Ultrasonic defect tracking and monitoring system for electric power inspection

A power inspection, tracking and monitoring technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and testing using acoustic measurements, etc. It can solve component damage and reduce ultrasonic detection cameras. Clearance, inability to ultrasonically detect the effective heat dissipation of the camera, etc., to achieve the effect of reducing the shaking amplitude, effective heat dissipation, and clear shooting pictures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

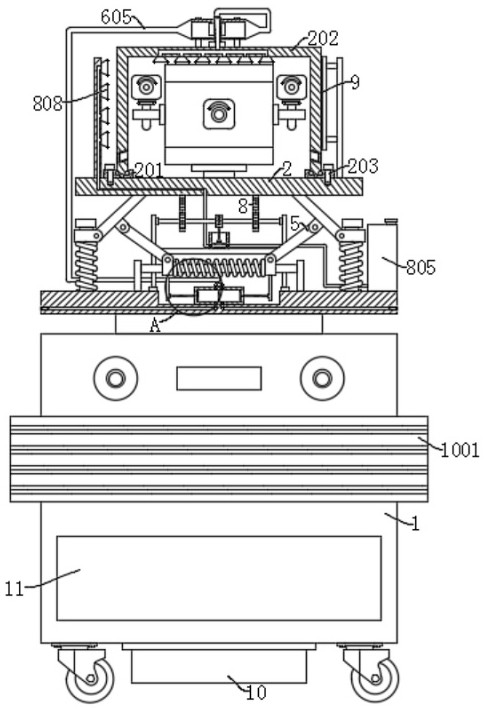

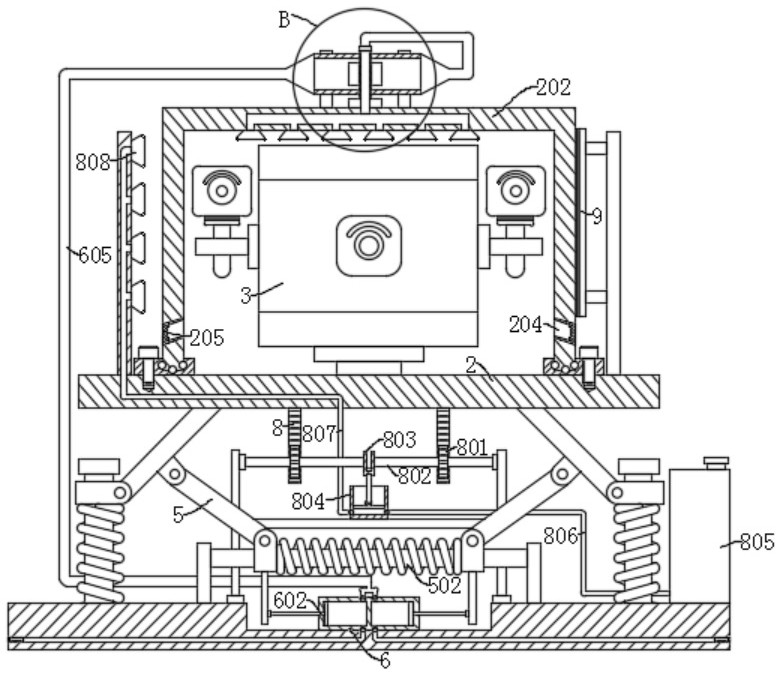

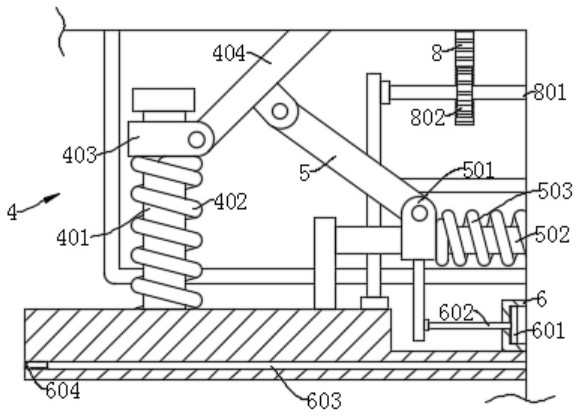

[0028] Embodiment 1: refer to Figure 1-6 , an ultrasonic defect tracking and monitoring system for power inspection, including an inspection robot 1, and also includes: a tray 2 arranged above the inspection robot 1, the tray 2 is connected to the top of the inspection robot 1 through a buffer assembly 4; The camera 3 is assembled on the tray 2; the rotating slide rail 201 is detachably connected to the tray 2, and the rotating slide rail 201 is equipped with a protective shell 202, and the protective shell 202 is provided with a cooling port 204; the guide rod 502, the sleeve The cylinder 6 and the water tank 805 are all arranged on the top of the inspection robot 1; two sets of sliding sleeves 501 are symmetrically arranged, and the two sets of sliding sleeves 501 are assembled on the guide rod 502, and a spring is connected between the two sets of sliding sleeves 501 Two 503; connecting rod 5, one end of which is rotatably connected to sliding sleeve 2 501, and the other e...

Embodiment 2

[0037] Embodiment 2: refer to figure 2 , the ultrasonic defect tracking and monitoring system used for electric power inspection is basically the same as that of Embodiment 1. Furthermore, the pipeline 2 605 is composed of two sections, and the top of the rotating shaft 1 7 is equipped with a rotary joint. When the rotating shaft 1 7 drives the protective shell 202 to rotate, the connection of the two sections of pipeline 605 is connected through a rotary joint, thereby effectively avoiding the interference of the pipeline 2 605 on the rotation of the protective shell 202.

Embodiment 3

[0038] Embodiment 3: refer to figure 2 , the ultrasonic defect tracking and monitoring system used for electric power inspection is basically the same as that of Embodiment 1, furthermore, the pipeline one 603 is equipped with a filter screen two 604, and the heat dissipation port 204 is equipped with a filter screen one 205; the piston disc 601 moves in the sleeve 6, and when the external air is extracted through the pipe 1 603, when the gas enters the pipe 1 603 through the filter screen 2 604, it can filter the dust particles in the gas to avoid being sucked into the sleeve 6 through the nozzle 1 703 When spraying, the nozzle one 703 is blocked, which affects the normal movement of the piston disc 601 in the sleeve 6, and the filter screen one 205 can effectively prevent external dust particles from entering the protective shell 202.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com