Heavy-load cradle head

A cloud platform and gravity compensation technology, applied in the field of cameras, can solve problems such as unstable working conditions, unbalanced gravity distribution, instability, etc., and achieve the effect of stable shooting pictures and smooth angle conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the drawings and examples.

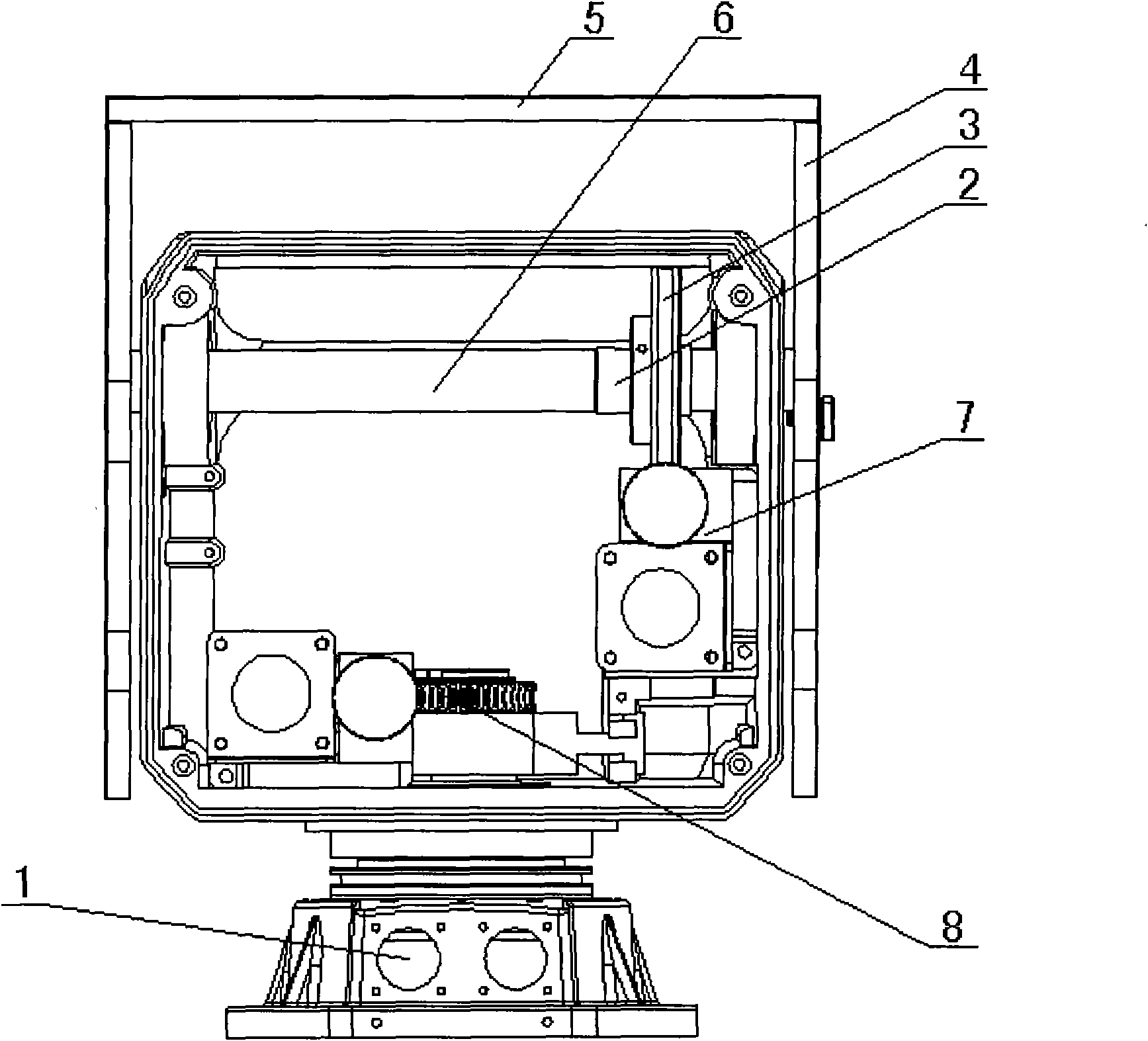

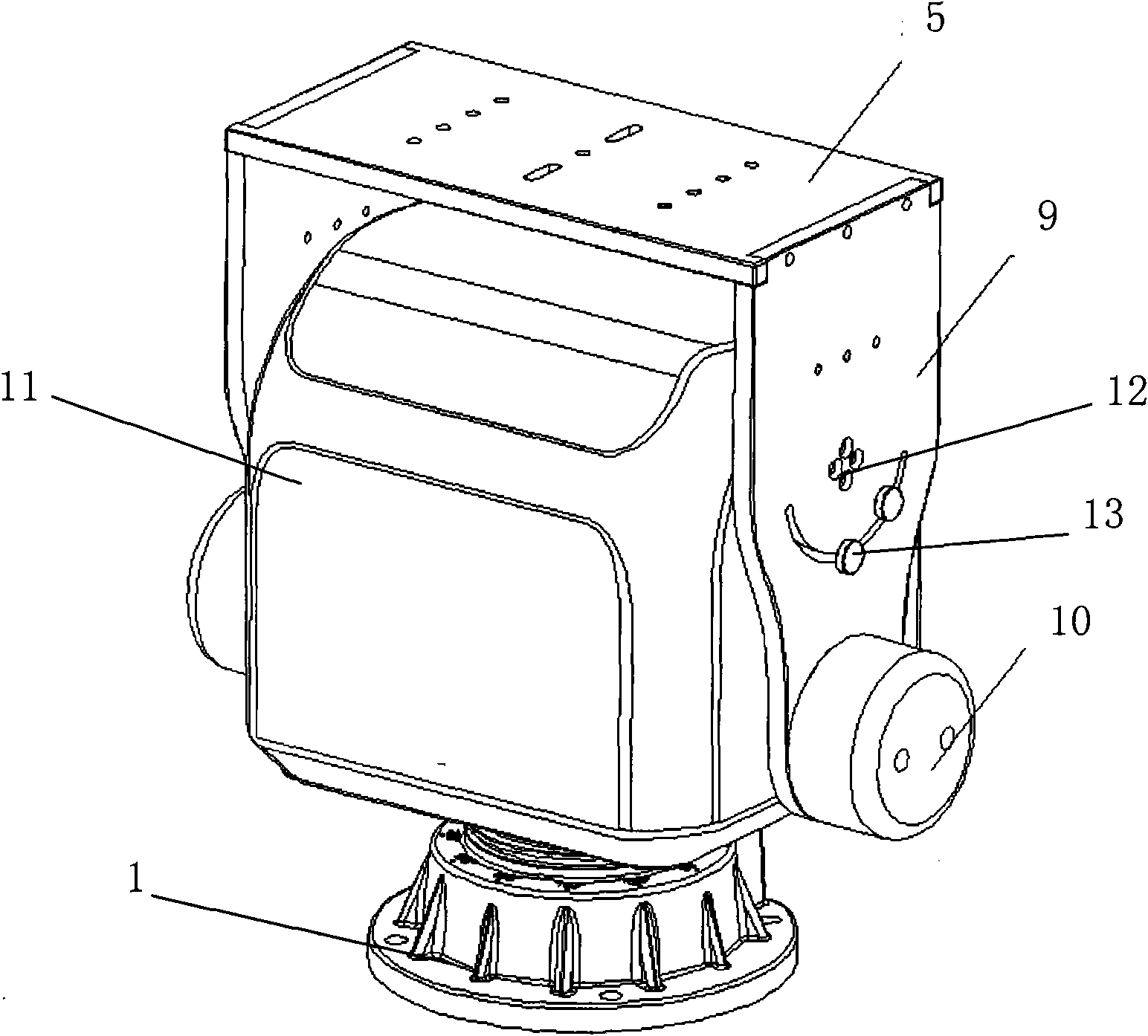

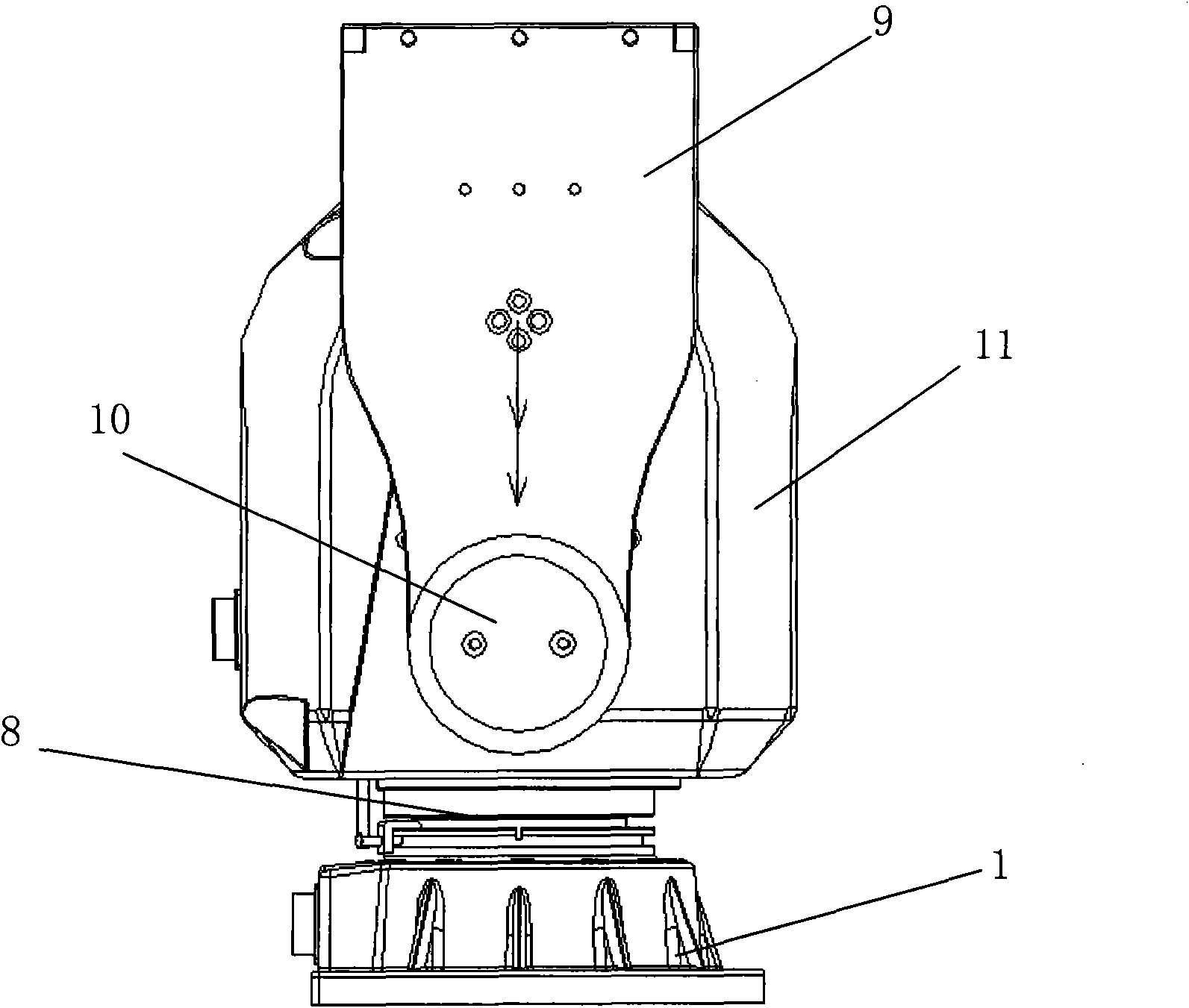

[0023] figure 2 It is a structural representation of the heavy-duty platform of the present invention; image 3 It is a side view of the heavy-duty platform of the present invention; Figure 4 It is a side view of the heavy-duty platform of the present invention during operation.

[0024] Such as Figure 2 to Figure 4 As shown, the heavy-duty platform of the present invention comprises: base 1, is fixed with the preset position of camera, supports heavy-duty platform and camera; The fixed camera of the cloud platform rotates vertically and horizontally; the shell 11 is arranged outside the core, surrounds and protects the core; The shield connecting plate 5 is formed, and the camera is fixed on the shield connecting plate, and mutually matched stop bolts 13 and guide grooves are respectively arranged on the shell and the end plate, thereby limiting the angle at wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com