Mechanical flat rotating disk

A flat-rotating, mechanical technology, applied in metal processing machinery parts, metal processing equipment, feeding devices, etc., can solve the problems of high maintenance cost, complex structure, high machine tool manufacturing cost, and achieve the effect of high precision, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

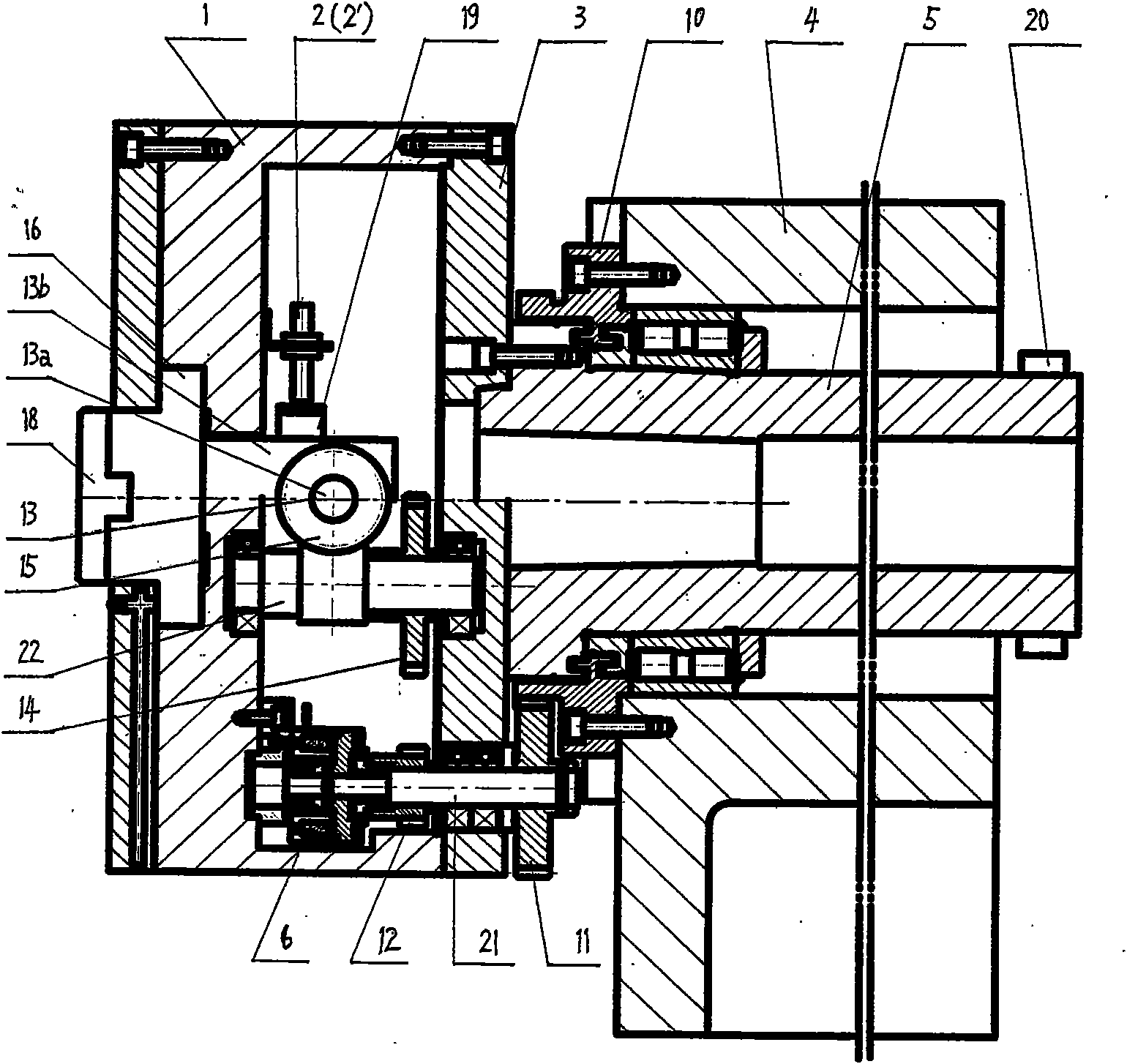

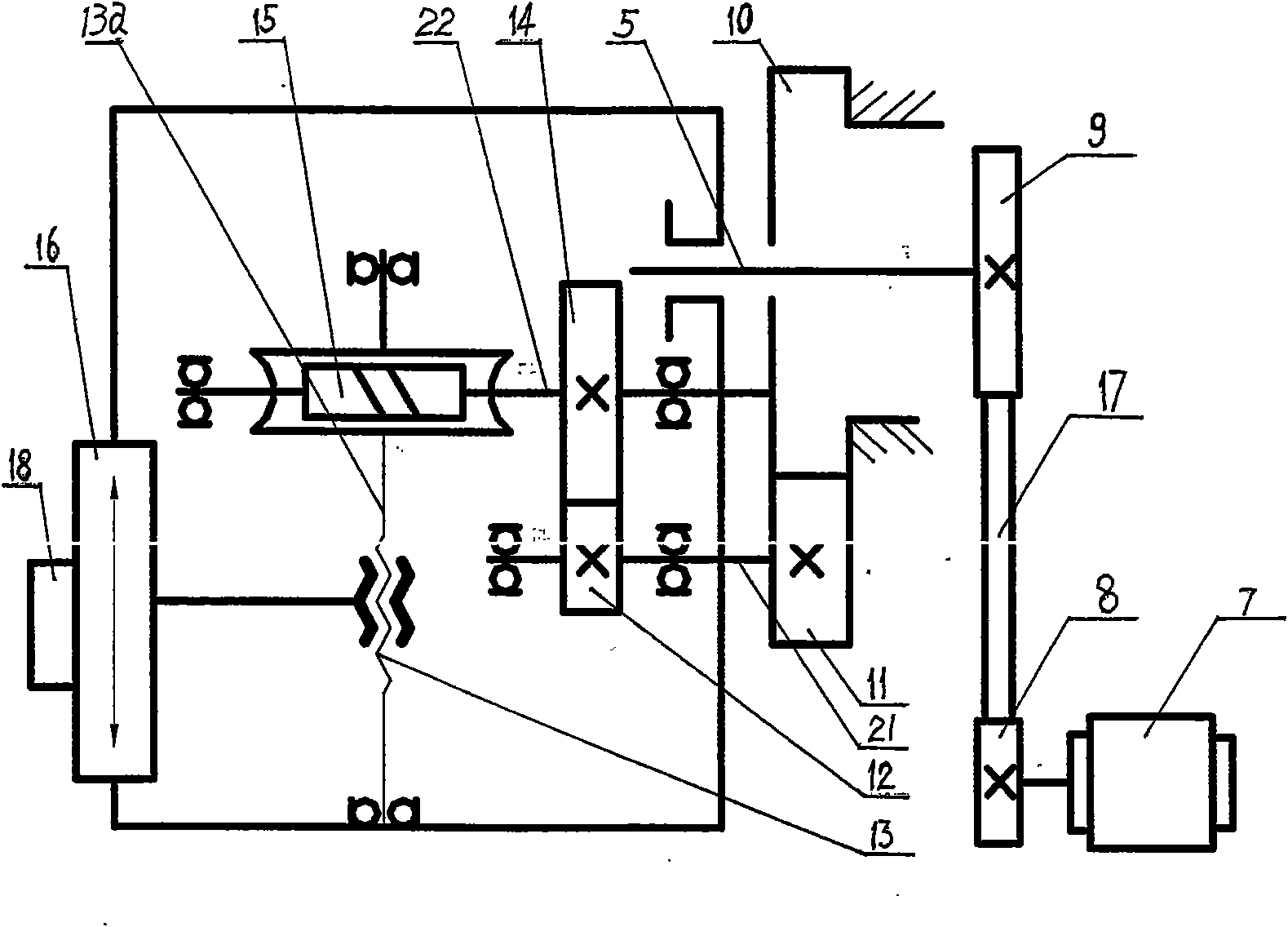

[0011] As shown in the figure, the present invention includes a main motor 7 connected to the driving pulley 8, the driving pulley 8 is connected to the driven pulley 9 through a multi-rib belt 17, and the main shaft 5 is fixed with the driven pulley 9 and the flange 3 , the fixed gear 10 is fixed on the headstock 4 , and the planetary gear 11 meshes with the fixed gear 10 and can rotate around the fixed gear 10 . The planetary gear 11 , the driving gear 12 and the clutch 6 are fixed on the central shaft 21 . A horizontal transmission shaft 22 and a screw pair 13 perpendicular to the transmission shaft are arranged in the flange 3, a worm gear pair 15 is connected to the transmission shaft and a driven gear 14 is installed, and the driving gear 12 meshes with the driven gear 14 , The worm pair 15 is connected to the screw pair 13 through the screw 13a, the slide plate 16 is connected to the screw nut 13b of the screw pair, and can also be fixedly connected to the flange 3 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com