Defect correction device and defect tracking method

A technology of the defect and correction department, which is applied in the field of defect correction devices and defect tracking, and can solve problems such as increased number of steps, longer time, and complicated operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

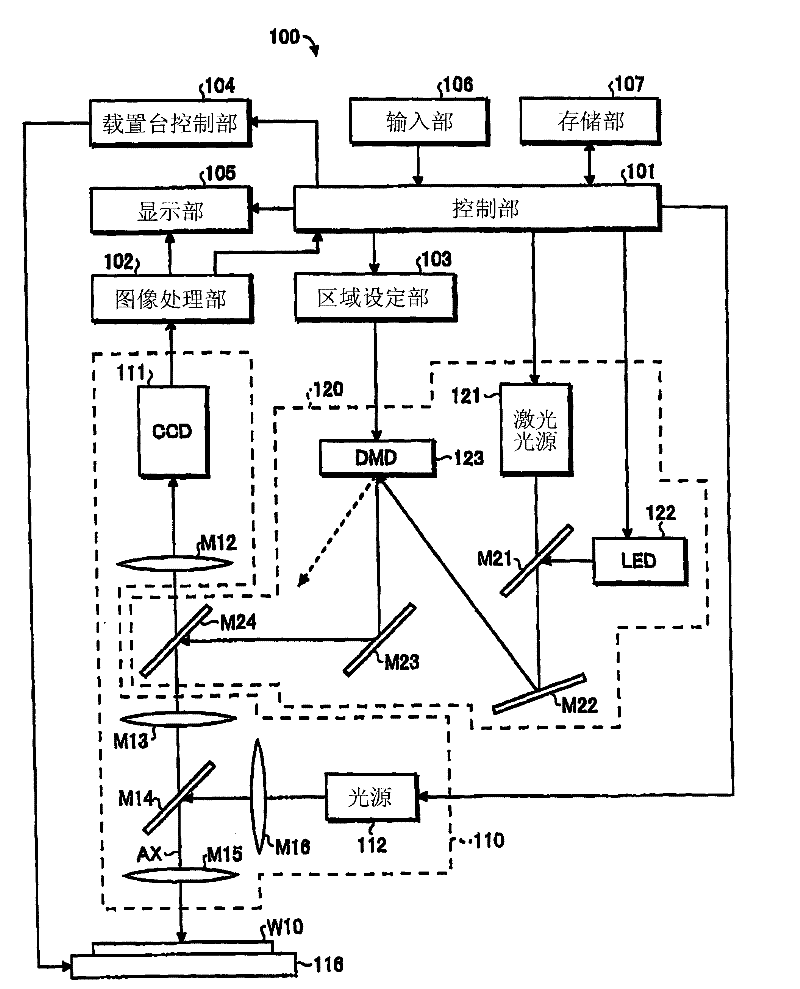

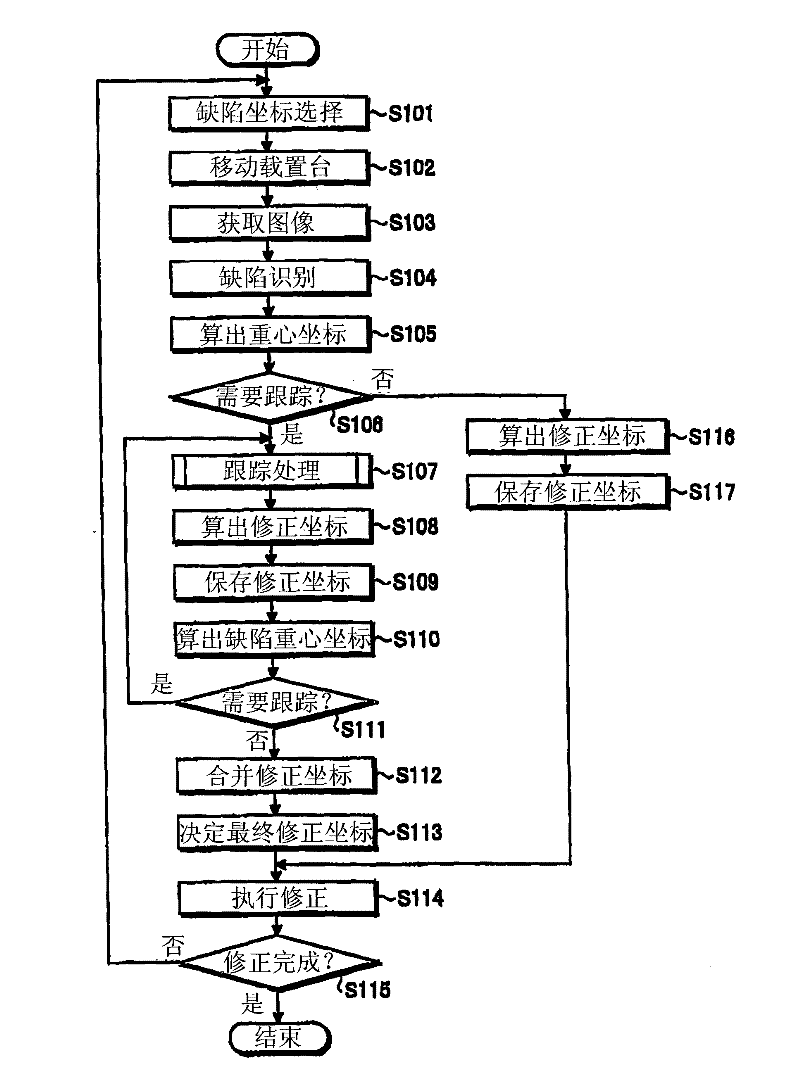

[0058] Next, the defect correction device, defect tracking method, and defect tracking program according to Embodiment 1 of the present invention will be described in detail using the drawings.

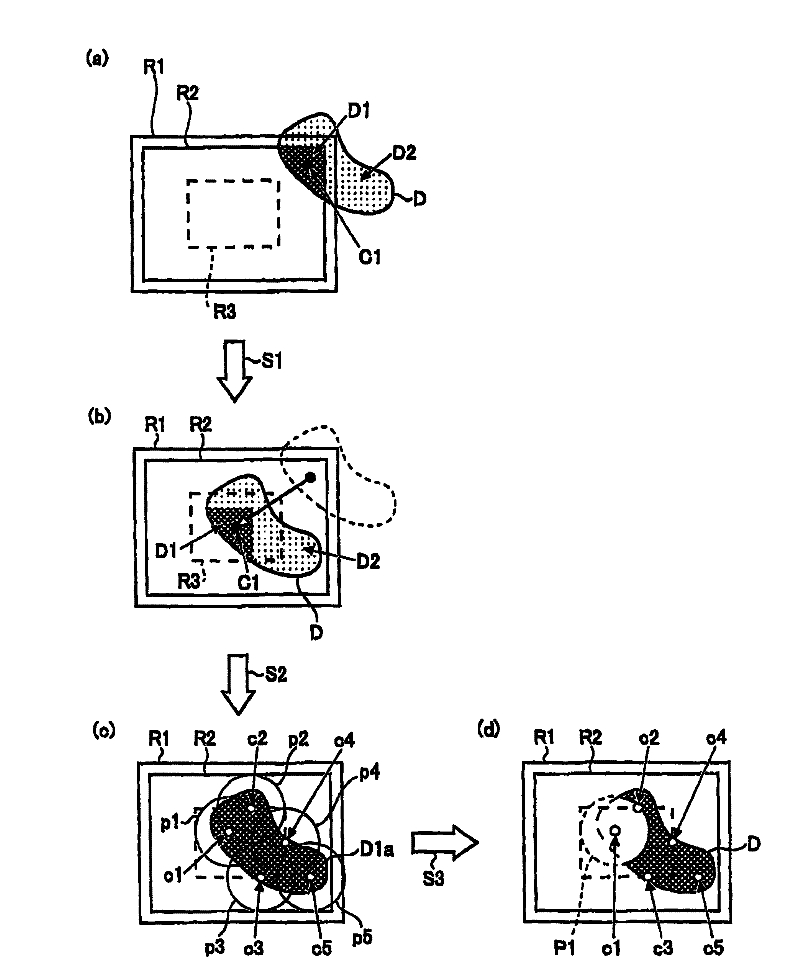

[0059] figure 1 is used to describe the defect correction device 100 incorporated in the first embodiment (refer to figure 2 Conceptual diagram of the outline of the defect tracking method of ). In this Embodiment 1, the coordinate of the defect specified by the external inspection means, such as an AOI (AUTOMATED OPTICAL INSPECTION: automatic optical inspection) system, is input to the defect correction apparatus 100, for example. This coordinate is called defect coordinate to distinguish it from other coordinates. Each defect is assigned a defect coordinate. In addition, in the following description, the coordinate refers to the surface of the workpiece or the upper surface of the stage with the reference position set on the upper surface of the stage on which the substrate (her...

Embodiment approach 2

[0091] Hereinafter, a defect correction device, a defect tracking method, and a defect tracking program according to Embodiment 2 of the present invention will be described in detail with reference to the drawings. In the above-described first embodiment, as the tracking process, the following case is taken as an example: the coordinates of the center of gravity C1 of the identification defect region D1 in the field of view region R1 are obtained, and the center of gravity C1 is dragged to the center of the field of view region R1. to track the defect D extending beyond the field of view area R1. In contrast, in the second embodiment, as the tracking process, correction coordinates are assigned to a portion previously identified as a defect in the field of view region R1 , and the correction coordinates are dragged to detect the defect D extending outside the field of view region R1 . Take the case of tracking as an example.

[0092] Figure 7 is used to describe the defect ...

Embodiment approach 3

[0110] Hereinafter, a defect correction apparatus, a defect tracking method, and a defect tracking program according to Embodiment 3 of the present invention will be described in detail with reference to the drawings. In the third embodiment, as the tracking process, a case where dragging the center coordinates (hereinafter referred to as side center coordinates) of line segments intersecting the four sides of the defect D and the field of view region R1 (corresponding to an image), respectively, is taken as an example. , to track the defect D extending beyond the field of view area R1.

[0111] Figure 10 is used to describe the defect correction device 100 incorporated in the third embodiment (see figure 2 ) conceptual diagram of the outline of the defect tracking method. In addition, in this Embodiment 3, the defect correction apparatus 100 is the same as the defect correction apparatus 100 of Embodiment 1 (refer to figure 2 )same.

[0112] In the defect tracking meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com