Method for preparing alkaline hydrogen peroxide in situ

A hydrogen peroxide, in-situ preparation technology, applied in the electrolysis process, electrodes, cells, etc., can solve the problems of easy explosion, hydrogen peroxide production pollution, etc., and achieve the effect of convenient output amplification and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

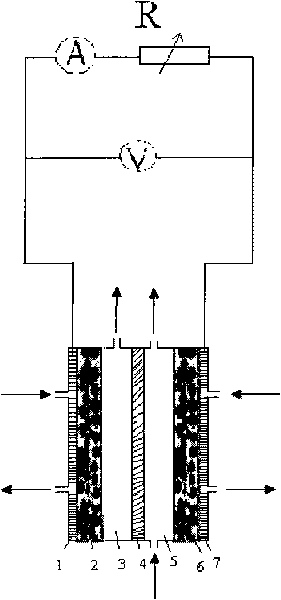

Method used

Image

Examples

Embodiment 1

[0033] Vucan XC-72 treated at a high temperature of 2100°C is used as the cathode catalyst, and the catalyst loading is 1mg / cm2; Pt / C is used as the anode catalyst, and the catalyst loading is 0.4mg(Pt) / cm 2 ., gold-plated stainless steel is the cathode and anode end plates, the anode hydrogen pressure is 0.01MPa, the flow rate is 76ml / min; the cathode oxygen pressure is 0.01MPa, the flow rate is 76ml / min, the operating temperature is 25°C, and the electrolyte is 2mol / L KOH solution , the electrolyte does not circulate. When the external circuit is closed, under this condition, the generation rate of hydrogen peroxide is 0.1mol / L cm 2 , current density 20mA / cm 2 .

Embodiment 2

[0035] Vucan XC-72 treated at 2100°C is used as the cathode catalyst, and the catalyst loading is 2mg / cm 2 ; Pt / C is the anode catalyst, and the loading of the catalyst is 0.4mg(Pt) / cm 2 ., gold-plated stainless steel is the cathode and anode end plates, the anode hydrogen pressure is 0.01MPa, the flow rate is 76ml / min; the cathode oxygen pressure is 0.01MPa, the flow rate is 76ml / min, the operating temperature is 25°C, the electrolyte is 2mol / L KOH solution, the electrolyte Do not loop. When the external circuit is closed, under this condition, the generation rate of hydrogen peroxide is 0.3mmol / L cm 2 , current density 40mA / cm 2 .

Embodiment 3

[0037] Vucan XC-72 treated at a high temperature of 2100°C is used as the cathode catalyst, and the catalyst loading is 3mg / cm2; Pt / C is used as the anode catalyst, and the catalyst loading is 0.4mg(Pt) / cm 2 ., gold-plated stainless steel is the cathode and anode end plates, the anode hydrogen pressure is 0.01MPa, the flow rate is 76ml / min; the cathode oxygen pressure is 0.01MPa, the flow rate is 76ml / min, the operating temperature is 25°C, the electrolyte is 2mol / L KOH solution, the electrolyte Do not loop. When the external circuit is closed, a voltage of 1V is applied to both ends of the reactor through a constant current power supply. Under this condition, the generation rate of hydrogen peroxide is 0.2mmol / L cm 2 , current density 30mA / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com