Patents

Literature

62 results about "Defect tracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In engineering, defect tracking is the process of tracking the logged defects in a product from beginning to closure (by inspection, testing, or recording feedback from customers), and making new versions of the product that fix the defects. Defect tracking is important in software engineering as complex software systems typically have tens or hundreds or thousands of defects: managing, evaluating and prioritizing these defects is a difficult task. When the numbers of defects gets quite large, and the defects need to be tracked over extended periods of time, use of a defect tracking system can make the management task much easier.

Automated software testing framework

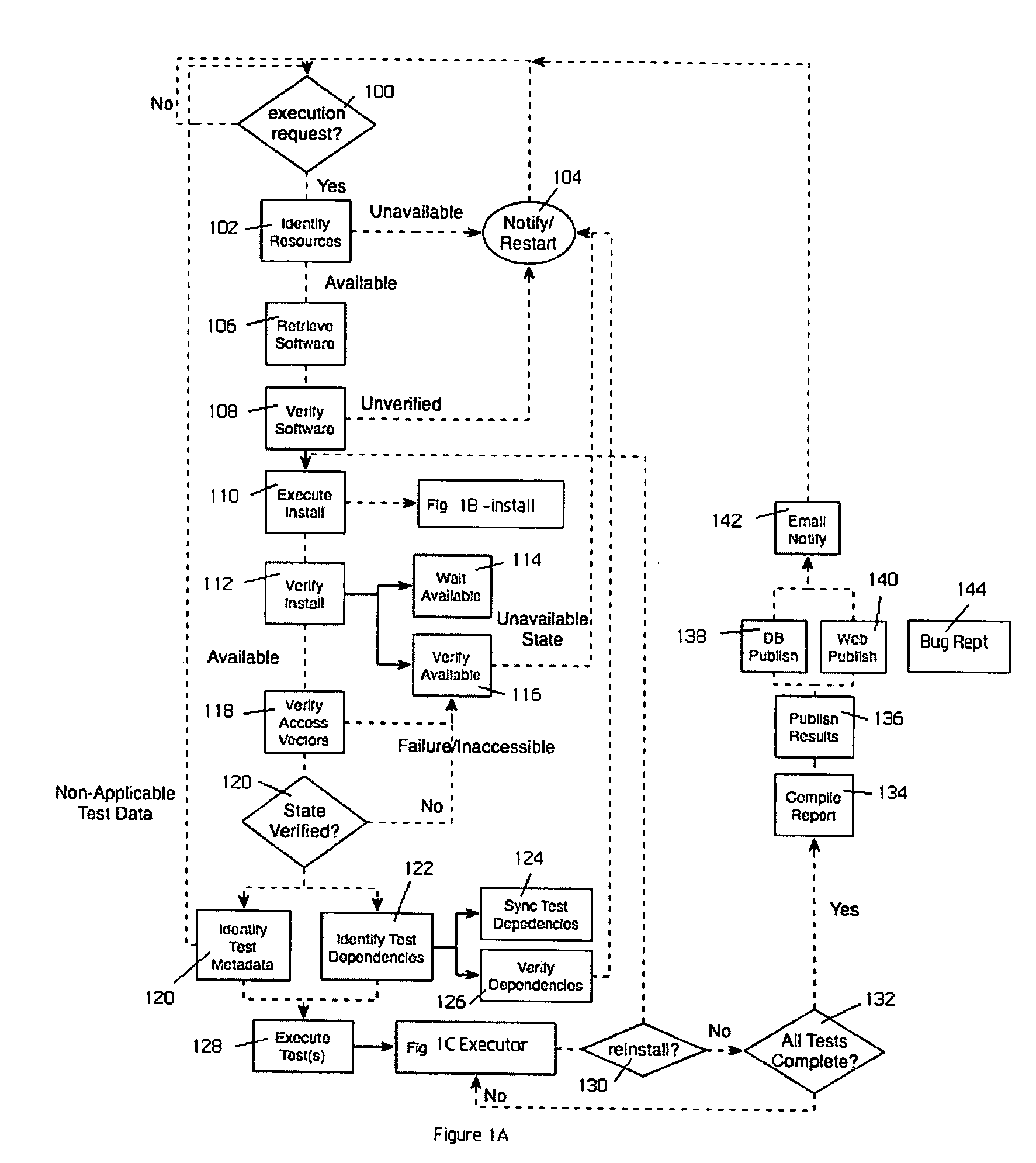

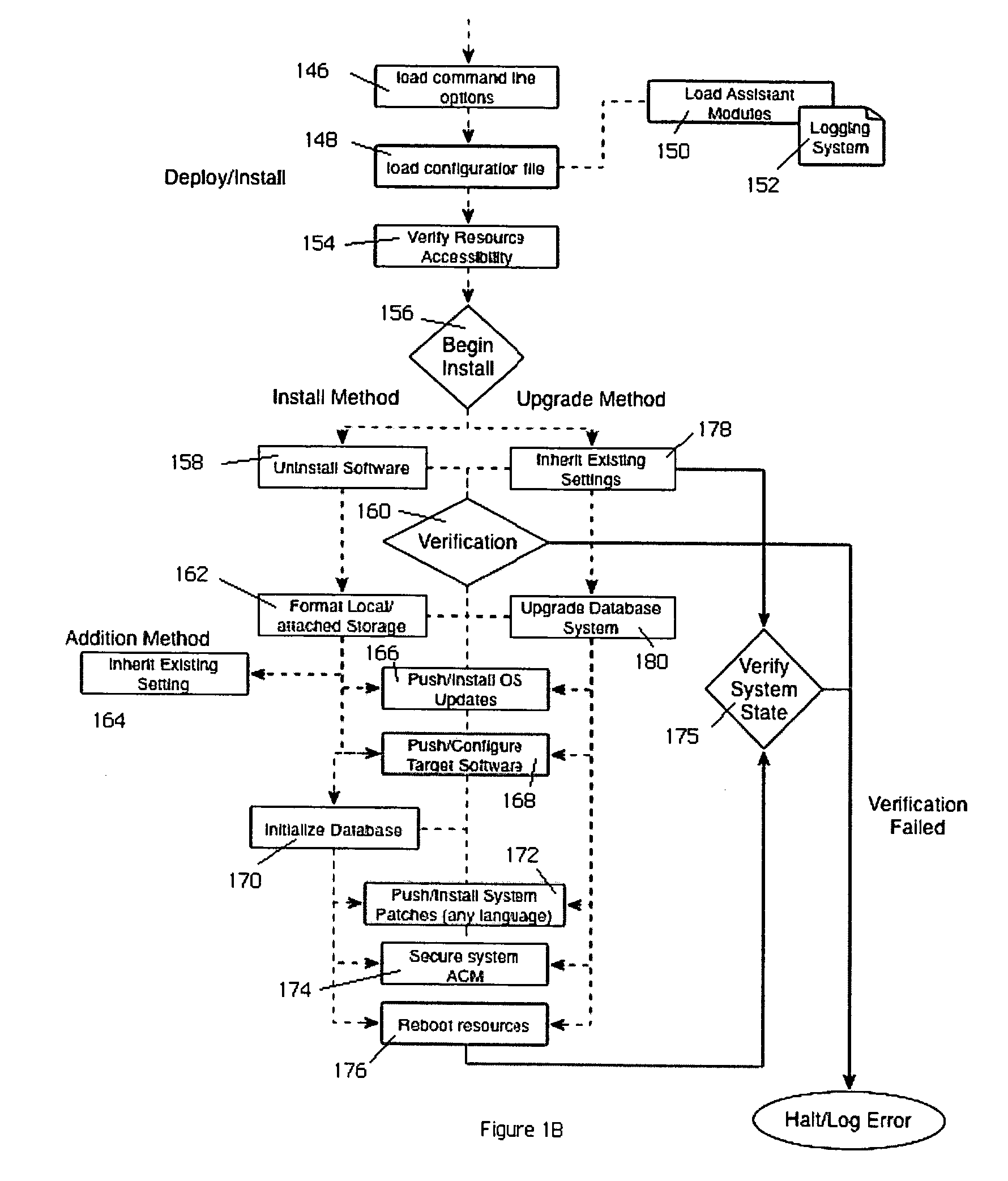

InactiveUS20070234293A1Improve scalabilitySimple and efficientError detection/correctionSpecific program execution arrangementsSpecific testWeb service

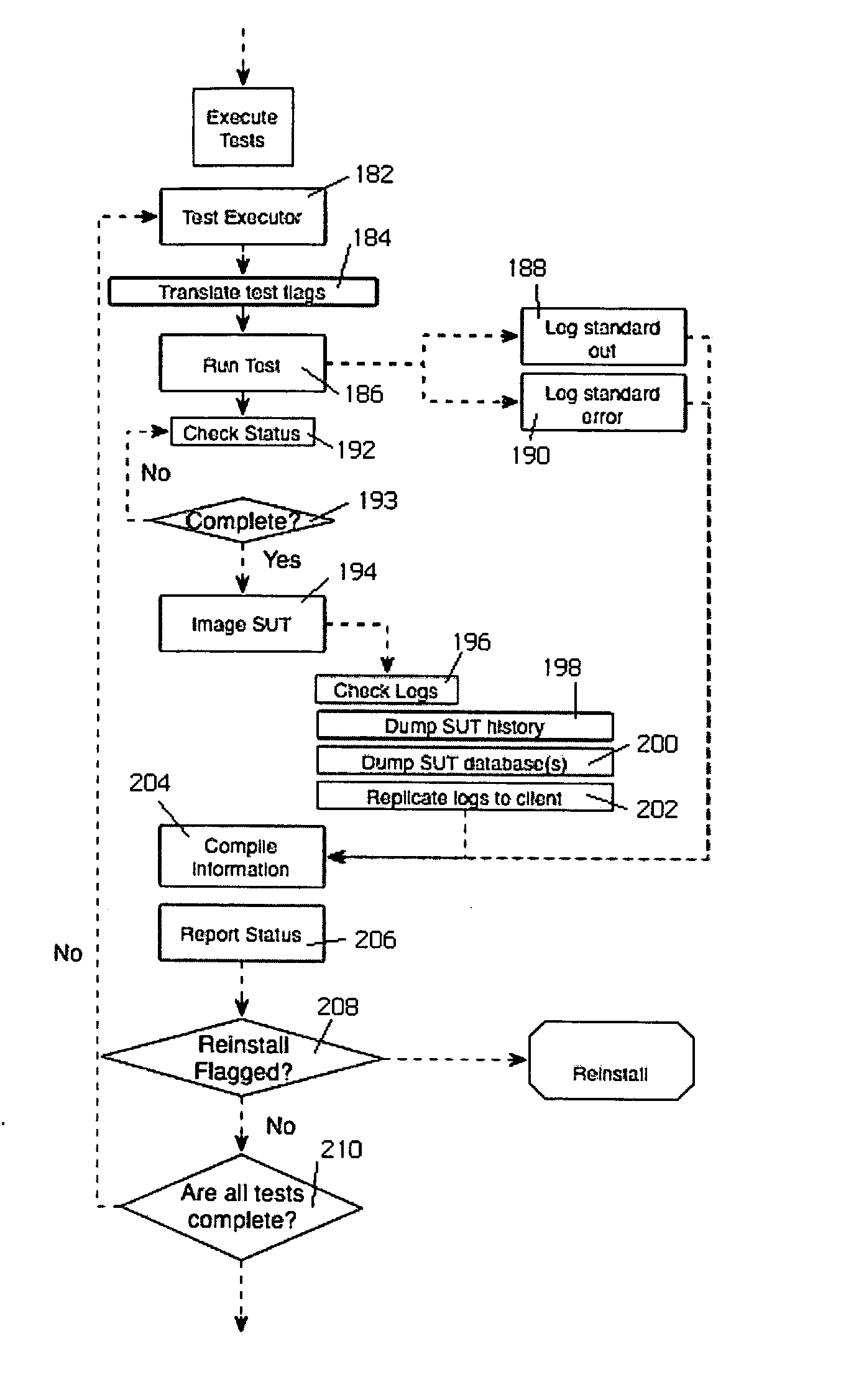

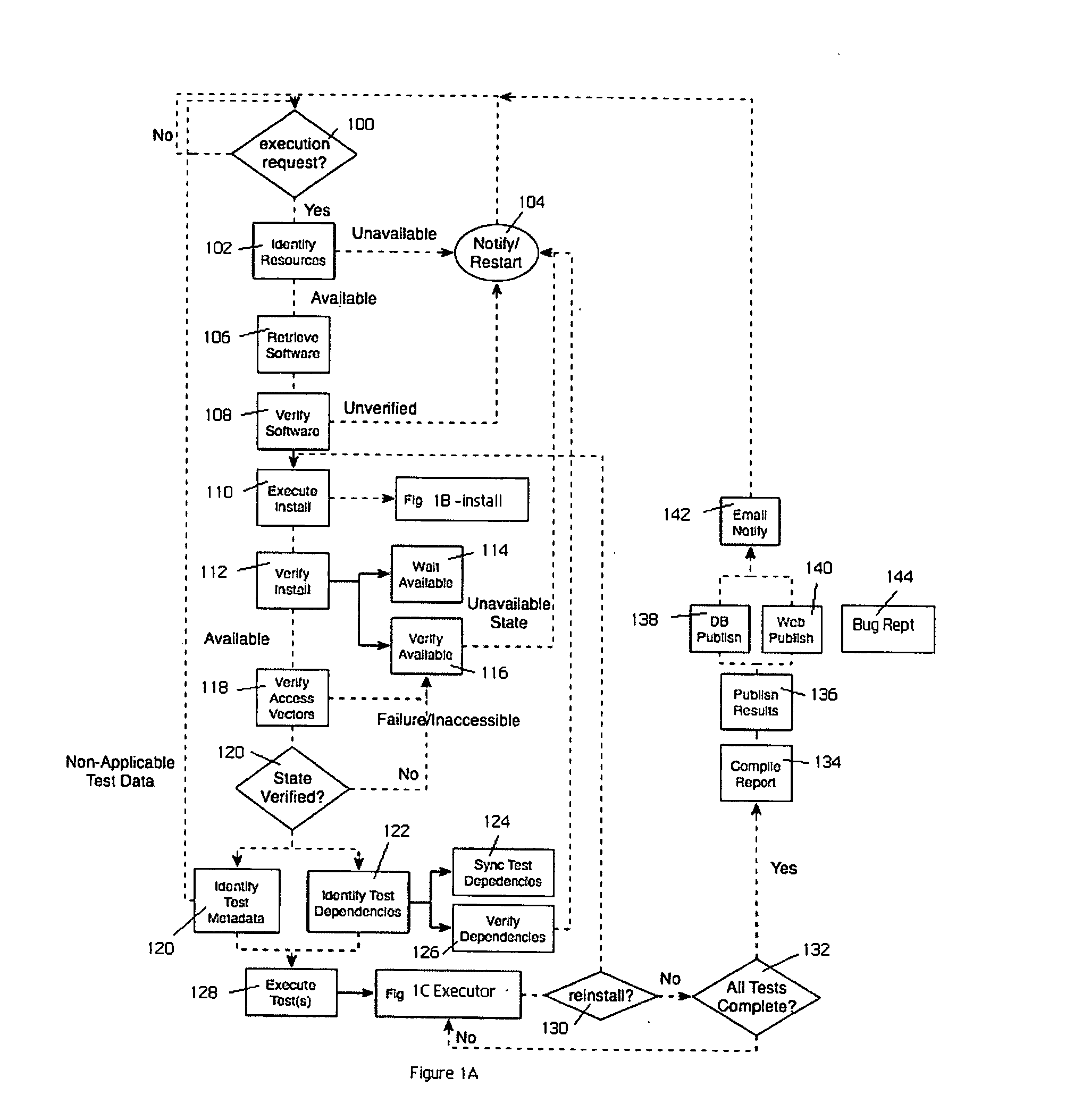

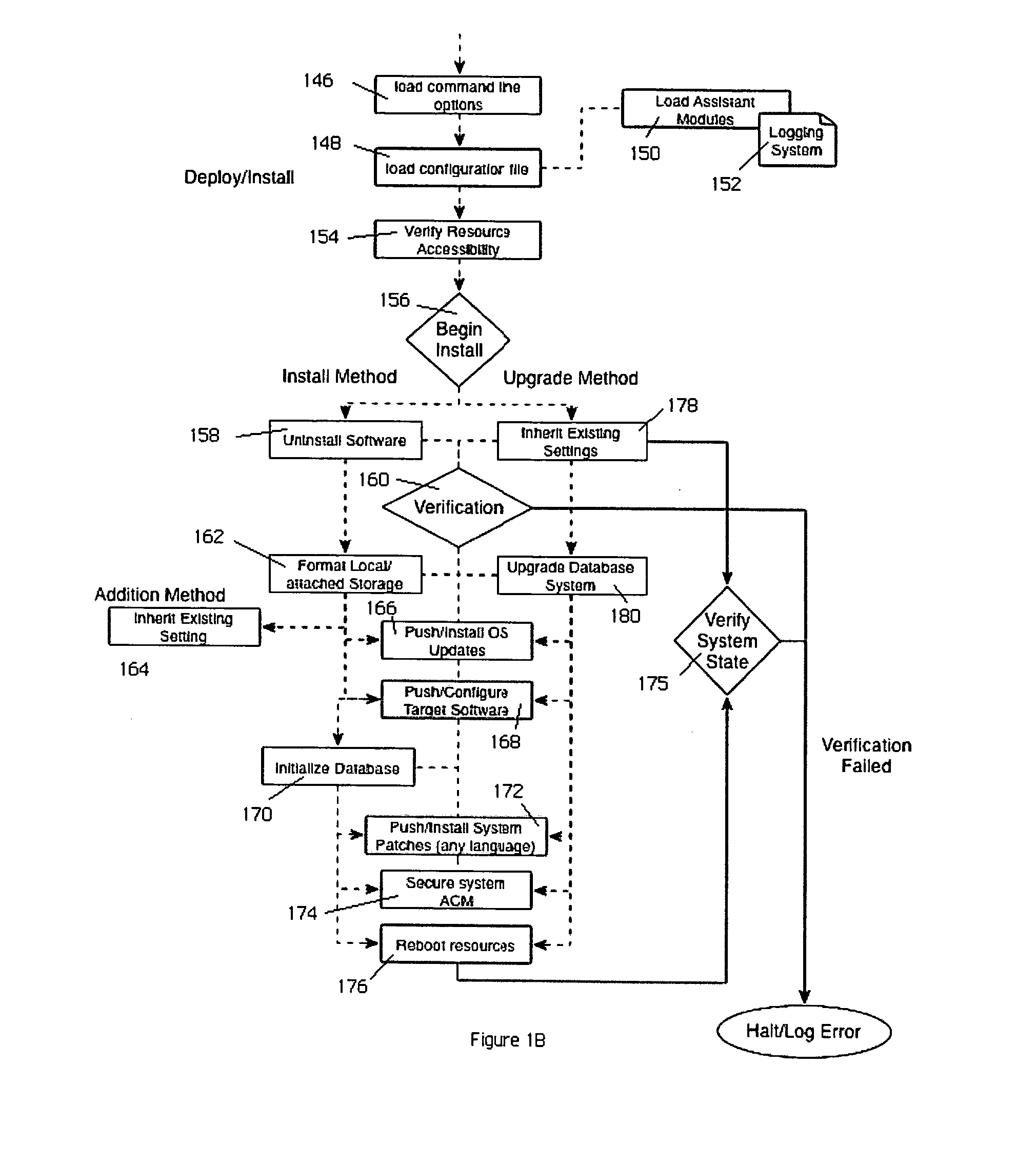

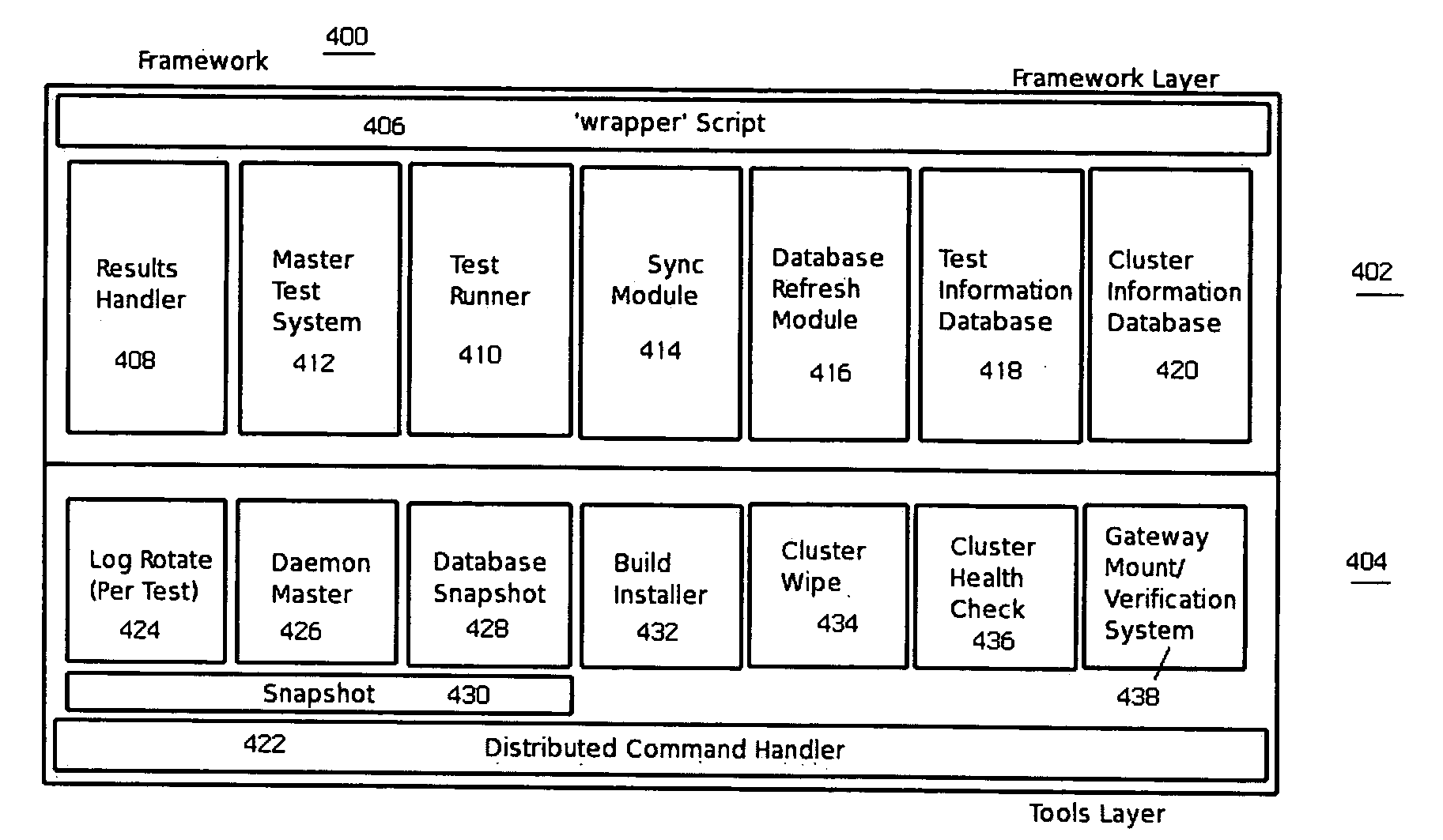

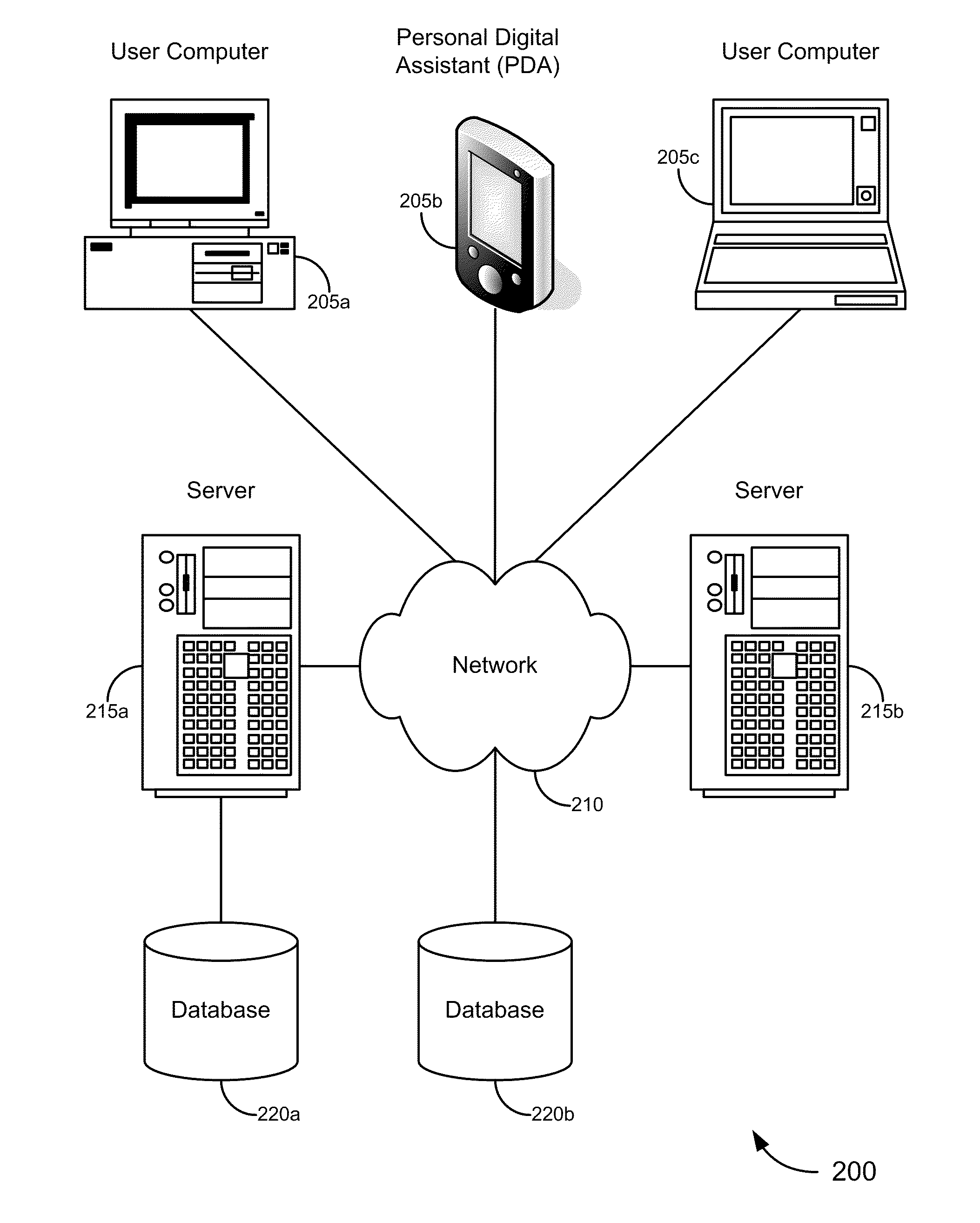

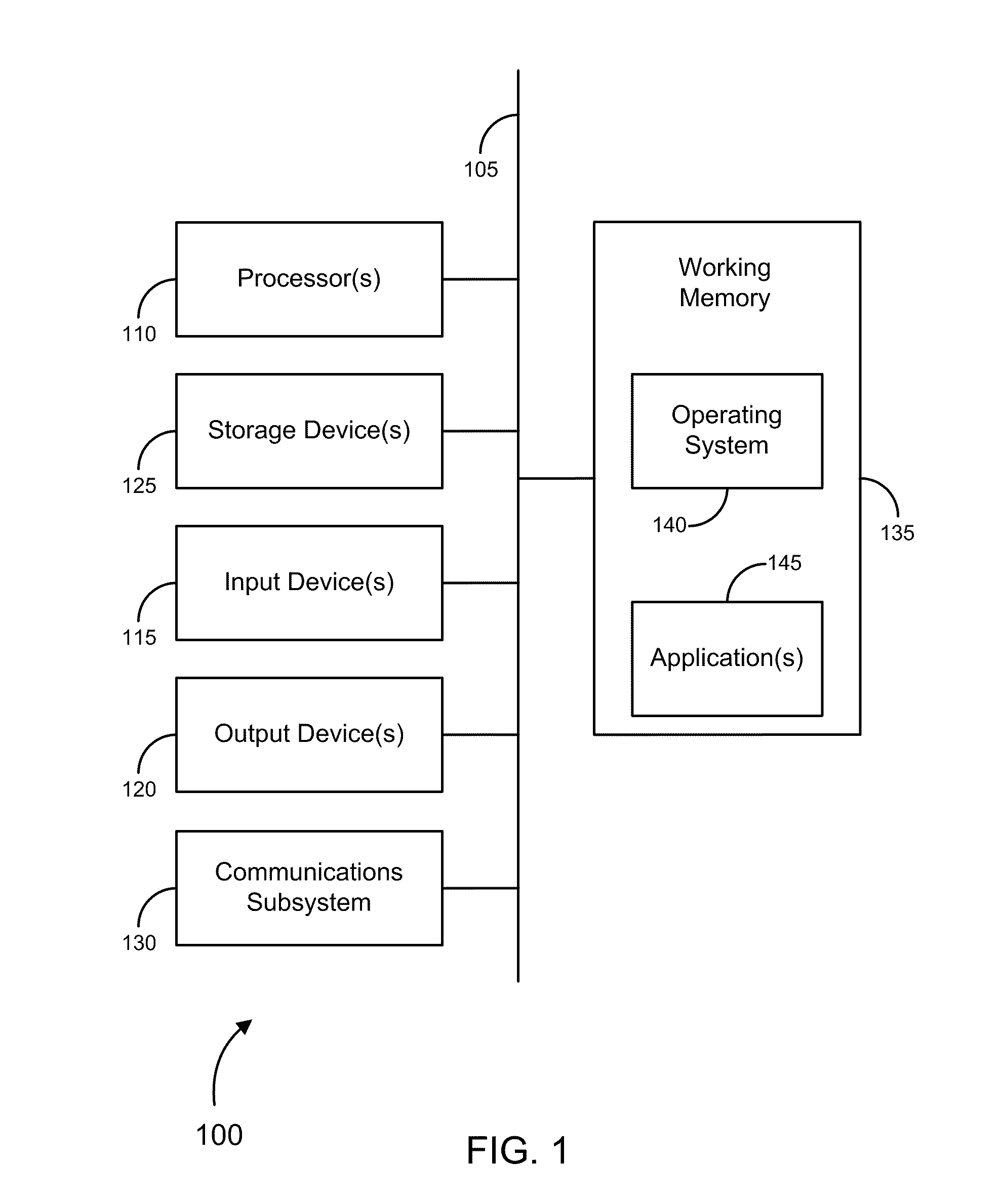

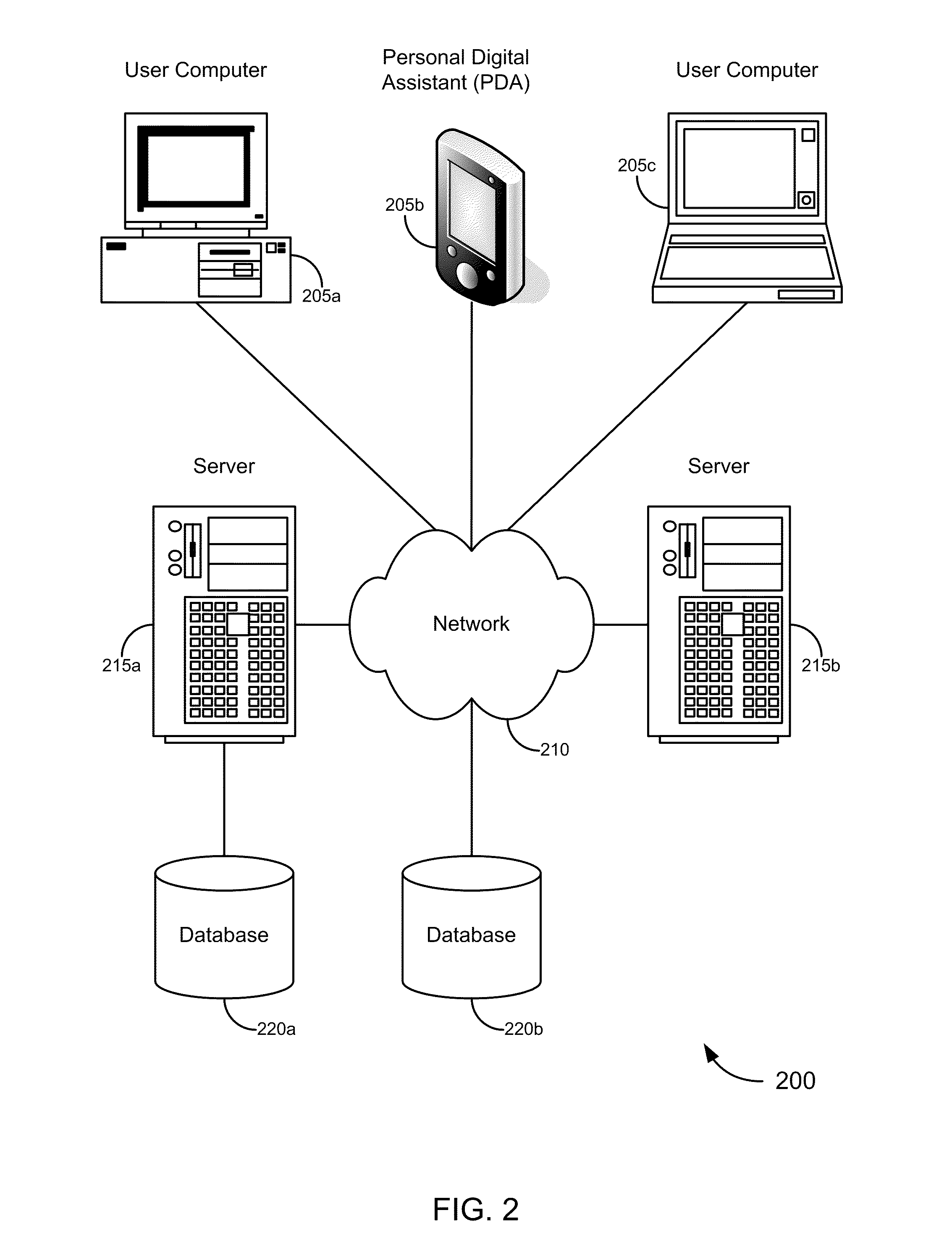

A generic testing framework to automatically allocate, install and verify a given version of a system under test, to exercise the system against a series of tests in a “hands-off” objective manner, and then to export information about the tests to one or more developer repositories (such as a query-able database, an email list, a developer web server, a source code version control system, a defect tracking system, or the like). The framework does not “care” or concern itself with the particular implementation language of the test as long as the test can issue directives via a command line or configuration file. During the automated testing of a given test suite having multiple tests, and after a particular test is run, the framework preferably generates an “image” of the system under test and makes that information available to developers, even while additional tests in the suite are being carried out. In this manner, the framework preserves the system “state” to facilitate concurrent or after-the-fact debugging. The framework also will re-install and verify a given version of the system between tests, which may be necessary in the event a given test is destructive or otherwise places the system in an unacceptable condition.

Owner:HITACHI DATA SYST CORP

Automated software testing framework

InactiveUS7694181B2Simple and efficientEasy to exportError detection/correctionSpecific program execution arrangementsWeb serviceSystem under test

A generic testing framework to automatically allocate, install and verify a given version of a system under test, to exercise the system against a series of tests in a “hands-off” objective manner, and then to export information about the tests to one or more developer repositories (such as a query-able database, an email list, a developer web server, a source code version control system, a defect tracking system, or the like). The framework does not “care” or concern itself with the particular implementation language of the test as long as the test can issue directives via a command line or configuration file. During the automated testing of a given test suite having multiple tests, and after a particular test is run, the framework preferably generates an “image” of the system under test and makes that information available to developers, even while additional tests in the suite are being carried out. In this manner, the framework preserves the system “state” to facilitate concurrent or after-the-fact debugging. The framework also will re-install and verify a given version of the system between tests, which may be necessary in the event a given test is destructive or otherwise places the system in an unacceptable condition.

Owner:HITACHI DATA SYST CORP

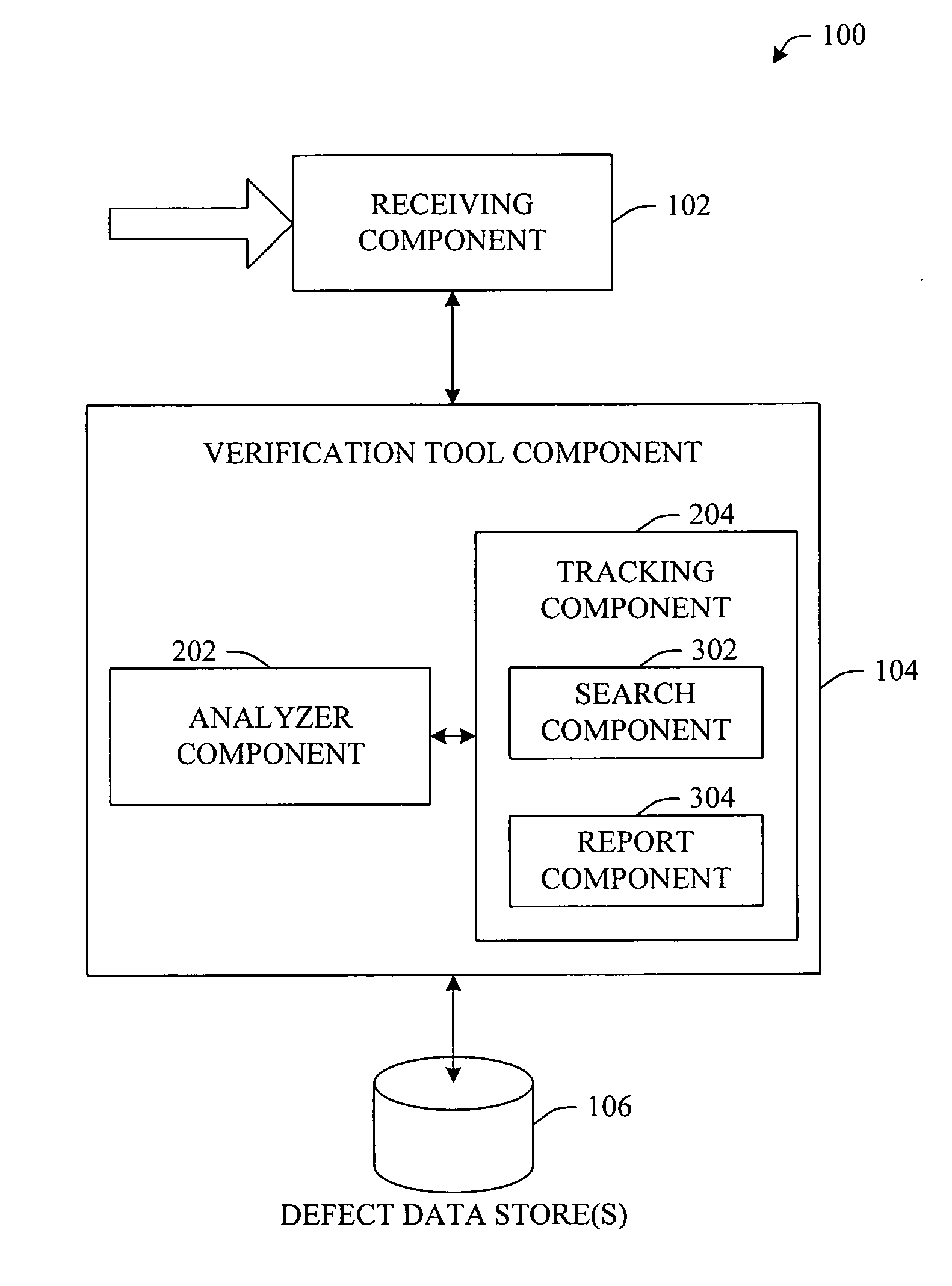

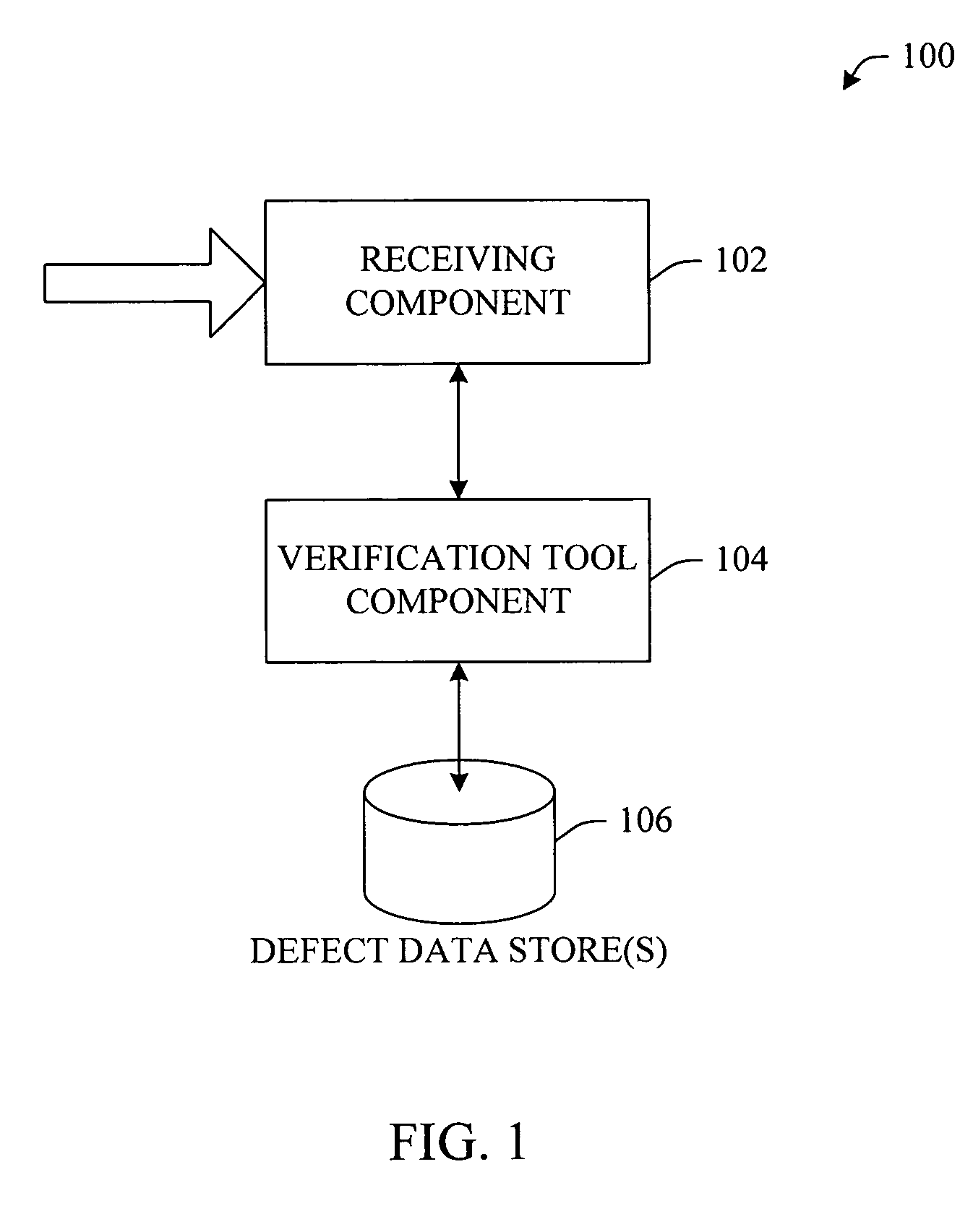

Automated product defects analysis and reporting

InactiveUS20070074149A1Well formedError detection/correctionDigital computer detailsSoftware faultData mining

An automation infrastructure which automatically analyzes software faults and / or bugs related to a product defect is provided. More particularly, the system can automatically analyze and detect symptoms in the forms of crash dump, memory leak, corruption and test issues etc. In accordance therewith, aspects can automatically search for and locate existing defect reports, if such existing reports are available. Moreover, aspects can automatically report new defects in a defect tracking database or other tracking mechanism.

Owner:MICROSOFT TECH LICENSING LLC

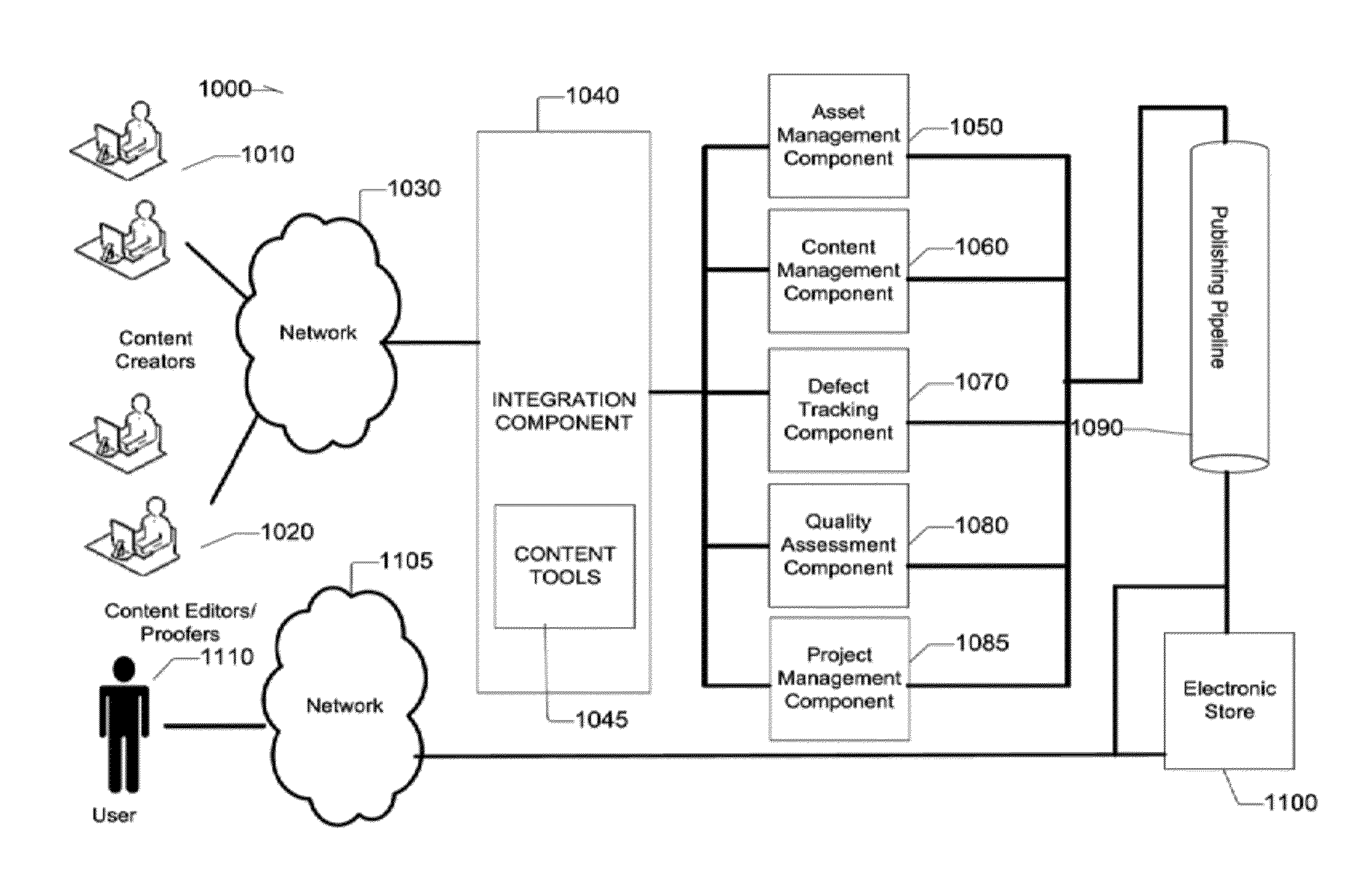

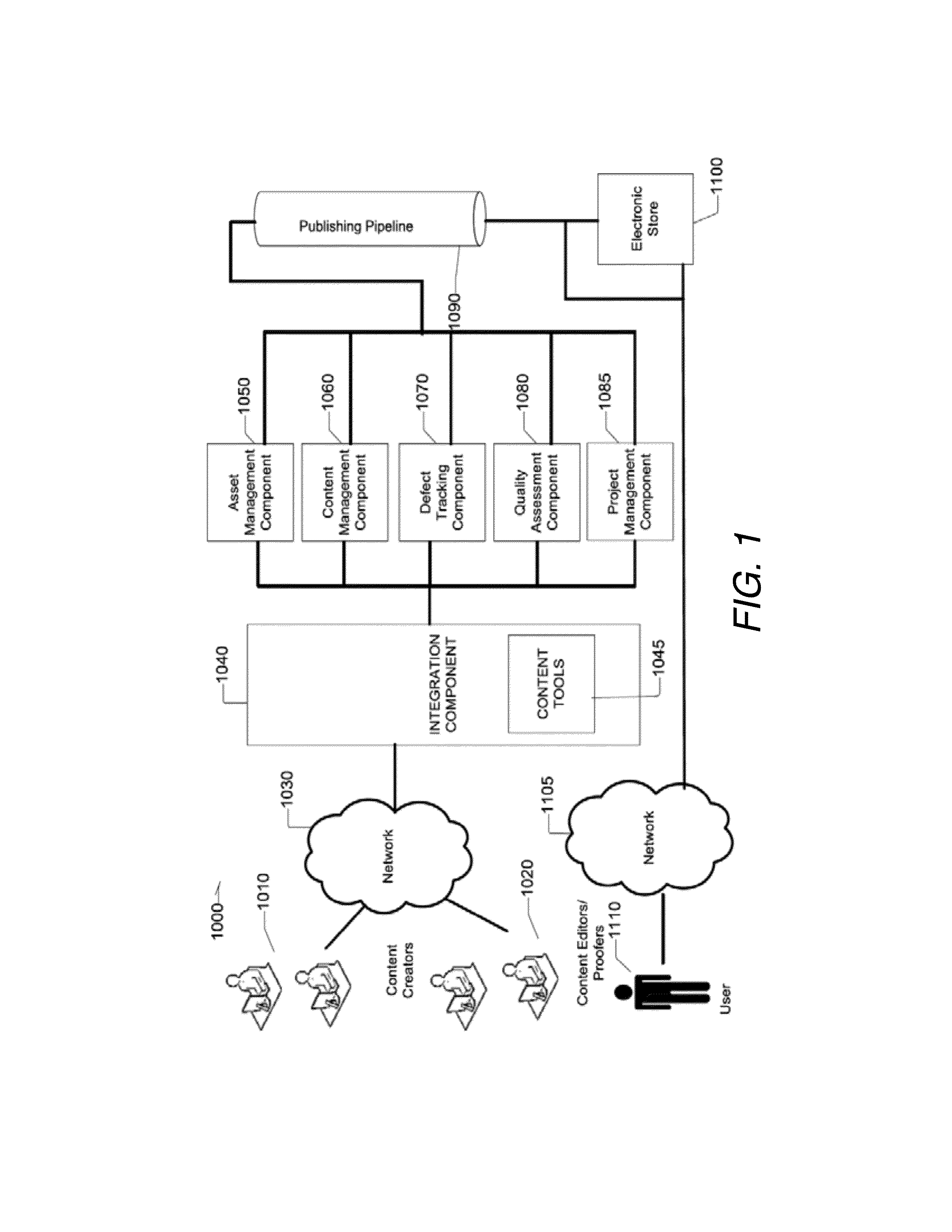

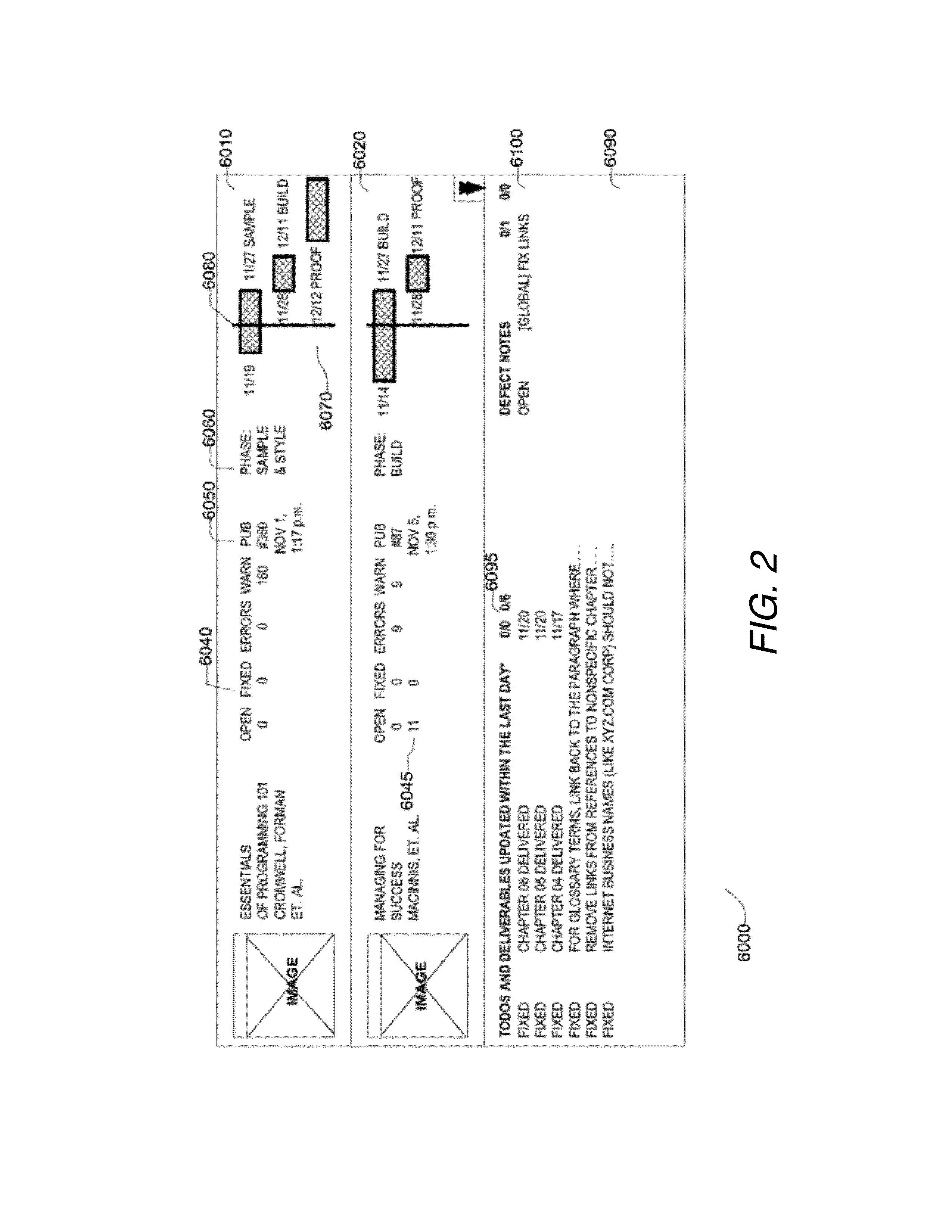

Systems and methods for creating, editing and publishing cross-platform interactive electronic works

ActiveUS20130179761A1Natural language data processingSpecial data processing applicationsGraphicsGraphical user interface

Systems and methods for creating, editing and publishing cross-platform interactive digital content works include a content management component configured to store portions of a digital content work and to implement version control of the digital content work; a defect tracking component configured to store a defect record related to a stored portion of the digital content work; a publication pipeline component configured to format the digital content work for publication; and a integration component configured to present a graphical user interface which allows for editing the stored portions of the digital content work, editing the defect record, and instructing the publication pipeline to format the digital content work for publication.

Owner:INKLING SYST

Automated product defects analysis and reporting

An automation infrastructure which automatically analyzes software faults and / or bugs related to a product defect is provided. More particularly, the system can automatically analyze and detect symptoms in the forms of crash dump, memory leak, corruption and test issues etc. In accordance therewith, aspects can automatically search for and locate existing defect reports, if such existing reports are available. Moreover, aspects can automatically report new defects in a defect tracking database or other tracking mechanism.

Owner:MICROSOFT TECH LICENSING LLC

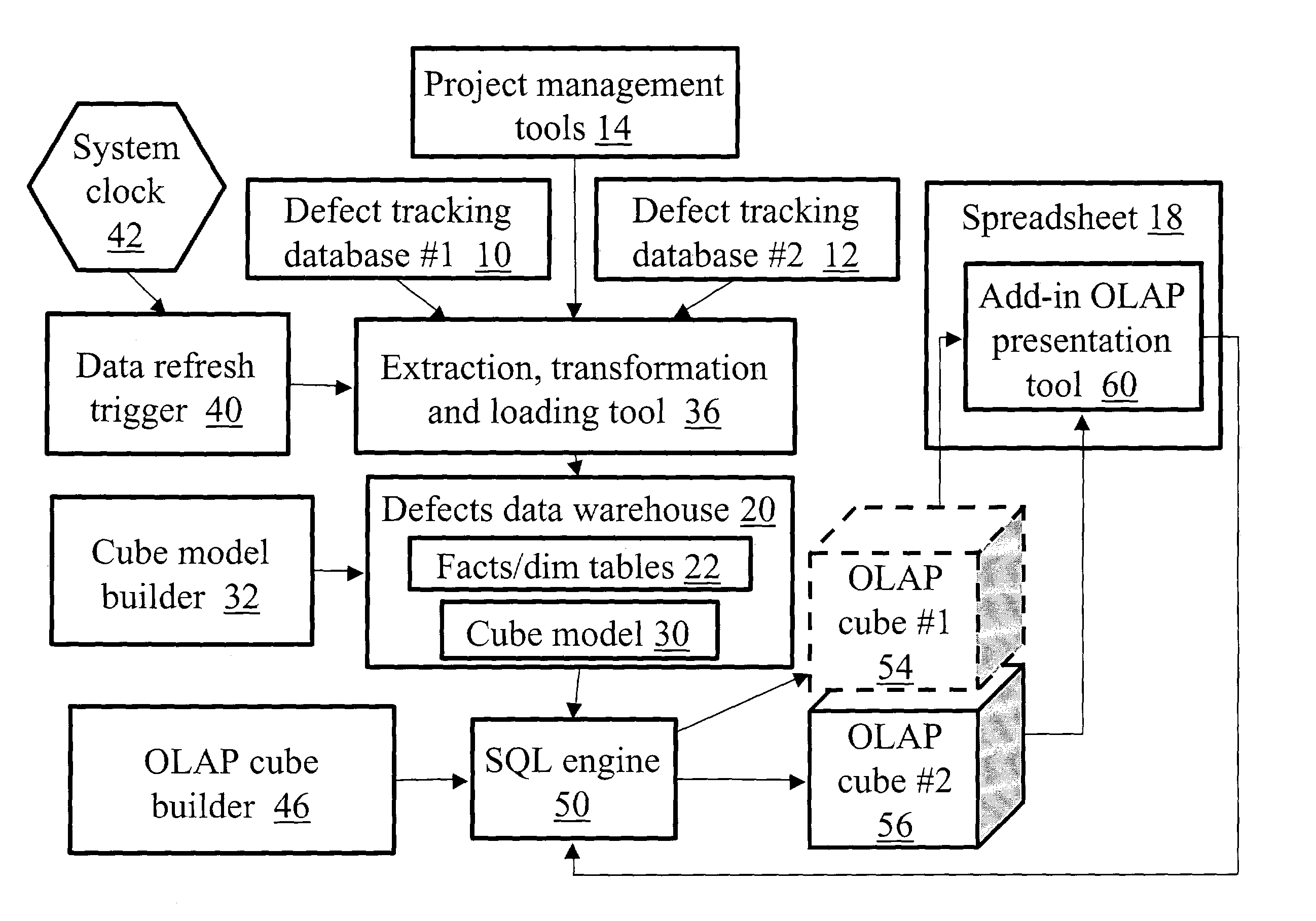

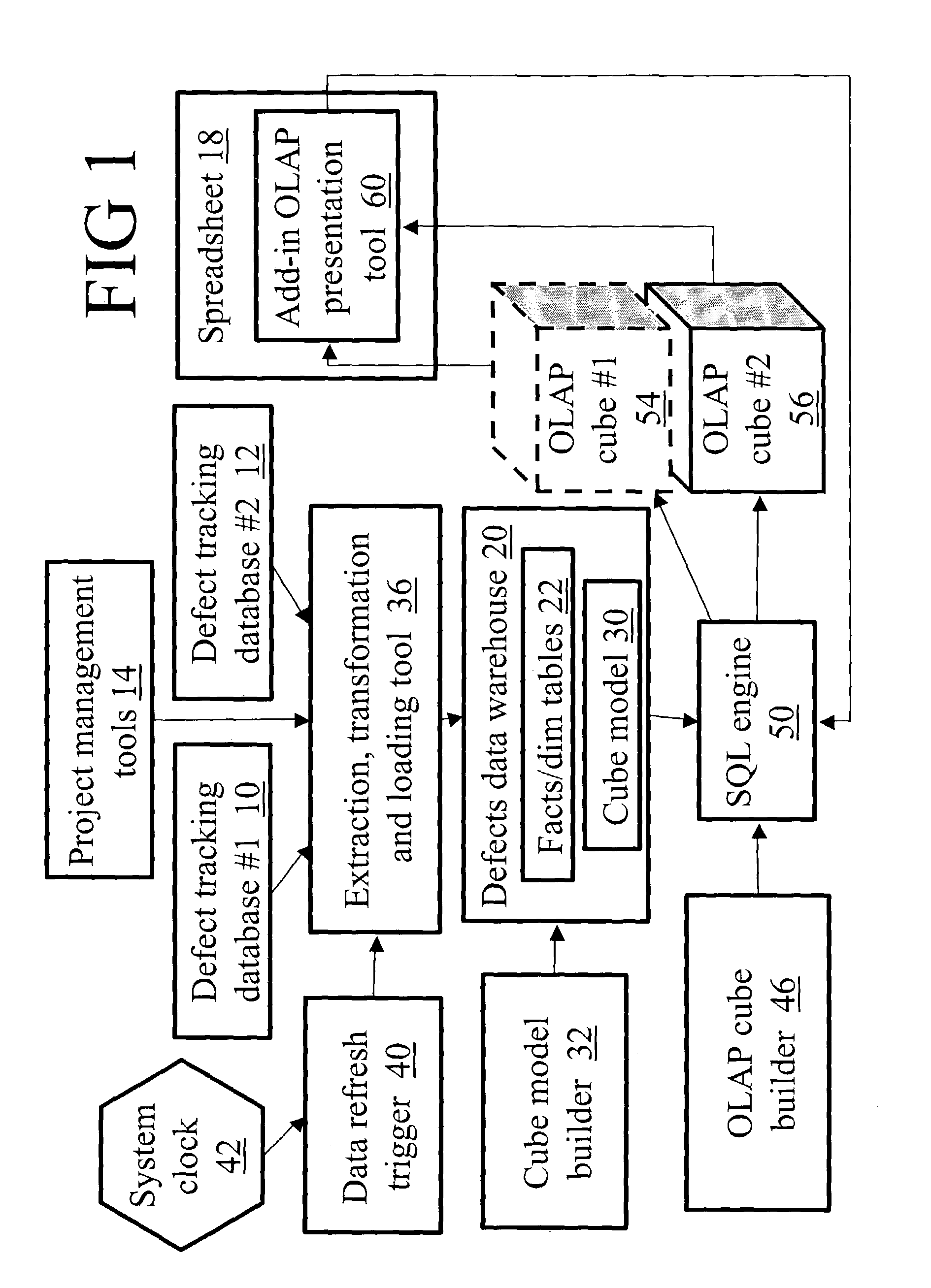

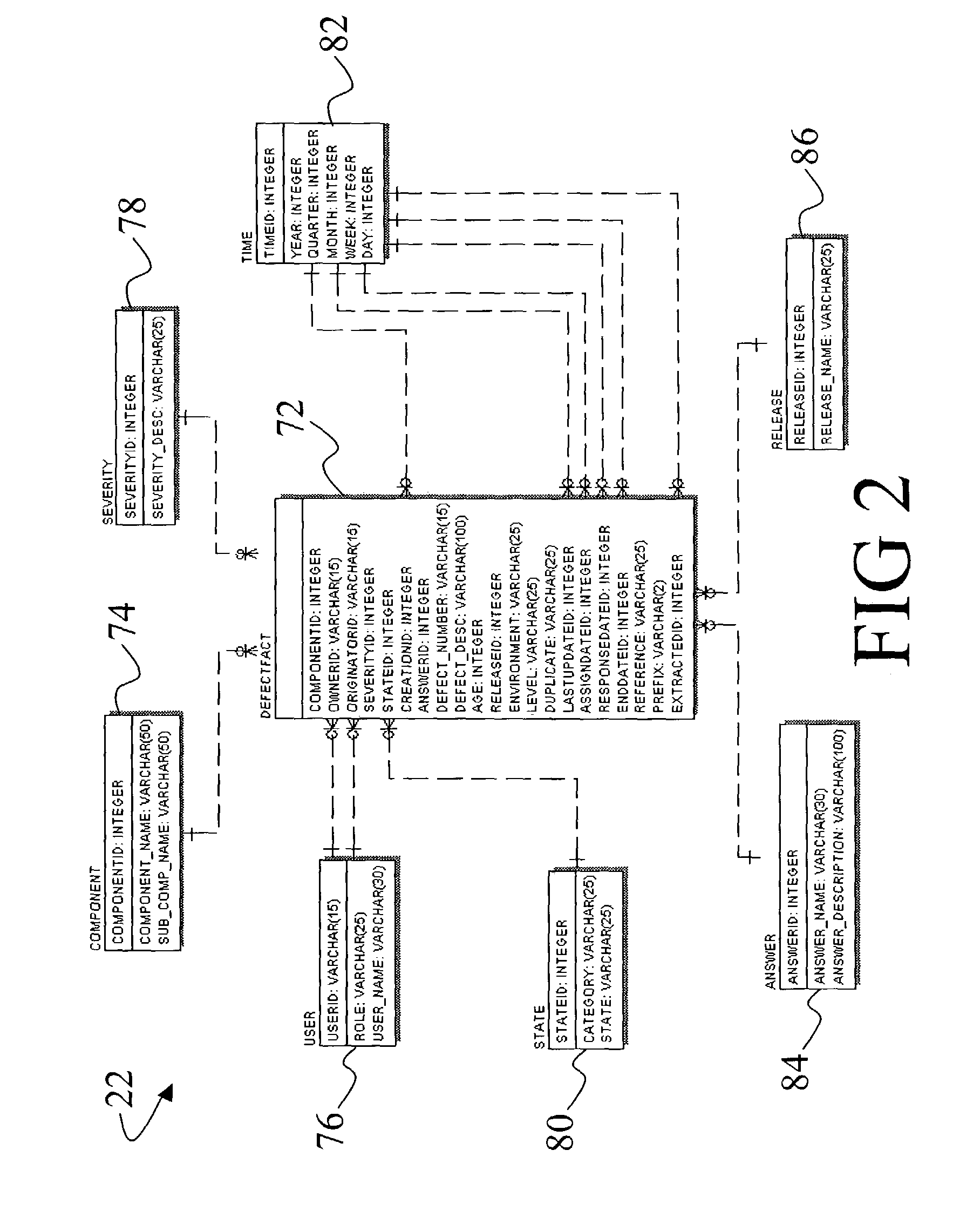

Method and apparatus for processing information on software defects during computer software development

ActiveUS7401321B2Error detection/correctionSpecific program execution arrangementsSoftware development processAgile software development

An apparatus for processing data relating to software defects operates within an on-line analytical processing environment that includes an on-line analytical processing presentation tool (60). An on-line analytical processing cube model builder (32) builds a plurality of interrelated tables (22) with on-line analytical processing cube model metadata (30). The cube model (30) is configured to be processed by the associated on-line analytical processing presentation tool (60). A data extraction tool (36) communicates with a defect tracking database (10, 12) containing said data relating to software defects. The data extraction tool (36) extracts said data from the defect tracking database (10, 12), transforms the extracted data into the software defect entries, and loads the software defect entries into the tables (22).

Owner:IBM CORP

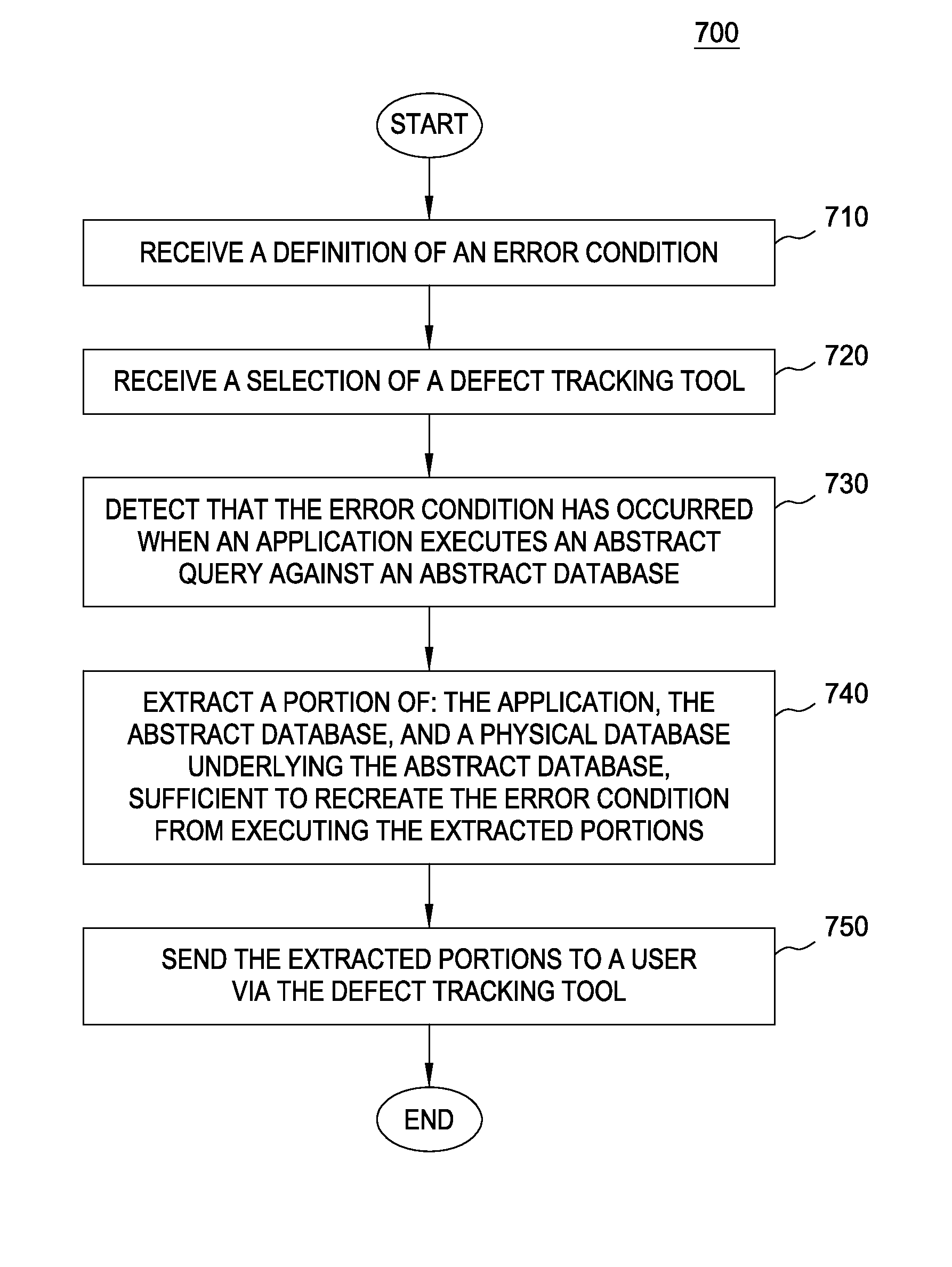

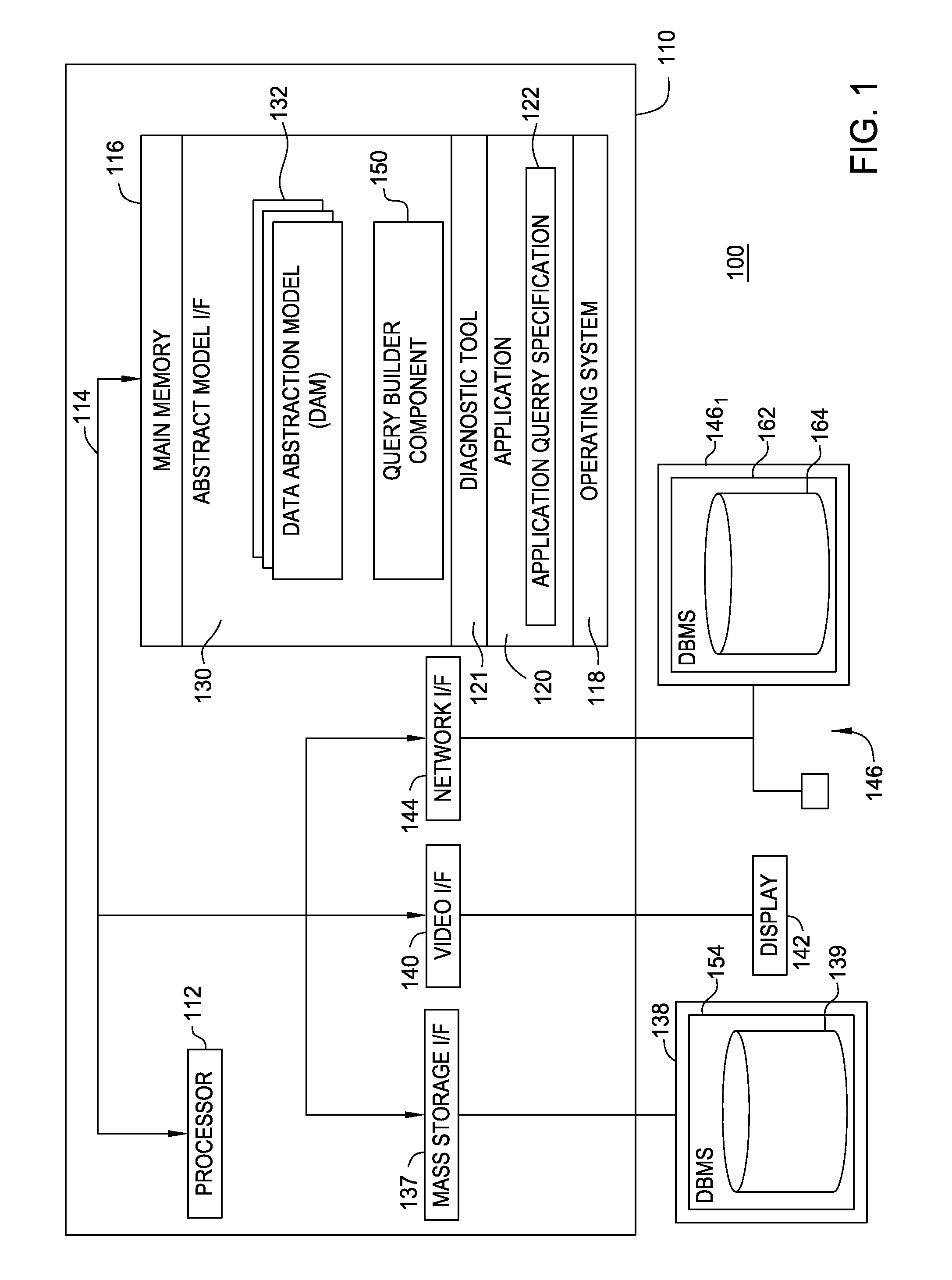

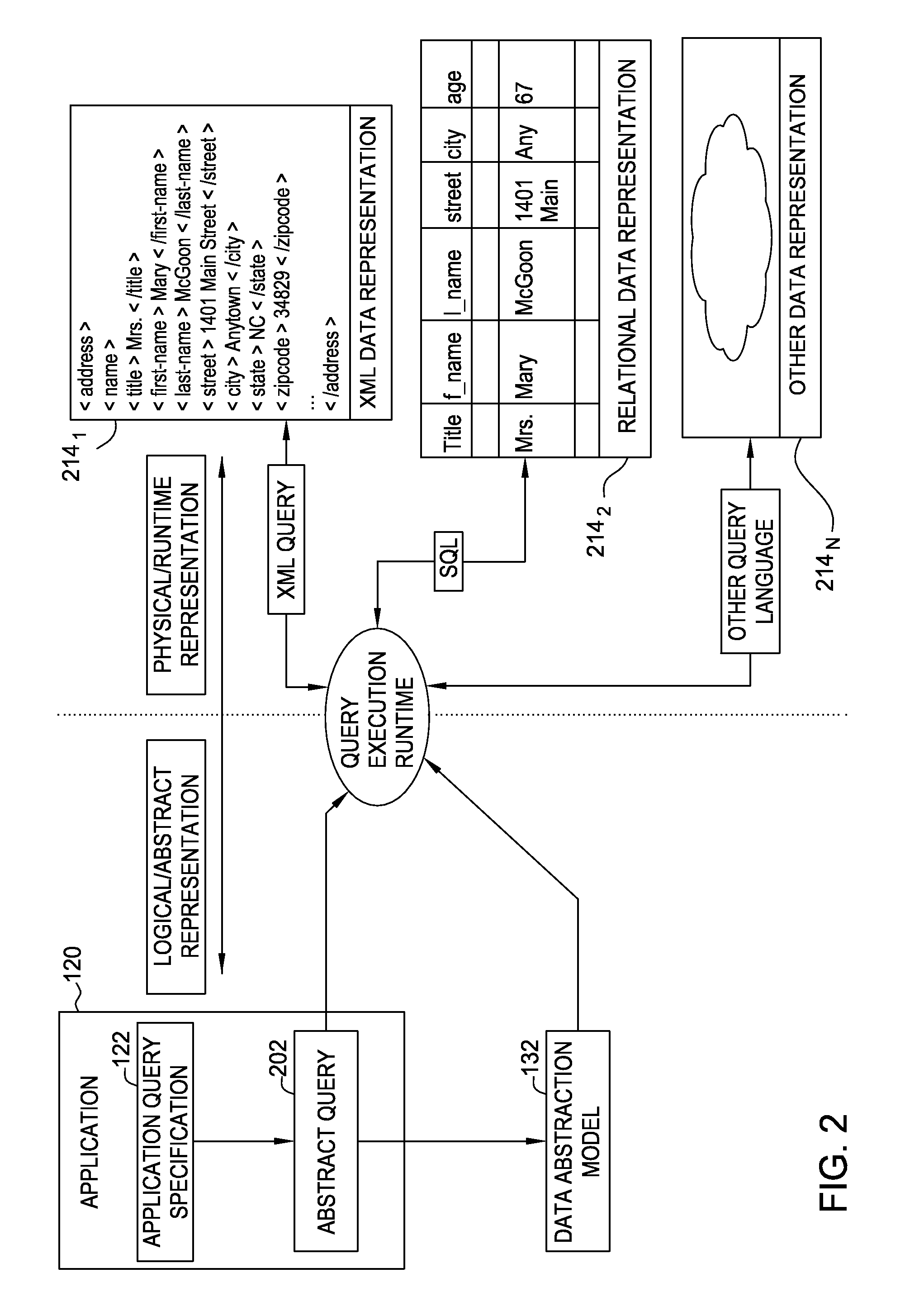

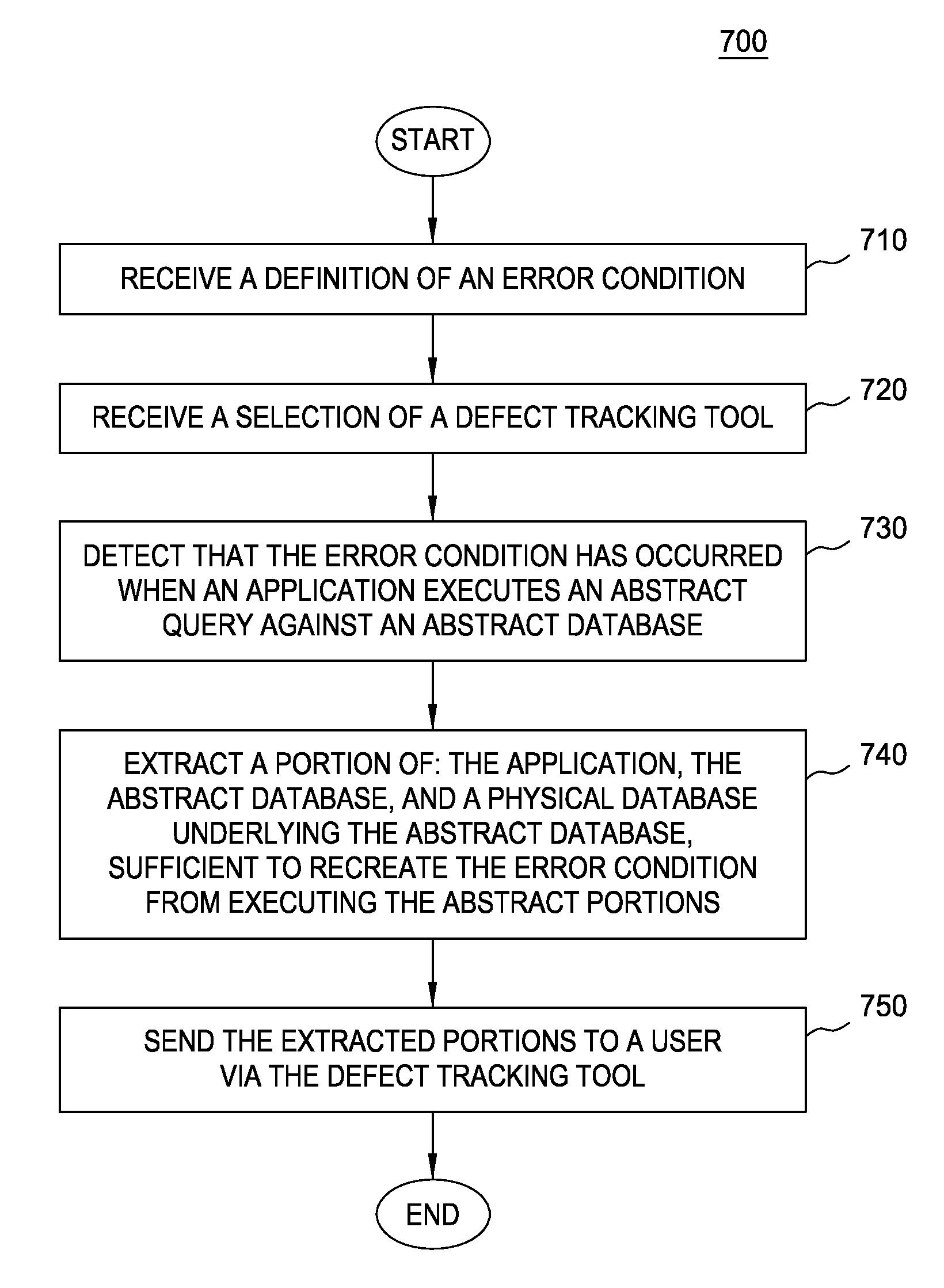

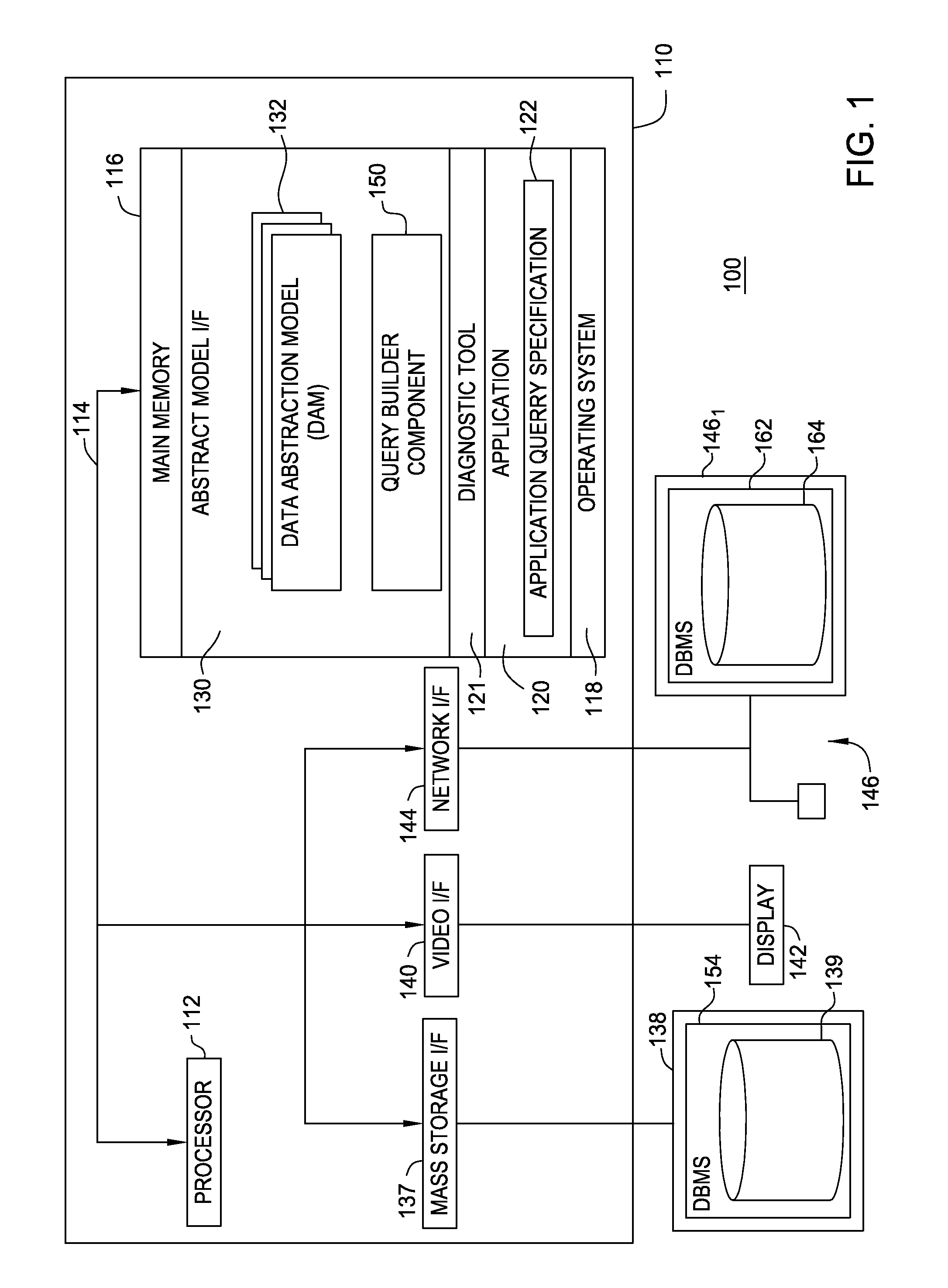

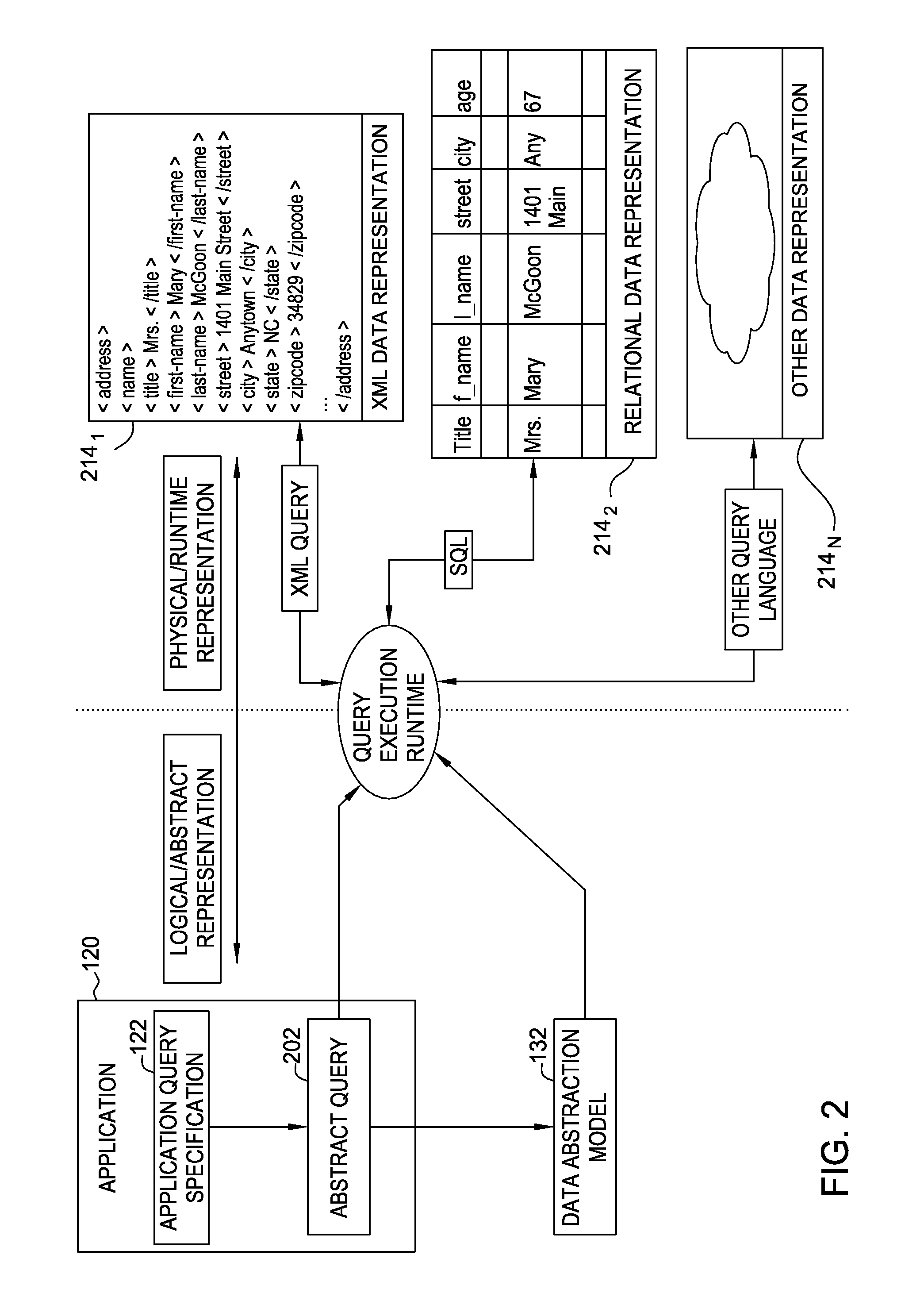

Extracting portions of an abstract database for problem determination

InactiveUS8738607B2Digital data processing detailsRelational databasesData miningProblem determination

Systems, methods and articles of manufacture are disclosed for extracting portions of an abstract database for problem determination. An error may be detected when an application executes an abstract query against the abstract database. A portion of the abstract database may be extracted for problem determination. A defect entry may be created in a defect tracking tool, to store the extracted portion. One or more administrative users may be notified of the defect entry.

Owner:INT BUSINESS MASCH CORP

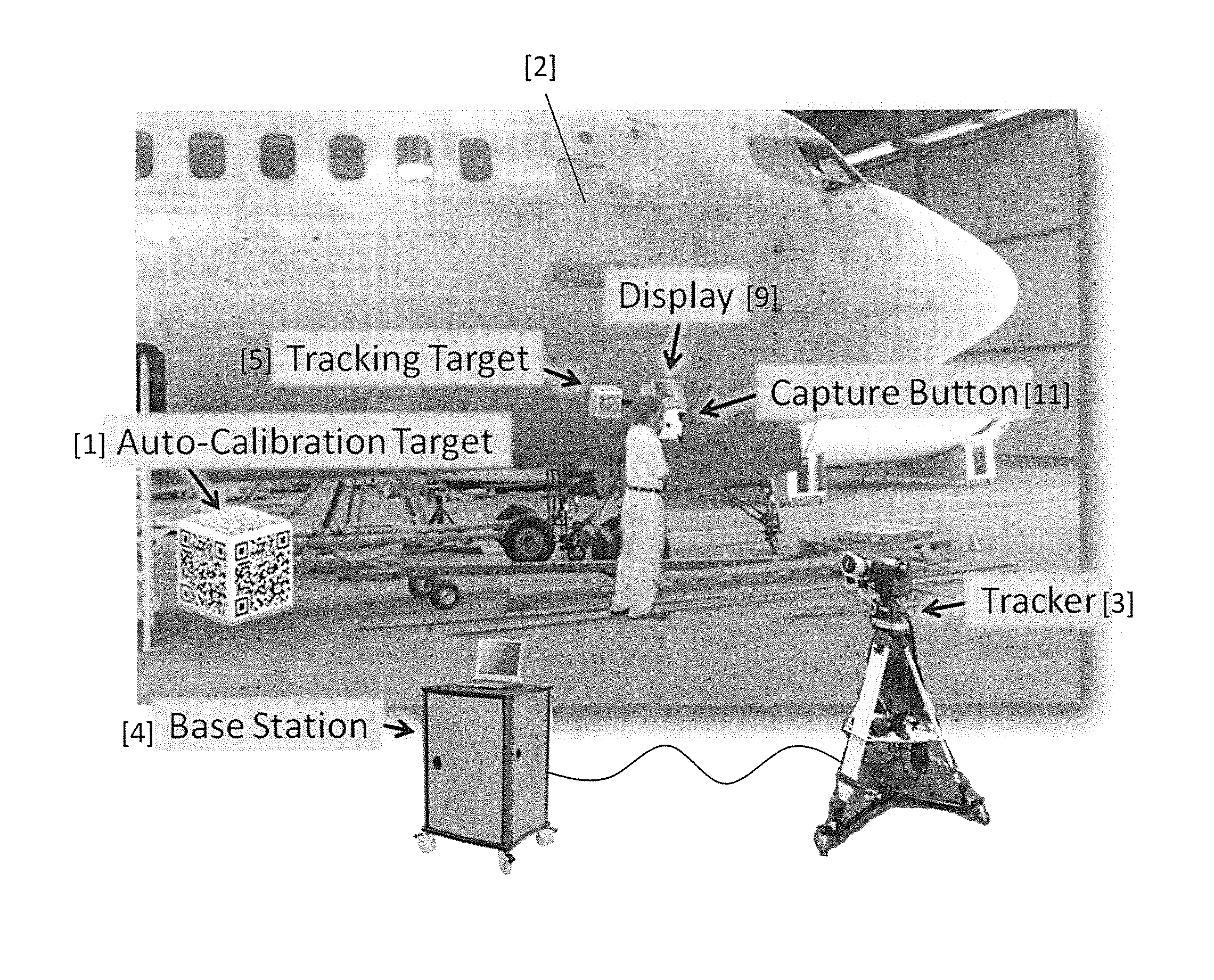

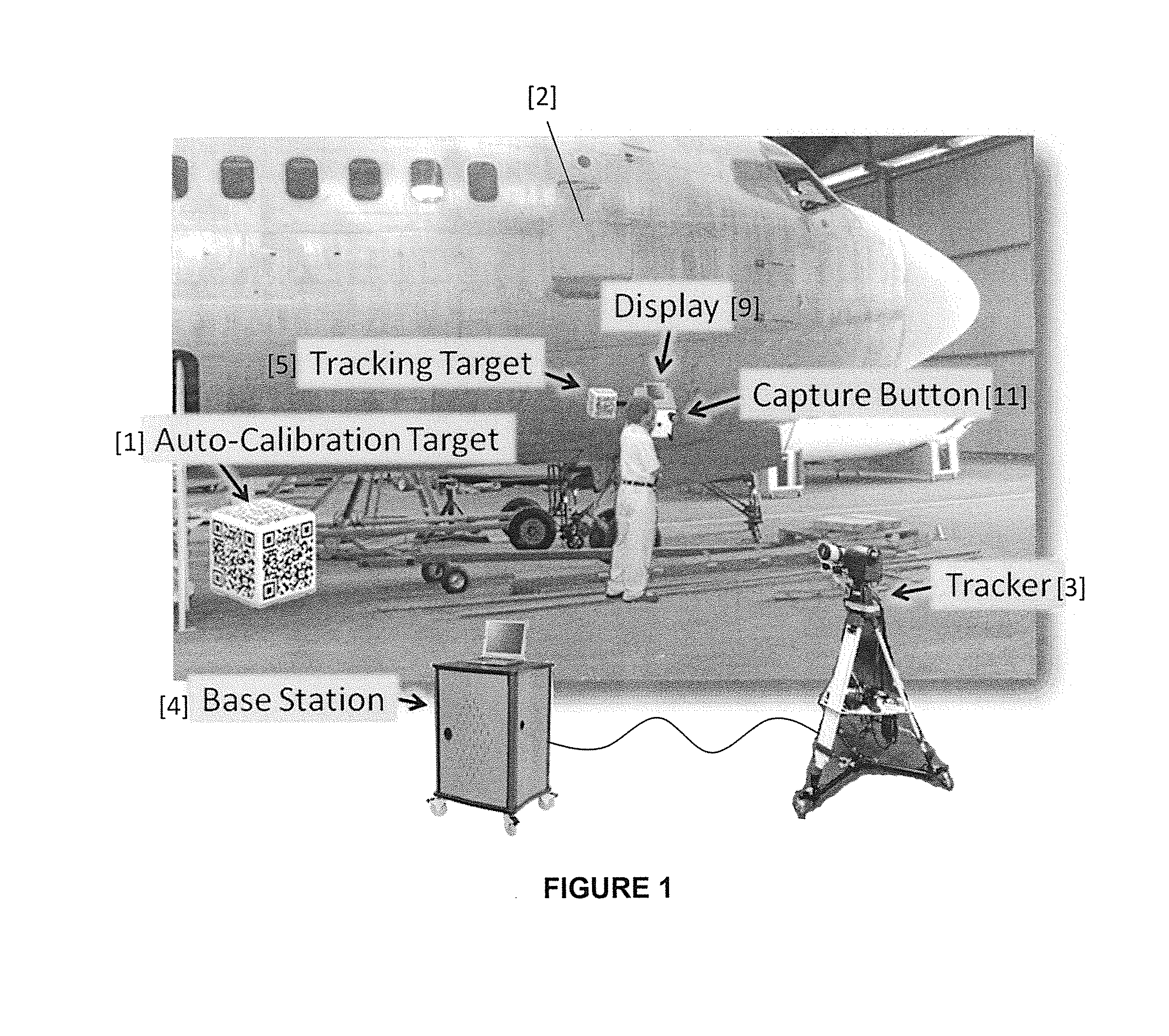

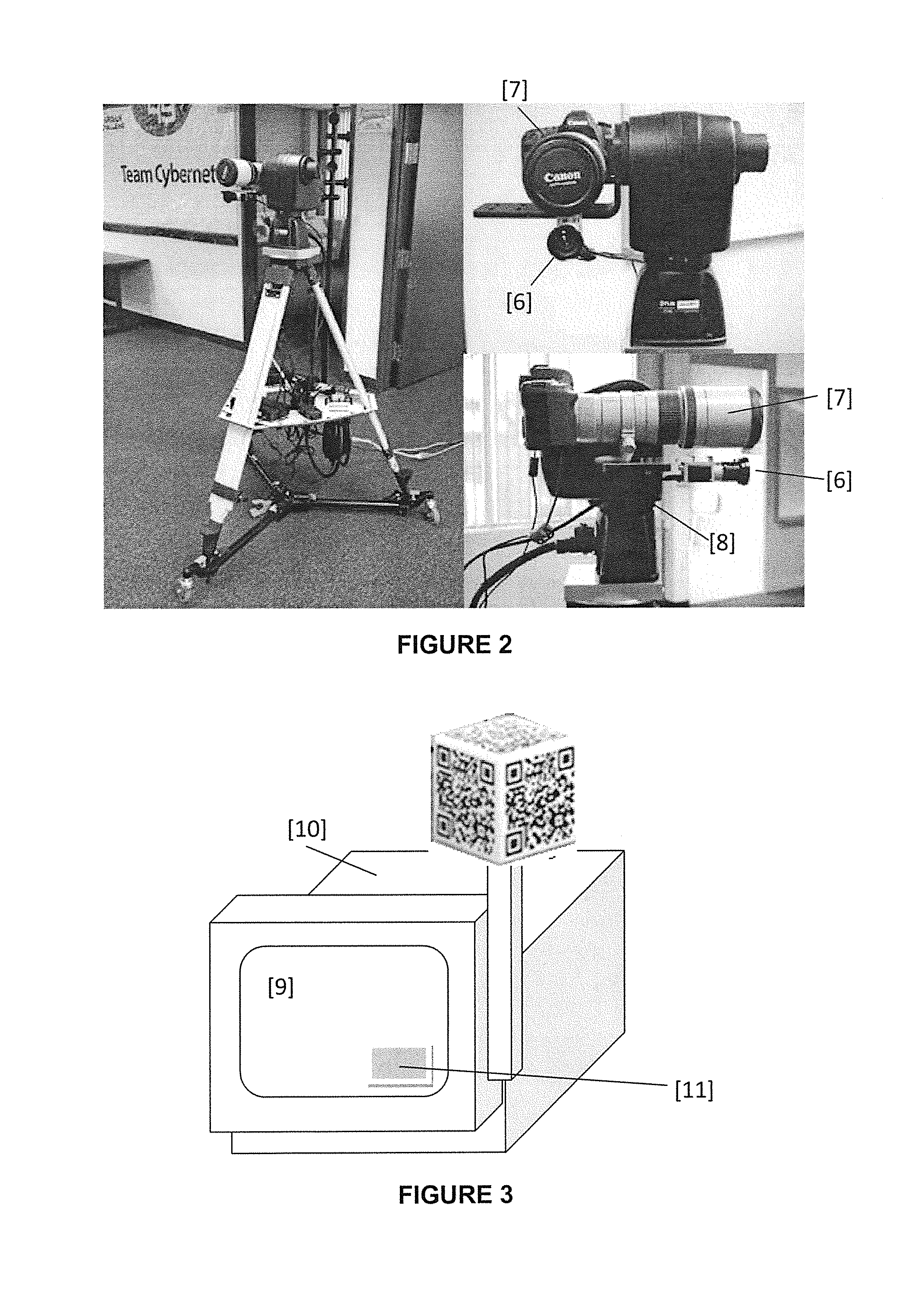

Method and apparatus for camera-based 3D flaw tracking system

Systems and methods facilitate long-range, accurate fiducial tracking using a mixture of pan-tilt and camera devices enabling generalized 3D tracking of fiducials with the automatic mapping of flaw data to component models within standard CAD packages. The invention is suitable to many various tracking applications, particularly large inspection sites such as aircraft surfaces which require vast coverage with a medium-degree of accuracy. A method of surface inspection comprises the steps of moving a fiducial target over a surface under inspection, and tracking the fiducial as it is moved by capturing and storing the coordinates of the fiducial in a database for subsequent retrieval. Machine vision is used to acquire surface inspection data associated with the coordinates of the fiducial as it is moved. The inspection data is integrated into a CAD model, enabling the use of finite element analysis (FEA) to determine or predict flaw and material behavior over time.

Owner:CYBERNET SYST

Welding seam film defect identification method and system

InactiveCN109115812ASolve the accuracy problemSolve the characteristicsMaterial analysis by transmitting radiationEngineeringWeld seam

The invention provides a welding seam film defect identification method and system. The method comprises the following steps: acquiring a welding seam film of a welding seam through a ray imaging technology; acquiring welding seam image texture characteristic data of the welding seam film by utilizing an image identification technology; establishing an identification model according to the weldingseam image texture characteristic data and a defect type of the welding seam film through a machine learning algorithm; acquiring welding seam image texture characteristic data of a welding seam filmto be detected; calculating a defect type of the welding seam film to be detected according to the welding seam image texture characteristic data of the welding seam film to be detected and the identification model. Therefore, the problem that the texture precision and the characteristic judgment of welding film welding are not accurate is effectively solved, the image edge detection and defect tracking and identification precision of a welding film is greatly improved and a foundation is laid for the development of a welding seam characteristic identification technology.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

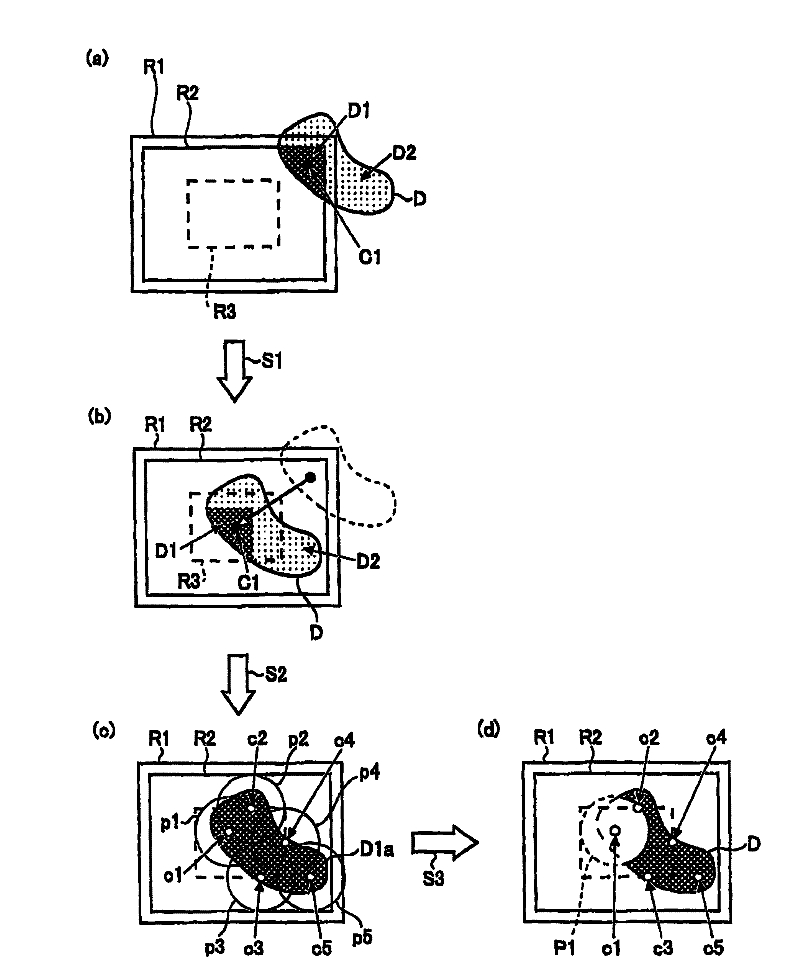

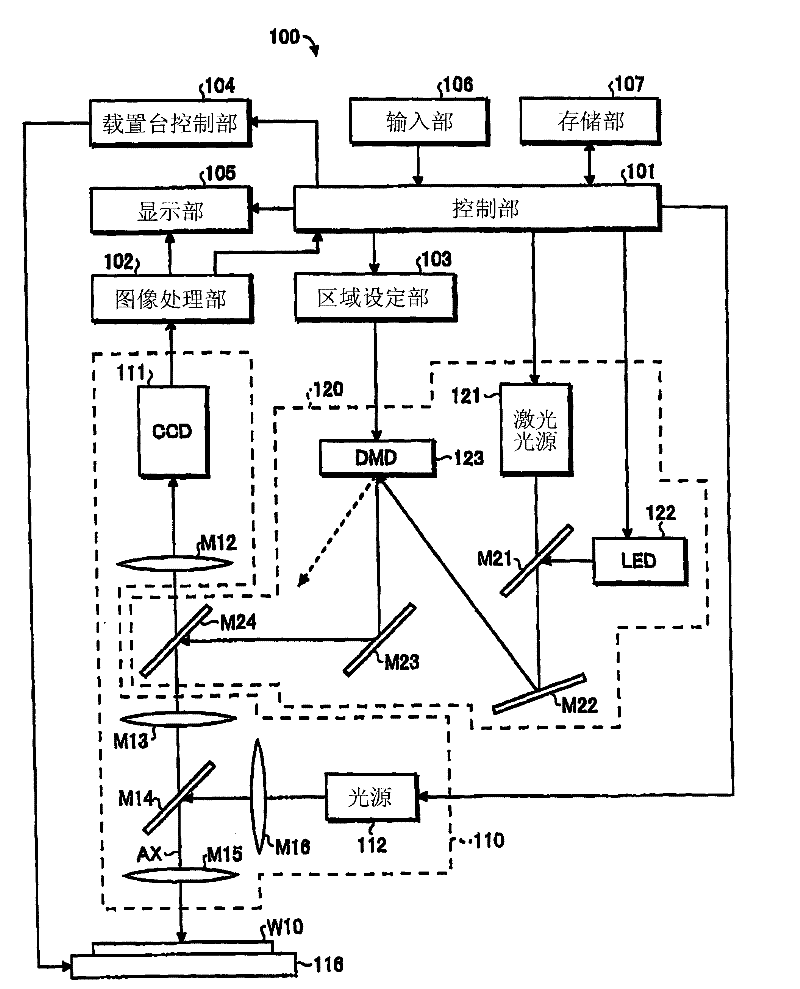

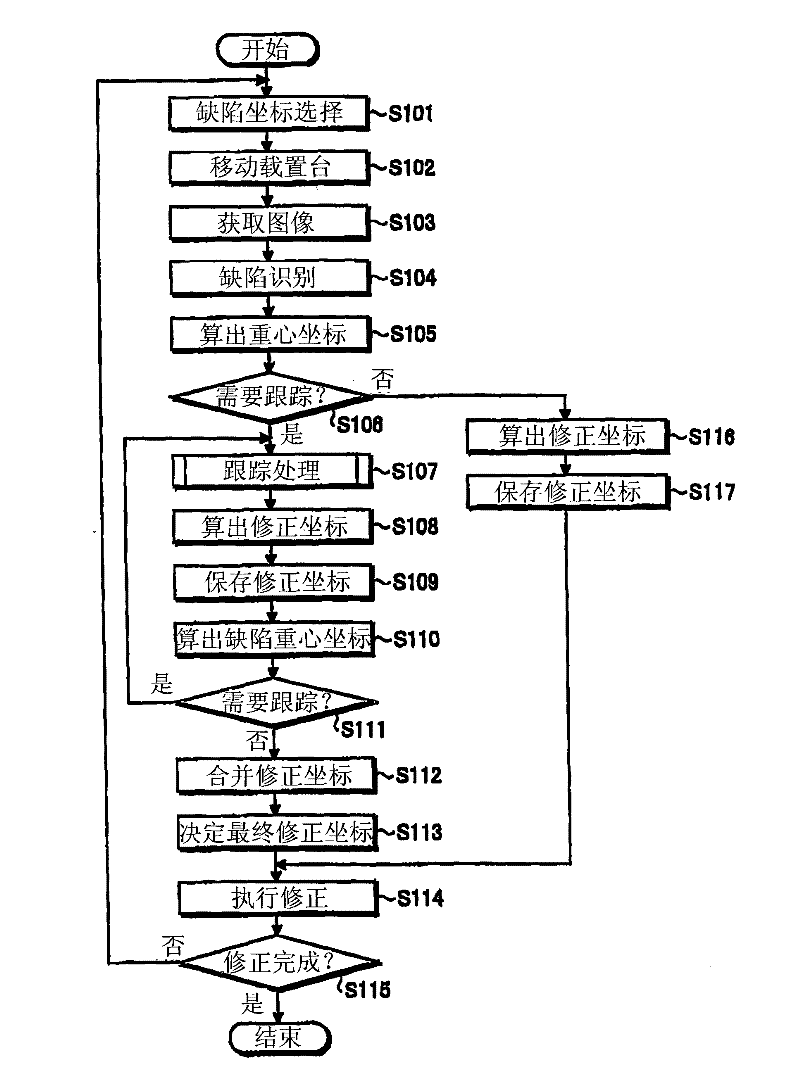

Defect correction device and defect tracking method

InactiveCN102189331AMaterial analysis by optical meansLaser beam welding apparatusComputer visionComputer science

The invention discloses a defect correction device and a defect tracking method. The defect correction device, which already comprises an image pickup part for obtaining an image after one part of an object substrate is amplified and a defect correction part for correcting the object substrate according to the image obtained by the image pickup part, comprises a judging part for judging whether the defect in the image obtained by the image pickup part extends outside of the image, a tracking part for tracking the part extending outside of the image when the defect extends outside of the image, and a setting part for setting more than one correction regions to the defect in the image obtained by the image pickup part. After the tracking part tracks the image, the setting part sets more than one correction regions to the defect in the image obtained by the image pickup part.

Owner:OLYMPUS CORP

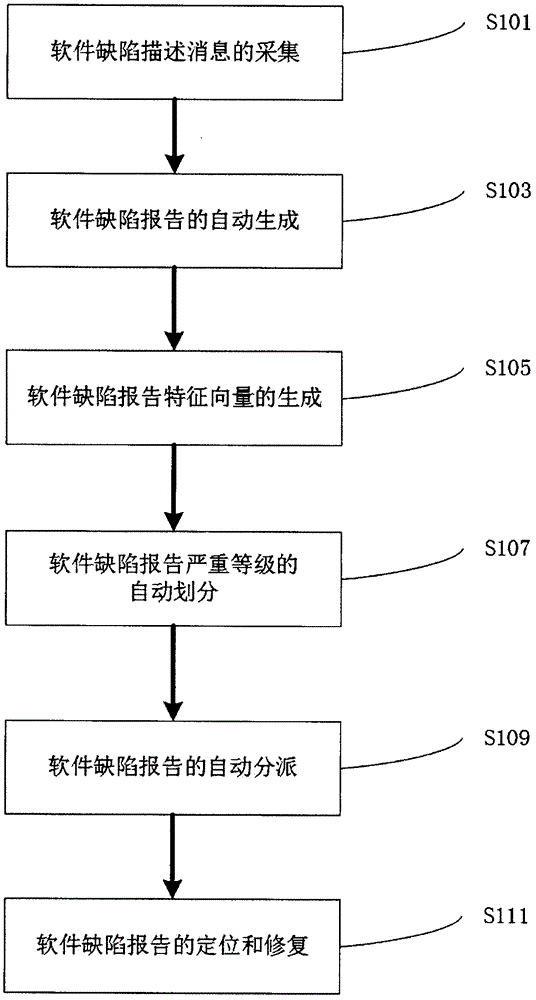

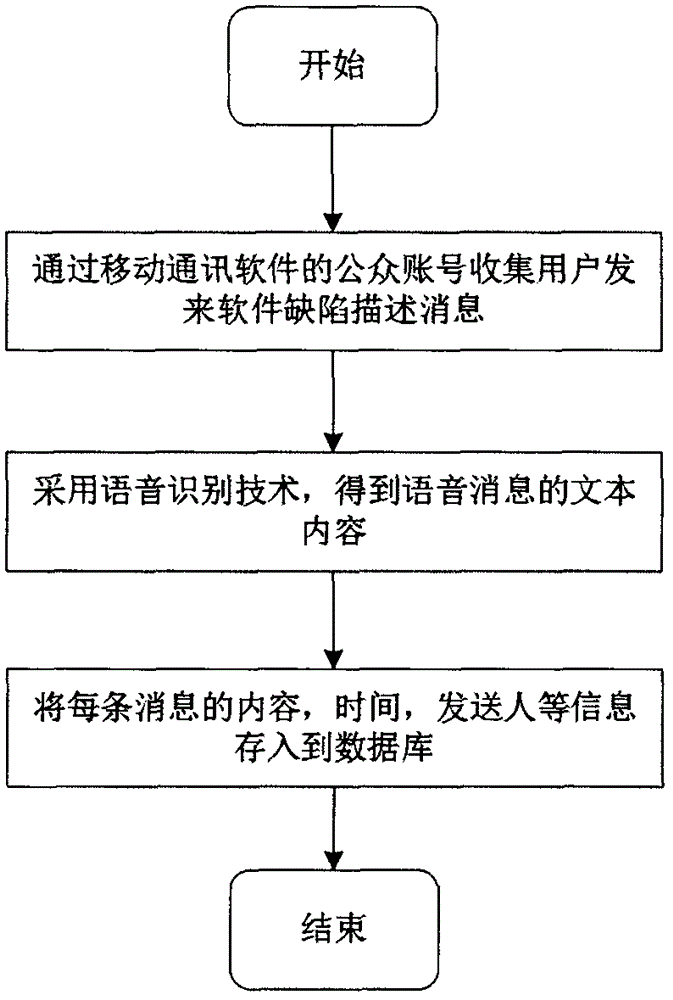

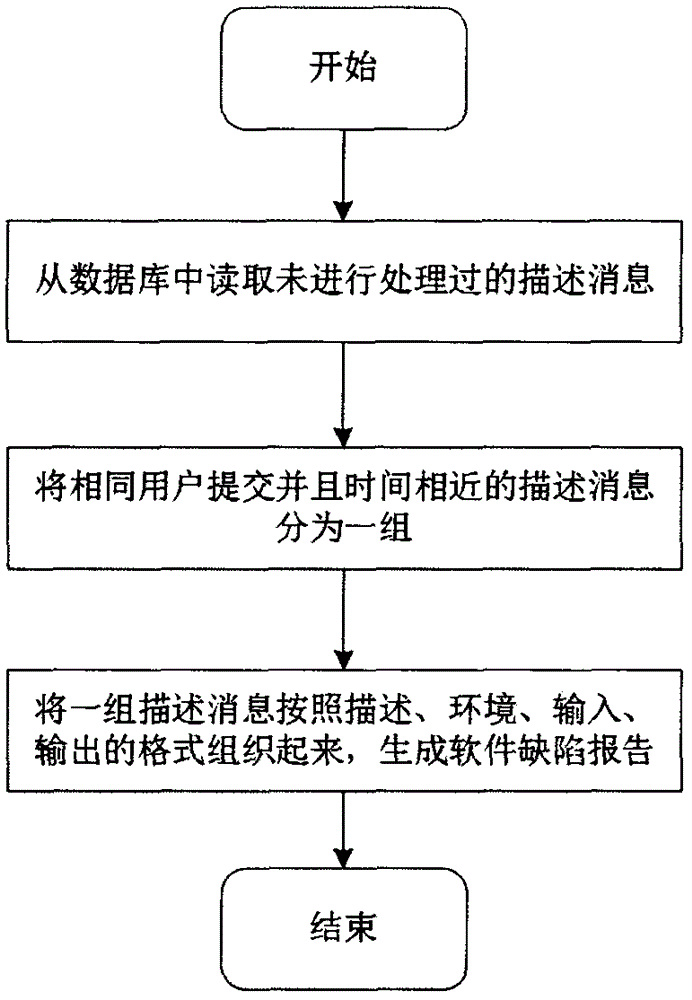

Intelligent software defect tracking management method based on mobile instant messaging software

InactiveCN104615533AImprove test productivityHigh degree of automationSoftware testing/debuggingFeature vectorSeverity level

The invention provides an intelligent software defect tracking management method based on mobile instant messaging software. The method includes the following steps that (1) software defect description messages are collected; (2) software defect reports are generated automatically; (3) the feature vectors of the software defect reports are generated; (4) the severity levels of the software defect reports are divided automatically; (5) the software defect reports are distributed automatically; (6) the software defect reports are positioned and repaired. By means of the intelligent software defect tracking management method, the problem that an existing software defect tracking management method cannot meet the development requirement of agile software is solved, the usability and the operation efficiency of software defect tracking management are greatly improved, the software testing work efficiency is improved, and therefore the product quality can be better controlled.

Owner:NANJING UNIV

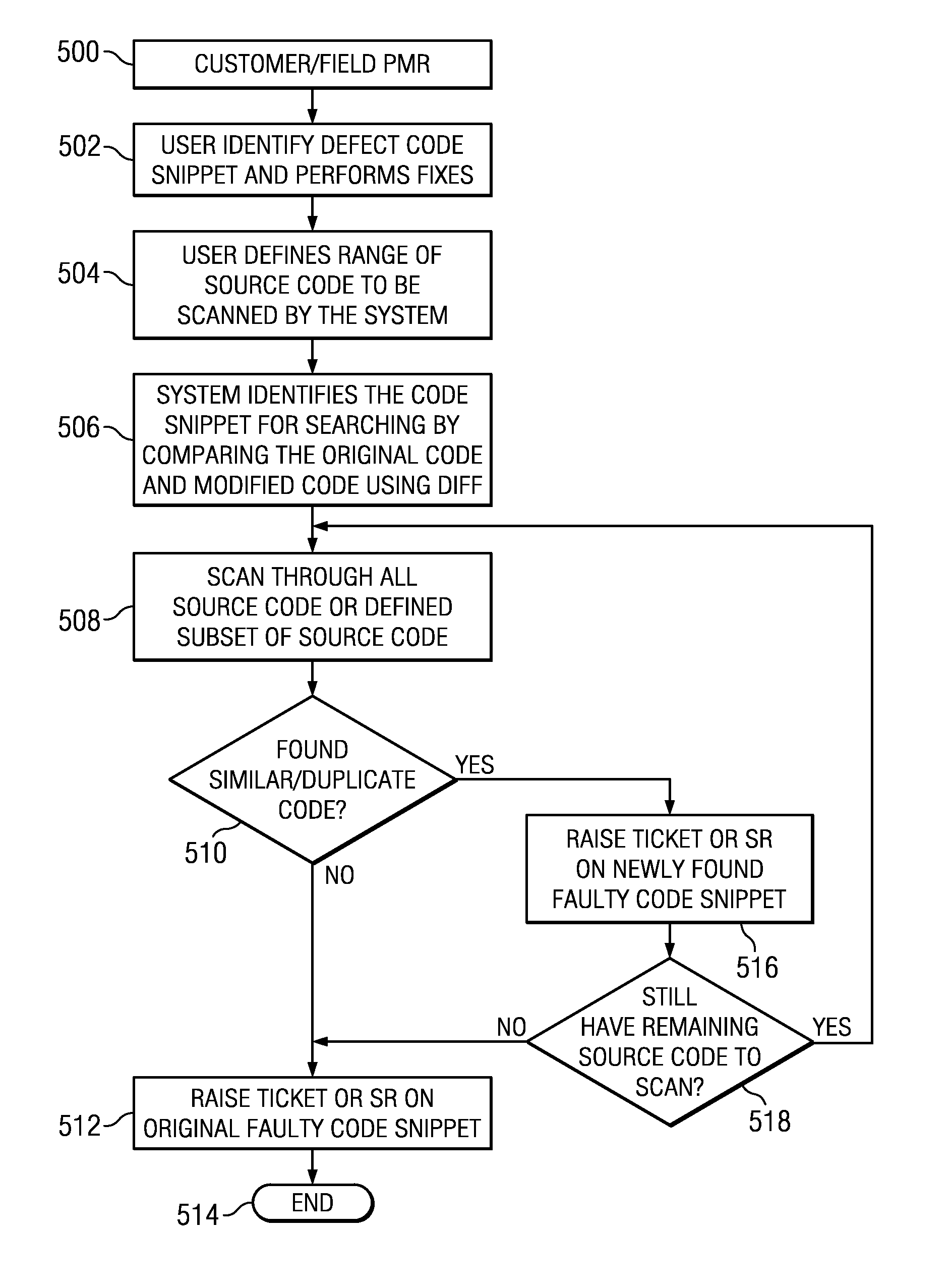

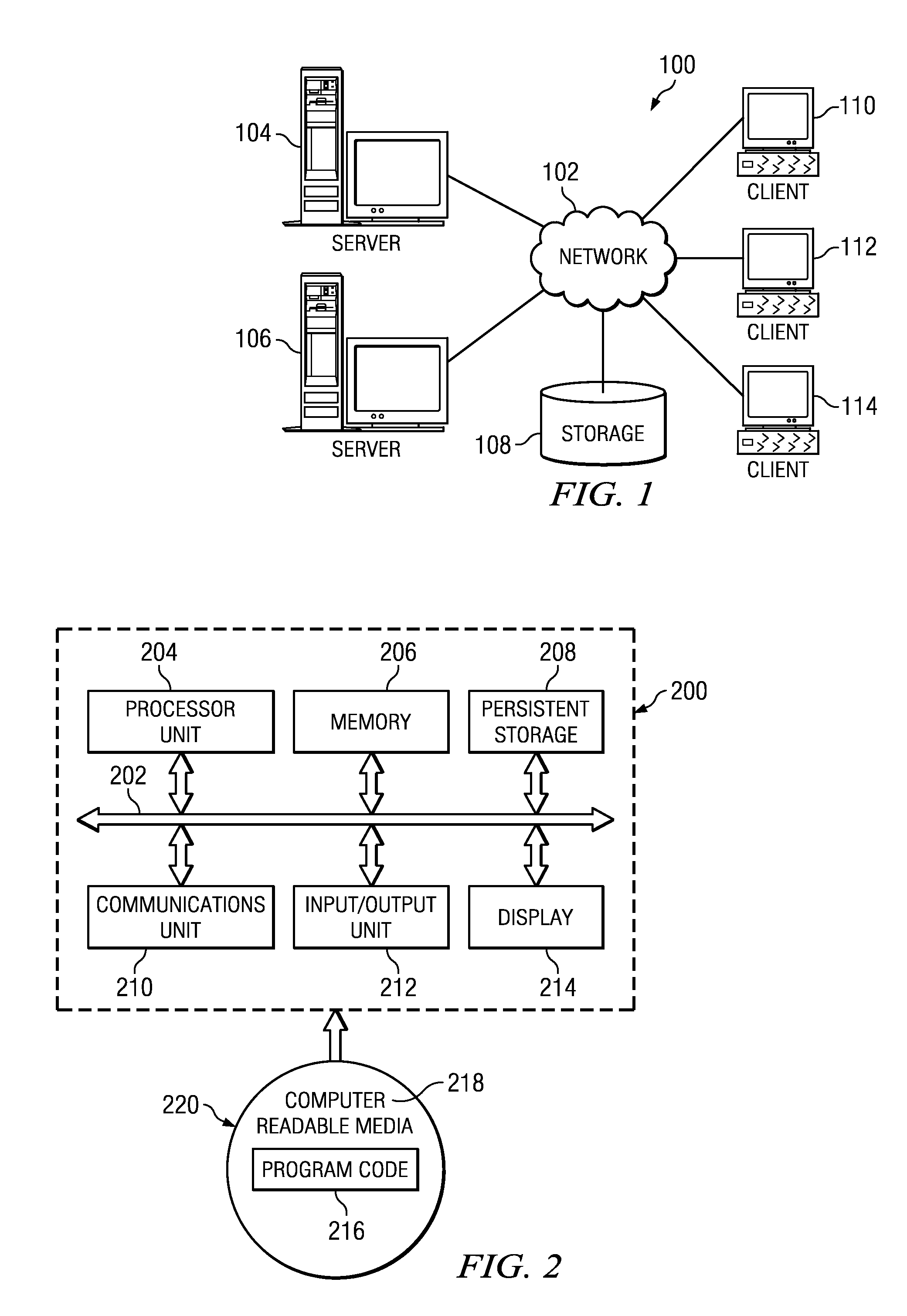

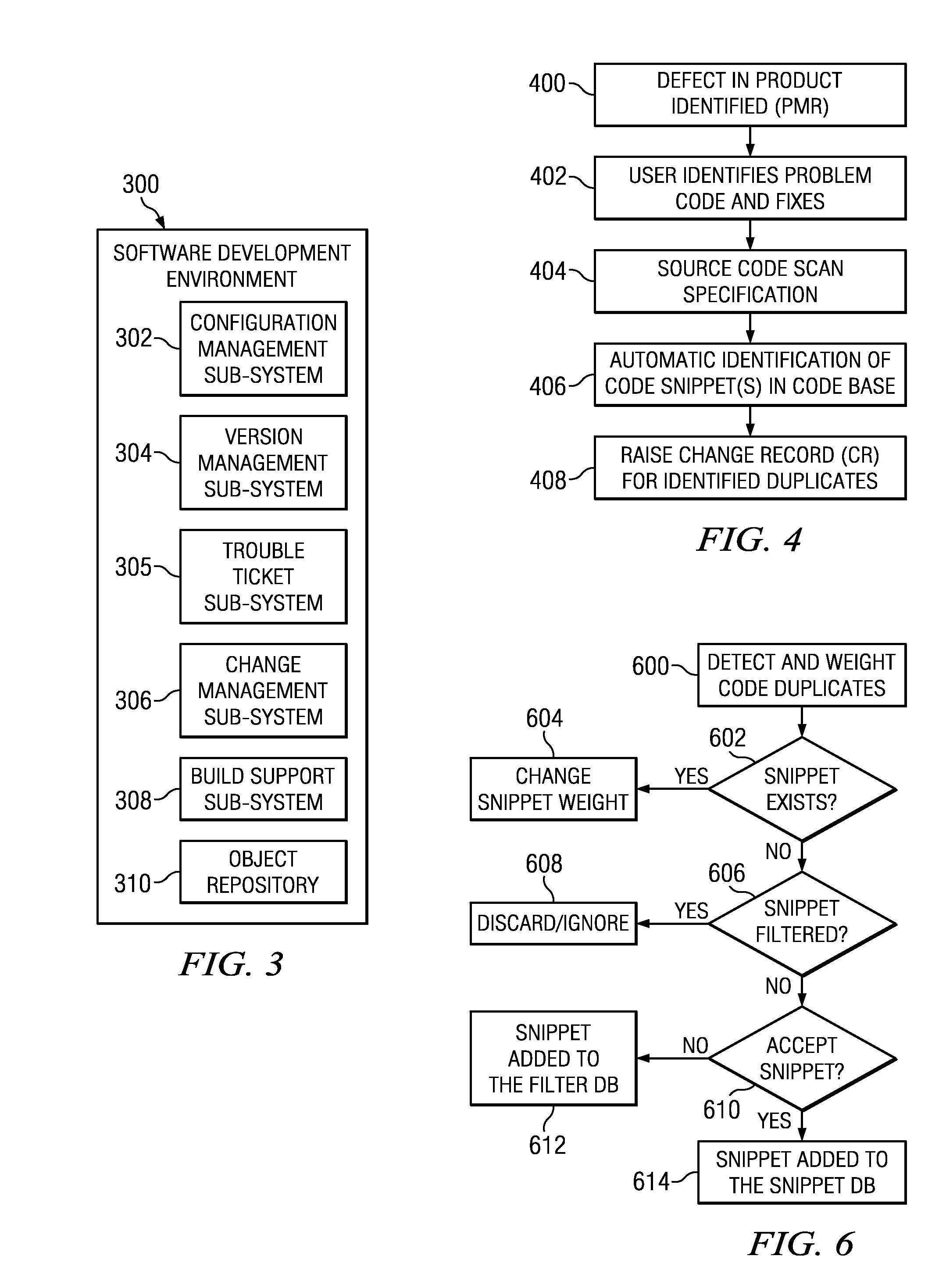

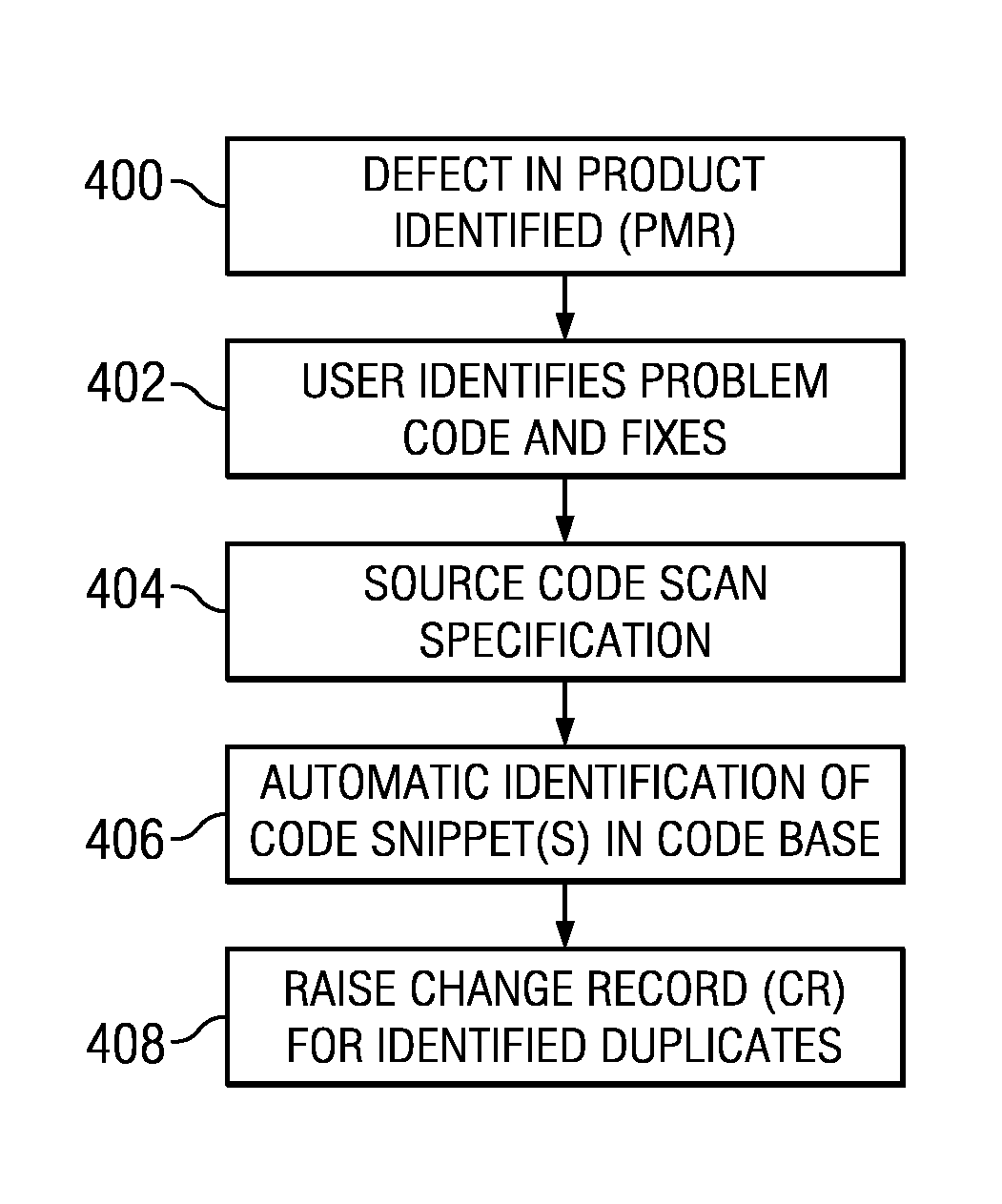

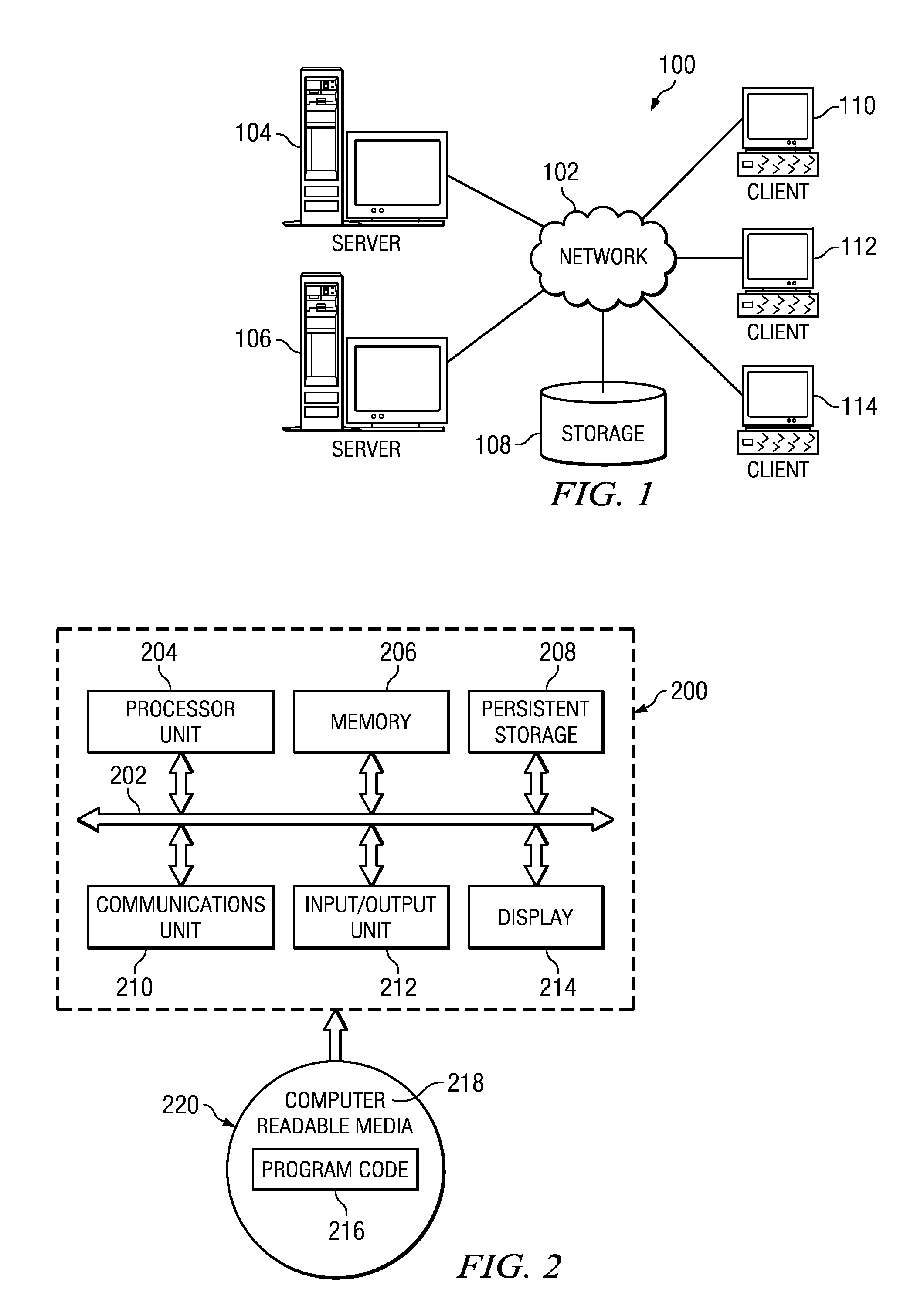

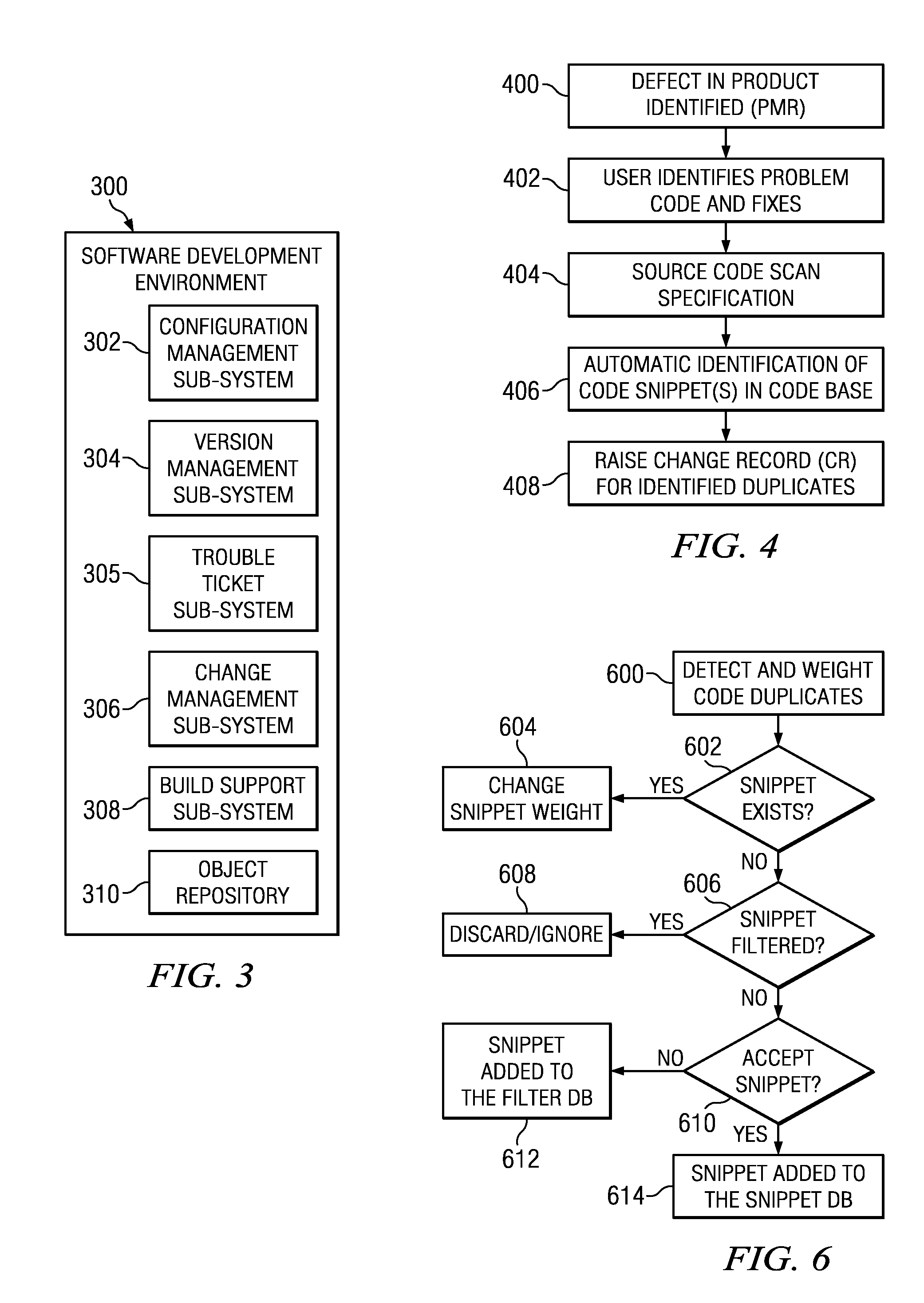

Automated tagging and tracking of defect codes based on customer problem management record

ActiveUS20130311975A1Facilitate software defect trackingEasy to correctVersion controlSoftware testing/debuggingProblem managementCode snippet

A routine for tagging and tracking source code may be implemented in a software development environment. The routine begins upon the identification of a defect in a software product or system. Once the defect has been identified and rectified, a search of other source code (typically located in a source code management system that supports version control) is specified. Using the search specification, the system automatically identifies the code snippet to be searched and begins searching the identified codebase for duplicates. A ticket or service record is then created for every duplicate / similar code snippet found during the search. The ticket / record enables software defect tracking to be carried out on the newly-located instances of the code. The system also automatically manages the code snippets identified by the duplicate detection.

Owner:IBM CORP

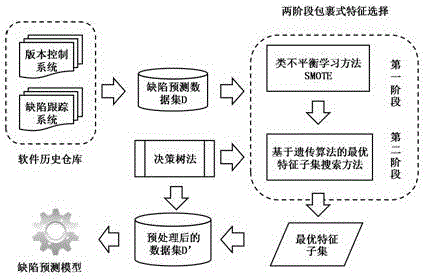

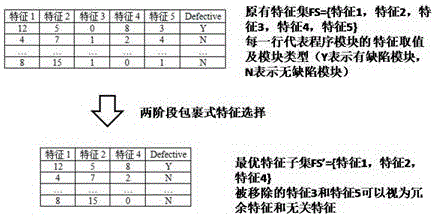

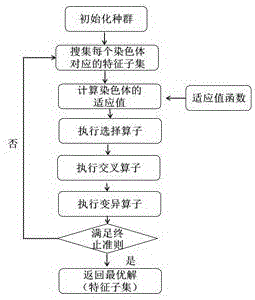

Software defect prediction method based on two-stage wrapping-type feature selection

ActiveCN106126413AImprove performanceGood feature subsetSoftware testing/debuggingData setFeature set

The invention discloses a software defect prediction method based on two-stage wrapping-type feature selection, and belongs to the field of software quality assurance. The software defect prediction method comprises the following steps: (1) mining the version control system and the defect tracking system of a software project, extracting a program module from the version control system and the defect tracking system, and carrying out type marking and software measurement on the program module to generate a defect prediction data set D; (2) carrying out two-stage wrapping-type feature selection on the defect prediction data set so as to remove redundant features and irrelevant features in the data set D as many as possible, and finally, selecting an optimal feature subset FS' from an original feature set FS; and (3) on the basis of the optimal feature subset FS', preprocessing the data set D, forming a preprocessed data set D', and finally, constructing a defect prediction model in virtue of a decision tree which is a classification method. By use of the software defect prediction method, on one hand, the redundant features and the irrelevant features in the defect prediction data set can be effectively identified and removed, on the other hand, a class imbalance problem in the defect prediction data set can be effectively alleviated, and finally, the performance of the defect prediction model can be effectively improved.

Owner:南京瑞沃软件有限公司

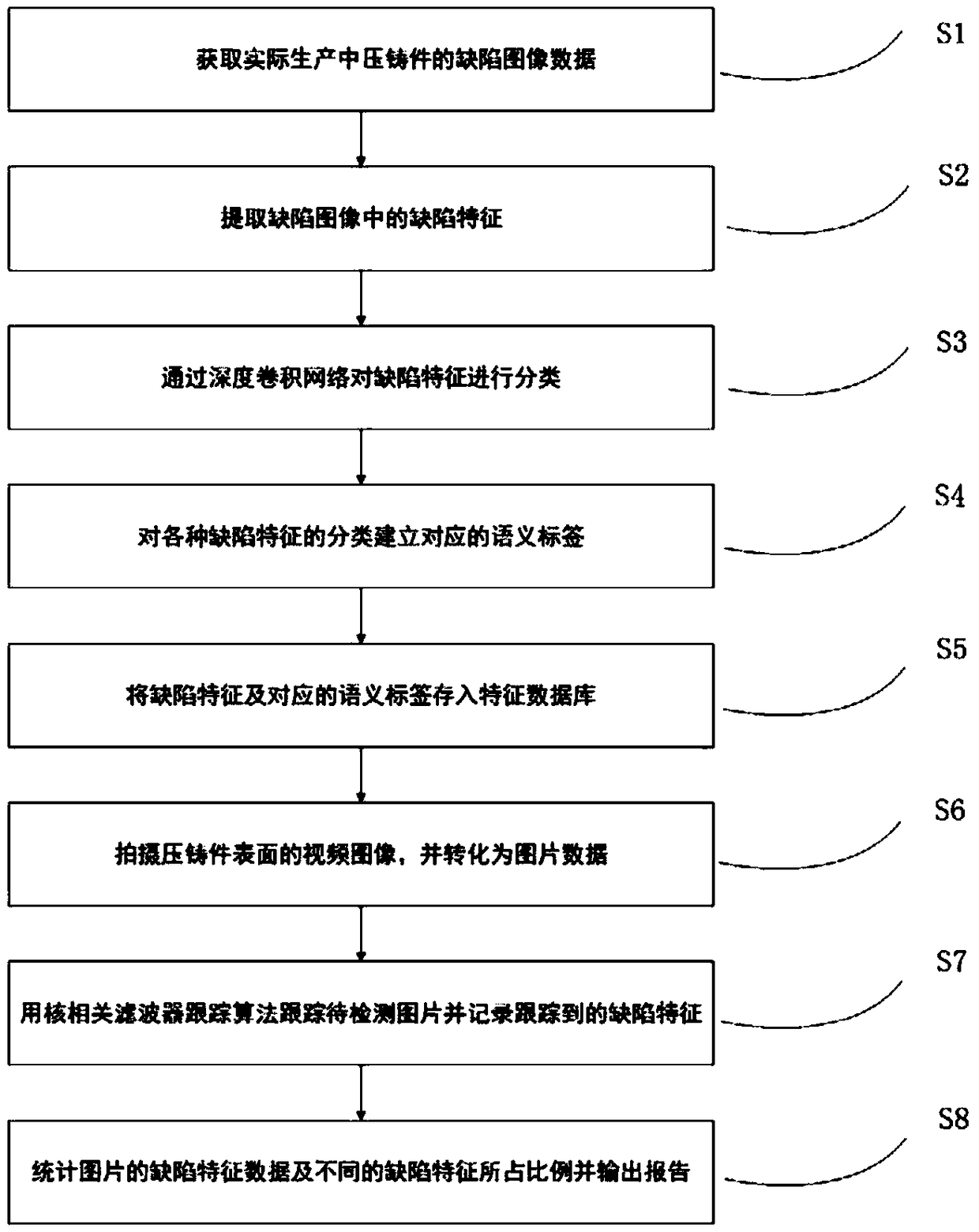

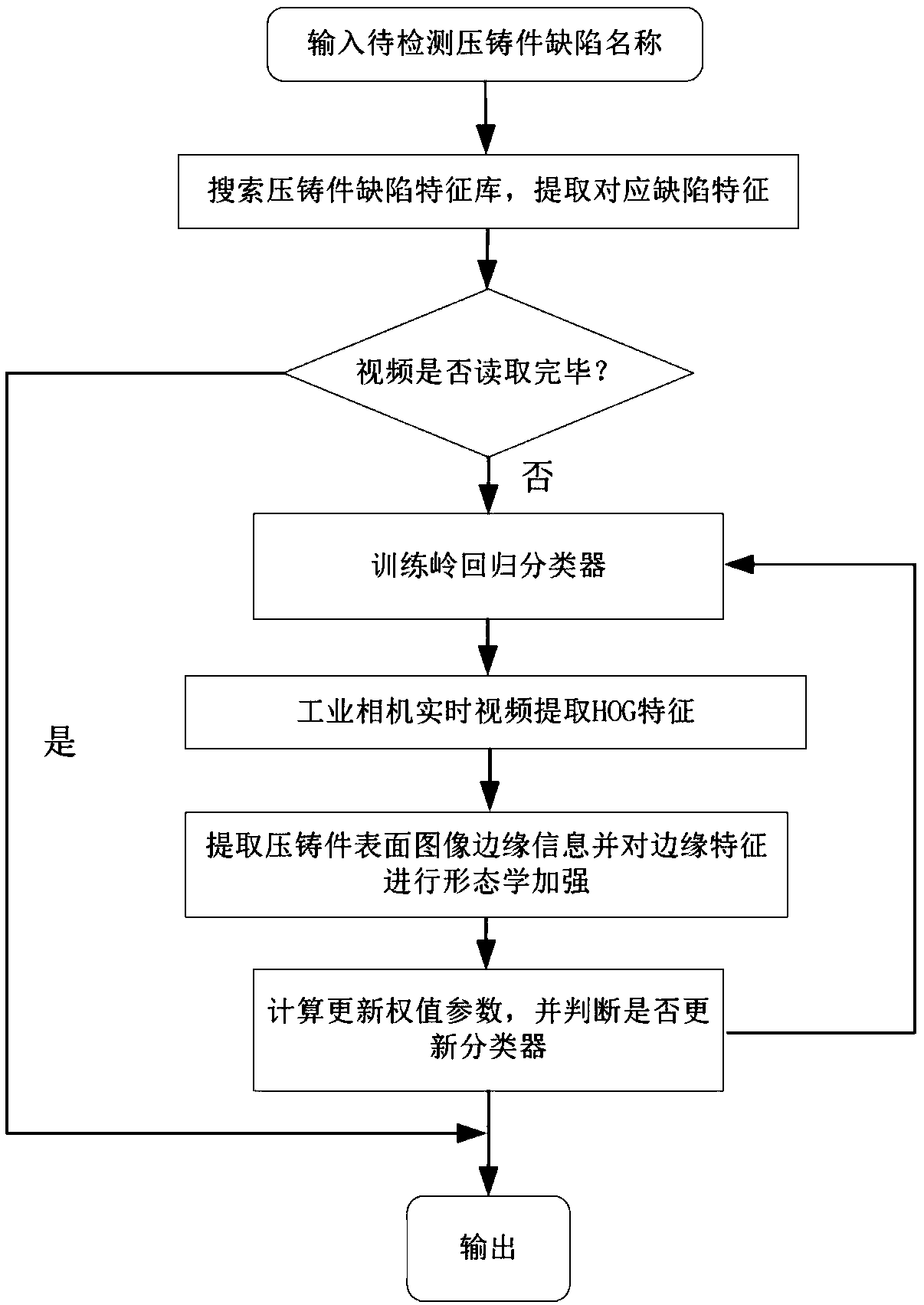

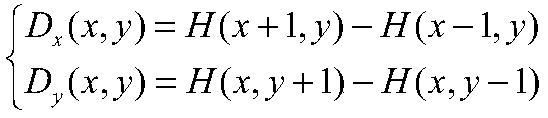

A method and a device for detect defects of a die casting part

A method and apparatus for detect defects of die casting parts are disclosed, By collecting pictures of die castings with defect features, the defect image is denoised, enhanced processing, The depthconvolution network Alexnet is trained with the defect pictures to classify the defect pictures, establish the corresponding semantic tags and store them in the defect feature database, track the defects of the die castings in real time. When the defects of the die castings are detected, the defects are fed back to the inspection device and the inspection data are counted to generate the defect inspection report of the die castings. The invention improves the defect detection efficiency and precision of the die casting, and has the advantages of high accuracy, high speed and good real-time performance, and can quickly and accurately find the defective die casting.

Owner:SHAOGUAN COLLEGE

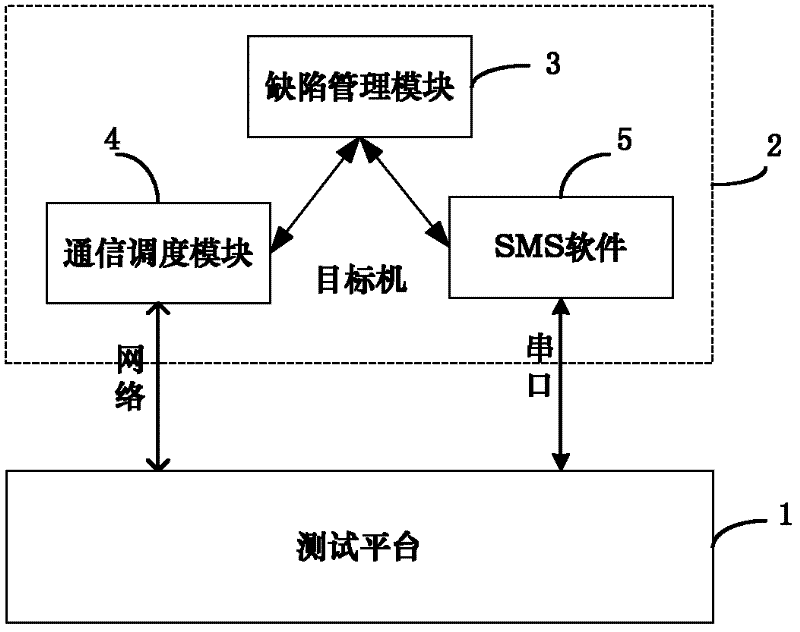

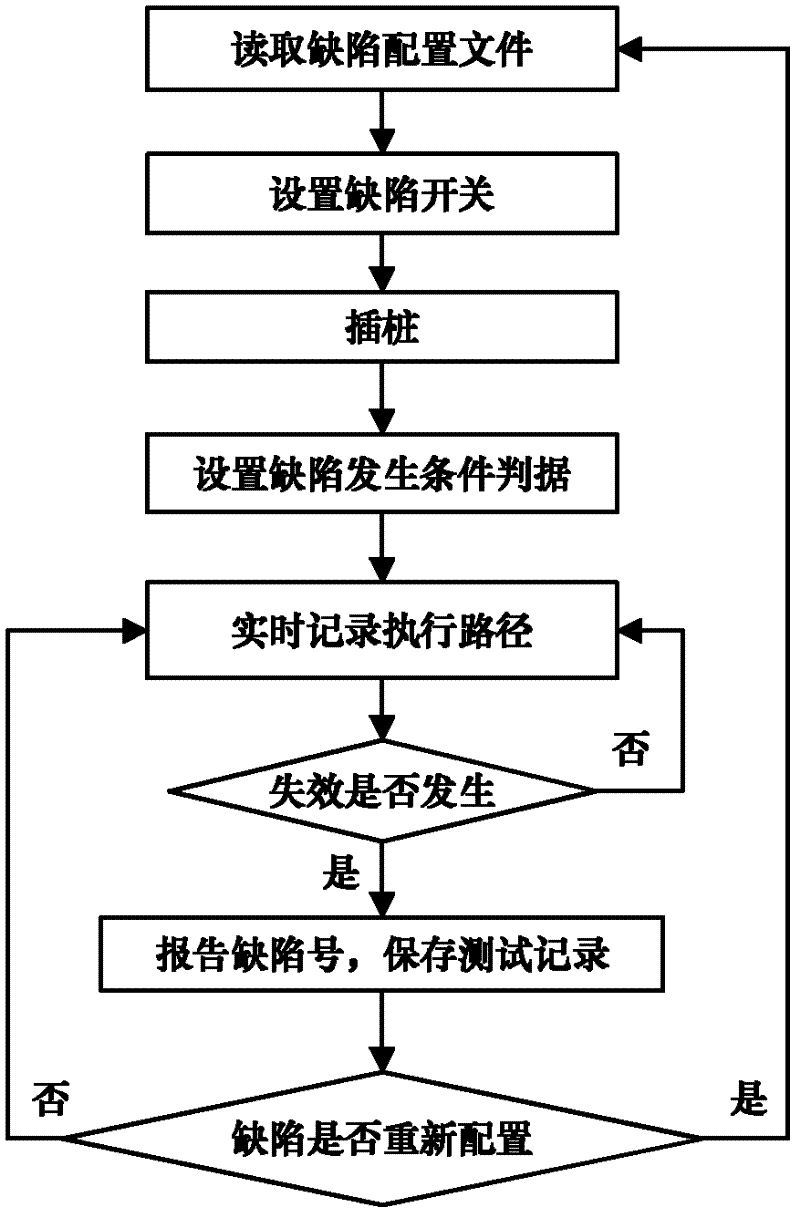

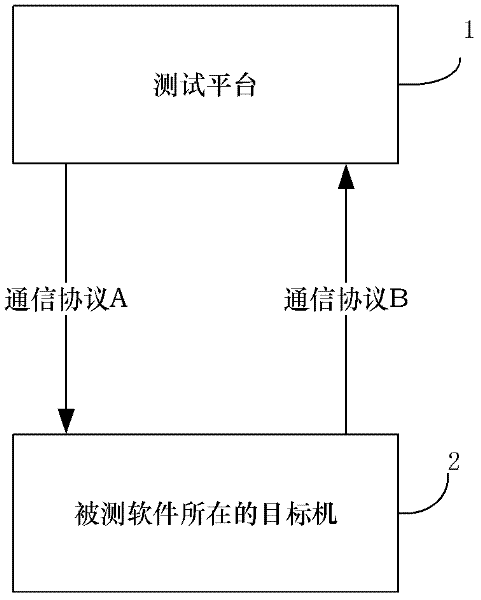

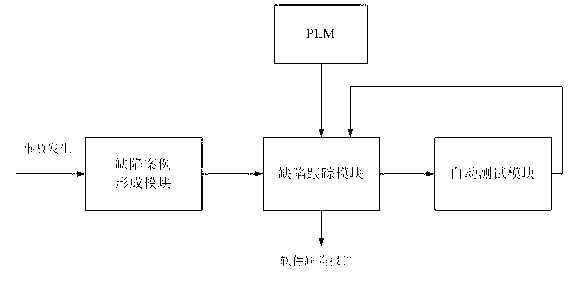

Reliability test defect injection and control method of embedded software

InactiveCN102541737AStrong process controllabilityImprove research efficiencySoftware testing/debuggingSoftware failureEmbedded software

The invention provides a reliability test defect injection and control method of embedded software, which comprises the following steps of: arranging a defect management module and a communication scheduling module in a target machine of the tested embedded software, enabling a researcher to carry out defect injection and control on the tested embedded software through a test platform, carrying out defect tracking control and software function execution on a synchronous basis in parallel, adopting different channels for the defect tracking control and the software function execution and generating no conflict among data. The reliability test defect injection and control method of the embedded software has the beneficial effects that software defects can be user-defined according to the actual demands of subject research and test; the software defects of the tested embedded software can be set according to the demands of the researcher; and after the software failure occurs, defect numbers which cause the failure are reported, so that a plenty of time required by debugging and troubleshooting is saved, thereby the efficiency of software failure subject research can be improved, the controllability of the software failure is improved, and the more targeted research on the software reliability is realized.

Owner:BEIHANG UNIV

Automated tagging and tracking of defect codes based on customer problem management record

ActiveUS9009665B2Easy to trackVersion controlSoftware testing/debuggingProblem managementCode snippet

A routine for tagging and tracking source code may be implemented in a software development environment. The routine begins upon the identification of a defect in a software product or system. Once the defect has been identified and rectified, a search of other source code (typically located in a source code management system that supports version control) is specified. Using the search specification, the system automatically identifies the code snippet to be searched and begins searching the identified codebase for duplicates. A ticket or service record is then created for every duplicate / similar code snippet found during the search. The ticket / record enables software defect tracking to be carried out on the newly-located instances of the code. The system also automatically manages the code snippets identified by the duplicate detection.

Owner:IBM CORP

Relay protection device software defect tracking management system and method

The invention relates to a relay protection device software defect tracking management system and a method. The relay protection device software defect tracking management system comprises a defect case forming module, a defect tracking module, a service life period managing module and an automatic testing module, wherein the defect case forming module performs defect analysis according to scene accident situations and accident causes to form a complete defect case; the defect tracking module generates a test case according to the defect case; the automatic testing module performs test case testing to relevant versions of software and feeds back a test result to the defect tracking module; and the defect tracking module generates a software defect report according to the test result and provides corresponding improvement solutions of the software. According to the relay protection device software defect tracking management system and the method, when relay protection accidents occur on the site, software defect analysis is performed, the defect case and the automatic test case are formed, and whether defects of the software exist in historical versions is tested, so that qualities of the relay protection device software are improved, relay protection running reliability is improved, and safe and stable running of power grids is enhanced.

Owner:XJ ELECTRIC +2

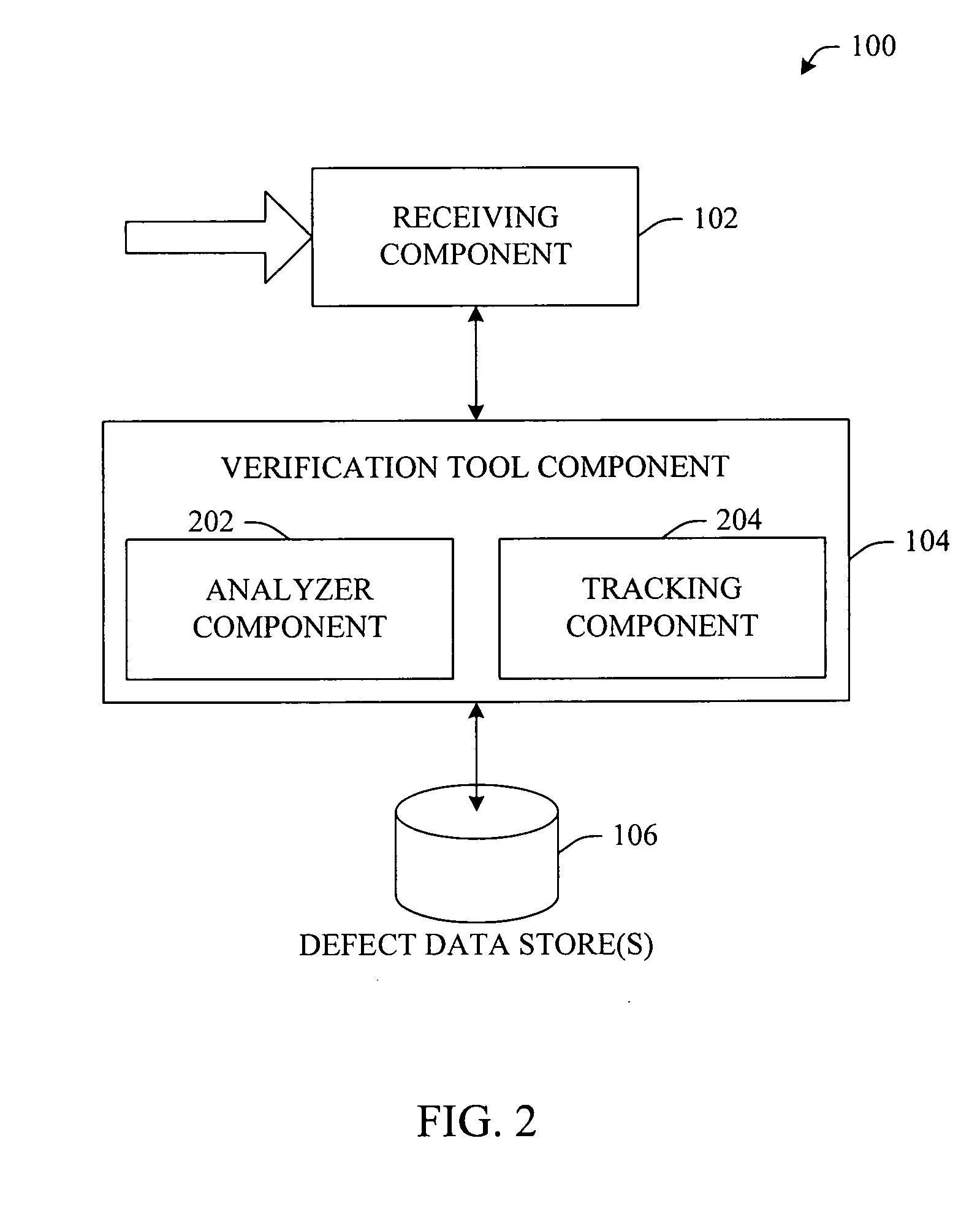

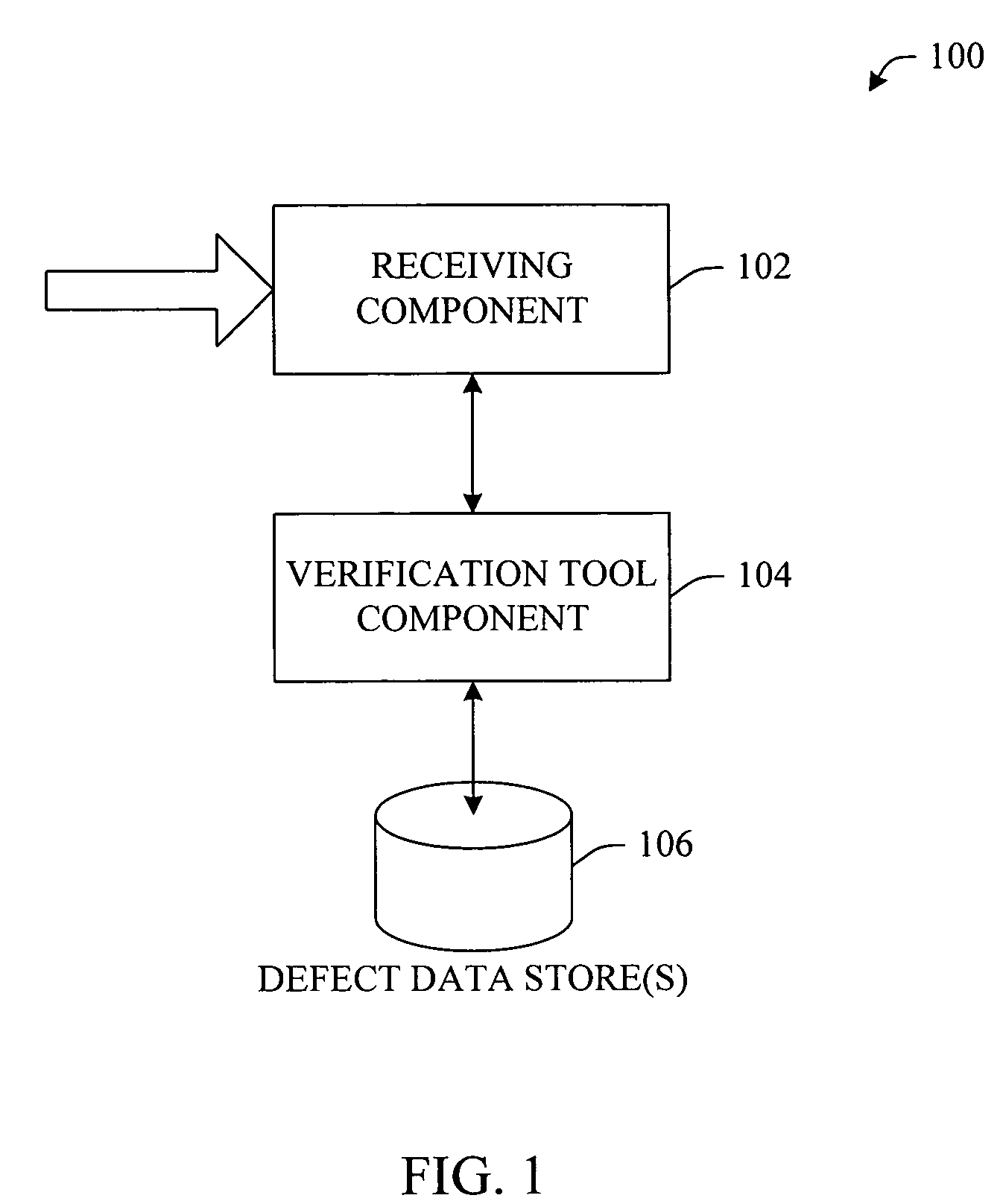

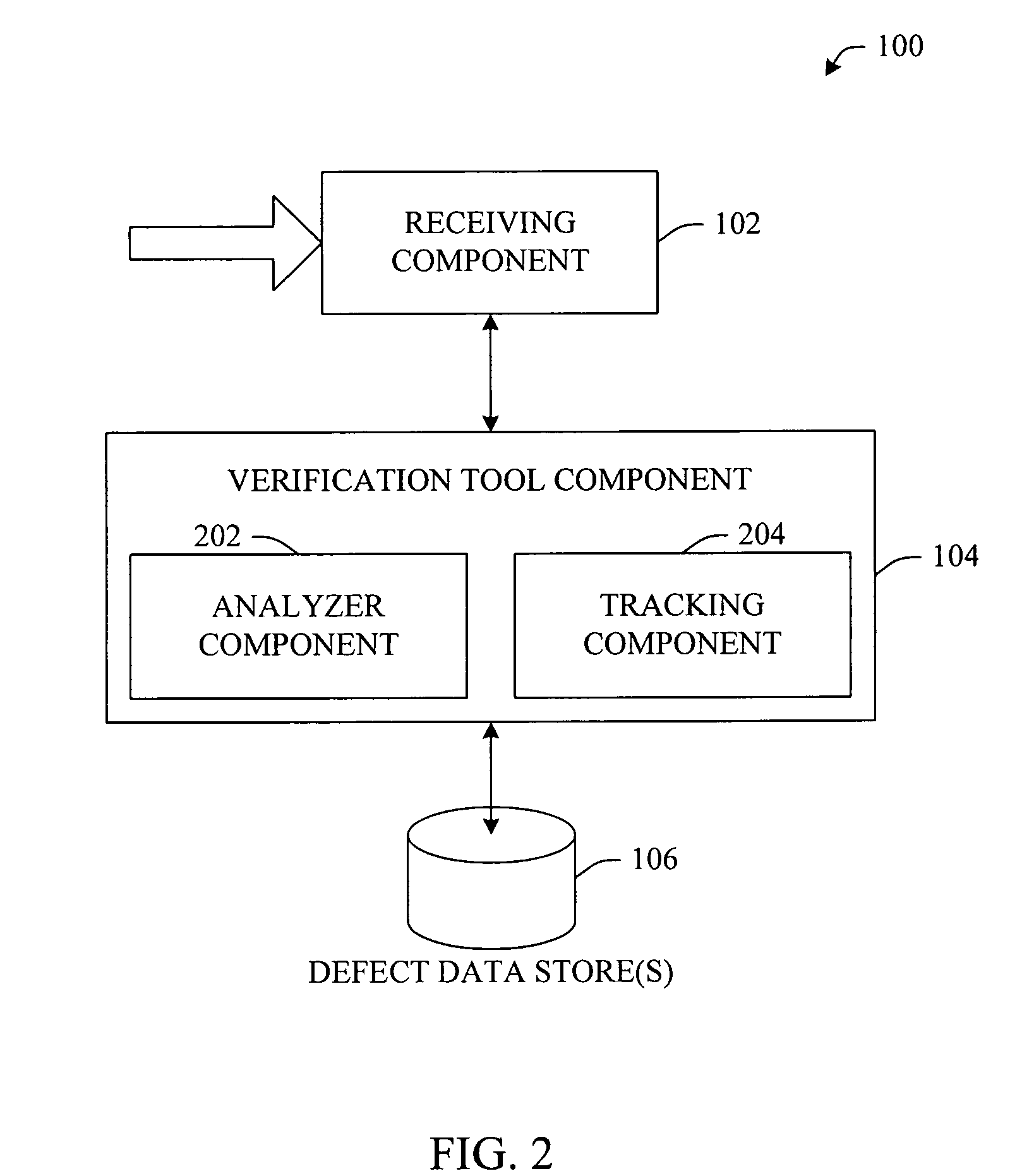

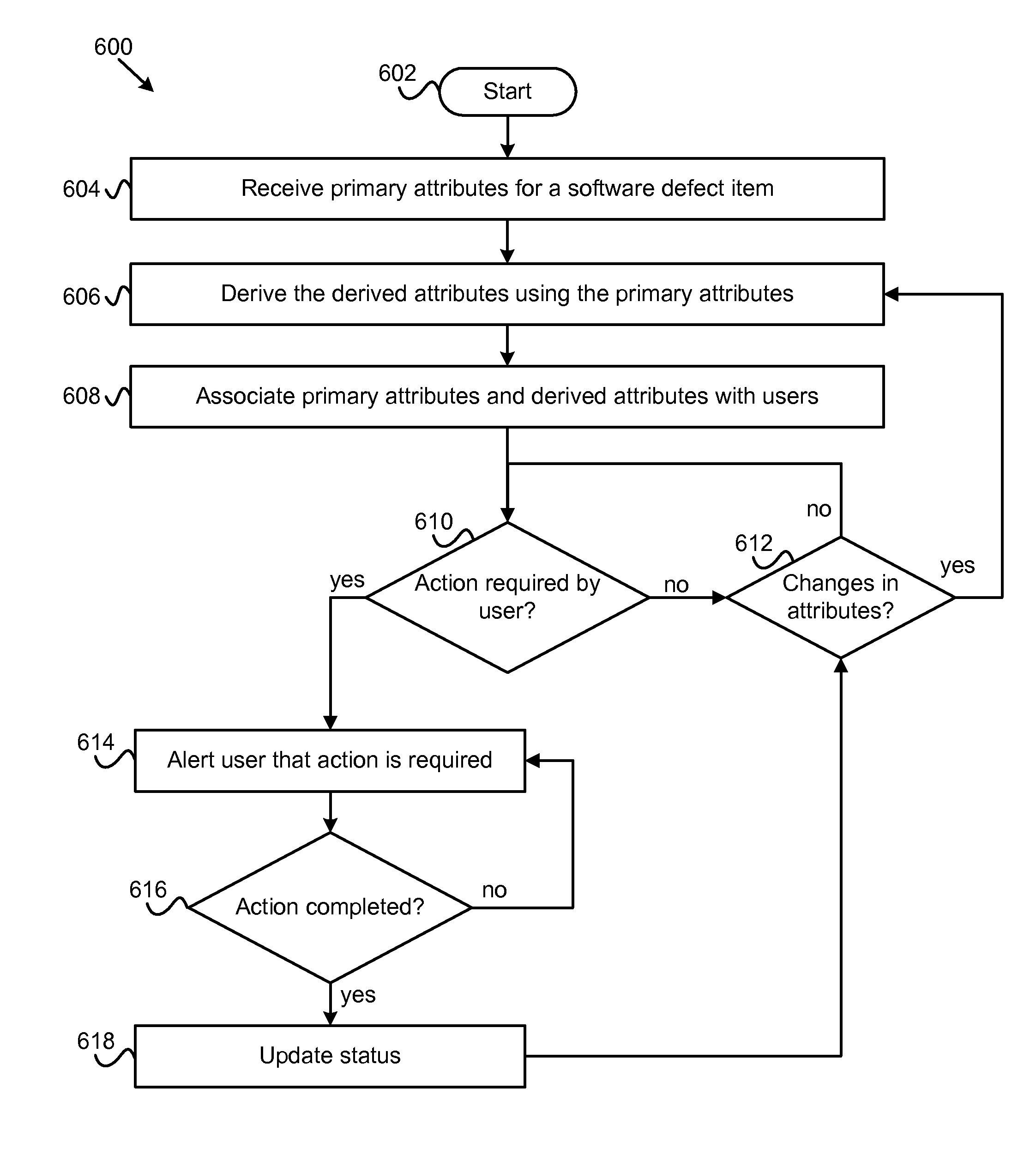

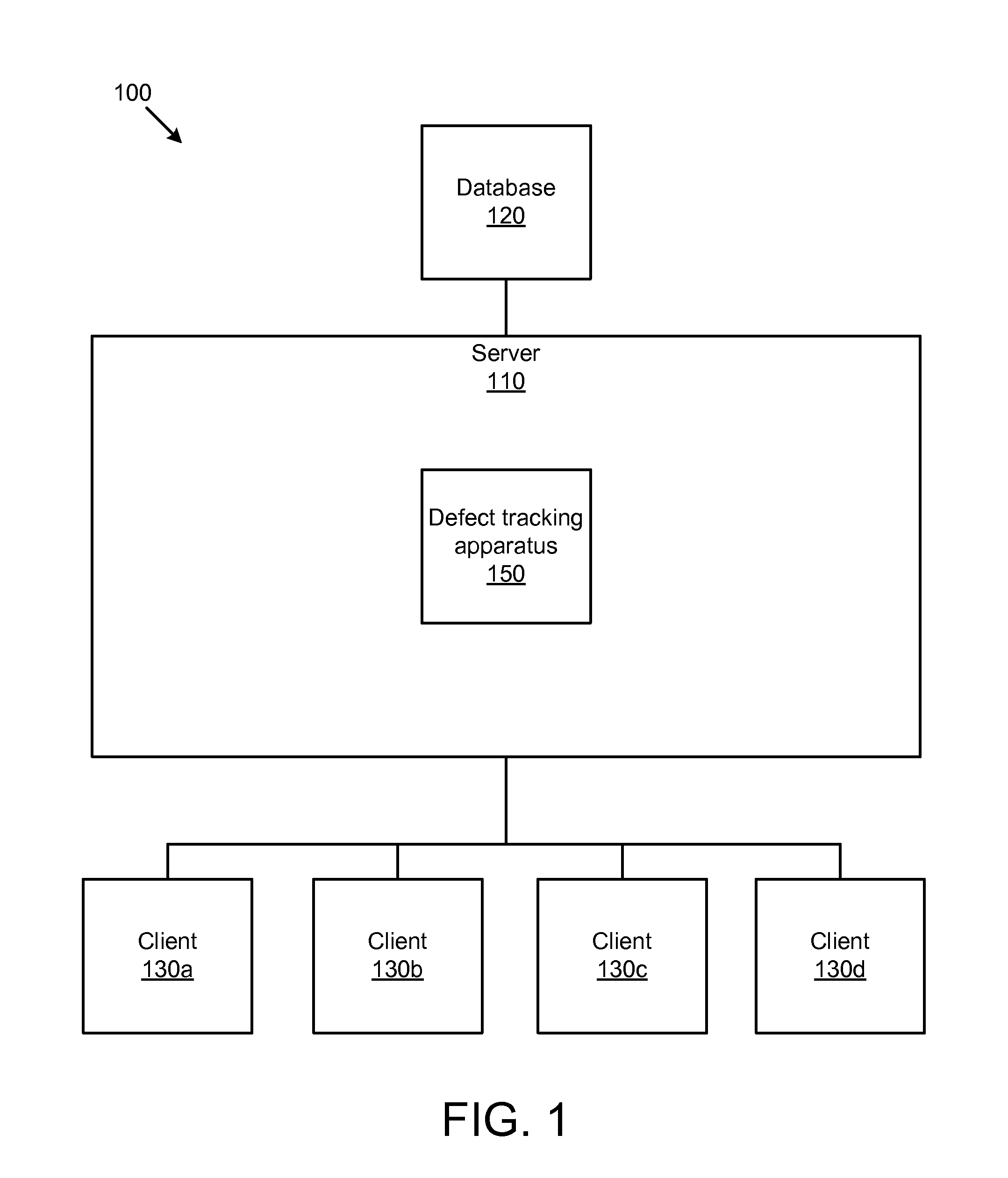

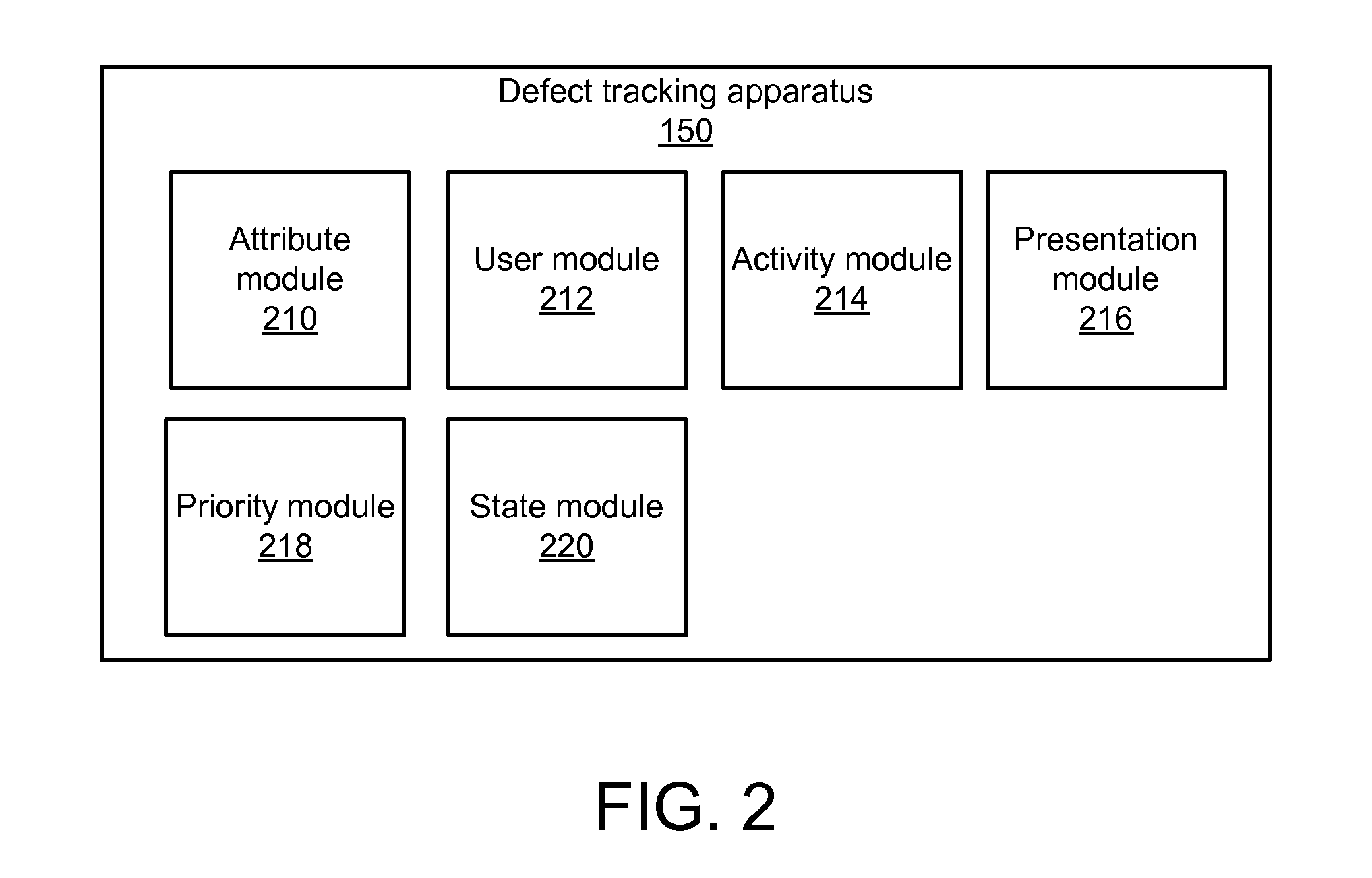

Software defect tracking

InactiveUS8615741B2Easy to runToo expensive to runError detection/correctionSpecific program execution arrangementsSoftware bugSoftware error

An apparatus, system, and method are disclosed for improved tracking of software item defects. The approach involves maintaining defect attributes for a particular software bug. Certain attributes are user-defined while others are derived. Attributes may be, for example, questions, requests for action, requests for approval, or others. The primary attributes and derived attributes for the bug are associated with users that are associated with the software bug, and a determination is made as to whether or not action is required by the individual users for the software bug using the attributes. If action is required, the user is alerted that action is required for the software bug. The actions and / or bugs may be presented to the user using an inbox format. The inbox may sort actions based on priority, what type of attribute is relevant to the user, or using other categorizations.

Owner:INT BUSINESS MASCH CORP

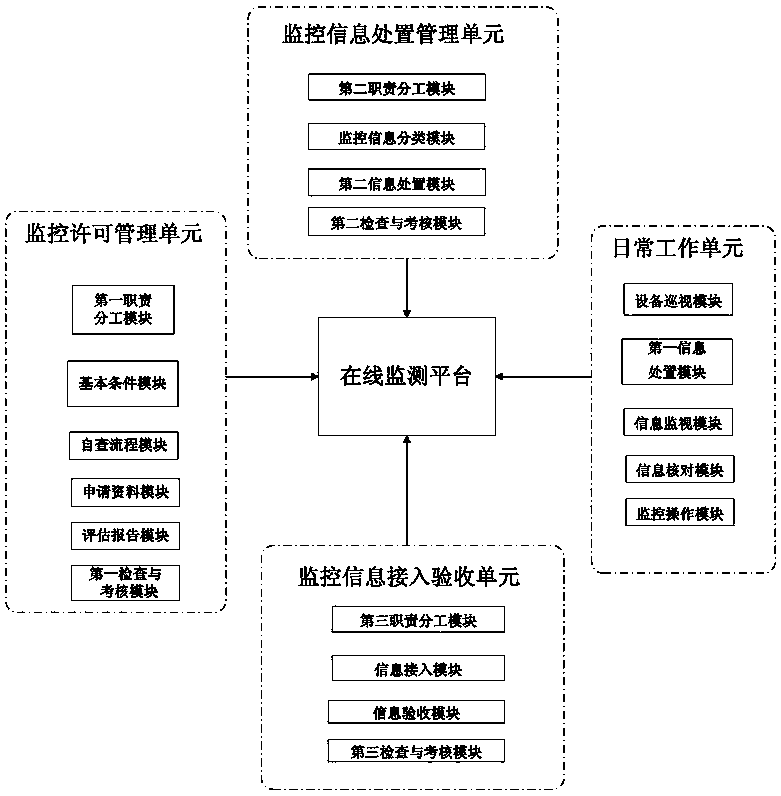

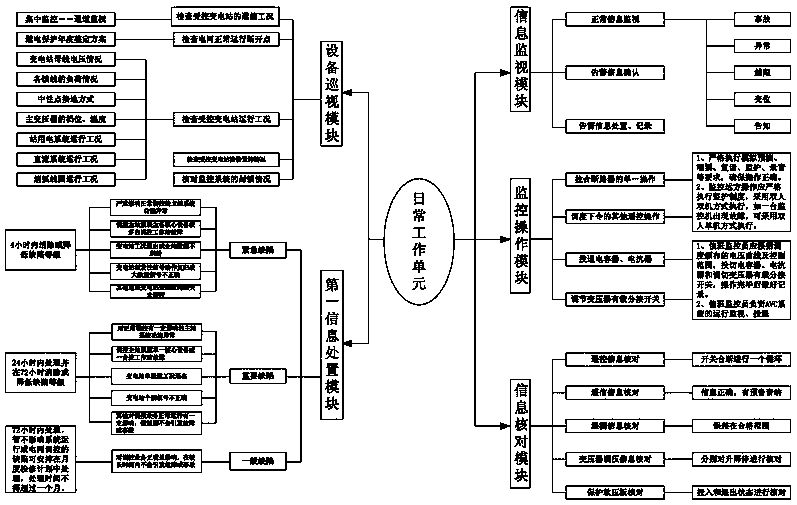

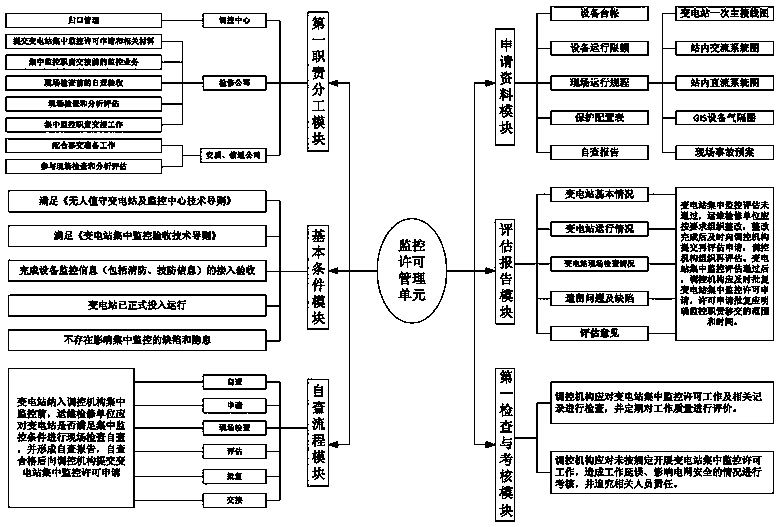

Substation centralized monitoring visualization system and use method thereof

ActiveCN107658985AEasy to handleEnhanced Monitoring Defect AnalysisCircuit arrangementsInformation technology support systemInformation processingManagement unit

The present invention relates to the technical field of substation monitoring and discloses a substation centralized monitoring visualization system and a use method thereof. The system comprises an on-line monitoring platform, a daily work unit, a monitoring permission management unit, a monitoring information disposal management unit and a monitoring information access acceptance unit. The dailywork unit, the monitoring permission management unit, the monitoring information disposal management unit and the monitoring information access acceptance unit are in communication connection with the online monitoring platform. According to the system, the data interaction with the online monitoring platform is realized, the system is installed in a monitoring host machine, monitoring personnelare effectively guided to carry out daily work, the monitoring personnel's ability of monitoring information processing, monitoring defect analysis, defect tracking and the like is enhanced, and the work efficiency is improved.

Owner:ALTAY POWER SUPPLY CO OF STATE GRID XINJIANG ELECTRIC POWER CO +1

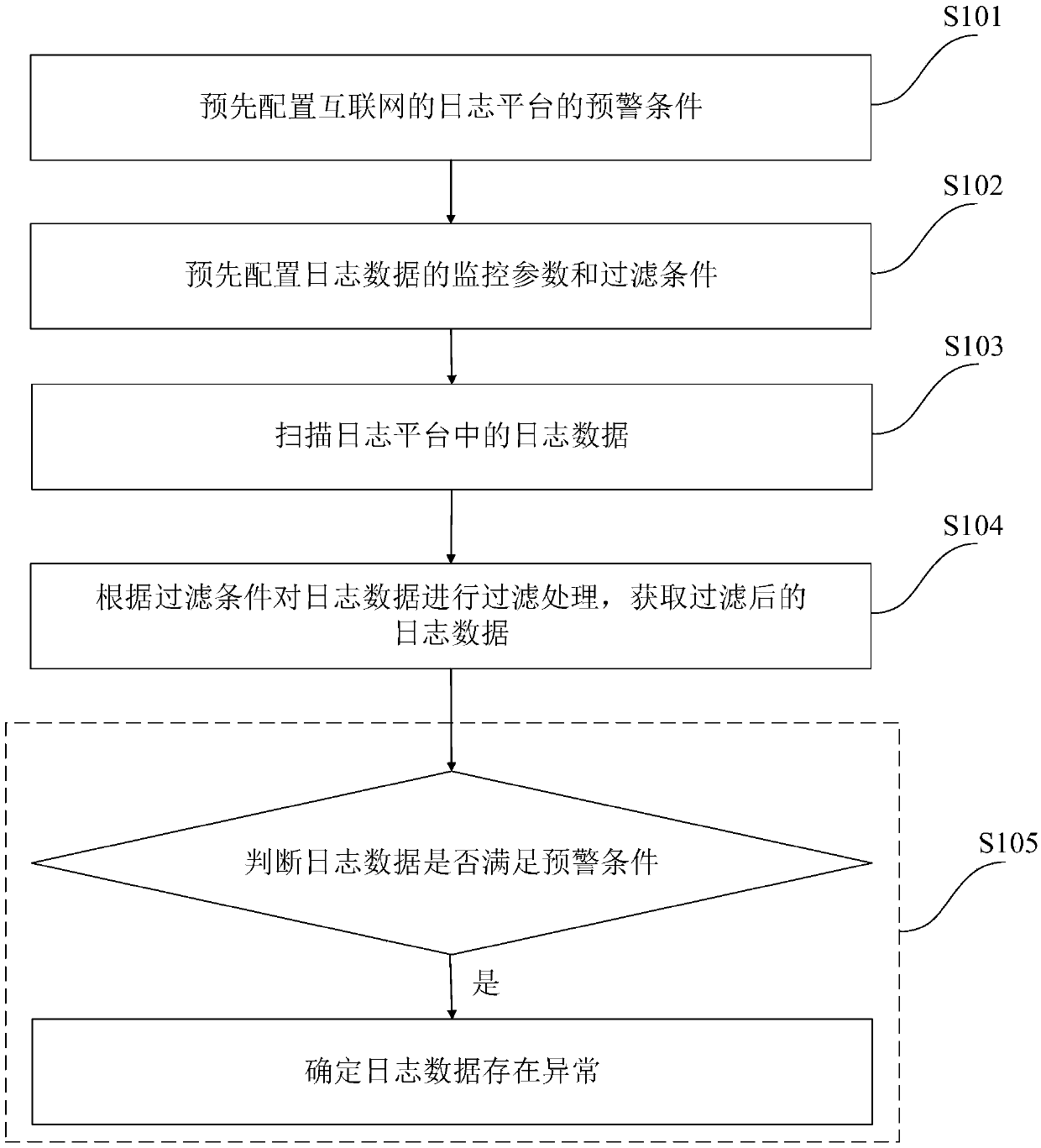

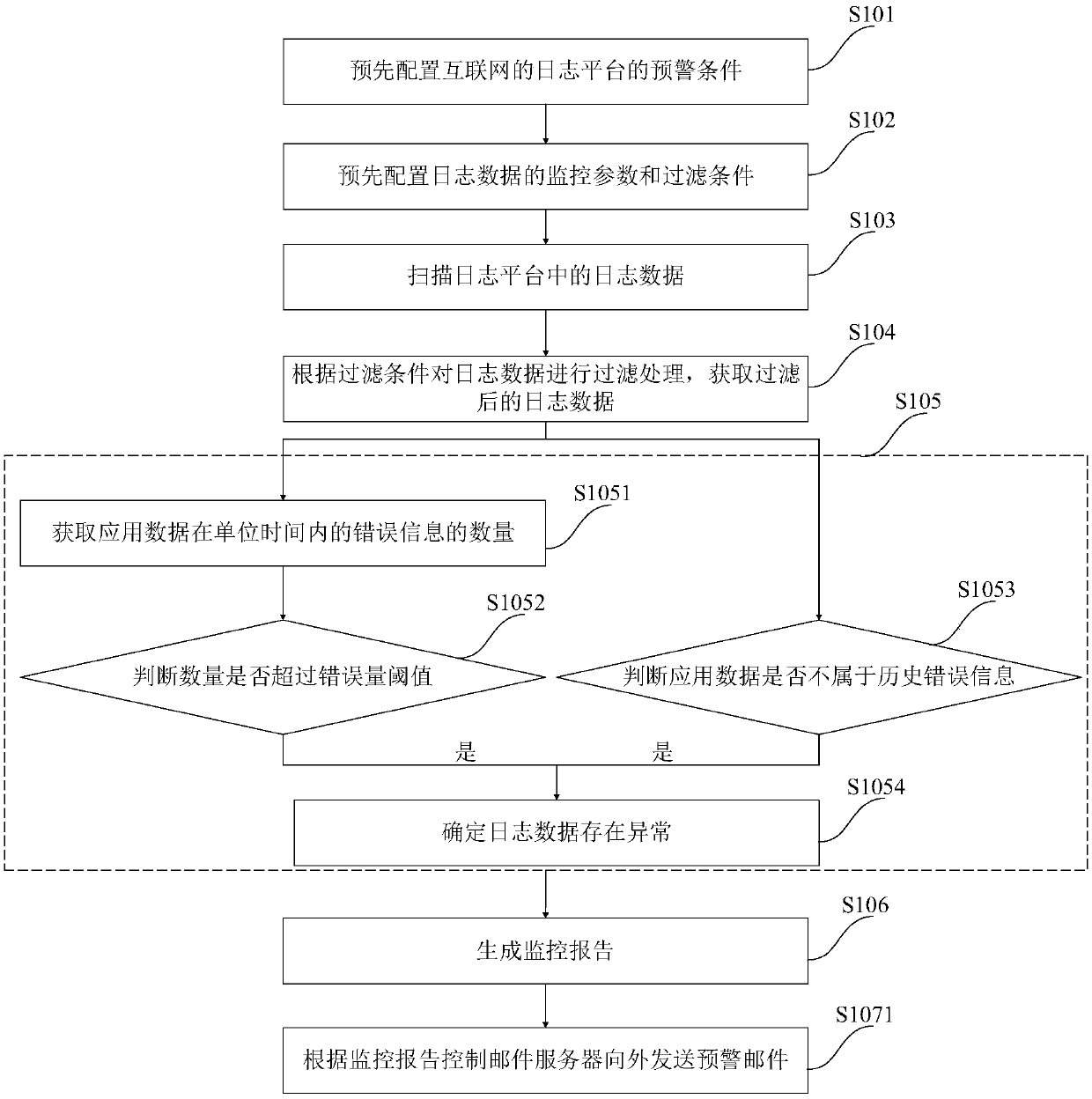

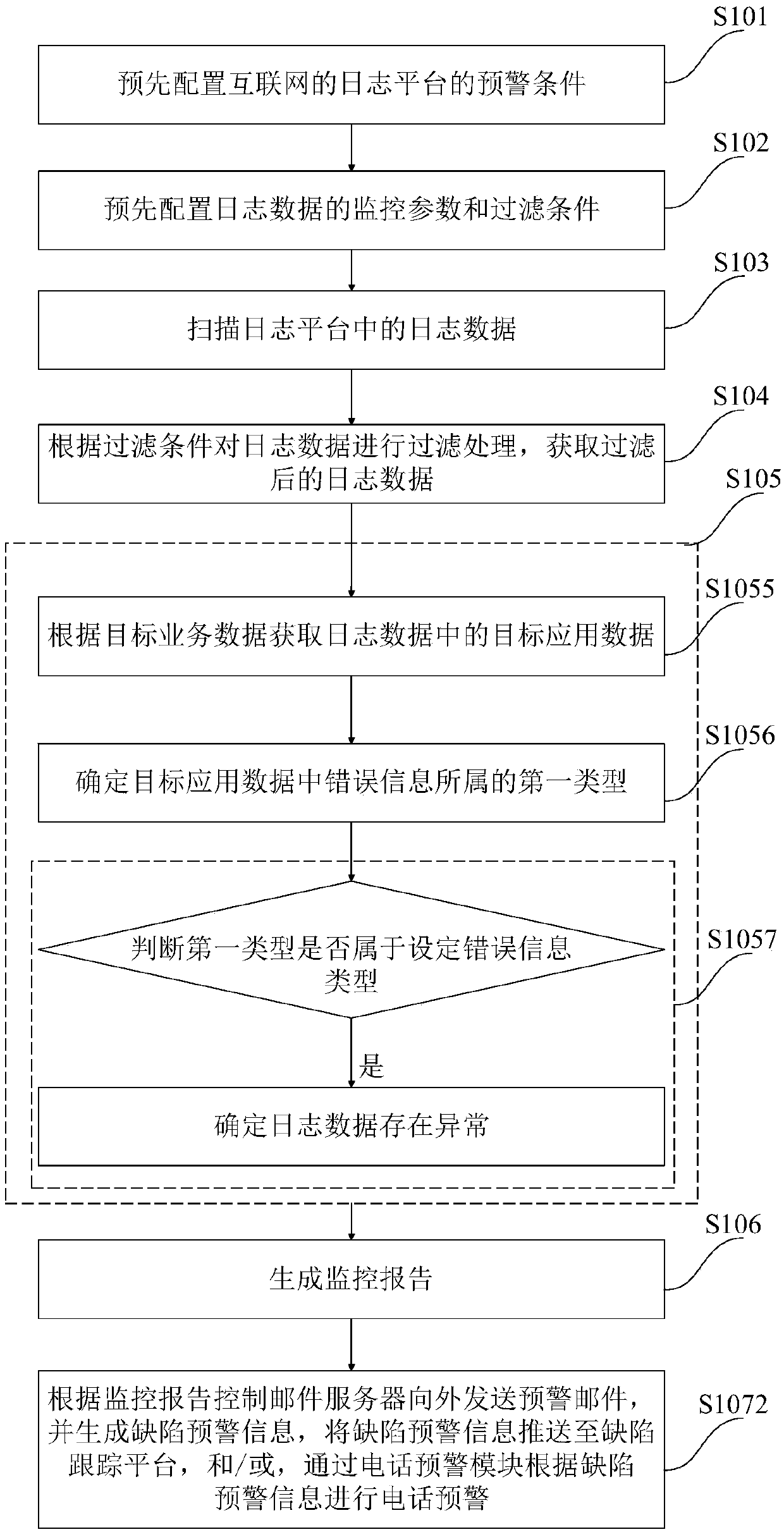

Monitoring method and system of log platform of internet

InactiveCN109617737AEffective early warningImprove processing efficiencyData switching networksThe InternetReal-time computing

The invention discloses a monitoring method and system of a log platform of an internet. The monitoring method includes: pre-configuring an early-warning condition of the log platform of the internet;scanning log data in the log platform; judging whether the log data meet the early-warning condition, and if yes, determining that the log data have an abnormality. According to the method, abnormallog data are accurately located in time according to the pre-configured early-warning condition of the log platform of the internet, an early-warning email is issued, defect alarming information is generated according to a severity degree, and is pushed to a defect tracking platform, telephone early-warning is carried out, and thus effects of precisely locating the abnormal service problem, and carrying out effective early warning for subsequent operation and maintenance personnel to find and process the same in time are realized.

Owner:CTRIP COMP TECH SHANGHAI

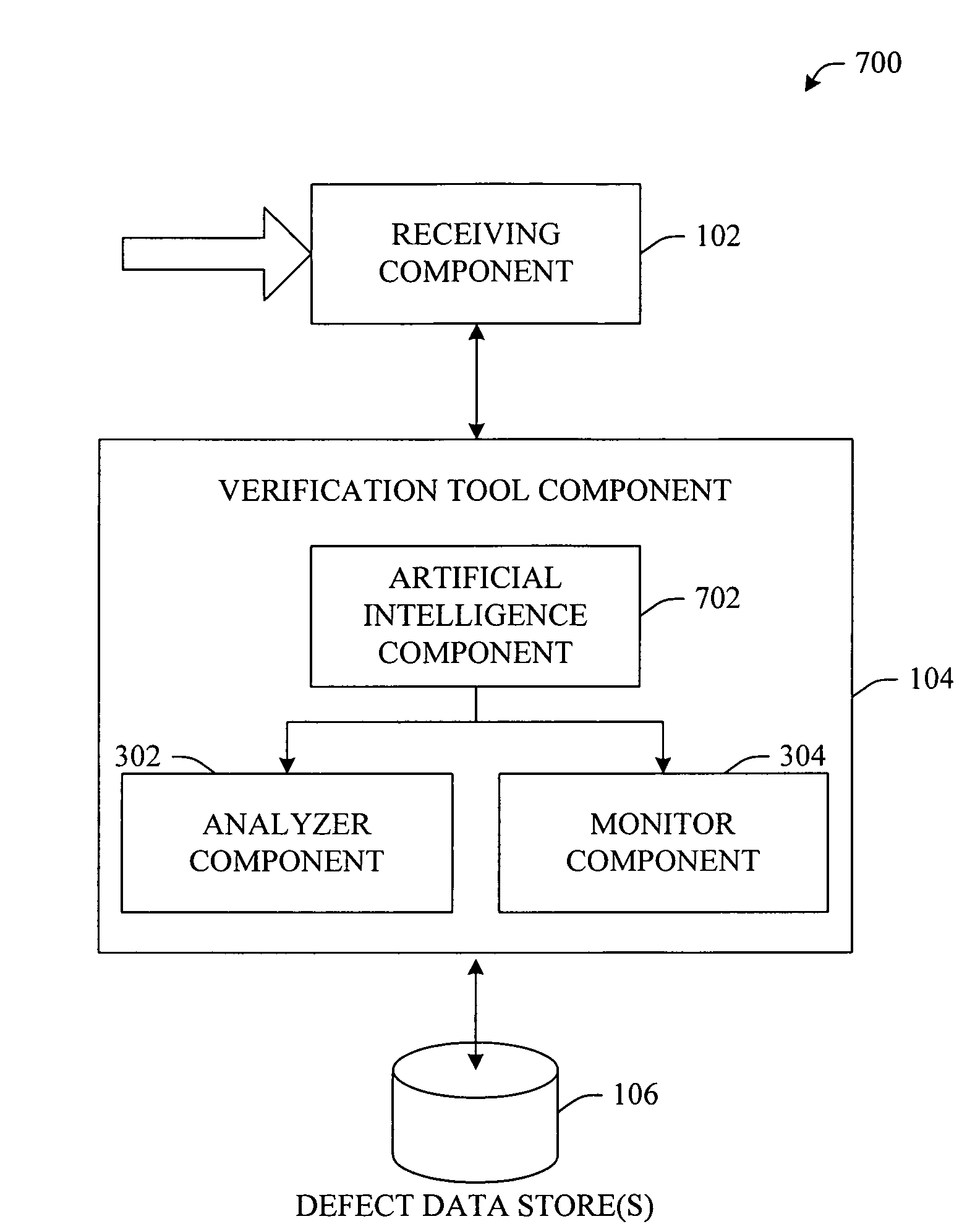

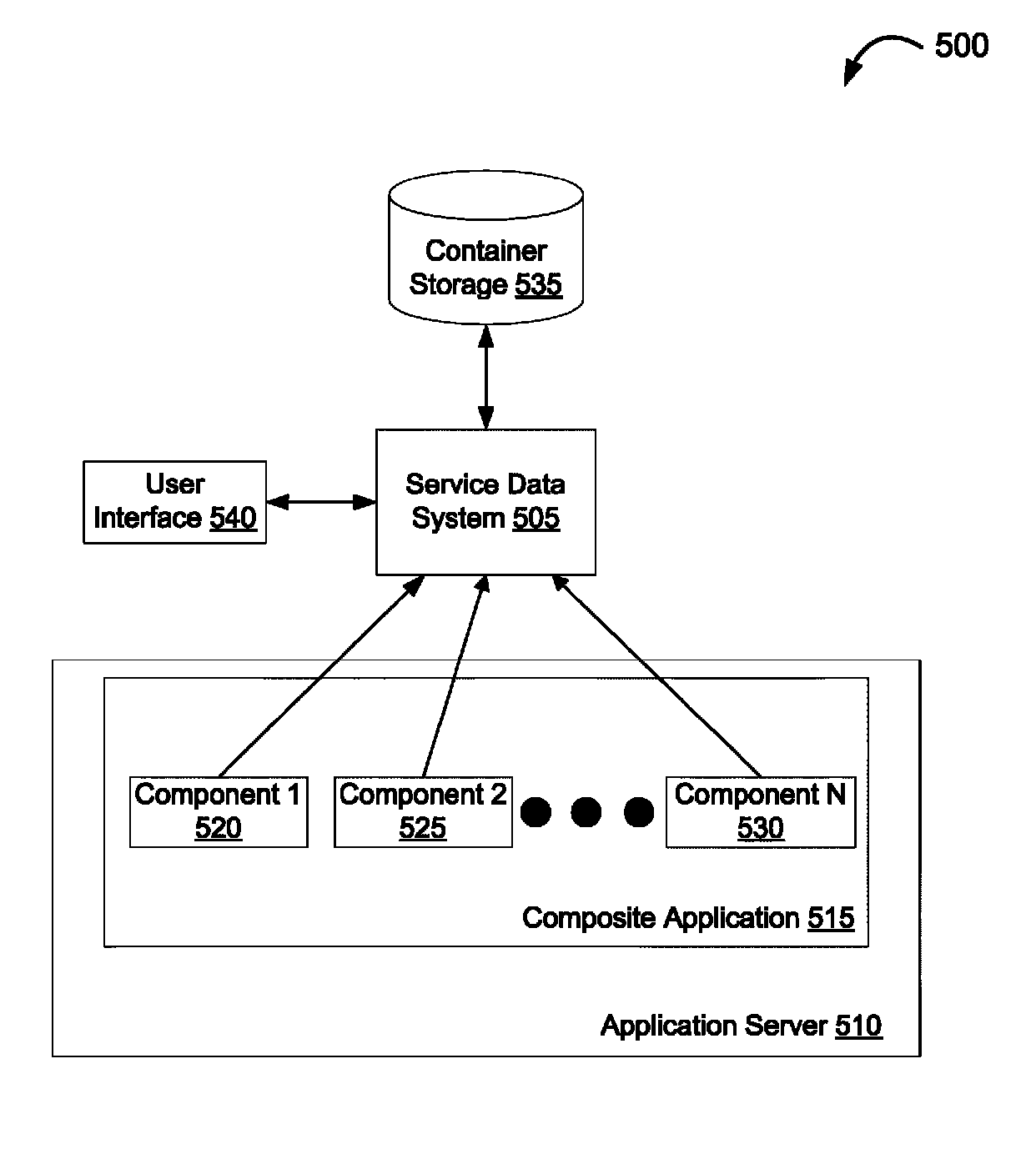

Agile help, defect tracking, and support framework for composite applications

ActiveUS8407724B2Easy loginDefect informationOffice automationElectric digital data processingComposite applicationComputerized system

This disclosure describes, generally, methods and systems for implementing agile and dynamic help, defect tracking, and support frameworks for composite applications. The method includes implementing, on a computer system including a storage database, a composite application including a plurality of application components and establishing, in the computer system's storage database, a storage container for each of the plurality of application components. The storage containers are configured to store support information for each of the component applications. The method further includes storing, in the storage database, support data for each of the plurality of component applications, removing at least one of the plurality of component applications from the composite application, and maintaining, in the storage database, the support data for the remaining component applications of the composite application.

Owner:ORACLE INT CORP

Extracting portions of an abstract database for problem determination

Systems, methods and articles of manufacture are disclosed for extracting portions of an abstract database for problem determination. An error may be detected when an application executes an abstract query against the abstract database. A portion of the abstract database may be extracted for problem determination. A defect entry may be created in a defect tracking tool, to store the extracted portion. One or more administrative users may be notified of the defect entry.

Owner:IBM CORP

Agile help, defect tracking, and support framework for composite applications

ActiveUS20110154372A1Easy loginDefect informationOffice automationSpecific program execution arrangementsComposite applicationComputerized system

This disclosure describes, generally, methods and systems for implementing agile and dynamic help, defect tracking, and support frameworks for composite applications. The method includes implementing, on a computer system including a storage database, a composite application including a plurality of application components and establishing, in the computer system's storage database, a storage container for each of the plurality of application components. The storage containers are configured to store support information for each of the component applications. The method further includes storing, in the storage database, support data for each of the plurality of component applications, removing at least one of the plurality of component applications from the composite application, and maintaining, in the storage database, the support data for the remaining component applications of the composite application.

Owner:ORACLE INT CORP

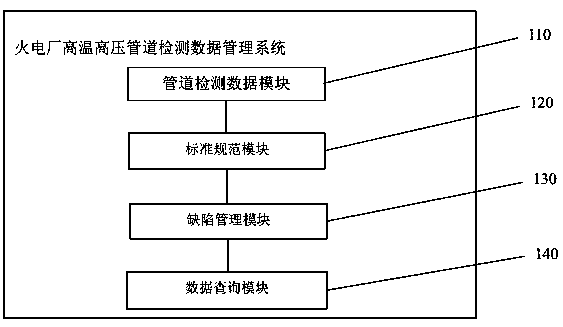

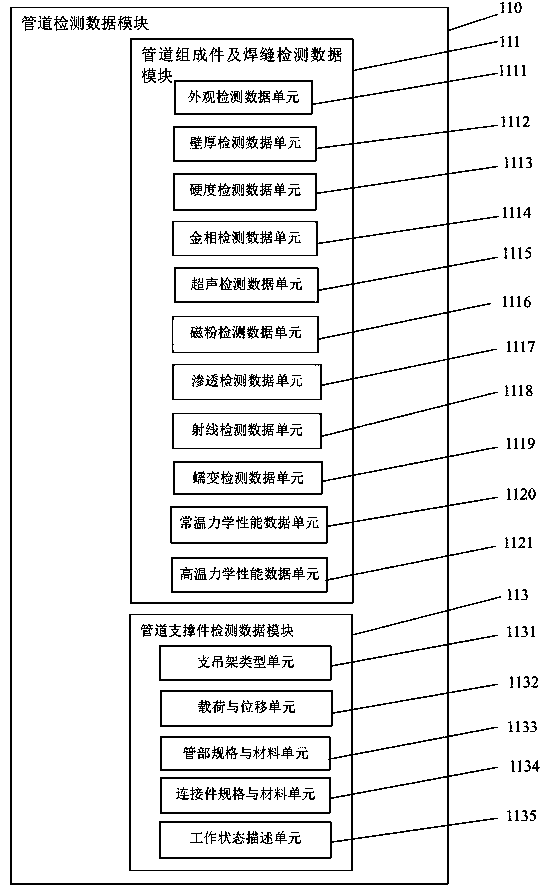

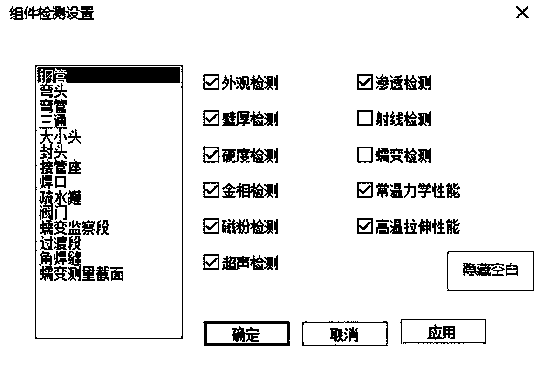

Management system of high temperature and high pressure pipeline detection data of thermal power plant and application method thereof

InactiveCN109141516APrevent and stop burstingPrevent and put an end to the vicious accident of fractureMeasurement devicesData managementEngineering

The invention relates to a management system of high temperature and high pressure pipeline detection data of a thermal power plant and an application method thereof and especially relates to the tracking management of detection data of a pipeline bearing a high temperature and high pressure medium in the thermal power plant. The system comprises a pipeline detection data module, a standard specification module, a defect management module and a data query module. The pipeline detection data module, the standard specification module, the defect management module and the data query module are sequentially connected. By inputting the detection data into the system and uploading a detection report, the permanent storage and rapid retrieval, inspection and output of the detection data and the detection report are achieved. The automatic comparison and tracking of the detection data of each component are achieved, the detection time interval management, the component defect tracking management and the tracking management of the organization and performance degradation of a high temperature and high pressure pipeline material are carried out according to a standard specification, and thesystematic, informationalized and the accurate management level of the detection data of a thermal power plant high temperature and high pressure pipeline, connection welds thereof and pipeline supports thereof is effectively improved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

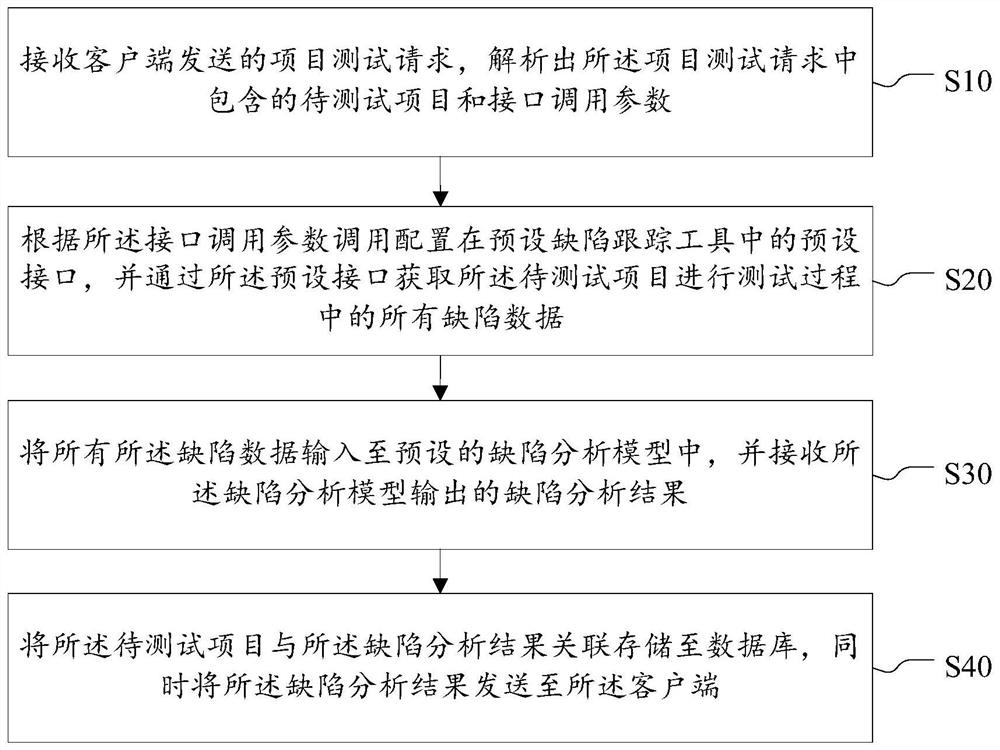

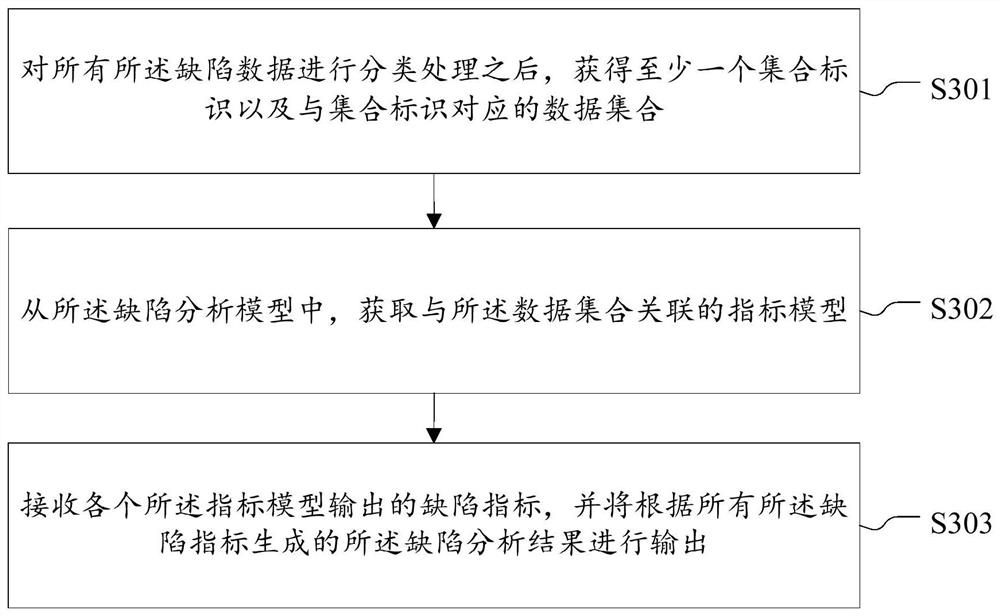

Project test defect analysis method, device, equipment and storage medium

PendingCN111611172AFine granularityEasy to judgeSoftware testing/debuggingAnalytic modelDependability

The invention discloses a project test defect analysis method, device and equipment and a storage medium. The method comprises the steps of receiving a project test request sent by a client, and analyzing a to-be-tested project and an interface call parameter contained in the project test request; calling a preset interface configured in a preset defect tracking tool according to the interface calling parameter, and obtaining all defect data of the to-be-tested project in the testing process through the preset interface; inputting all defect data into a preset defect analysis model, and receiving a defect analysis result output by the defect analysis model; and associatively storing the to-be-tested project and the defect analysis result in a database, and sending the defect analysis result to the client. According to the invention, the labor cost is saved, the defect data granularity is finer, and the data processing efficiency and the reliability of the defect analysis result are improved.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

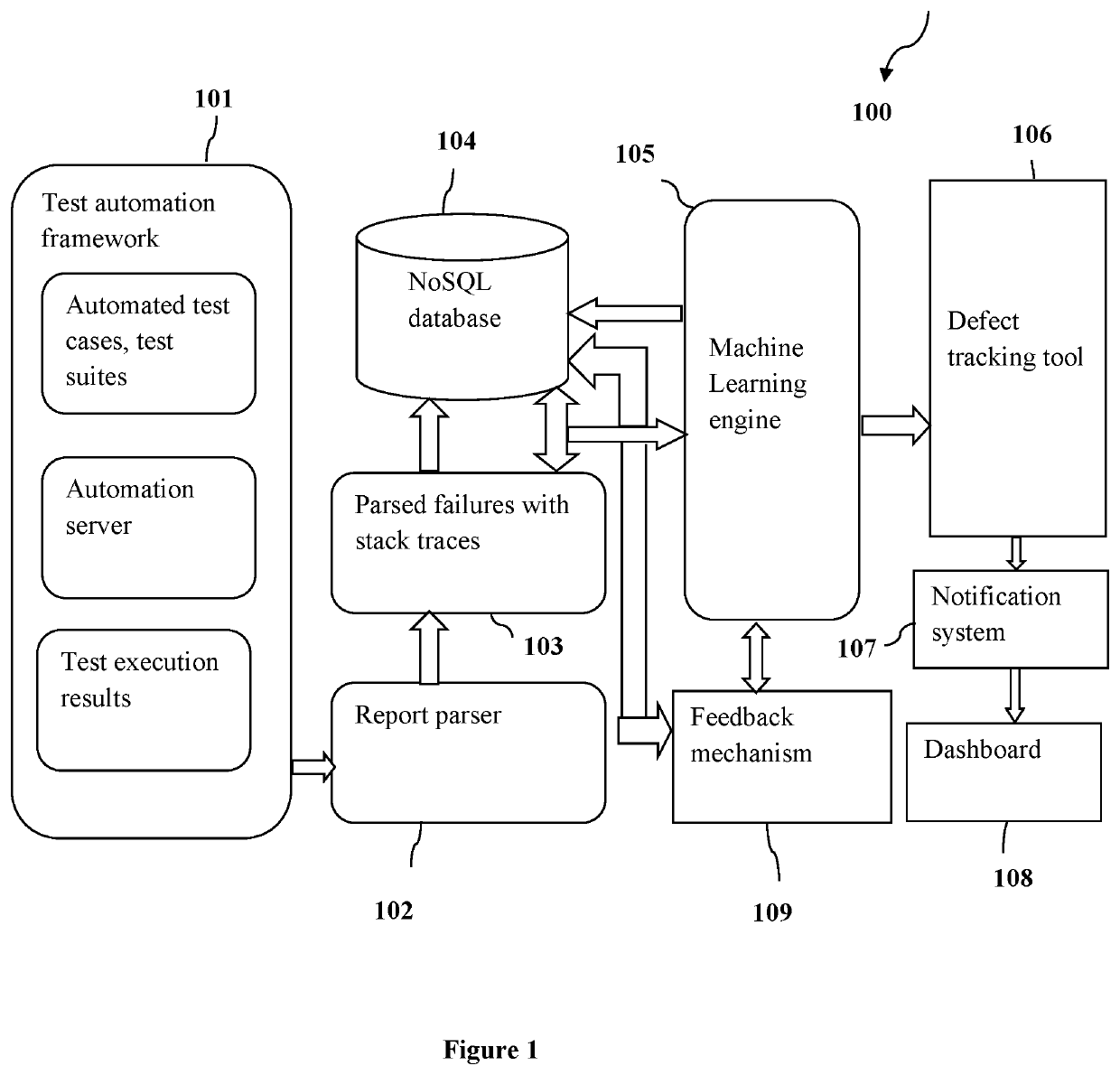

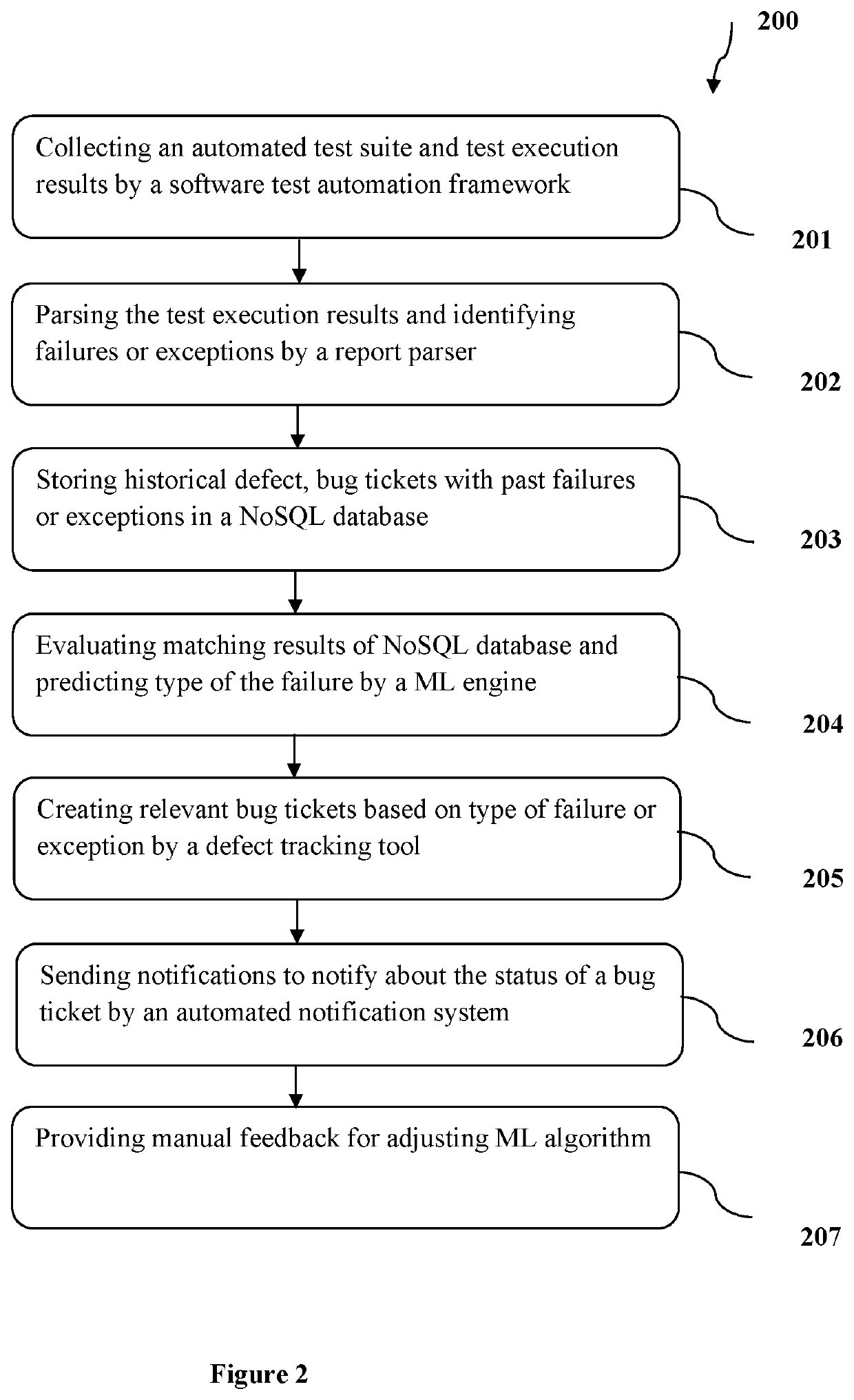

System and method for automated software testing based on machine learning (ML)

ActiveUS10572374B2Efficient and precise mannerPromote resultsReliability/availability analysisSoftware testing/debuggingTicketTest engineer

The invention provides a system and method for automated software testing based on Machine Learning (ML). The system automatically picks up results of the software test automation reports from software test automation framework. The report parser parses the failures from the report. A ML engine compares them with the failures that are known or present in the NoSQL database. After the creation of bug ticket in the defect-tracking tool, an automated notification system notifies the stakeholders via email or instant messaging about the status of the respective ticket. A feedback to the system by software test engineer helps to make the system learn or adjust the decision making to be more precise.

Owner:SHARMA MAYANK MOHAN +1

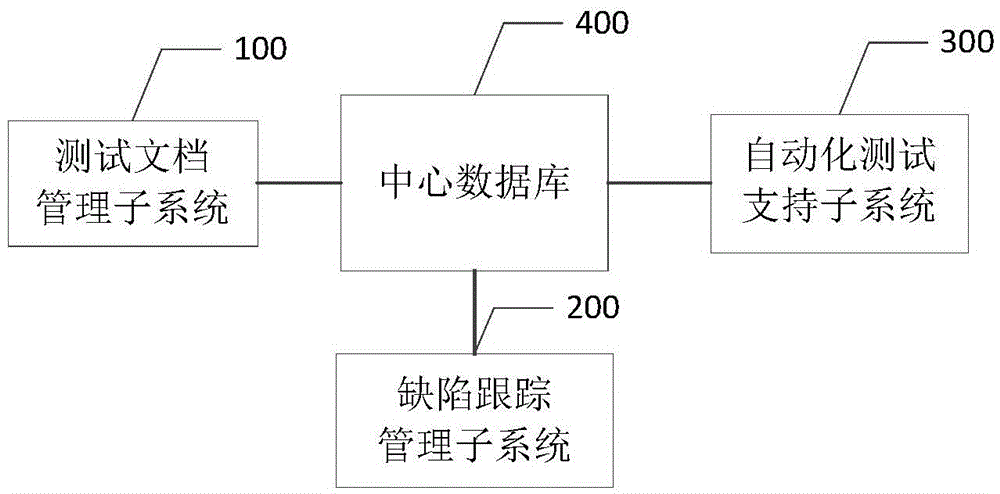

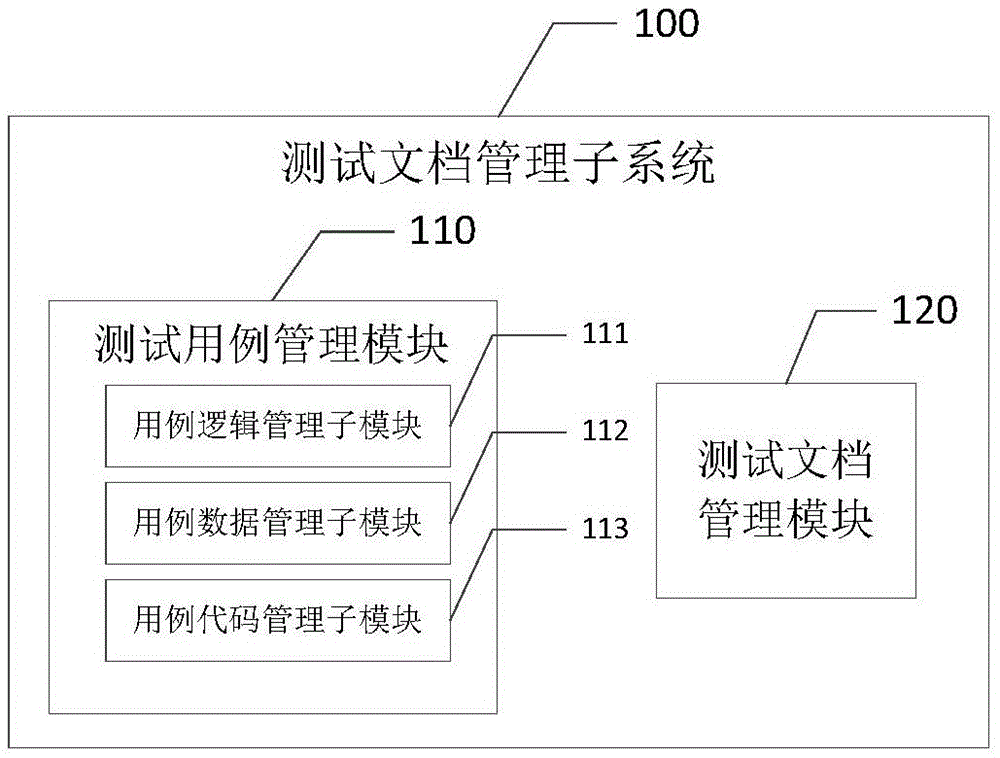

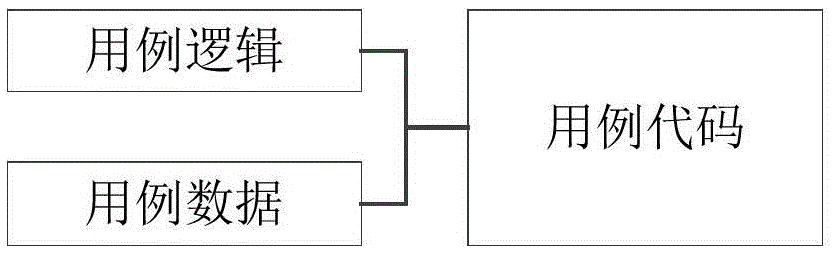

Automated test management system

InactiveCN105550116AImprove reusabilityImprove maintainabilitySoftware testing/debuggingTest documentTest management

The invention discloses an automated test management system. The system comprises a test document management subsystem, a defect tracking management subsystem, an automated test support subsystem and a central database, wherein the test document management subsystem, the defect tracking management subsystem and the automated test support subsystem perform data interaction through the central database; the test document management subsystem is used for managing test cases and test documents; the defect tracking management subsystem is used for managing and tracking control software defects; and the automated test support subsystem is used for managing and implementing test activities.

Owner:PHICOMM (SHANGHAI) CO LTD

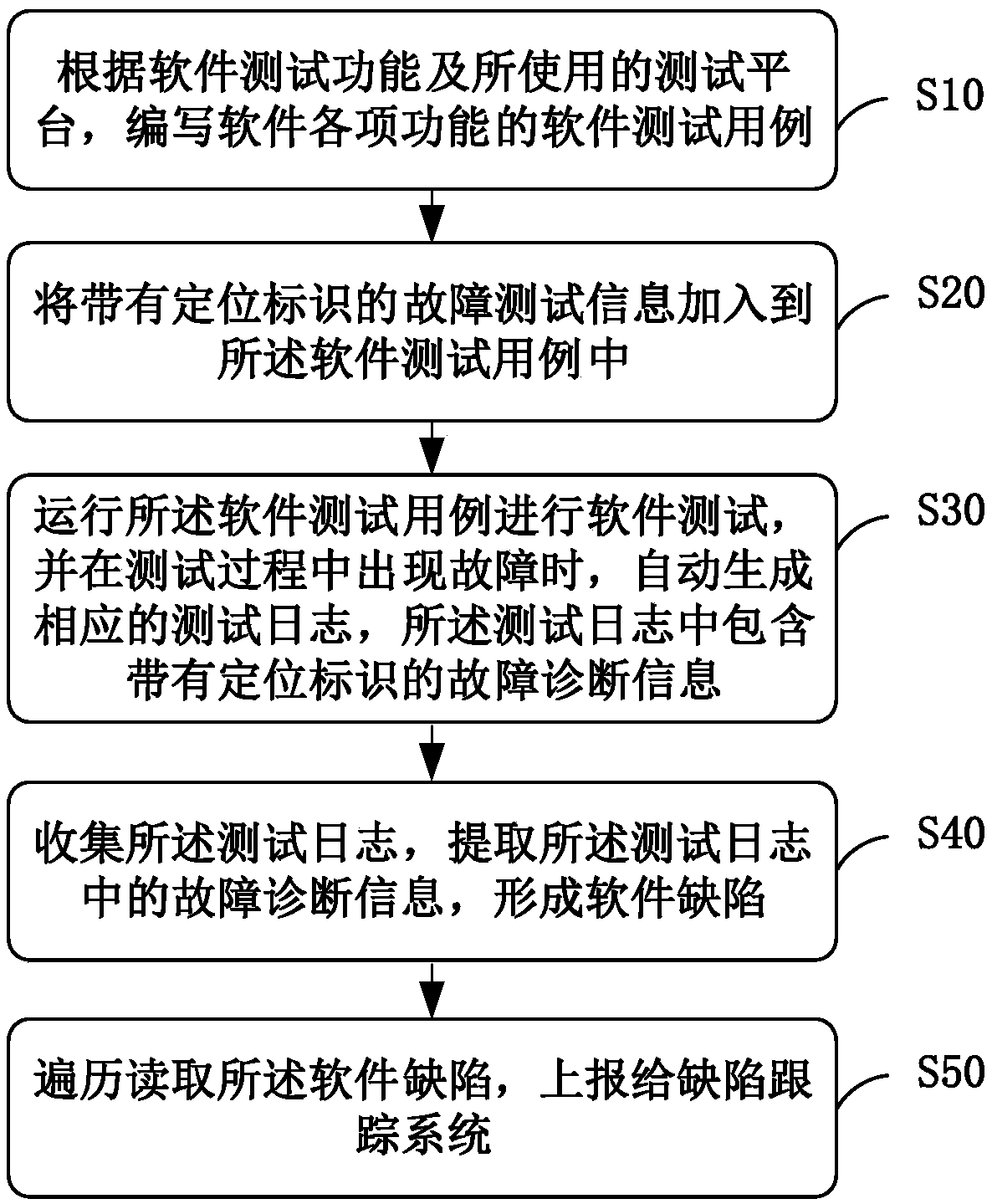

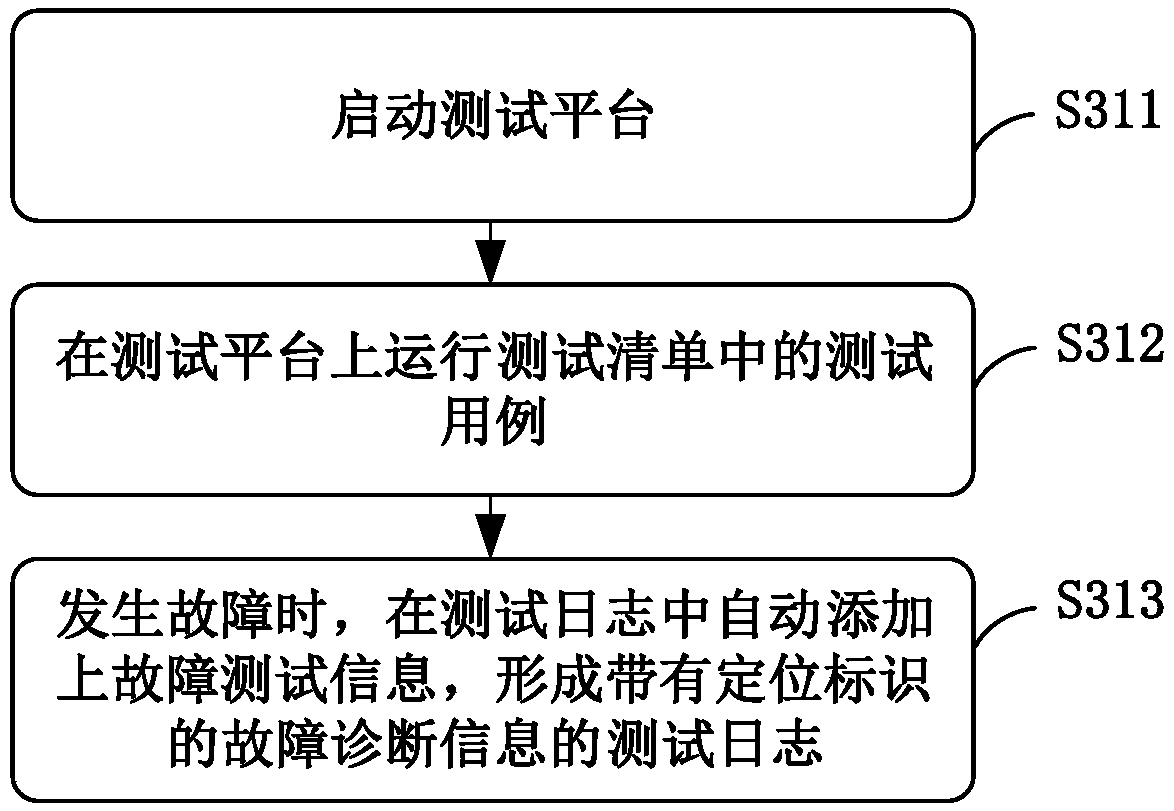

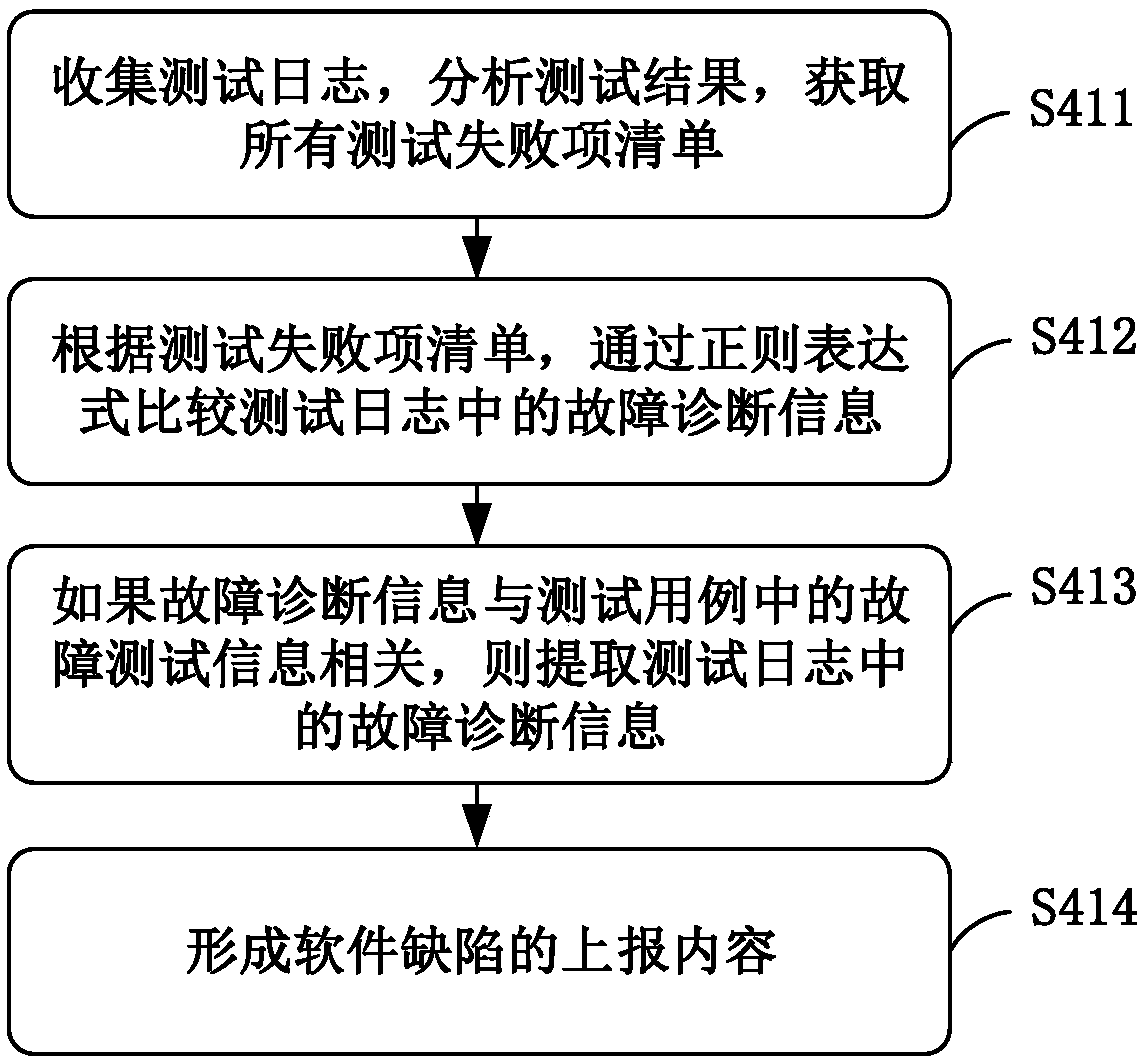

Method and system for automatically reporting software defects

InactiveCN109189674AHigh degree of automationReduce manual interventionSoftware testing/debuggingContinuous integrationSoftware failure

The invention discloses a method and system for automatically reporting software defects, wherein, the method comprises the following steps: according to a software test function and a test platform used, a software test case is compiled; fault test information with location identification is added to software test cases; the test case is automatically run for software testing and a test log is generated when software failure occurs, wherein the test log contains fault diagnosis information with a positioning mark; the fault diagnosis information in the test log is extracted, and software defects are formed and reported to the defect tracking system. The invention adds fault test information with positioning mark to test case, and during the testing process, the fault diagnosis informationwith a positioning mark is generated and reported to the defect tracking system, so that there is no need to set up various bug templates in advance, the manual intervention in the later testing period is reduced, the automation degree of the continuous integration platform is improved, and the whole testing, analysis and reporting process is easy to expand and has high flexibility.

Owner:FENGHUO COMM SCI & TECH CO LTD

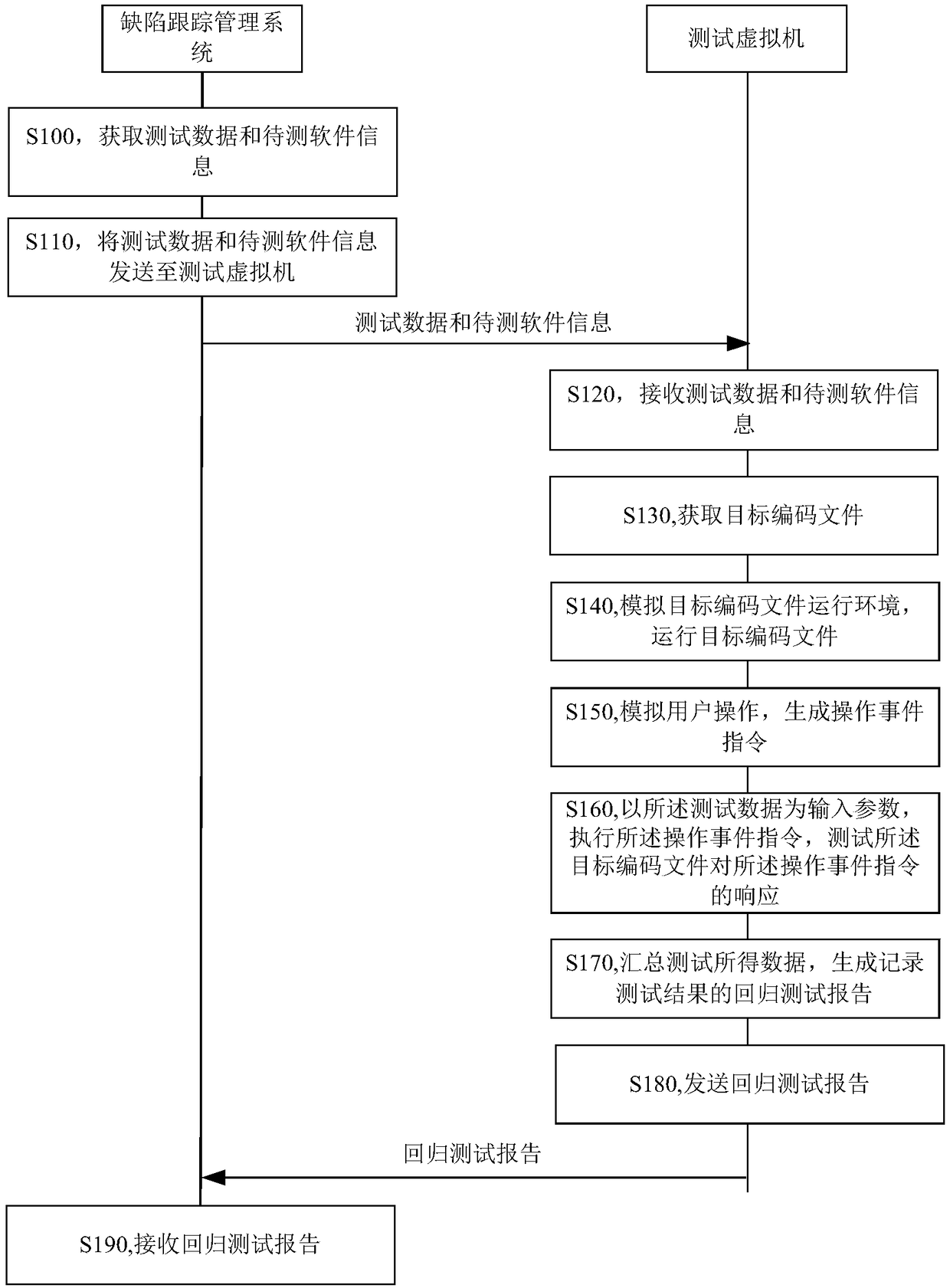

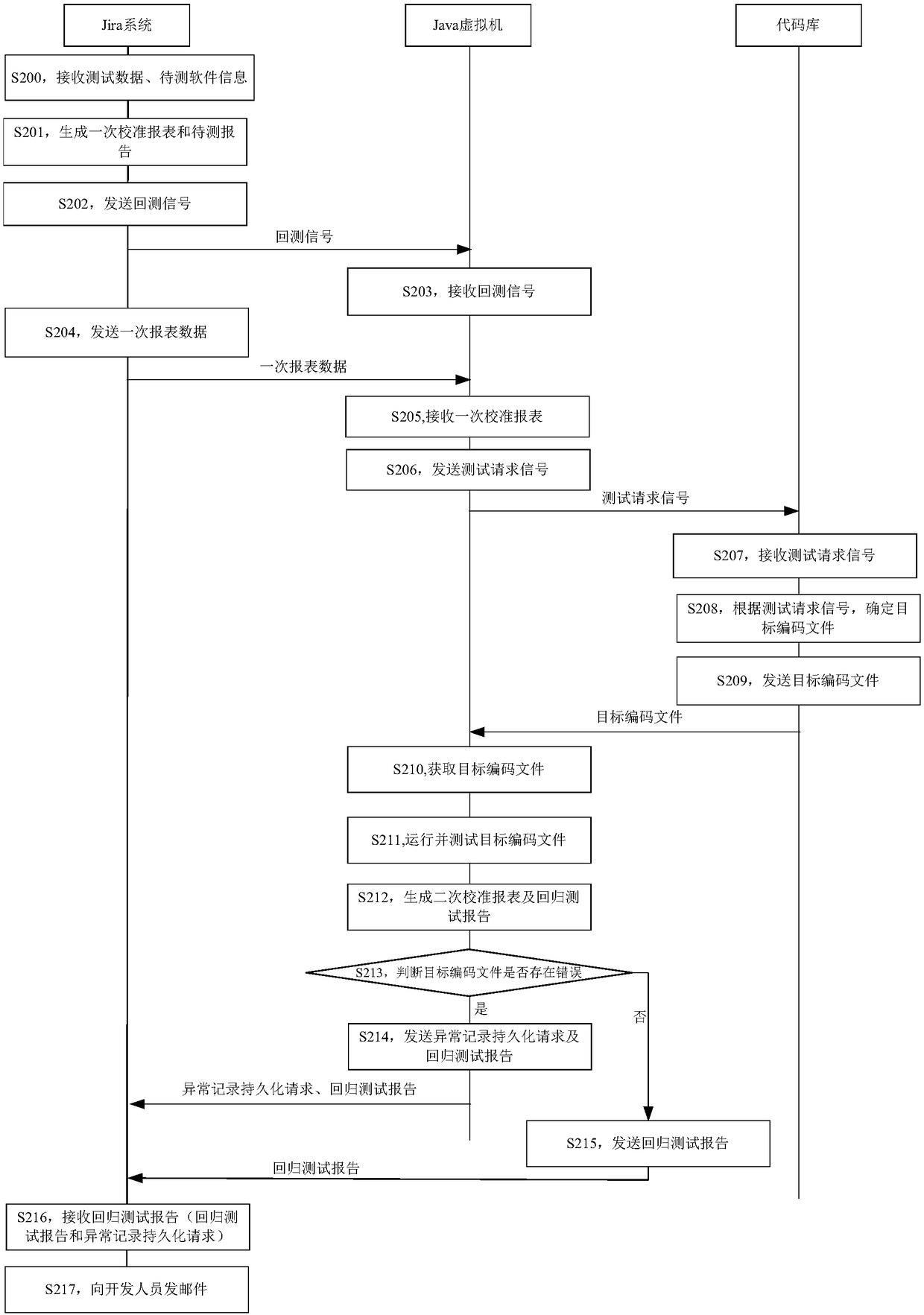

Regression testing method, device and server

InactiveCN108563572AShort timeShorten the development cycleSoftware testing/debuggingRegression testingTest efficiency

The invention provides a regression testing method, device and server and is applied to the technical field of software development. The defect tracking management system in the method sends the acquired information to the test virtual machine after acquiring test data and software information to be measured, the test virtual machine obtains the target coding file according to the software information to be measured, simulates the running environment of the target coding file, runs the target coding file, further tests the target coded file according to the test data, simulates the operation of the user, generates the operation instruction, tests the response of the target code file to the operation instruction, and ,generates the regression test report automatically after the test is finished. The regression testing method has the advantages that a large amount of repeated actions are achieved by software, instead of manual operation, the working load of the tester is reduced, the time consumption of the regression test is shortened, the testing efficiency is improved, and the development period of the software is further shortened.

Owner:西安泛息智慧信息技术有限公司

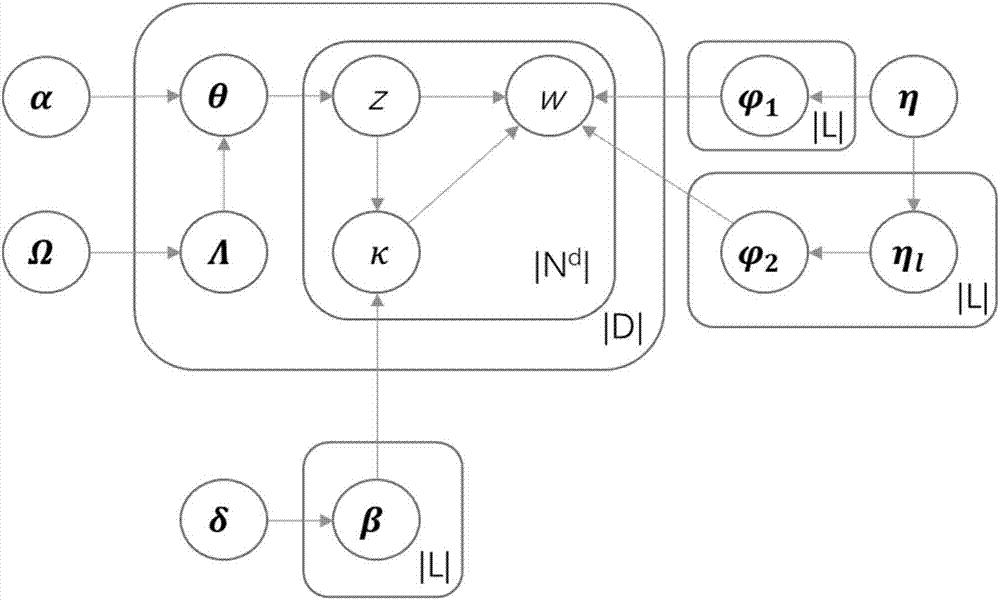

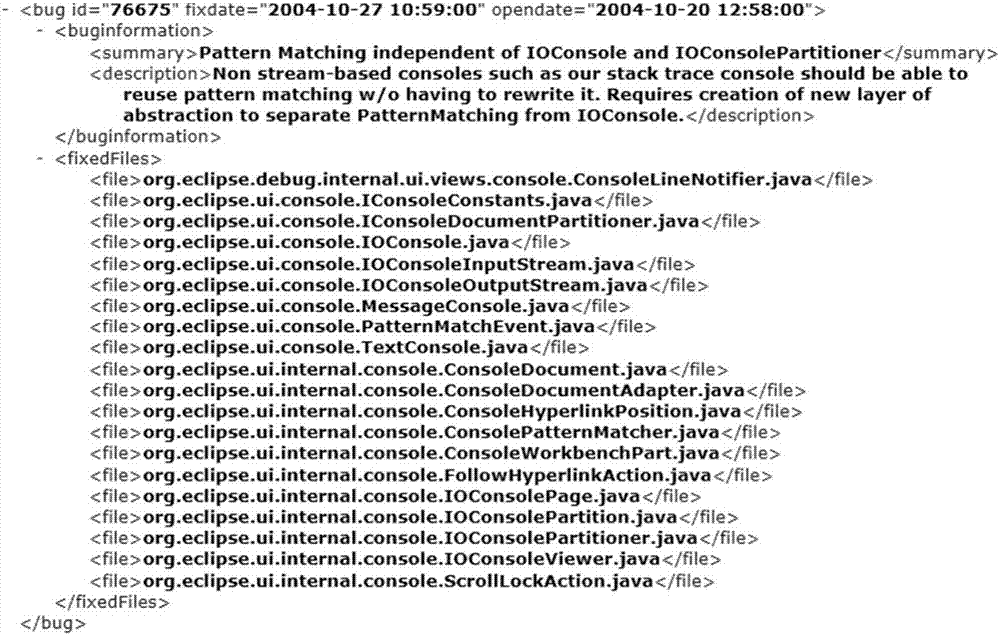

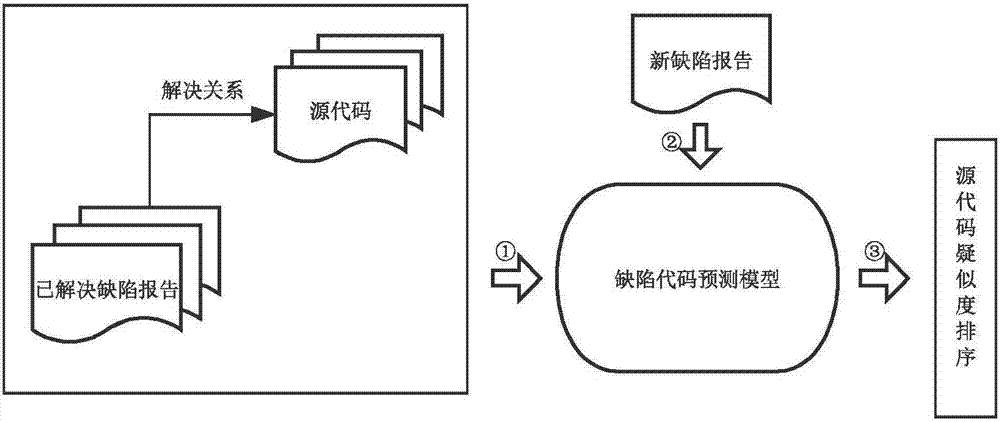

Defect location method based on text subject analysis of defect reports

ActiveCN106874203AImprove accuracyImprove recallSoftware testing/debuggingSubject analysisSource code file

The invention discloses a defect location method based on text subject analysis of defect reports. The defect location method based on the text subject analysis of the defect reports comprises the steps that to solve the problem that the defect reports bring serious burdens to developers, the text analysis is conducted on solved defect reports in a defect tracking management system, a correlation between the defect reports and repairing codes is obtained, and unsolved defect reports are analyzed with the correlation, possible source code file lists to be repaired of new defect reports are provided for the developers, and therefore the maintenance efficiency of a software project is improved. On the basis of a supervised type text subject model Labeled-LDA (LLDA), a modified model of Label to Substrings (L2SS) is put forward. Experiments on an open source project Eclipse data set show that the defect location method based on the L2SS model has higher predictive effect than that of a traditional text subject model.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com