Management system of high temperature and high pressure pipeline detection data of thermal power plant and application method thereof

A data management system and pipeline detection technology, which is applied in the field of high-temperature and high-pressure pipeline detection data management systems in thermal power plants, can solve problems such as difficulty in continuously tracking pipeline component detection information, inability to effectively use pipeline detection data, inconvenient query and retrieval, etc., to achieve Avoid the problem of out-of-control defect parts management, eliminate the effect of efficient and quick reference, and avoid missed inspection and over-inspection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0030] Example.

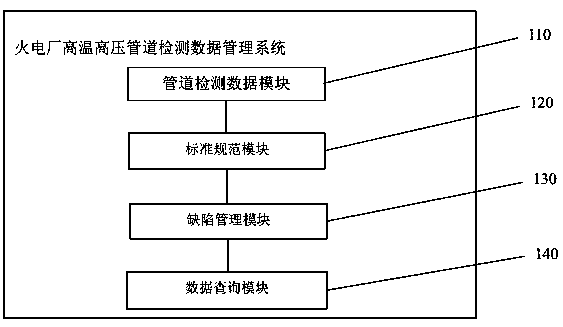

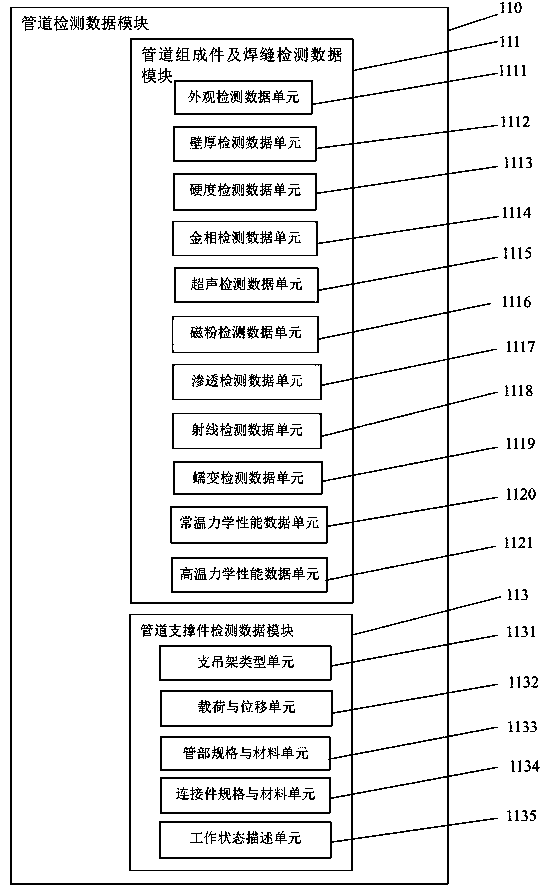

[0031] see figure 1 , a high temperature and high pressure pipeline detection data management system in a thermal power plant, including a pipeline detection data module 110 , a standard specification module 120 , a defect management module 130 and a data query module 140 . The pipeline inspection data module 110, the standard specification module 120, the defect management module 130 and the data query module 140 are connected in sequence to jointly realize the input of high temperature and high pressure pipeline inspection data, report upload, search query, inspection time interval reminder, defect reminder, material organization Seriously degraded performance reminders and other detection data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com