Composite catalytic layer proton exchange membrane fuel cell electrode and its preparing method

A fuel cell electrode, proton exchange membrane technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of "water-flooded" hydrophobic electrode catalyst utilization, high electrocatalyst utilization, large proton conduction resistance, etc. Good electron conduction and proton conduction, good gas conduction and water transport, the effect of improving output power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

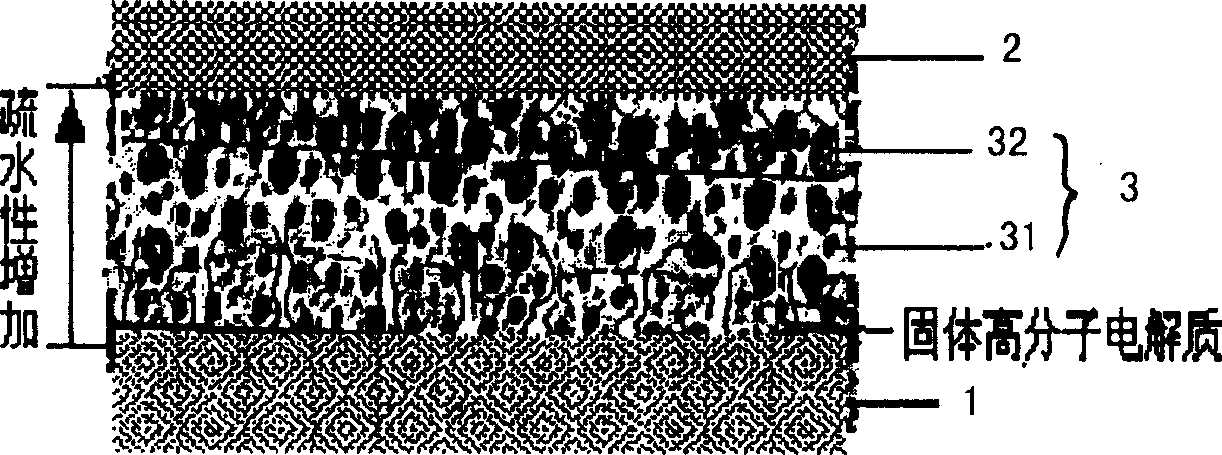

Method used

Image

Examples

Embodiment 1

[0042] a) According to 0.25mgPt / cm 2 The amount of catalyst used is to weigh the Pt / C catalyst with a Pt loading of 40wt% and put it into a beaker, add a small amount of deionized water to soak the catalyst, and use 50ml of absolute ethanol per gram of catalyst. After weighing, add the ethanol After the catalyst beaker, mix and stir evenly, and the material is slurry. Then according to the ratio of Pt / C: PTFE = 1: 1.5, weigh PTFE and add it to the feed liquid, mix evenly, and mature.

[0043] Scrape-coat the above-mentioned cured slurry on one side of the gas diffusion layer leveling layer that has been hydrophobized and leveled on one side, dry at 160°C for 30 minutes under the protection of nitrogen, and then heat up to 250°C and bake for 30 minutes, then raise the temperature To 360°C, bake for 30 minutes. After cooling, weigh 5wt% Nafion solution in an amount of 1 mg polymer electrolyte per square centimeter; add appropriate isopropanol, mix evenly, and spray evenly on t...

Embodiment 2

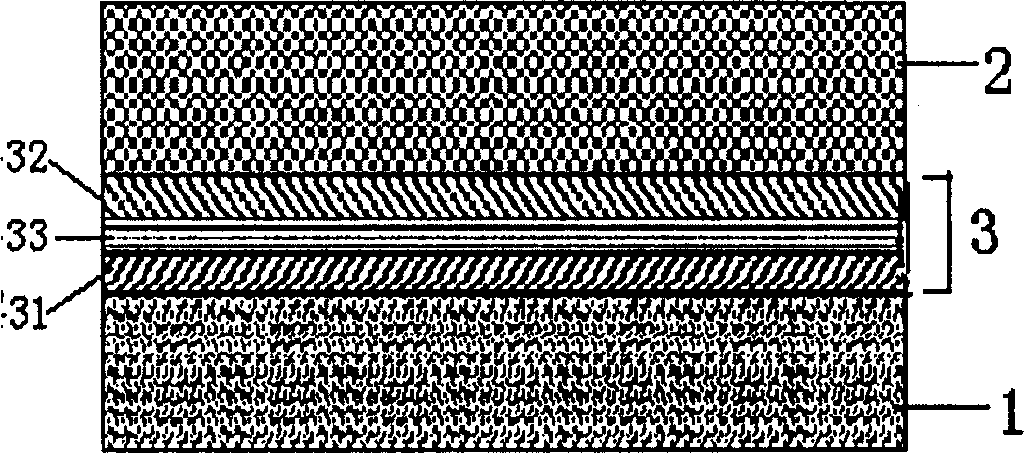

[0050] a) The hydrophobic catalyst slurry was prepared according to the method in a) of Example 1, and the hydrophobic catalytic layer was prepared on the gas diffusion layer according to the method of Example 1, and the hydrophobic catalytic layer was three-dimensionalized.

[0051] b) prepare hydrophilic catalytic layer slurry by b) method of embodiment 1, this slurry is sprayed onto the surface of PTFE membrane equably, the usage amount of hydrophilic catalytic layer Pt is by 0.25mg / cm 2 adjust. After drying, put two pieces of hydrophilic catalytic layer prepared on PTFE membrane on both sides of a pre-treated Nafion 112 membrane, heat press to transfer the hydrophilic catalytic layer to both sides of the proton exchange membrane, and then place the two The three-dimensionally treated hydrophobic electrodes are respectively placed on the above-mentioned hydrophilic catalytic layer, and hot-pressed to obtain a three-in-one membrane electrode.

Embodiment 3

[0053] The electrode manufactured in Example 1 was used as a cathode, and the electrode manufactured in Comparative Example was used as an anode, which were hot-pressed with Nafion 1035 membrane to obtain a three-in-one membrane electrode.

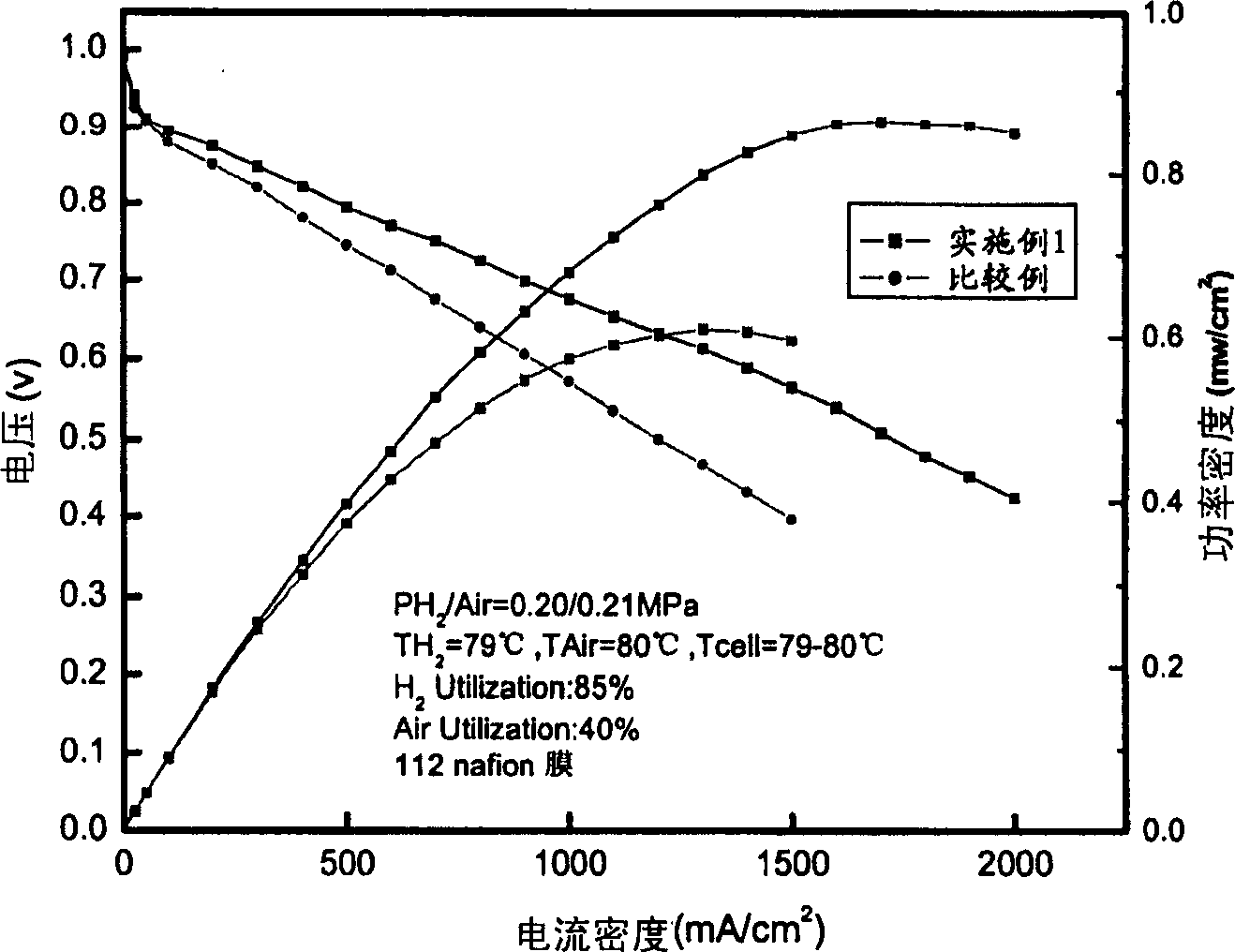

[0054] The three-in-one membrane electrodes prepared in the above-mentioned Example 1, Example 2, Example 3 and Comparative Example were respectively assembled into single cells and evaluated on a fuel cell evaluation system. Its evaluation results, such as image 3 , Figure 4 , Figure 5 shown in the curve. The specific operating parameters of the fuel cell are as follows. The working temperature of the fuel cell is 80°C, the temperature of the humidifier is 78-80°C, the working pressure of the fuel cell is 0.2MPa, and the hydrogen and air volumes are strictly controlled. The hydrogen stoichiometric ratio is 1.17 and the air stoichiometric ratio is 2.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com