Intelligent logistics transmission system

A transmission system and intelligent logistics technology, applied in the field of intelligent logistics transmission system, can solve the problems of limited capacity of transmission bottles, low comprehensive efficiency, low comprehensive transmission efficiency, etc., to facilitate standardized management, reduce operating costs and improve efficiency, and reduce logistics. The effect of logistics pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Attached below figure 1 To attach Figure 6 The present invention will be further described.

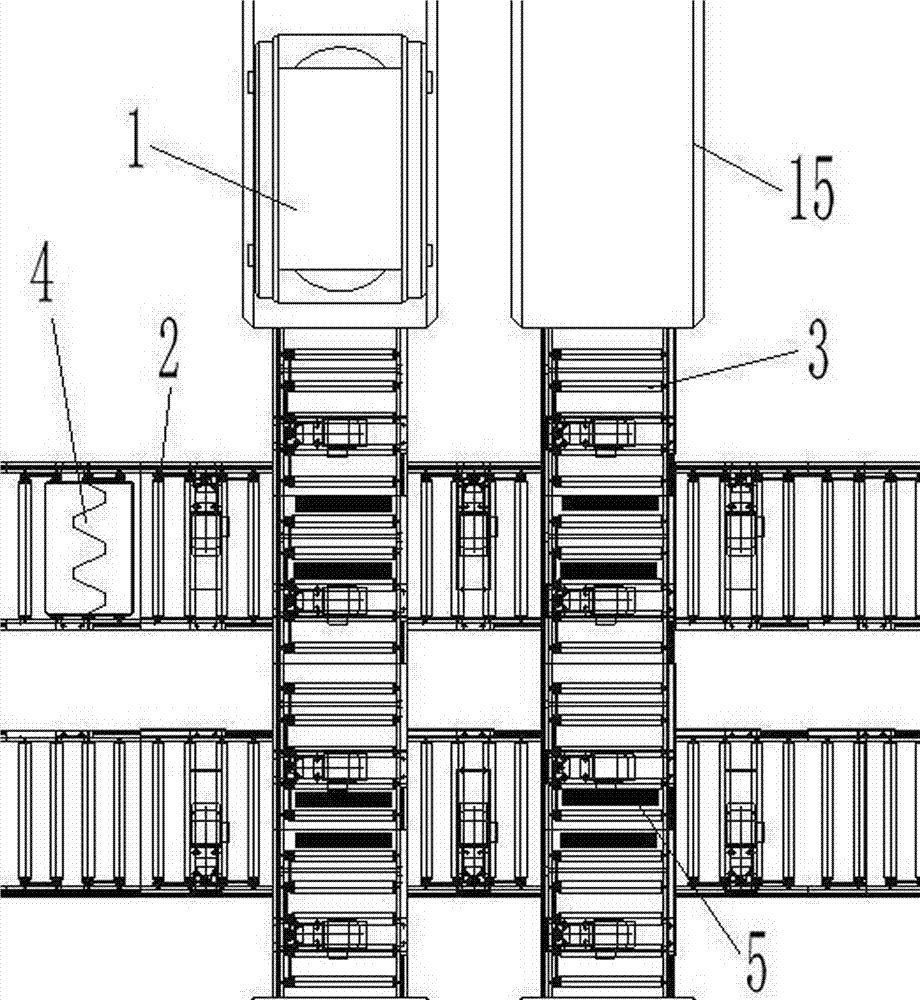

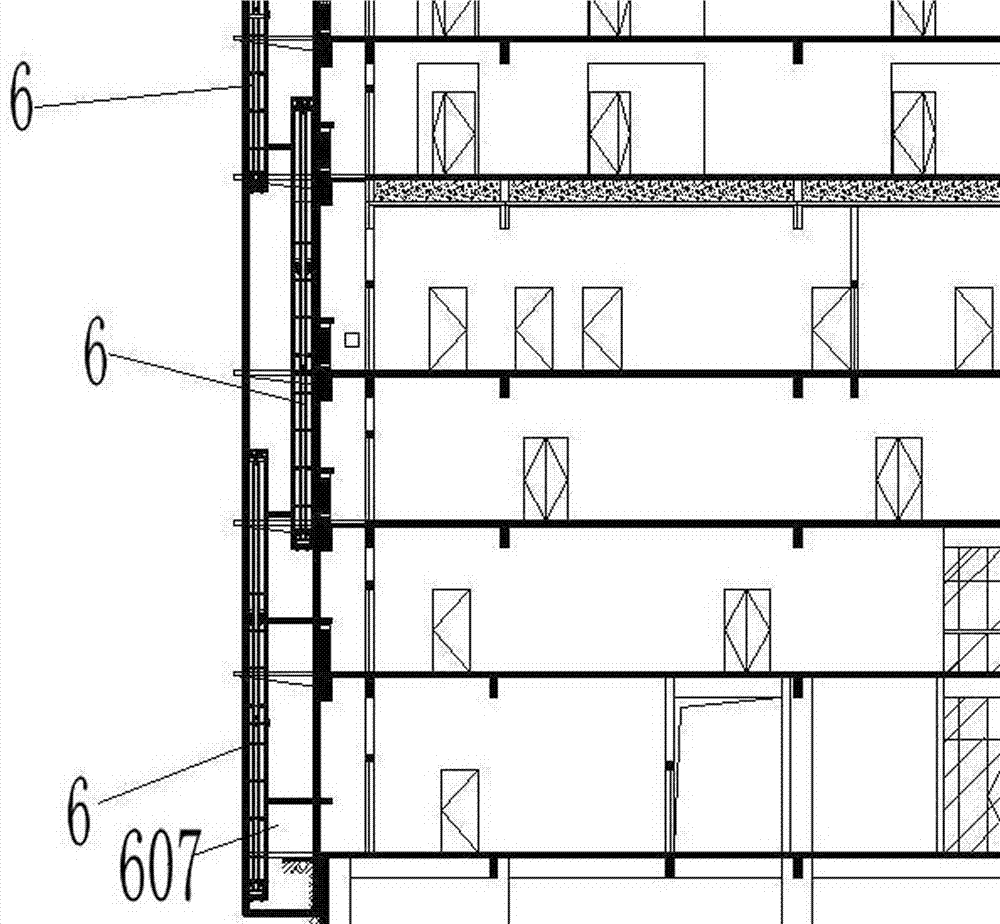

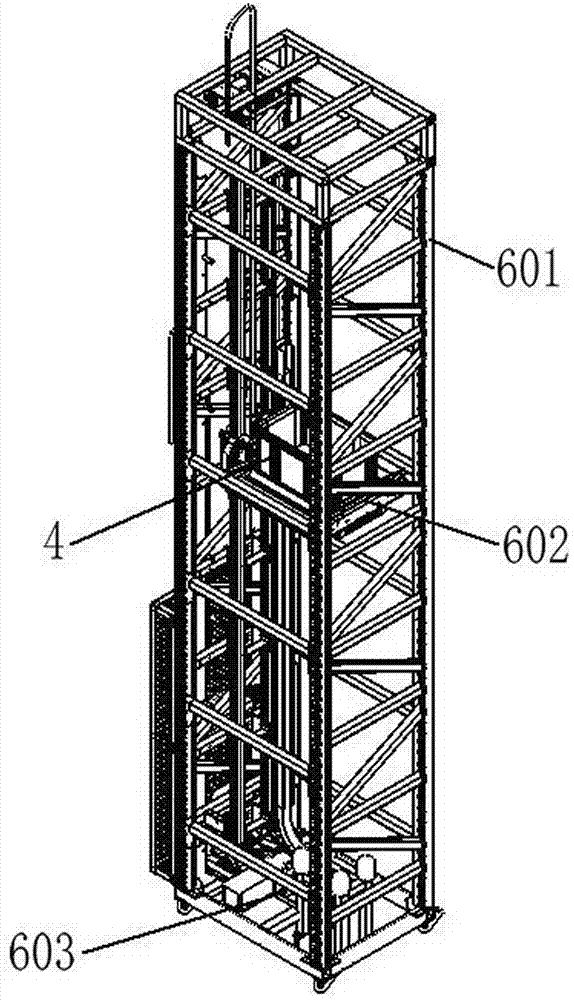

[0036] An intelligent logistics transmission system, comprising: a cargo transmission carrier for loading medical supplies; N transfer stations, composed of a horizontal roller conveyor 2 and a longitudinal roller conveyor 3, and the horizontal roller conveyor 2 and the longitudinal roller conveyor The conveyor 3 is arranged in a cross shape, and N is a natural number greater than or equal to 1; the jacking transplanter 5 is arranged on the horizontal roller conveyor 2 or the longitudinal roller conveyor 3, and is used to transfer the goods from the horizontal roller conveyor to the horizontal roller conveyor. The cylinder conveyor 2 is transferred to the longitudinal roller conveyor 3 or transferred from the longitudinal roller conveyor 3 to the horizontal roller conveyor 2; the vertical transmission system 6 is vertically arranged in the building, and is used to transport t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com