Hub characteristic detecting device for production line

A feature detection and assembly line technology, applied in the direction of measuring devices, mechanical devices, optical devices, etc., can solve the problems of poor efficiency and consistency, and achieve the effects of convenient processing, saving test time, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

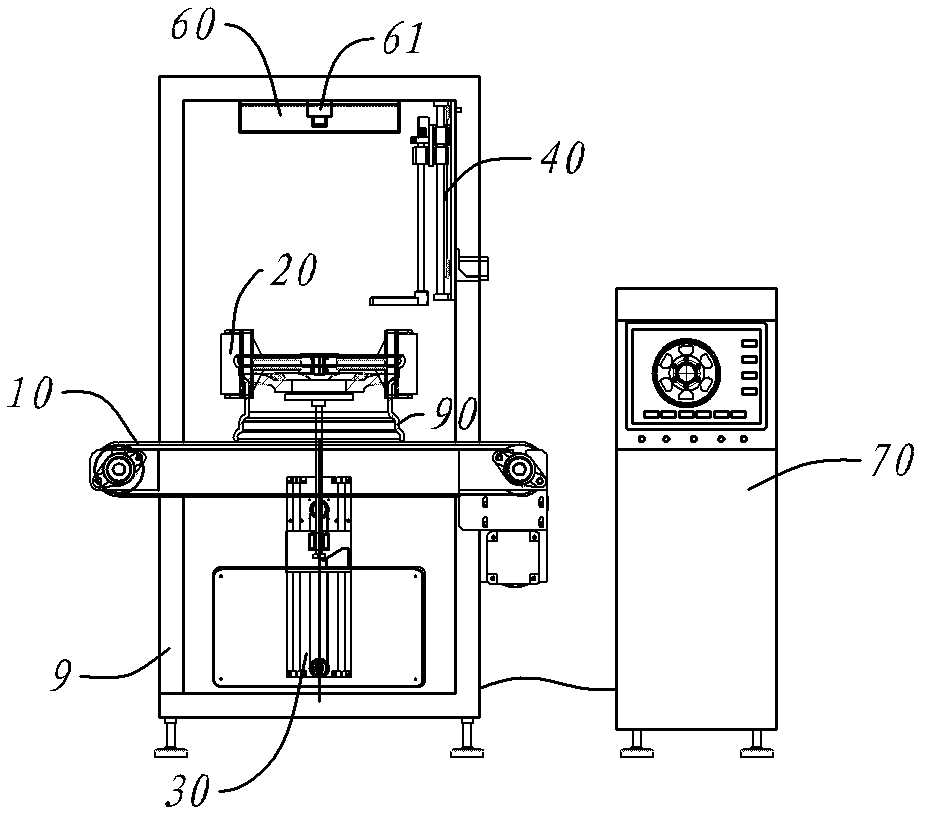

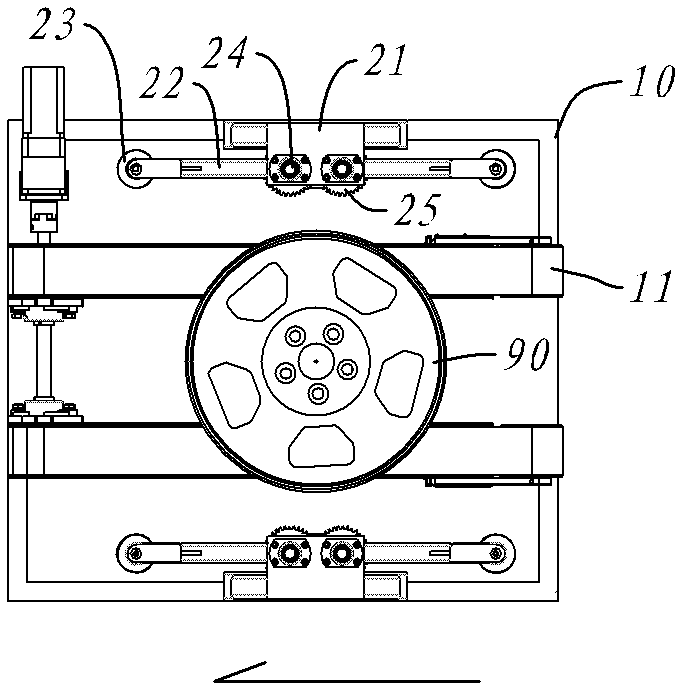

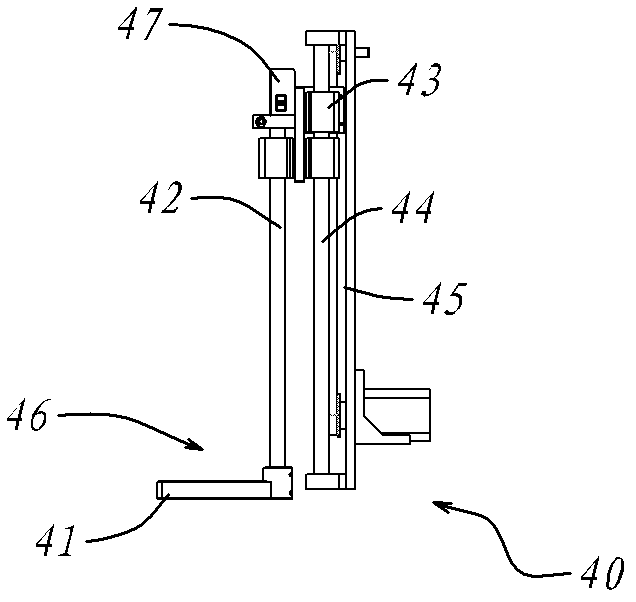

[0030] Such as figure 1 Front view of an embodiment of the present invention; figure 2 yes figure 1 The schematic diagram of the top view of the horizontal transmission mechanism of the embodiment shown; it will be explained in conjunction with these two figures:

[0031] This wheel hub feature detection device has a frame 9, the middle of which is fixed with a horizontal transmission mechanism 10; on this horizontal transmission mechanism 10, there is a horizontal one-way conveyor belt 11 and a part fixed on the frame 9, and the wheel hub 90 is in the process of traveling Lay flat on the conveyer belt 11, and its rotating shaft keeps vertical. Conveyor belt 11 is two rows of parallel persons, and other devices therebetween can be avoided.

[0032] The wheel hub 90 starts from one end of the horizontal transmission mechanism 10 and advances horizontally under the drive of the conveyor belt 11. According to the set distance, the hub 90 advances to the central position by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com