Automatic stirring mortar and tile coating mechanism and method

An automatic mixing and mortar technology, applied in cement mixing devices, chemical instruments and methods, building structures, etc., to achieve the effects of reducing labor intensity, ensuring uniformity and smoothness, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

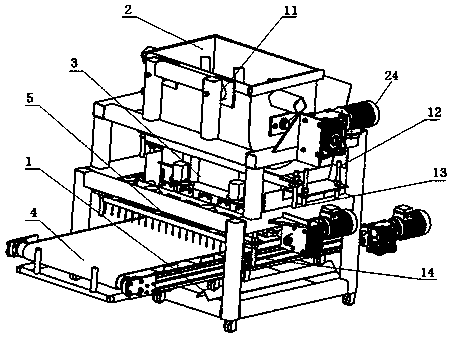

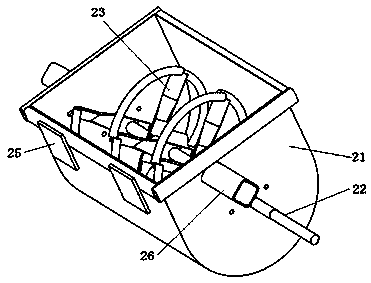

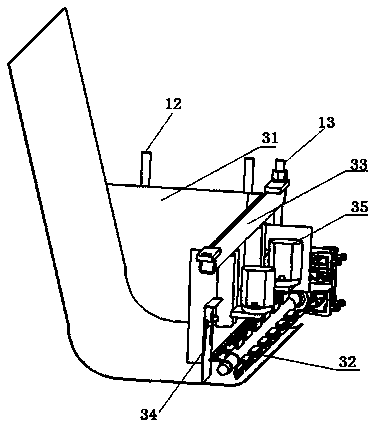

[0036] Combine below Figure 1 to Figure 5 Embodiments of the present invention are described in detail.

[0037] Automatic mortar mixing and tile coating mechanism, including a frame 1 with universal casters at the bottom, characterized in that the frame 1 is equipped with a mixing bucket assembly 2 for mixing mortar raw materials to form mortar and pouring out the mortar, and a receiving mixing bucket Component 2 pours out the mortar and outputs the mortar to the lower hopper component 3 on the tiles, the horizontal transmission component 4 located below the lower hopper component 3 for driving the tiles to move horizontally, and the scraper component for leveling the mortar on the tiles 5. The scraper assembly 5 is located above the horizontal transmission assembly 4 and in front of the outlet of the mixing bucket assembly 2. The back of the tile is placed on the horizontal transmission assembly 4, and the mortar output by the lower hopper assembly 3 is received as the hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com