Method and device for lifting door/window glass of car

A door and window glass and lifting device technology, applied in the field of auto parts, can solve the problems of short fatigue life cycle, fast wear of parts, glass lifting and tilting, etc., and achieve the effects of high transmission precision, strong self-locking performance and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

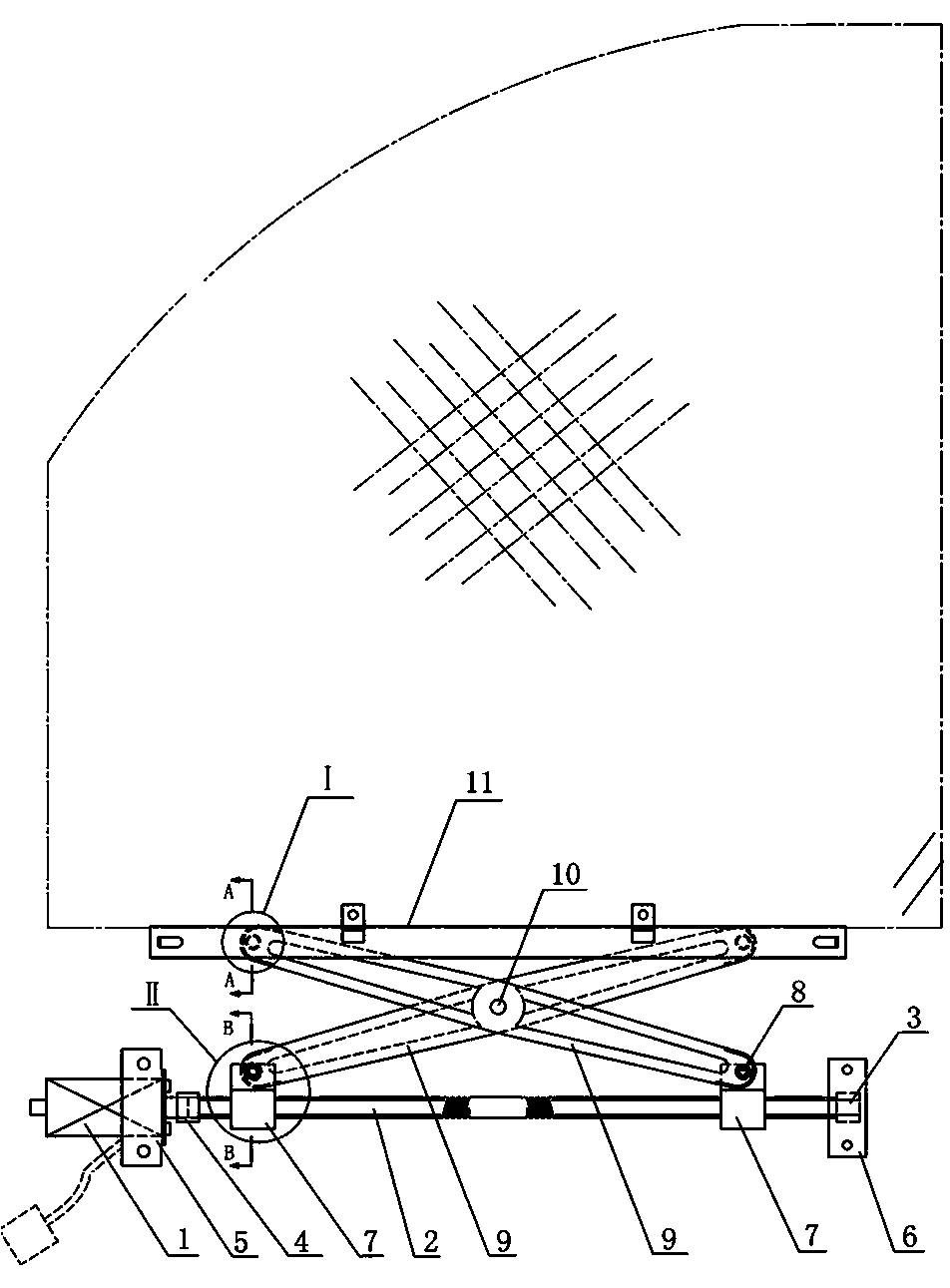

[0035] A method for lifting and lowering an automobile door and window glass, comprising the following steps:

[0036] 1) Horizontally install a motor seat and a bearing support on the inner panel of a car door;

[0037] 2) Then install the motor on the motor seat, and install the bearing on the bearing support;

[0038] 3) Set the thread structure on the lead screw into two sections on the left and right, and the two sections of threads have opposite directions of rotation and the same length, and install a nut support on the corresponding positions of the two sections of threads to form a screw pair;

[0039] 4) Connect one end of the lead screw of the above-mentioned screw pair to the output shaft of the motor, and the other end of the lead screw is sleeved on the bearing as a support;

[0040] 5) Connect the two nut supports to the lower arms of the two lifting transmission arms respectively through the rotating shaft, and the upper arms of the two lifting transmission ar...

Embodiment 2

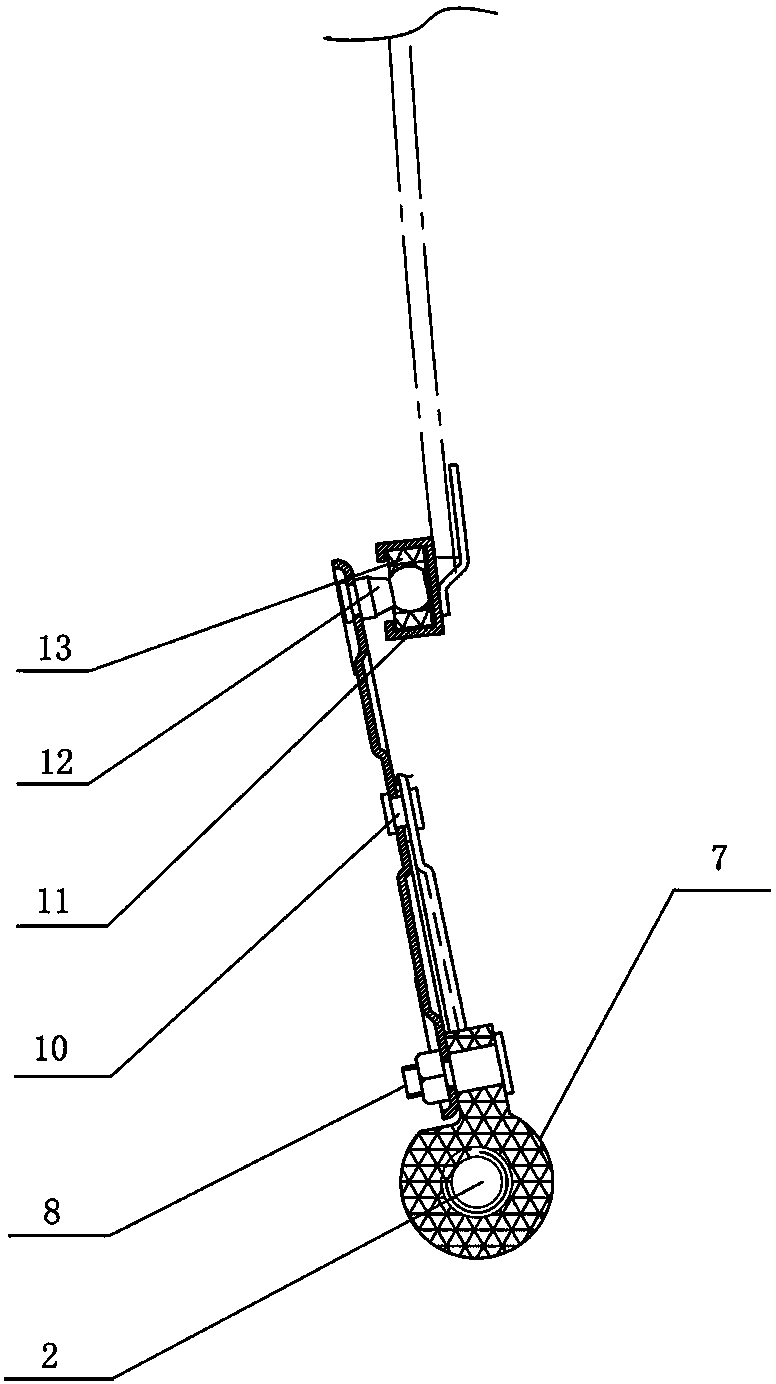

[0049] A method for lifting and lowering an automobile door and window glass, comprising the following steps:

[0050] 1) Vertically install a motor seat and a bearing support on the inner panel of a car door;

[0051] 2) Then install the motor on the motor seat, and install the bearing on the bearing support;

[0052] 3) Install a nut support on the thread position of the lead screw to form a screw pair;

[0053] 4) Connect one end of the lead screw of the above-mentioned screw pair to the output shaft of the motor, and the other end of the lead screw is sleeved on the bearing;

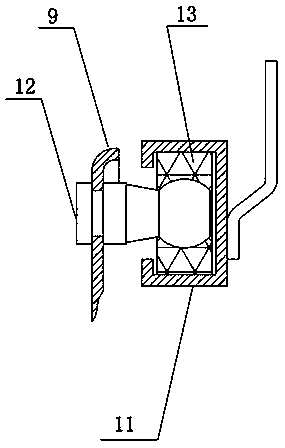

[0054] 5) The nut support of the above-mentioned helical pair is connected with a glass carriage through a ball head sliding rod;

[0055] 6) Install the glass on the glass carriage through the glass guide channel;

[0056] 7) Turn on the power switch, and the motor drives the lead screw of the screw pair to rotate;

[0057] 8) When the lead screw rotates, it converts the rotary motion into linea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com