A kind of sodium borohydride hydrolysis hydrogen production device

A technology of hydrogen production by hydrolysis and sodium borohydride, applied in hydrogen, inorganic chemistry, hydrogen production, etc., can solve the problems of low fuel conversion rate, low hydrogen production purity, uncontrollable hydrogen production rate, etc., and achieve high fuel conversion rate , high hydrogen production purity, and controllable hydrogen production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in further detail below in conjunction with accompanying drawing:

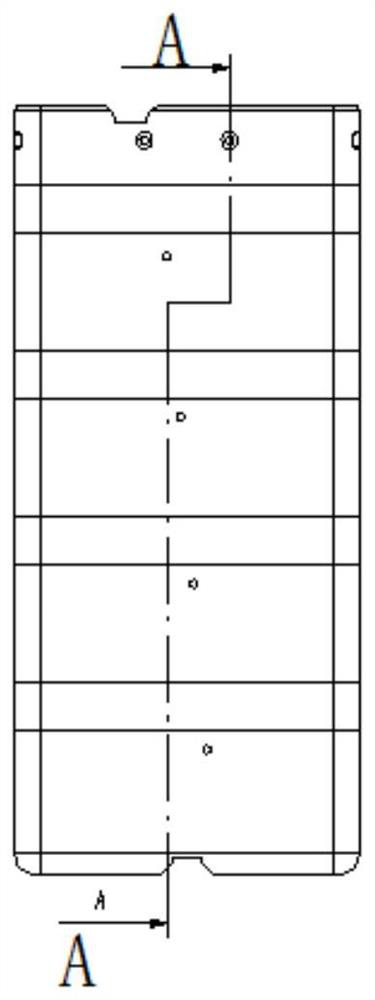

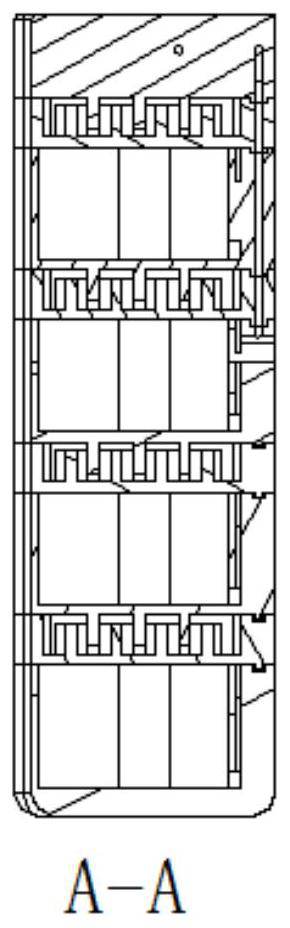

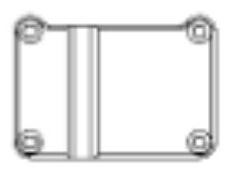

[0031] refer to Figure 1a to Figure 3c , the sodium borohydride hydrolysis hydrogen production device described in the present invention comprises an upper cover plate 1 and a plurality of fuel reaction chambers 3; the upper cover plate 1 and each fuel reaction chamber 3 are distributed sequentially from top to bottom, and the adjacent fuel reaction chambers 3 and between the upper cover plate 1 and the uppermost fuel reaction chamber 3 are provided with an overflow plate 2; the upper cover plate 1, each fuel reaction chamber 3 and each overflow plate 2 are fixedly connected, and each fuel reaction chamber The chamber 3 is provided with solid fuel; the upper cover plate 1 is provided with a number of first vertical water distribution channels 1H, each overflow plate 2 is provided with a number of second vertical water distribution channels 2A, and the side walls of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com