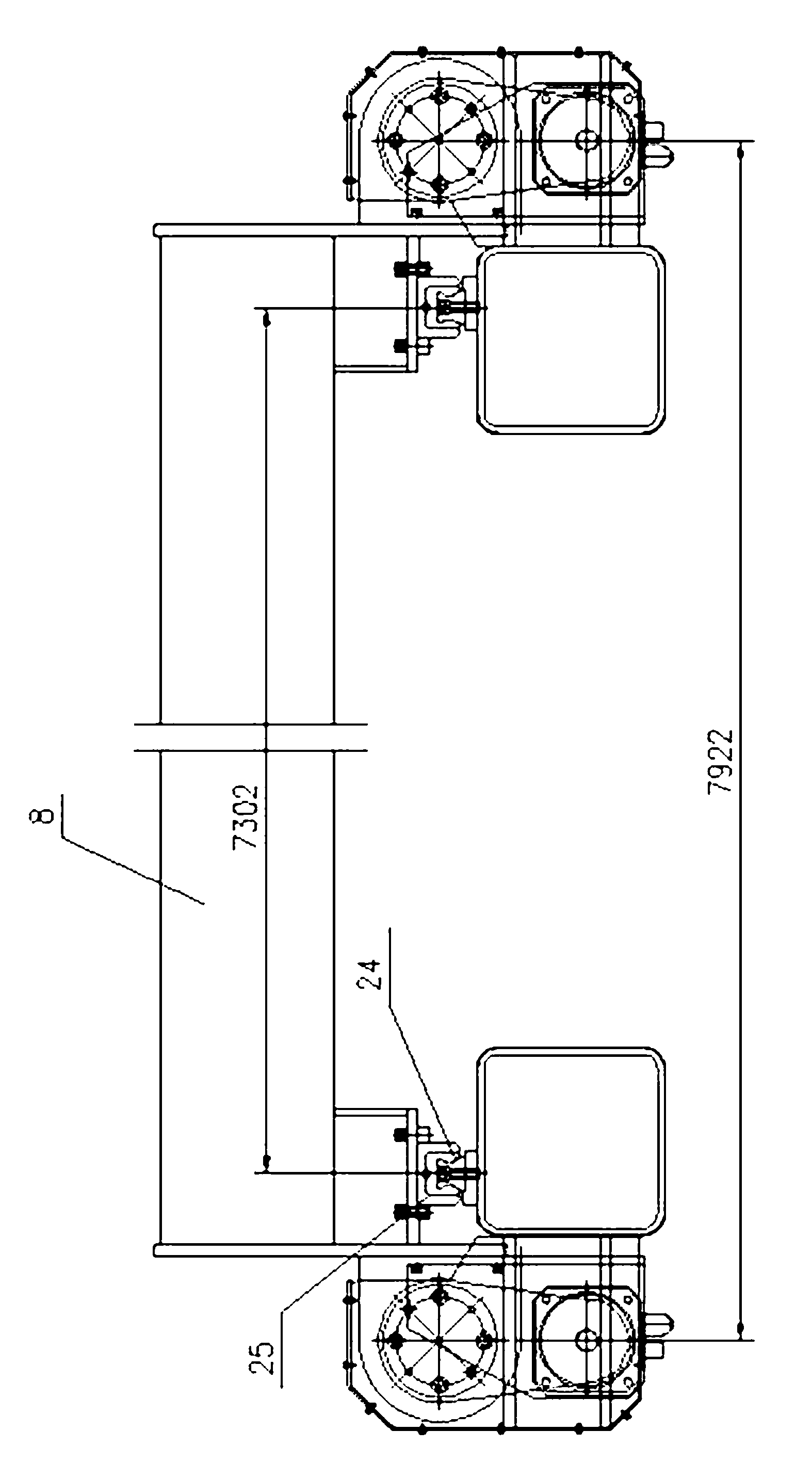

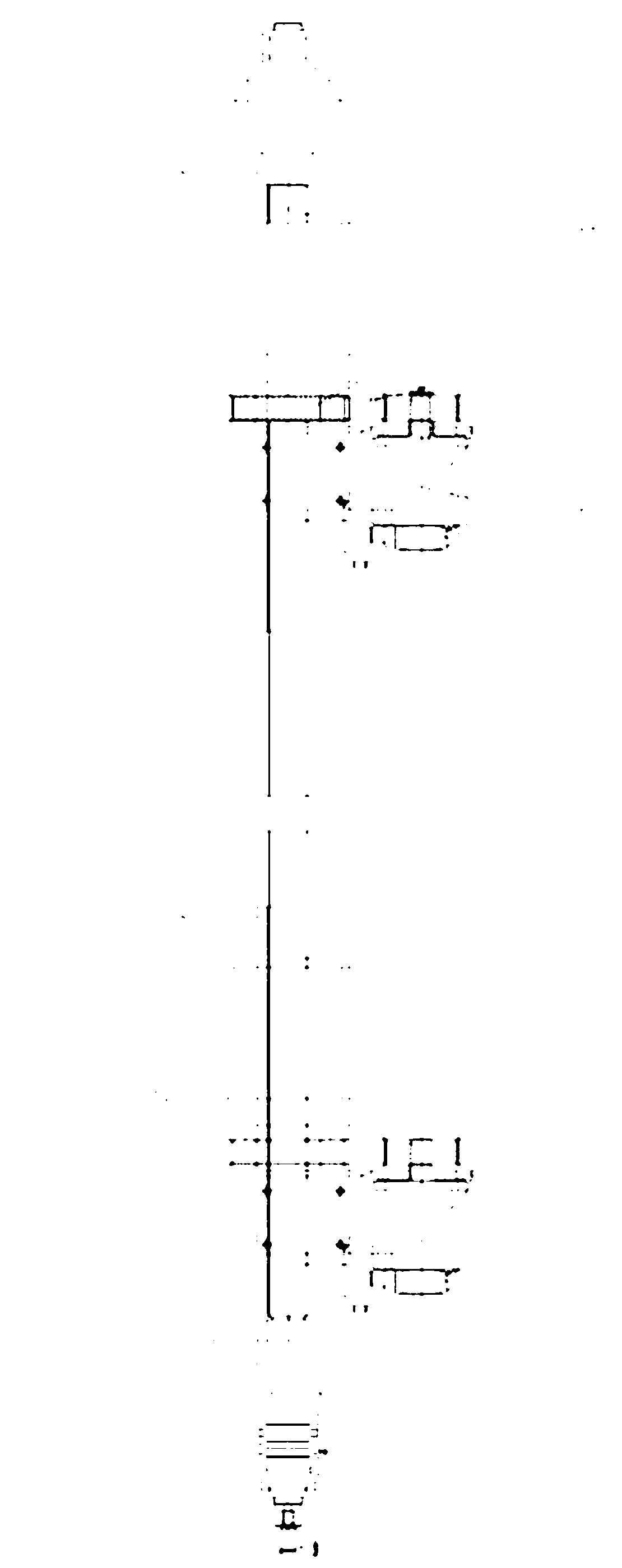

[0016] Such as figure 1 , 2 , As shown in 3, a nut rotating ball screw auxiliary transmission unit includes a fixed bracket 9, a servo motor 1, a ball screw 7, and a feeding beam 8. The feeding beam 8 is an integrally welded rectangular cross-section beam, with nut seats 5 welded at both ends for installing ball screw auxiliary nuts 6, and the distance between centers of the nut seats 5 is 7922mm. Servo motor brackets 23 are respectively installed at both ends of the feeding beam 8, and roller sliders 25 are installed on the bottom surface of the feeding beam 8. Here, a double slider structure is adopted, with 2 sliders arranged on one side, and the center distance of the sliders is 7302㎜ . The fixed brackets 9 are arranged symmetrically at both ends of the feeding beam 8 respectively, and the linear guide rails 24 are installed on the fixed brackets 9 . The rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com