Method for processing threads on ends of stainless steel bar

A technology of stainless steel and thread, which is applied in the field of thread processing at the end of stainless steel bars. It can solve the problems of different strength and performance of stainless steel bars, no thread processing, and thread processing of stainless steel bars. It is easy to popularize and apply, and the steps are simple and reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

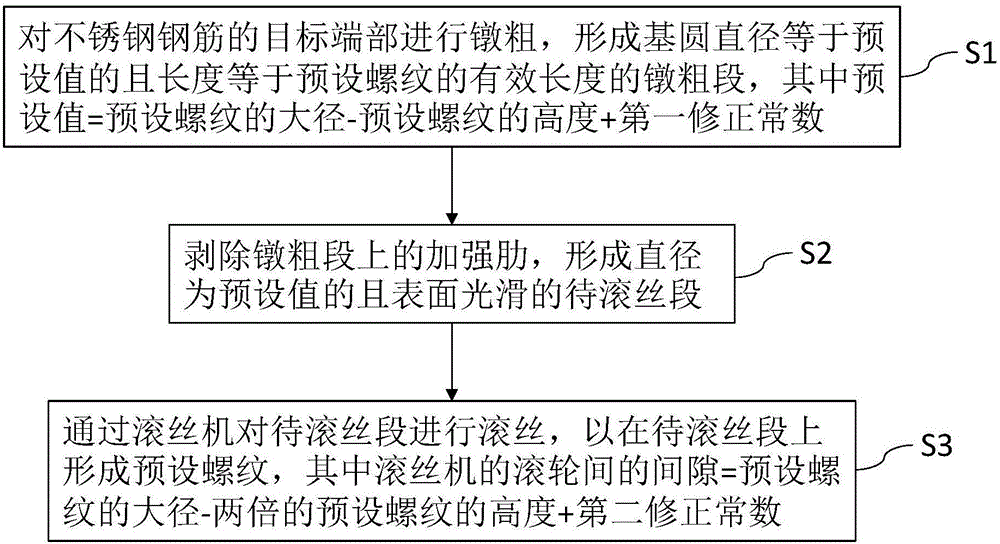

Method used

Image

Examples

Embodiment 1

[0021] Materials to be processed: S25 stainless steel bars:

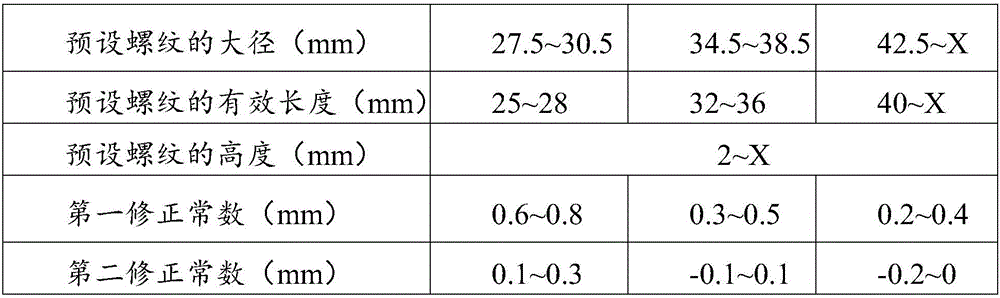

[0022] Preset thread parameters: The major diameter of the preset thread is 27.5mm, the effective length of the preset thread is 25mm, and the height of the preset thread is 2mm

[0023] Calculation formula and related correction knowledge: preset value = major diameter of preset thread - height of preset thread + first correction constant, wherein the first correction constant is 0.7mm; gap between rollers of thread rolling machine = preset The major diameter of the thread - twice the height of the preset thread + a second correction constant, wherein the second correction constant is 0.2mm.

[0024] The method of threading the end of the stainless steel bar of S25 specification is:

[0025] Upsetting step: Calculate the base circle diameter according to the calculation formula of "preset value = major diameter of preset thread - height of preset thread + first correction constant", that is, 27.5-2+0.7=26.2 mm, a...

Embodiment 2

[0029] Materials to be processed: S28 stainless steel bars:

[0030] Preset thread parameters: The major diameter of the preset thread is 30.5mm, the effective length of the preset thread is 28mm, and the height of the preset thread is 2mm

[0031]Calculation formula and related correction knowledge: preset value = major diameter of preset thread - height of preset thread + first correction constant, wherein the first correction constant is 0.7mm; gap between rollers of thread rolling machine = preset The major diameter of the thread - twice the height of the preset thread + the second correction constant, the second correction constant is 0.2 mm.

[0032] The method of threading the end of the stainless steel bar of S28 specification is:

[0033] Upsetting step: Calculate the base circle diameter according to the calculation formula of "preset value = major diameter of preset thread - height of preset thread + first correction constant", that is, 30.5-2+0.7=29.2 mm, and the...

Embodiment 3

[0037] Materials to be processed: S32 stainless steel bars

[0038] Preset thread parameters: The major diameter of the preset thread is 34.5mm, the effective length of the preset thread is 32mm, and the height of the preset thread is 2mm

[0039] Calculation formula and related correction knowledge: preset value = major diameter of preset thread - height of preset thread + first correction constant, wherein the first correction constant is 0.4mm; gap between rollers of thread rolling machine = preset The major diameter of the thread - twice the height of the preset thread + the second correction constant, the second correction constant is 0mm.

[0040] The method of threading the end of the stainless steel bar of S32 specification is:

[0041] Upsetting step: calculate the base circle diameter according to the calculation formula of "preset value = major diameter of preset thread - height of preset thread + first correction constant", that is, 34.5-2+0.4=32.9 mm, and then u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com