Boron nitride/epoxy resin composite and preparation method and application thereof

A technology of epoxy resin and composite materials, which is applied in the direction of chemical instruments and methods, heat exchange materials, etc., can solve the problems of inability to form thermal conduction paths, and the thermal conductivity of thermal interface materials is not very obvious, so as to achieve easy operation and environmental friendliness , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] (1) Solution preparation: Take 6.87g of boron nitride powder and disperse in 200mL of isopropanol and deionized water (volume ratio 1:1) mixed solution at room temperature, ball mill for more than 12h to make it evenly dispersed, ultrasonic for 1h, 2000r / min Centrifuge for 5 minutes, take the supernatant and centrifuge at 9000 r / min for another 5 minutes, remove the supernatant, and freeze-dry the solid at the bottom to obtain boron nitride nanosheets.

[0060] Take 0.27g of polyvinyl alcohol and 17mL of deionized water, heat at 90°C for 30 minutes to completely dissolve the polyvinyl alcohol in deionized water, add 6.87g of boron nitride nanosheets, stir evenly, ultrasonicate for 1 hour, and vacuum remove air bubbles to obtain a relatively stable mixture solution, wherein the volume fraction of boron nitride nanosheets is 15 vol%, and the volume fraction of polyvinyl alcohol is 2 vol%.

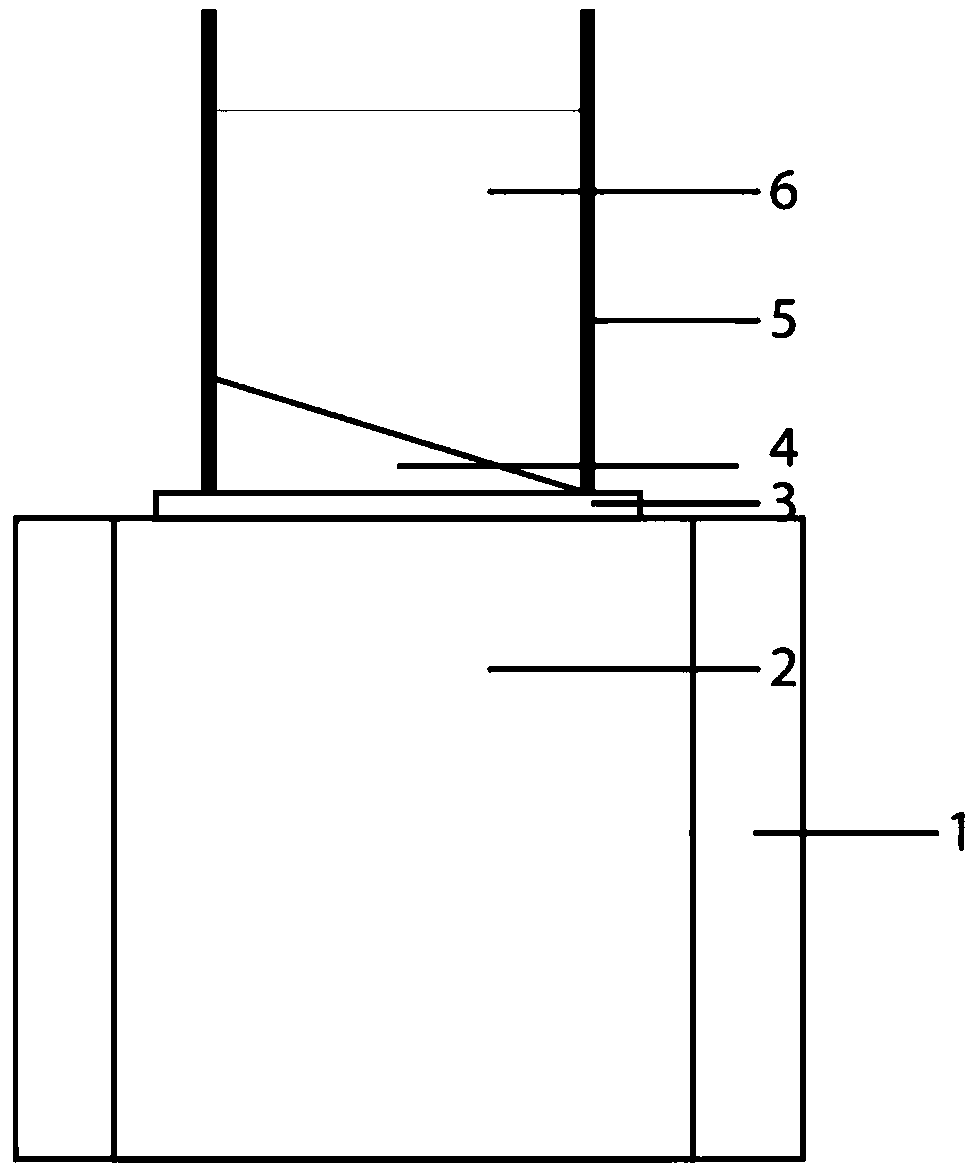

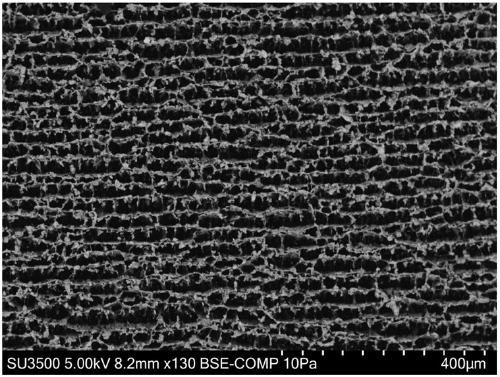

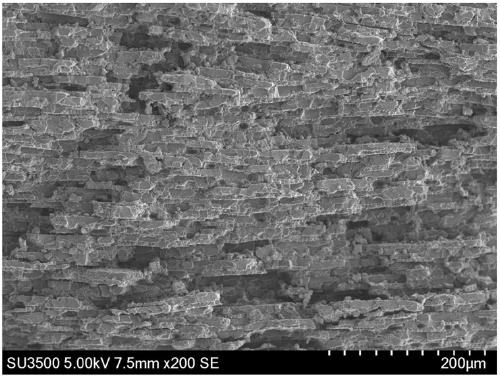

[0061] (2) Two-way freezing: the mixed solution obtained in step (1) is placed in ...

Embodiment 2

[0065] (1) Solution preparation: Take 6.87g of boron nitride powder and disperse in 200mL of isopropanol and deionized water (volume ratio 1:1) mixed solution at room temperature, ball mill for more than 12h to make it evenly dispersed, ultrasonic for 1h, 2000r / min Centrifuge for 5 minutes, take the supernatant and centrifuge at 9000 r / min for another 5 minutes, remove the supernatant, and freeze-dry the solid at the bottom to obtain boron nitride nanosheets.

[0066] Take 0.27g of polyvinyl alcohol and 17mL of deionized water, heat at 90°C for 30 minutes to completely dissolve the polyvinyl alcohol in deionized water, add 6.87g of boron nitride nanosheets, stir evenly, ultrasonicate for 1 hour, and vacuum remove air bubbles to obtain a relatively stable mixture solution, wherein the volume fraction of boron nitride nanosheets is 15 vol%, and the volume fraction of polyvinyl alcohol is 2 vol%.

[0067] (2) Two-way freezing: the mixed solution obtained in step (1) is placed in ...

Embodiment 3

[0071] (1) Solution preparation: Take 6.87g of boron nitride powder and disperse in 200mL of isopropanol and deionized water (volume ratio 1:1) mixed solution at room temperature, ball mill for more than 12h to make it evenly dispersed, ultrasonic for 1h, 2000r / min Centrifuge for 5 minutes, take the supernatant and centrifuge at 9000 r / min for another 5 minutes, remove the supernatant, and freeze-dry the solid at the bottom to obtain boron nitride nanosheets.

[0072] Take 0.27g of polyvinyl alcohol and 17mL of deionized water, heat at 90°C for 30 minutes to completely dissolve the polyvinyl alcohol in deionized water, add 6.87g of boron nitride nanosheets, stir evenly, ultrasonicate for 1 hour, and vacuum remove air bubbles to obtain a relatively stable mixture solution, wherein the volume fraction of boron nitride nanosheets is 15 vol%, and the volume fraction of polyvinyl alcohol is 2 vol%.

[0073] (2) Two-way freezing: the mixed solution obtained in step (1) is placed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com