Twist tray ice maker system

a technology of twist tray and ice maker, which is applied in the field of twist tray ice maker systems, can solve the problems of ice cubes sticking to the mold inside the mold, jamming of the ice dispensing mechanism, and several known failure modes of the existing twist tray ice maker system, and achieves the effects of increasing the amount of ice, improving the heat transfer, and significantly increasing the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

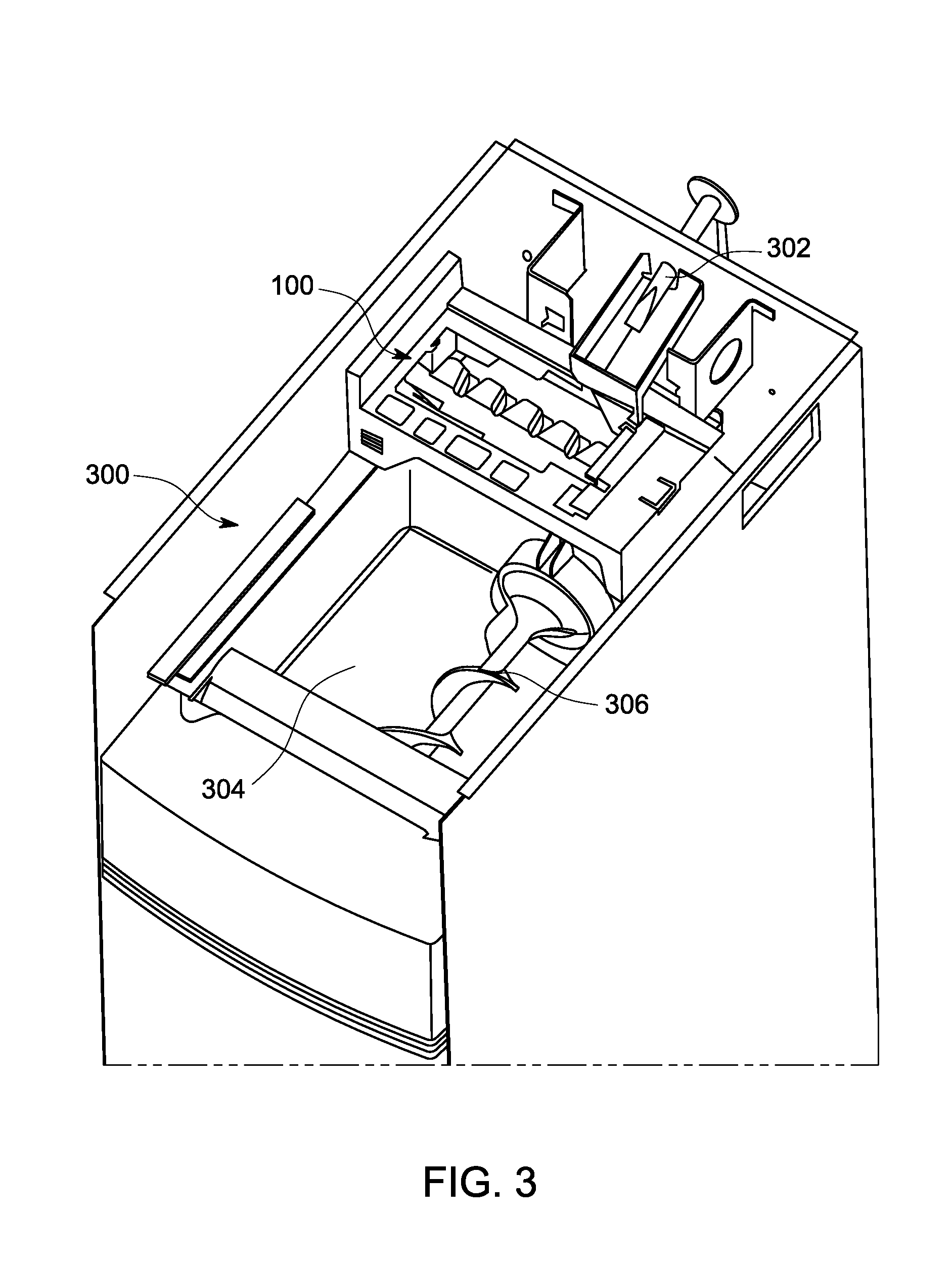

[0023]One or more of the embodiments of the invention will be described below in the context of an ice maker system in a refrigerator appliance, such as a household refrigerator. However, it is to be understood that techniques of the invention are not intended to be limited to ice maker systems in household refrigerators. Rather, techniques of the invention may be applied to and implemented in any other suitable environments in which it would be desirable to improve the reliability and ice making performance of an ice maker system.

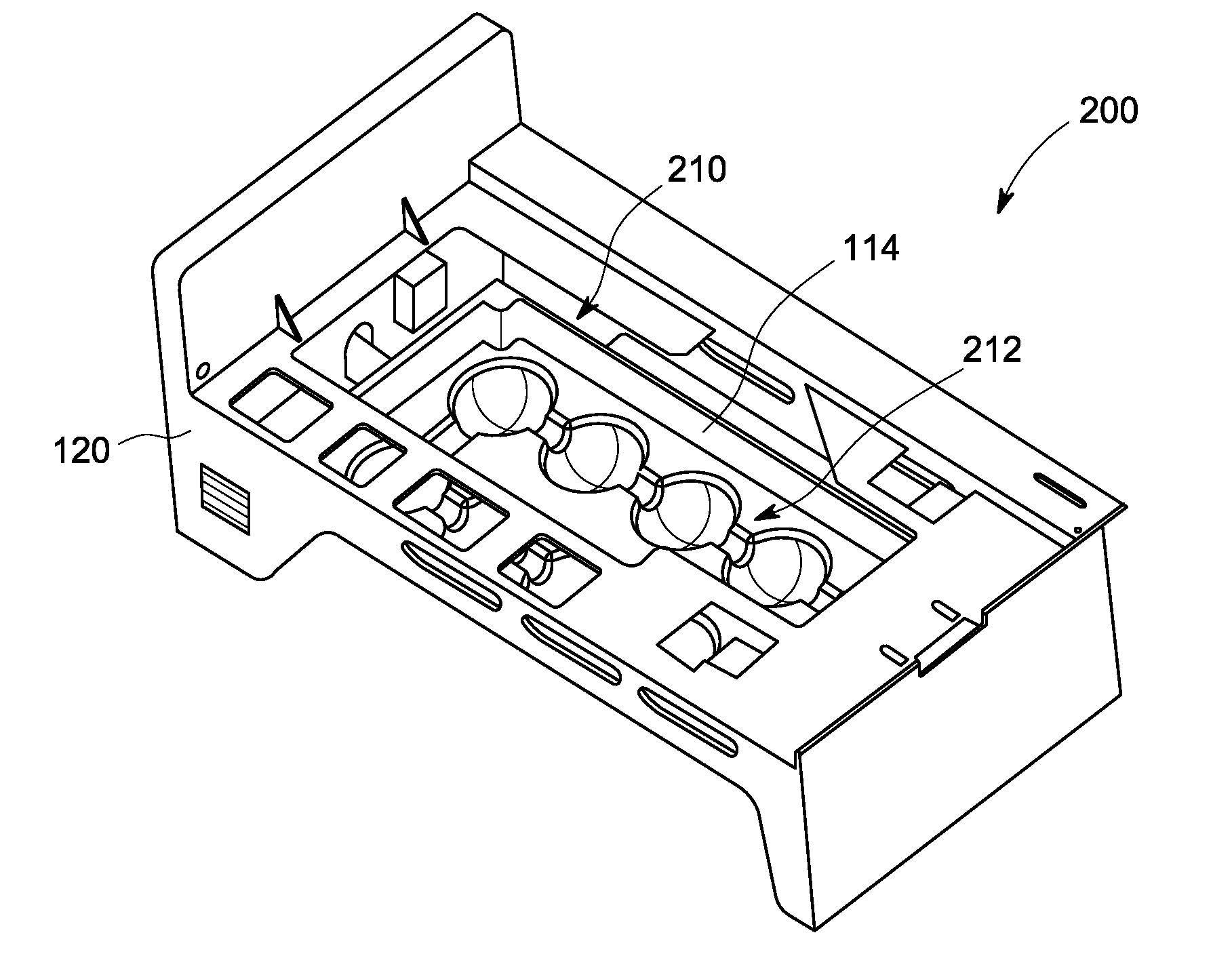

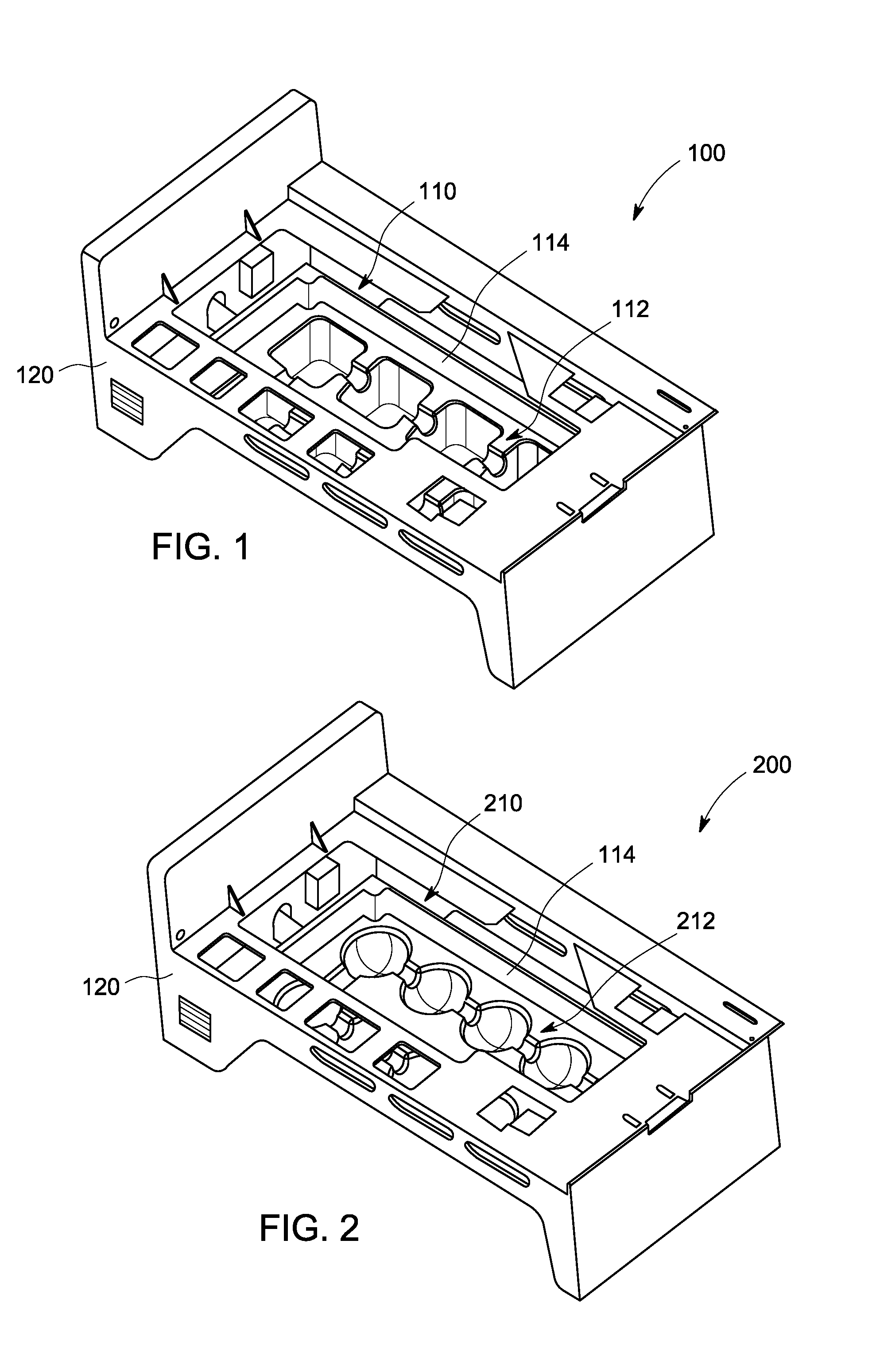

[0024]Principles of the invention realize that to improve reliability and ice making performance, it is desirable to form the ice mold body or tray out of a metal material. Metal has a thermal conductivity much higher than that of plastic. This improves the transfer of heat away from the water thereby increasing the amount of ice that can be made in a given period of time. The use of metal also allows for the use of several non-stick coatings such as, by w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com