Ice maker with ice bin level control

a level control and ice maker technology, applied in the field of ice production, can solve the problems of melting the ice stored in the ice maker, ice cubes that cannot be sprayed, and ice to spill out of the ice maker

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

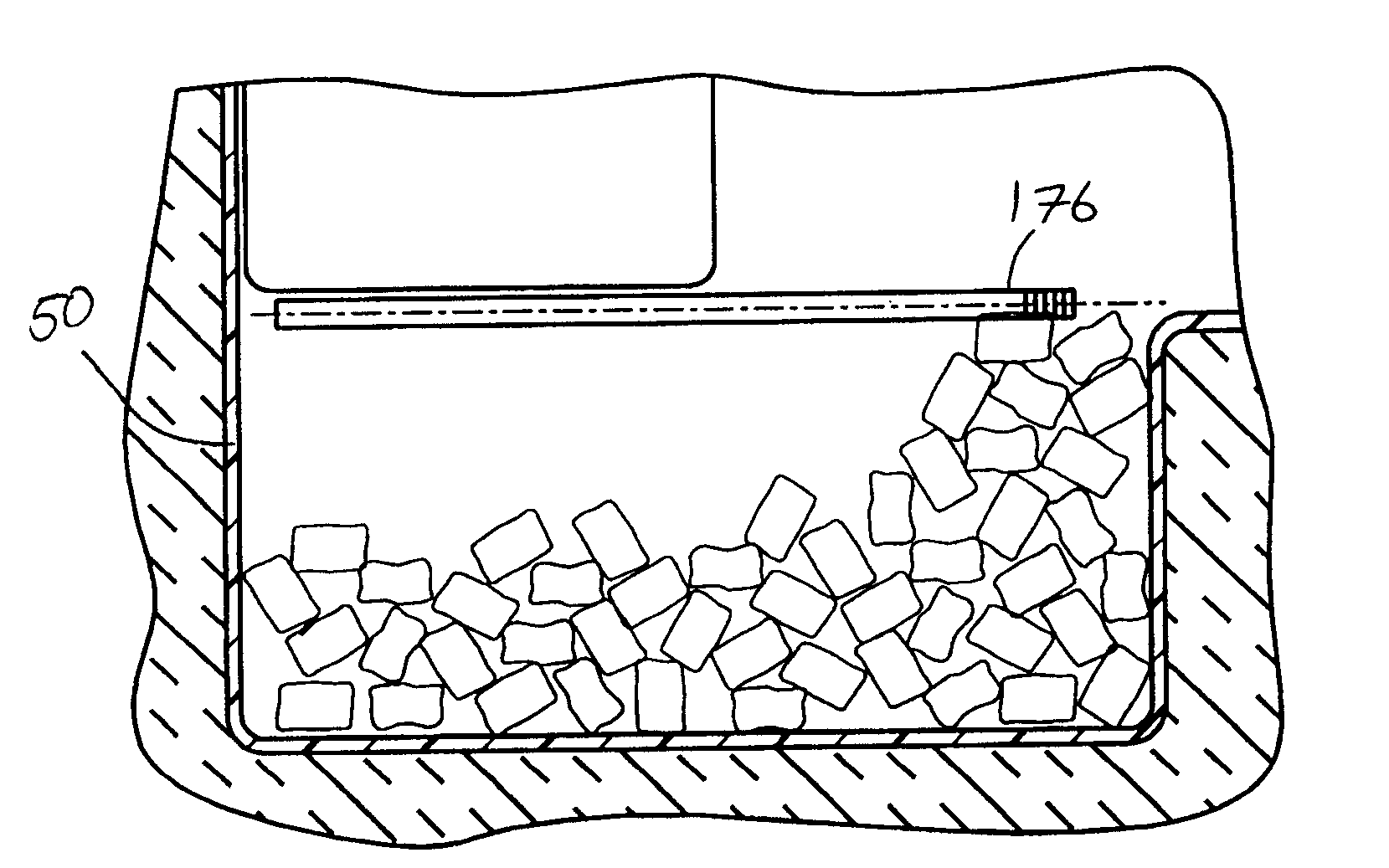

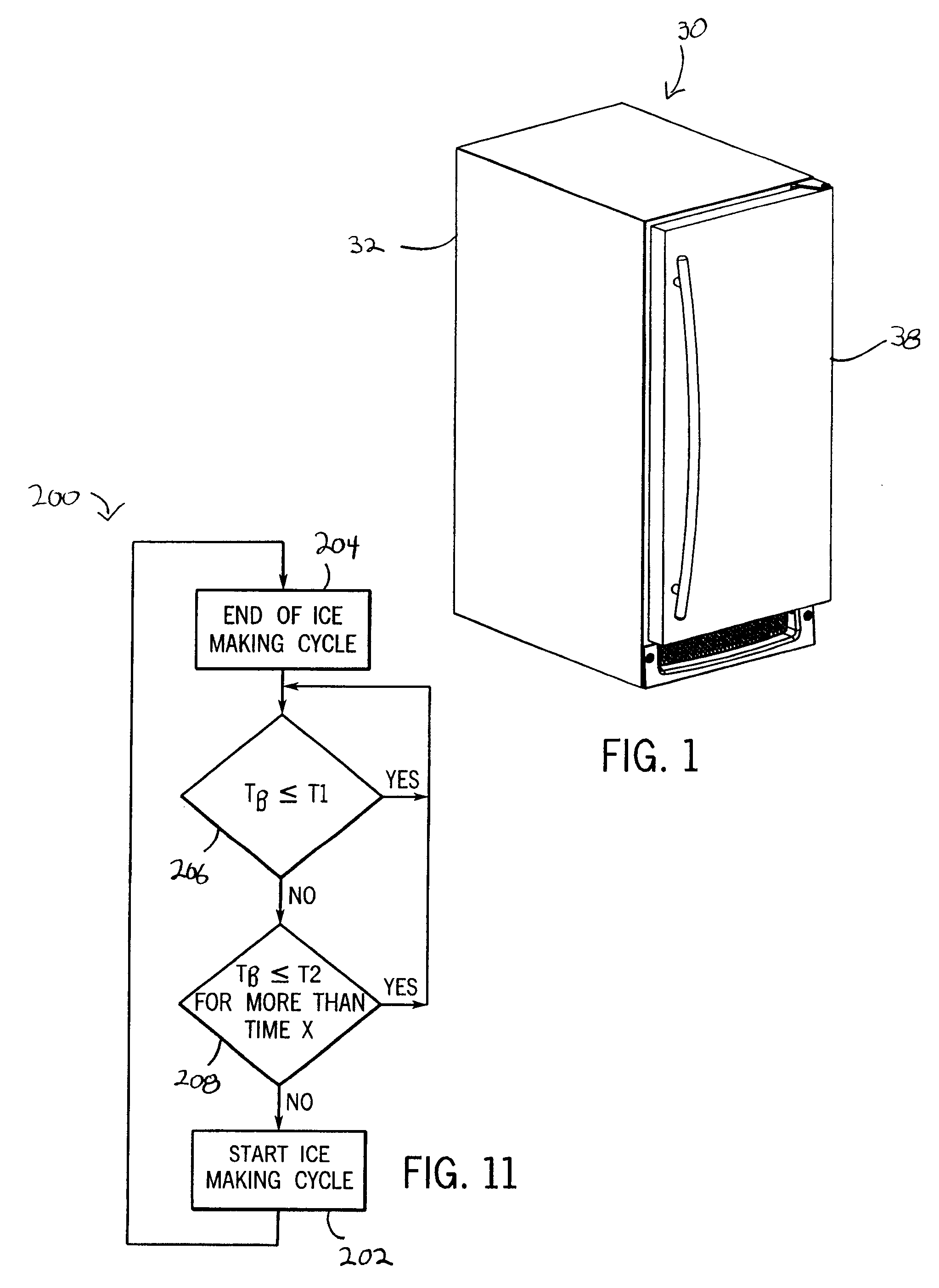

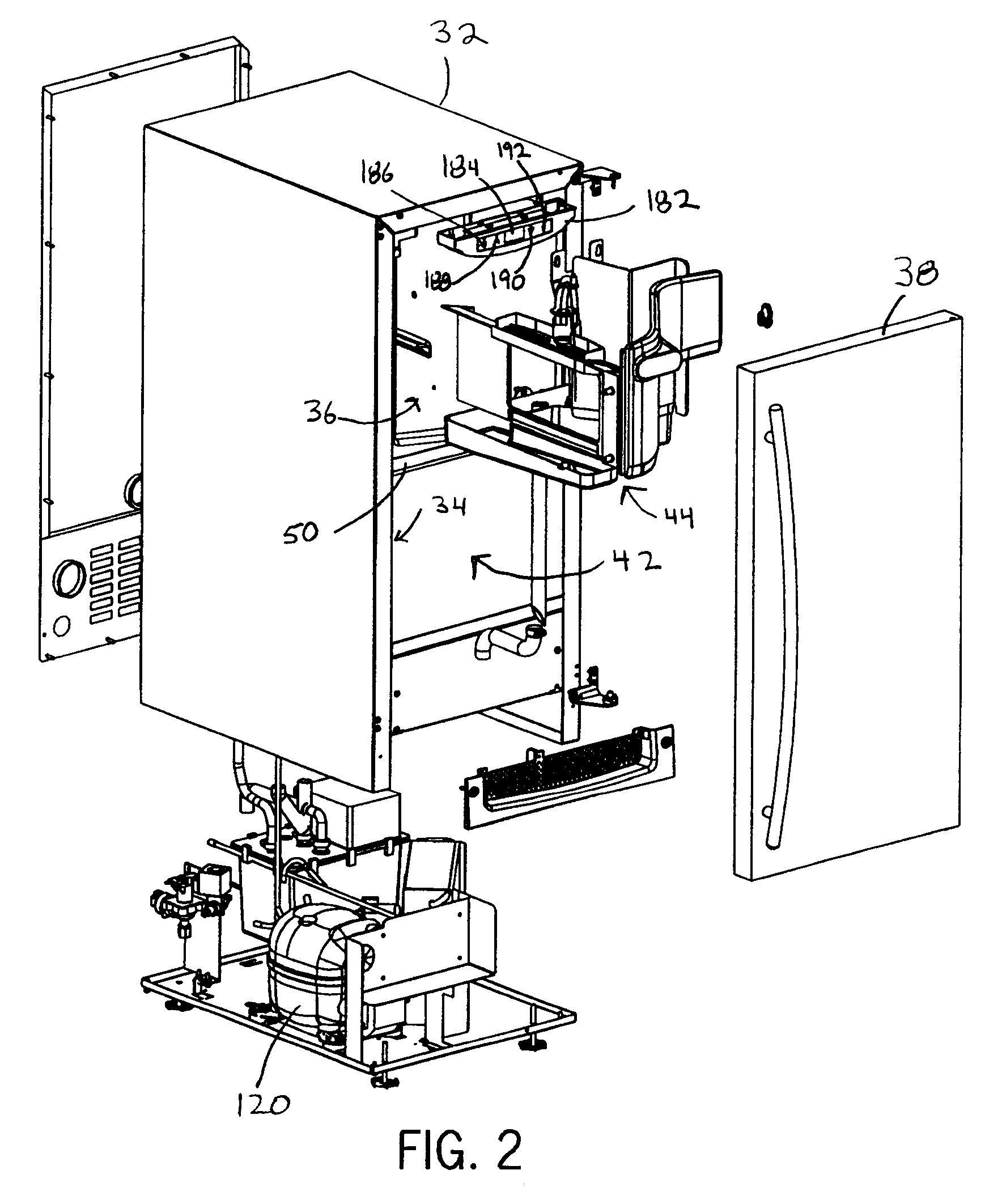

[0040]Referring to FIGS. 1-2, a clear ice maker 30 includes a cabinet 32 with an upper forward opening 34 and an interior 36. The opening 34 is closed by a door 38 that is hinged to the cabinet 32. The interior 36 includes an ice making area 40 in the upper portion of the cabinet 32 and a bin area 42 below the ice making area 40. The ice making area 40 includes a clear ice maker assembly 44. As discussed below, the clear ice maker assembly 44 is electrically connected to a controller 46 and connected to a refrigeration system 48. The bin area 42 includes a rectangular ice bin 50. The bin area 42 and ice in the ice bin 50 are not cooled by the refrigeration system 48. Both the cabinet 32 and the door 38 are formed of inner molded plastic members and outer formed metal members with the space filled with an insulating layer of foam material, all of which is well known in the art. Thus, ice in the ice bin 50 is insulated from the ambient air.

[0041]Referring now to FIGS. 2-5, the clear i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com