Method for preparing quantum dots from hyperbranched polymer

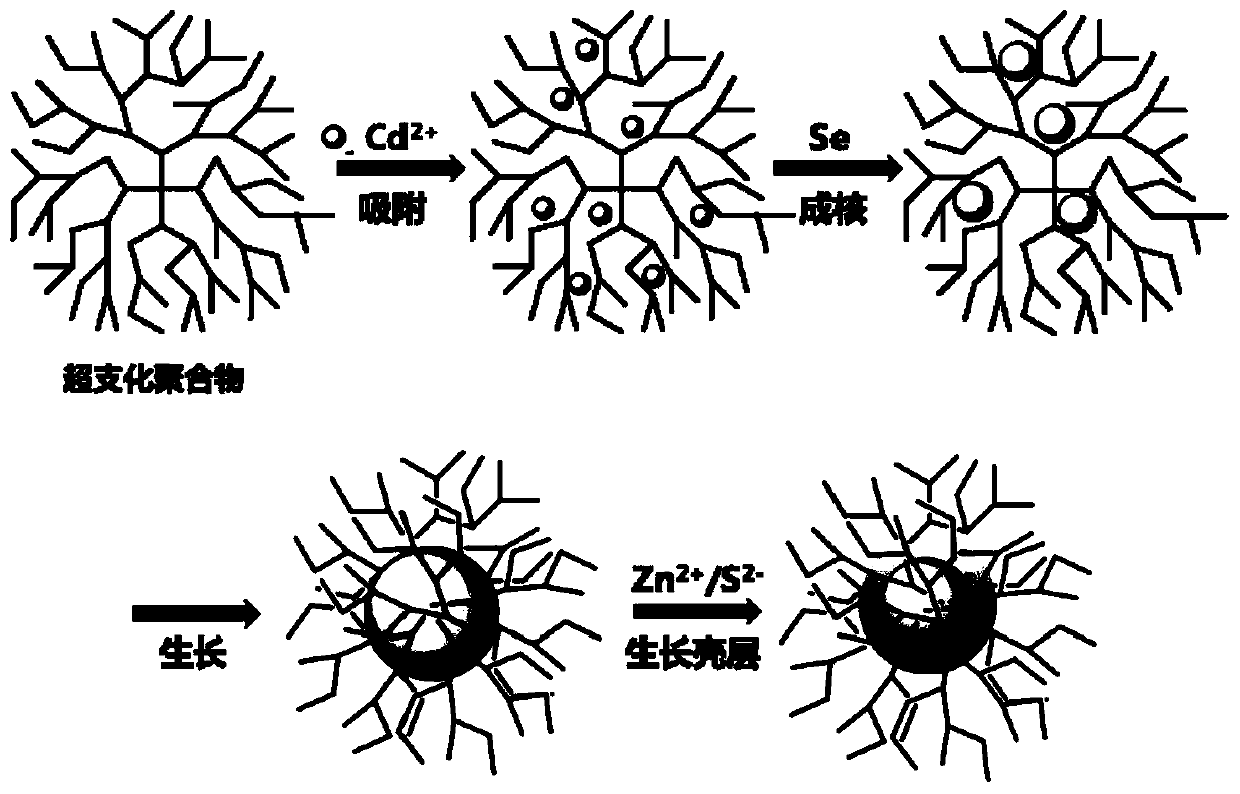

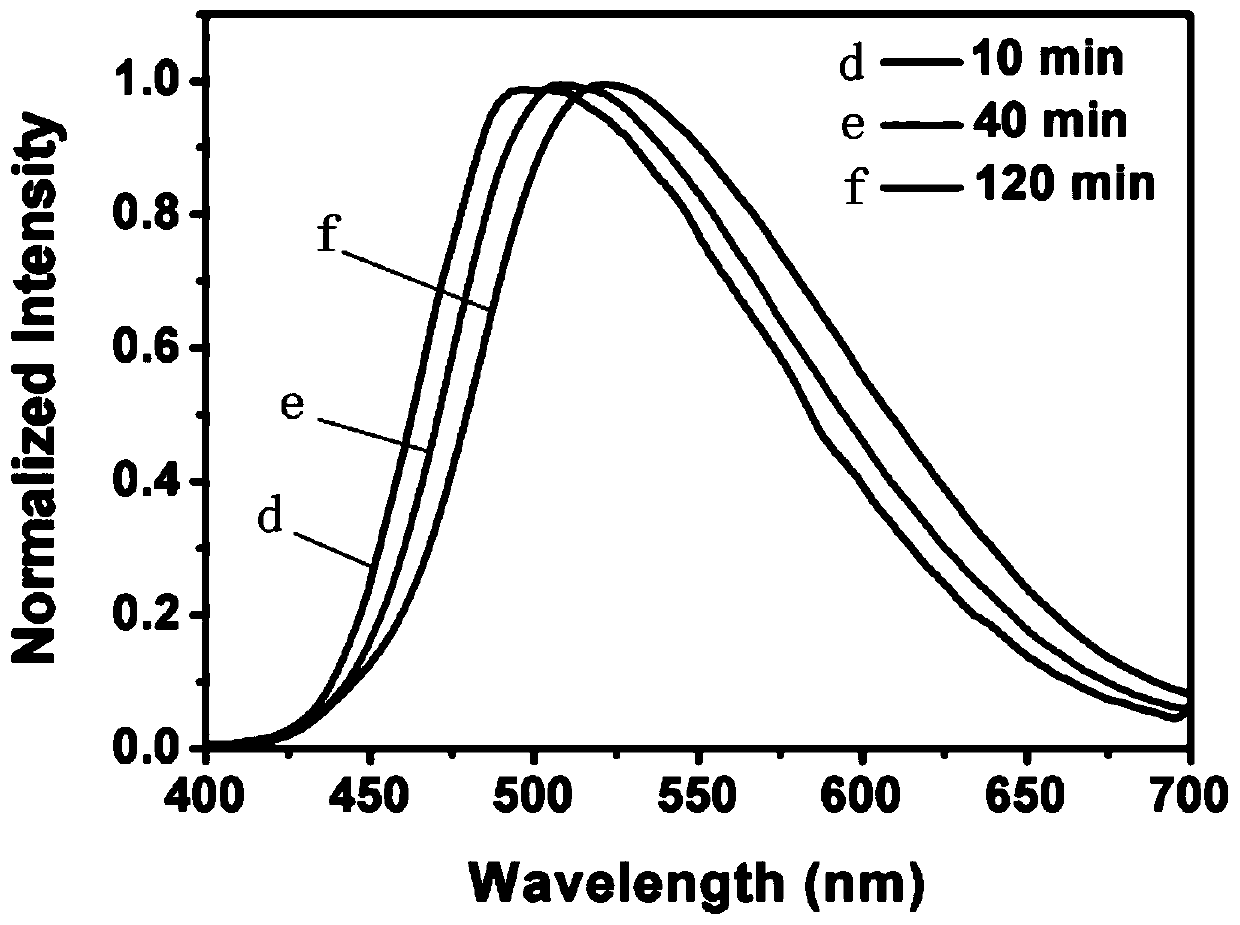

A technology of hyperbranched polymers and quantum dots, which is applied in chemical instruments and methods, binary selenium/tellurium compounds, nanotechnology, etc. Quantum dots mass production and other issues, to achieve simple and reliable steps, good industrialization prospects, and achieve the effect of fluorescence spectrum tunability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

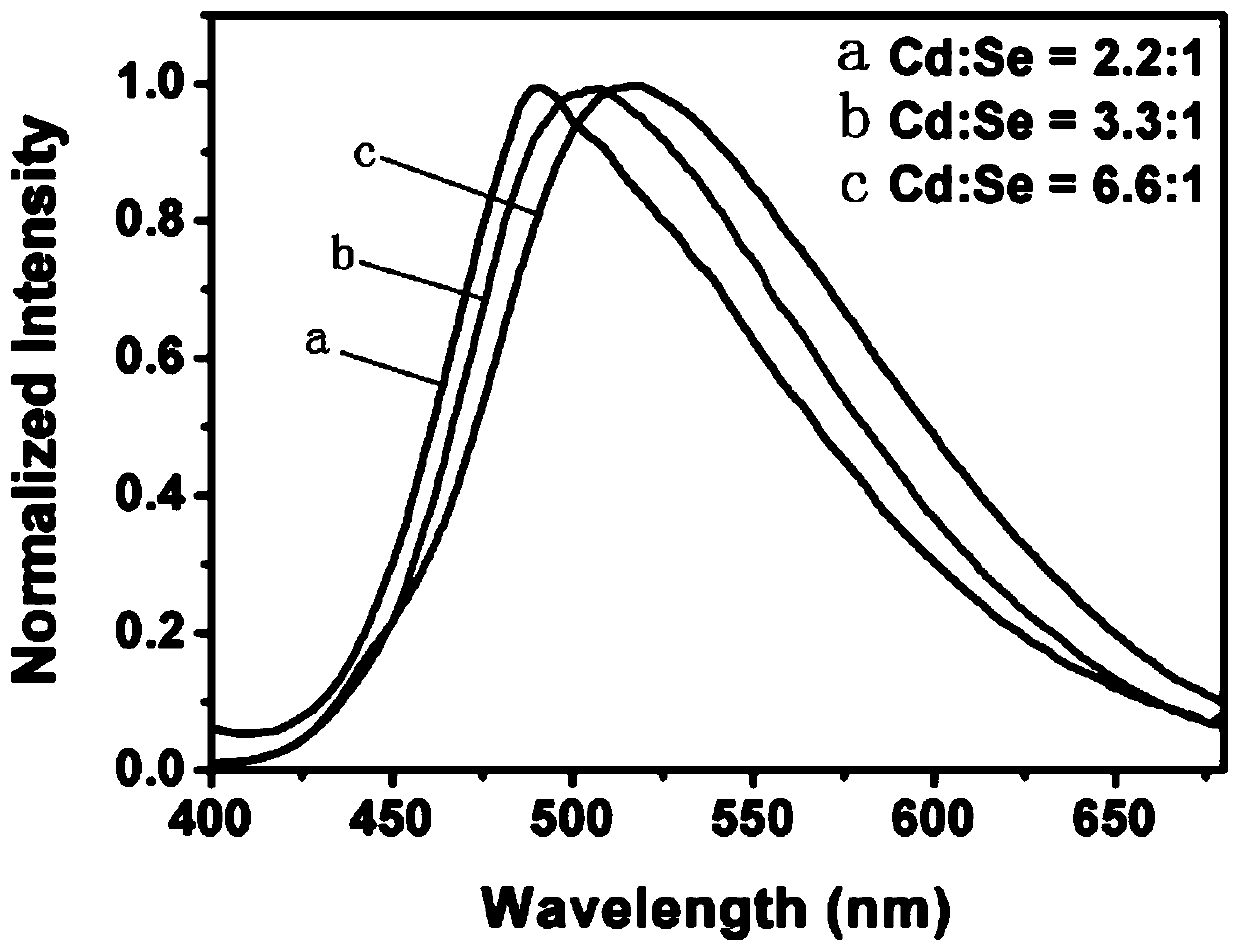

[0038] First, under an inert gas atmosphere, 40 mg of selenium powder and 115 mg of sodium borohydride were added to 30 mL of ultrapure water, and vigorously stirred at room temperature for 30 min until the selenium powder was completely dissolved to obtain a colorless and transparent A solution. Subsequently, 200 mg of hyperbranched polyethyleneimine was dissolved in 20 mL of ultrapure water to obtain a 10 mg / mL aqueous solution of hyperbranched polyethyleneimine, to which 175 mg of CdCl was added 2 .2.5H 2 O (cadmium chloride hydrate), stirred at room temperature for 8 hours to obtain B solution. Finally, in the glove box, under vigorous stirring, the solution A was slowly added dropwise to the solution B, and then placed in an oil bath at 100° C. for 1 hour to react to prepare cadmium selenide quantum dots.

[0039] The fluorescence emission wavelength of the quantum dots obtained in this example is 487 nm.

Embodiment 2

[0041] Under an inert gas atmosphere, 40 mg of selenium powder and 115 mg of sodium borohydride were added to 30 mL of ultrapure water, and stirred vigorously at room temperature for 30 min until the selenium powder was completely dissolved to obtain a colorless and transparent A solution. Subsequently, 200 mg of hyperbranched polyethyleneimine was dissolved in 20 mL of ultrapure water to obtain a 10 mg / mL aqueous solution of hyperbranched polyethyleneimine, to which 263 mg of CdCl was added 2 .2.5H 2 O (cadmium chloride hydrate), stirred at room temperature for 8 hours to obtain B solution. Finally, in the glove box, under vigorous stirring, the solution A was slowly added dropwise to the solution B, and then placed in an oil bath at 100° C. for 1 hour to react to prepare cadmium selenide quantum dots.

[0042] The fluorescence emission wavelength of the quantum dots obtained in this example is 503 nm.

Embodiment 3

[0044] Under an inert gas atmosphere, 40 mg of selenium powder and 115 mg of sodium borohydride were added to 30 mL of ultrapure water, and stirred vigorously at room temperature for 30 min until the selenium powder was completely dissolved to obtain a colorless and transparent A solution. Subsequently, 200 mg of hyperbranched polyethyleneimine was dissolved in 20 mL of ultrapure water to obtain a 10 mg / mL aqueous solution of hyperbranched polyethyleneimine, to which 528 mg of CdCl was added 2 .2.5H 2 O (cadmium chloride hydrate), stirred at room temperature for 8 hours to obtain B solution. Finally, in the glove box, under vigorous stirring, the solution A was slowly added dropwise to the solution B, and then placed in an oil bath at 100° C. for 1 hour to react to prepare cadmium selenide quantum dots.

[0045] The fluorescence emission wavelength of the quantum dots obtained in this example is 515 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com