Making method and making device of clean transparent ice

A manufacturing method and transparent technology, which can be used in the manufacture of ice, lighting and heating equipment, ice making, etc., can solve the problems of ice crystal growth resistance, slow down the speed of ice crystal growth, etc., and achieve simple structure, improved transparency and purity, and convenience. effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

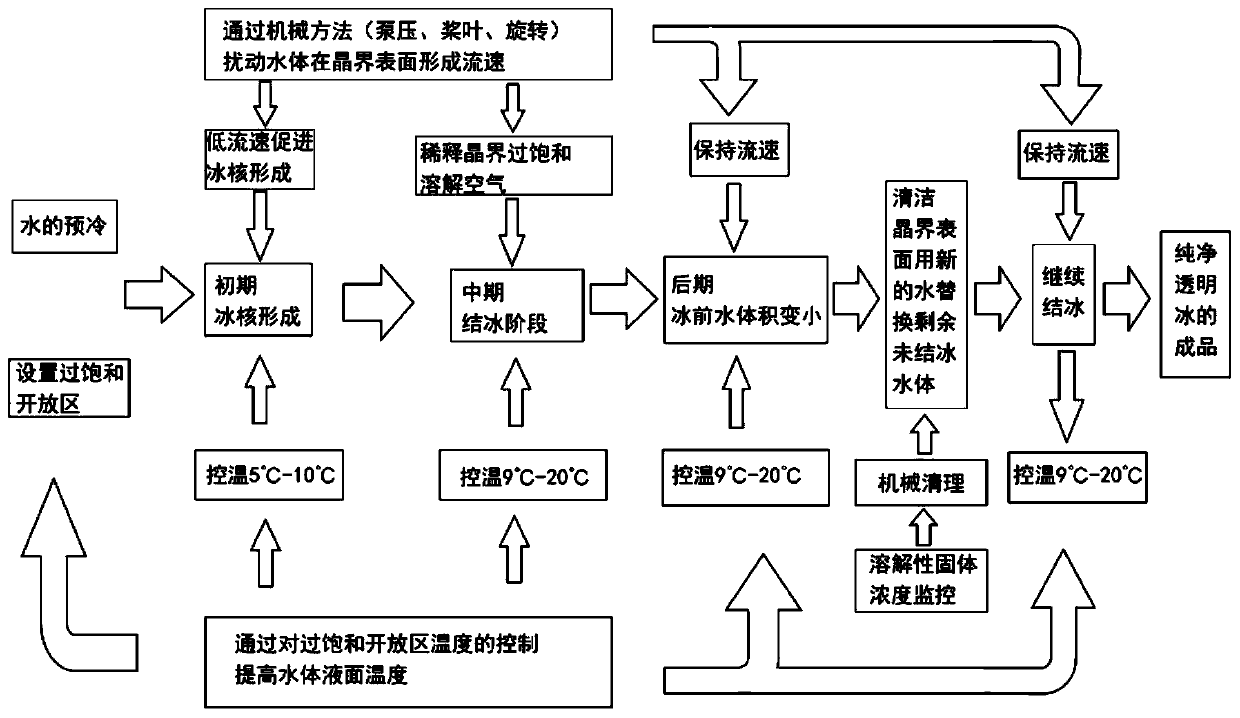

[0042] Embodiment 1: see Figure 1-Figure 11 , the manufacturing method of clean transparent ice of the present embodiment, concrete steps are:

[0043] Step 1. Preparation before making ice:

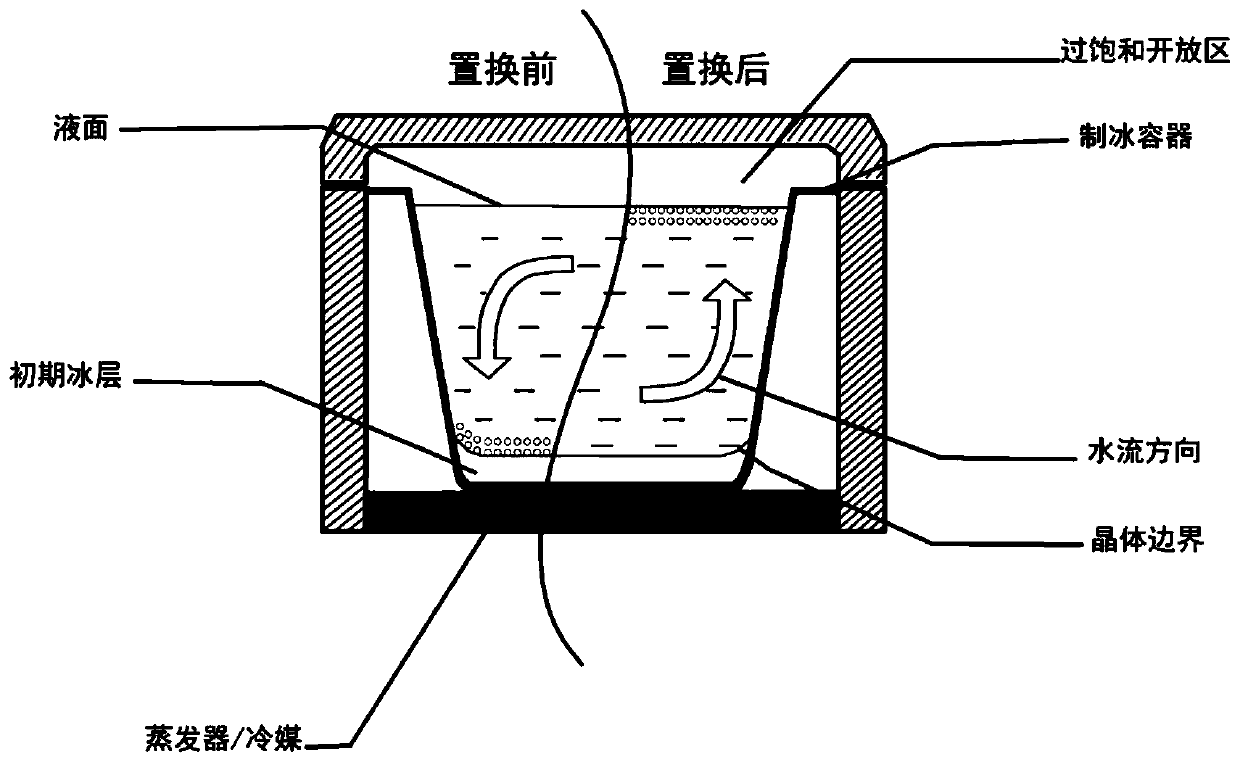

[0044] Set up a supersaturated open area for displacing dissolved air in the ice-making container, specifically: a supersaturated open area is formed from the liquid level in the ice-making container to the upper opening of the ice-making container, and the supersaturated open area maintains communication with the external atmosphere to maintain supersaturation The air pressure in the open area is constant, and a heating and temperature control device is installed on the heat preservation cover to increase the external ambient temperature in the supersaturated open area and reduce the liquid surface tension; Figure 4-6 As shown, a heating and temperature control device is installed in the space of the supersaturated open area to maintain the temperature of the open area. According to...

Embodiment 2

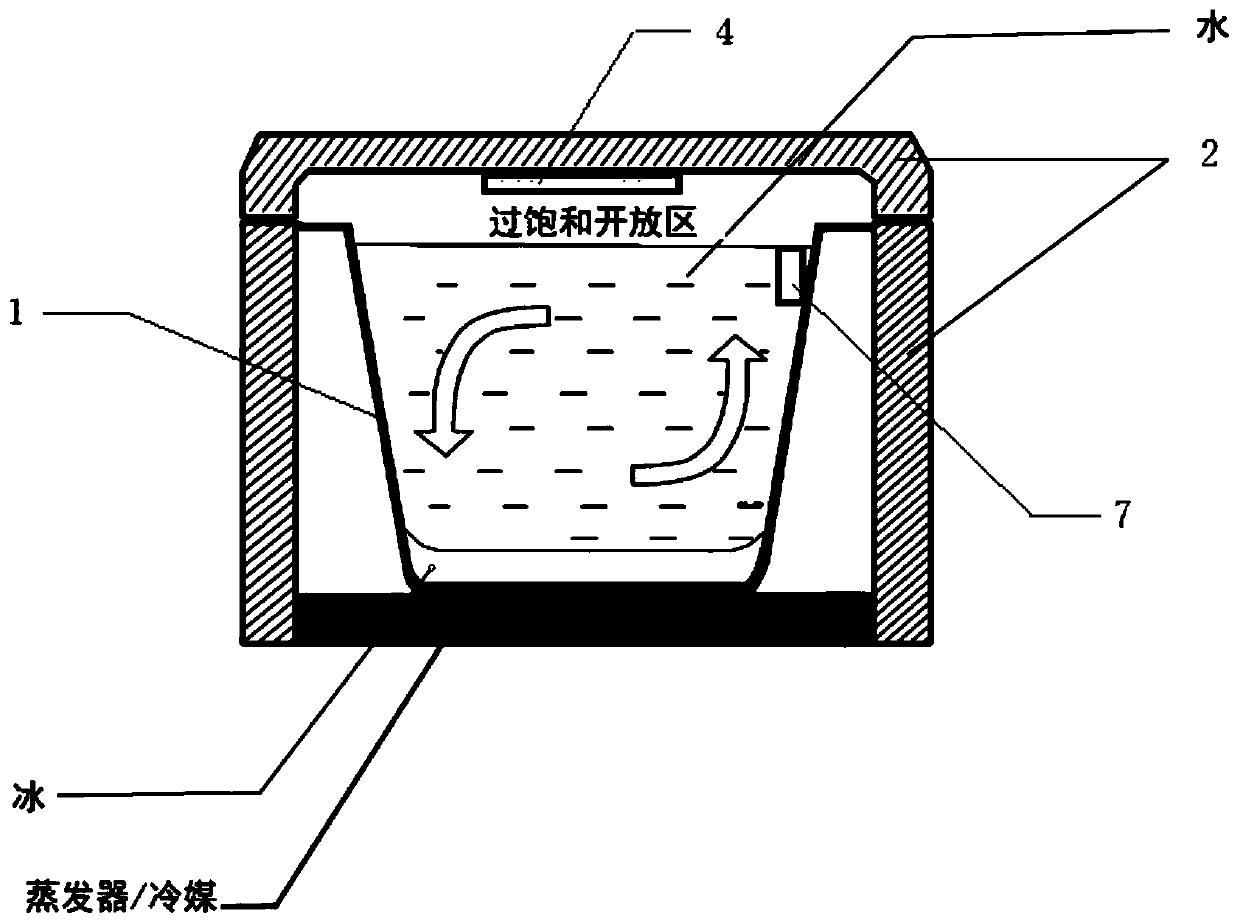

[0053] Example 2: see figure 2 The clean and transparent ice manufacturing device of the present embodiment specifically includes an ice-making container 1, an incubator 2, a heating temperature control device 4 and a water pump 7, the ice-making container 1 is arranged in the incubator 2, and the ice-making container 1 is filled with Water, the refrigeration container is refrigerated by the evaporator or refrigerant, the liquid level of the water in the ice making container 1 forms a supersaturated open area at the upper opening of the ice making container, and the supersaturated open area is kept connected with the external atmosphere, and the top cover of the incubator 2 A heating and temperature control device 4 is arranged on the inside; a water pump 7 is arranged on the inner wall of the ice-making container 1, and the water pump 7 can be adjusted and installed on the ice-making container 1. The water pump is used to flush the crystal interface, dilute or replace the cry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com