Patents

Literature

93results about "Mass resistors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

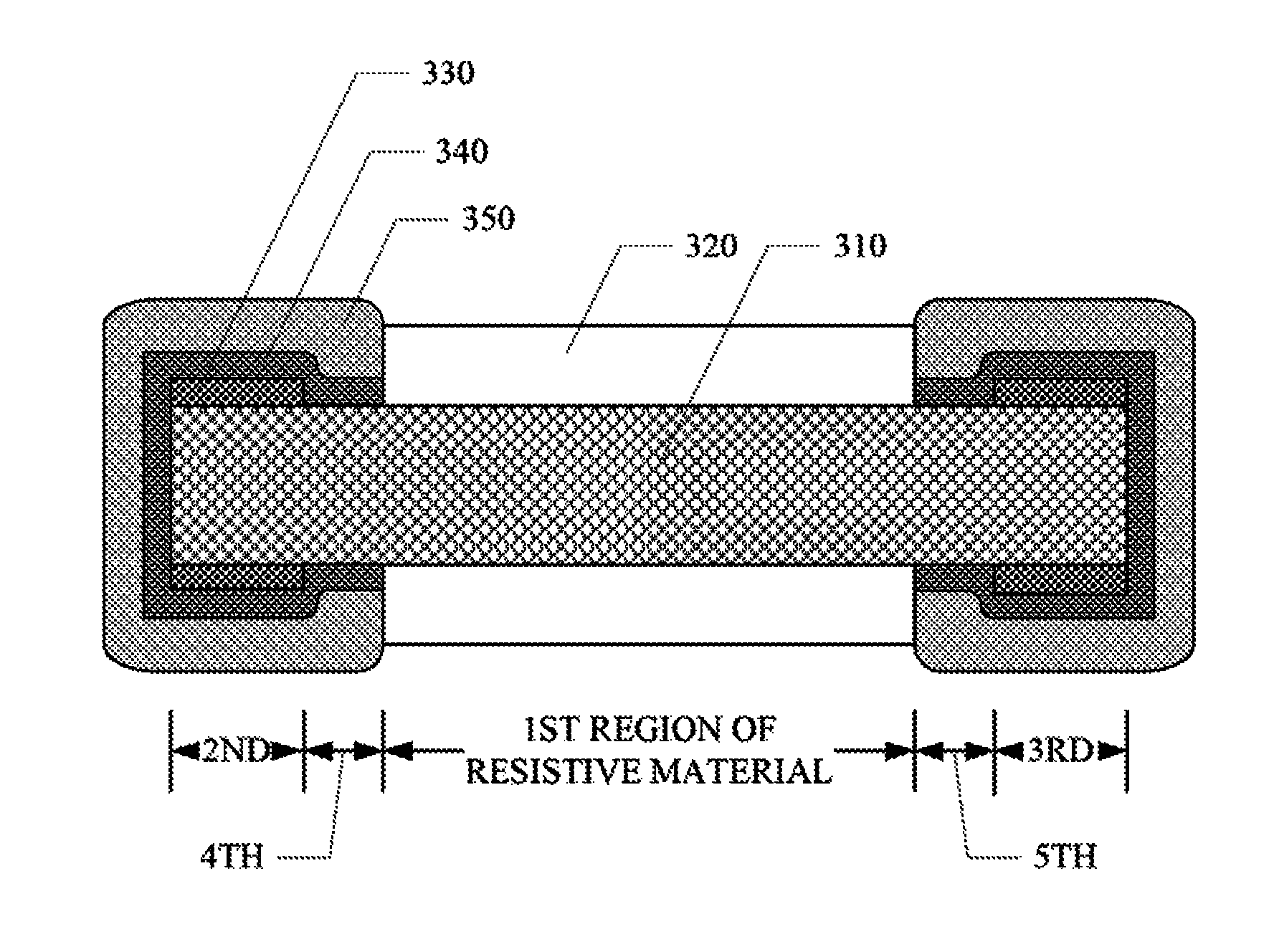

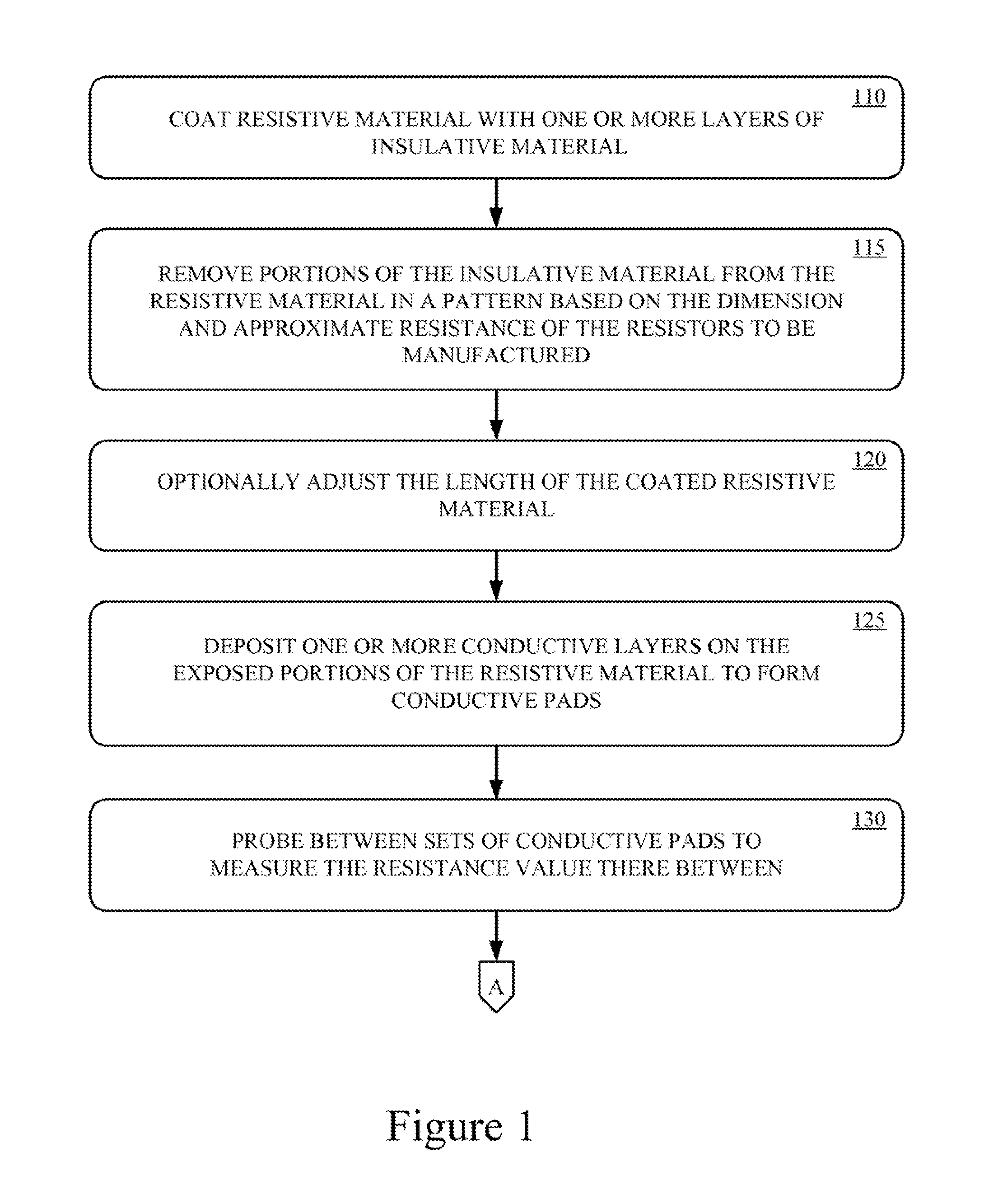

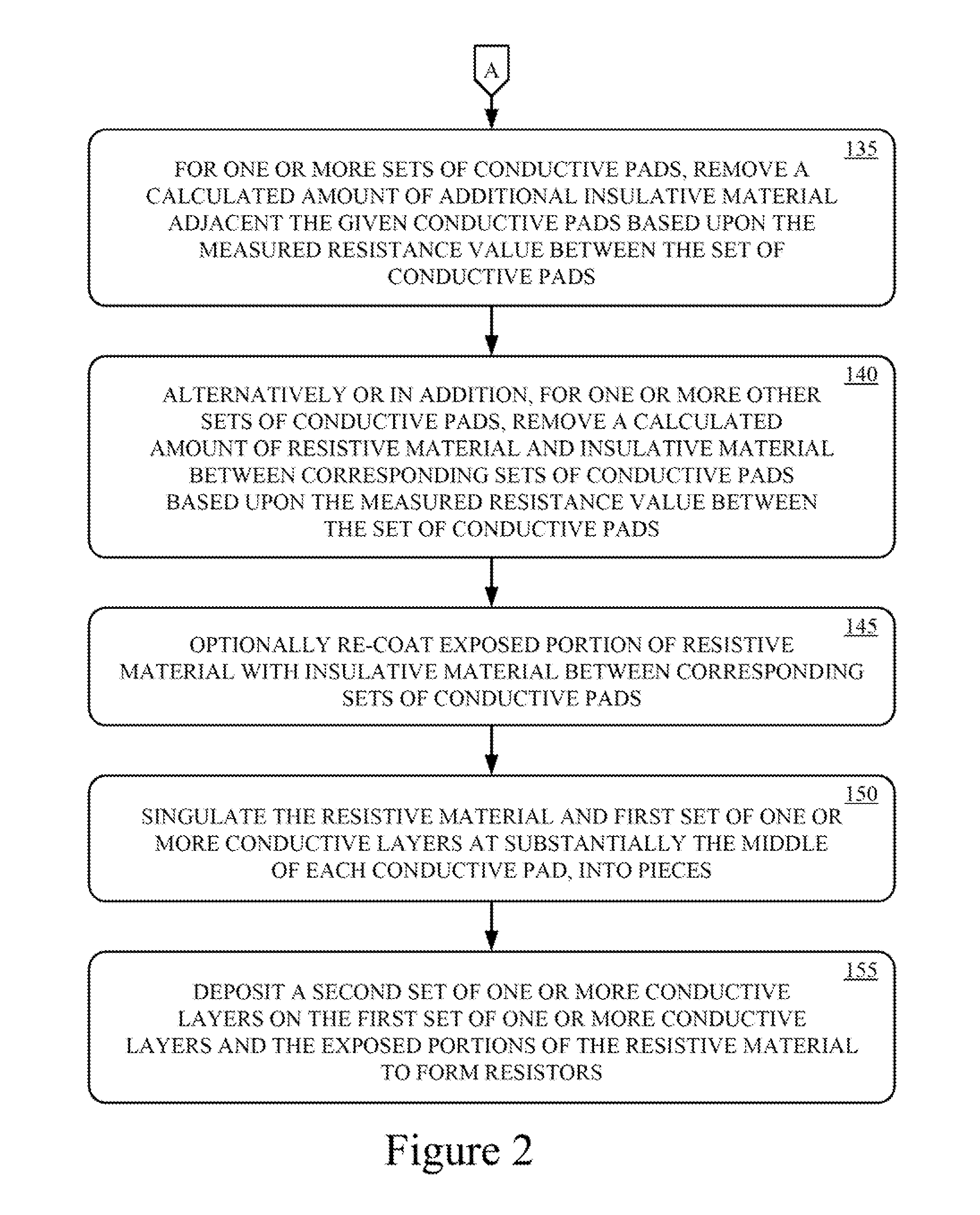

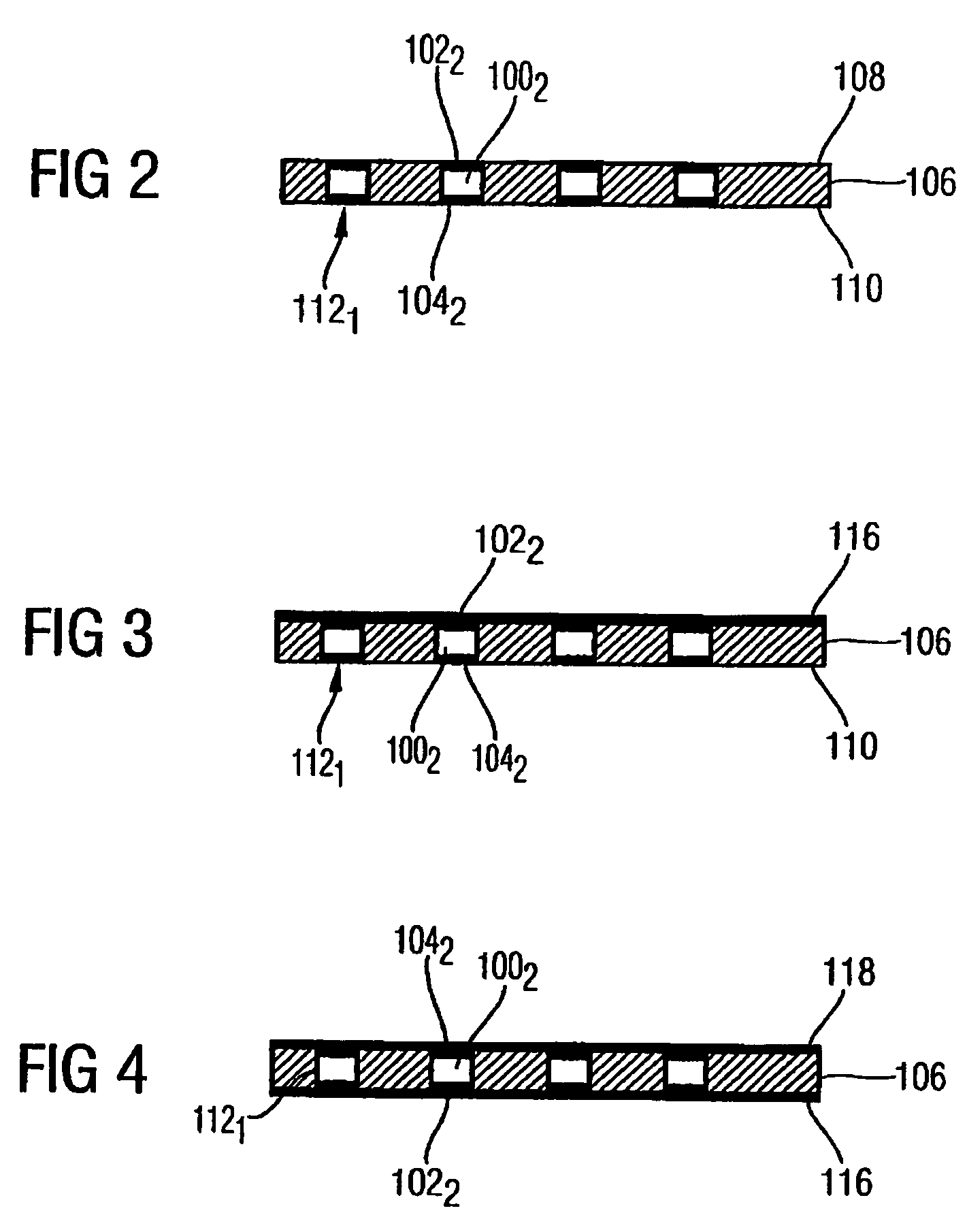

Resistor and method of manufacture

ActiveUS9396849B1Mass resistorsEnvelope/housing resistor manufactureResistorElectrical and Electronics engineering

The present technology is directed toward a resistor and method of manufacturing the resistor. One or more layers of insulative material are formed on a length of resistive material. Portions of the one or more layers insulative material are removed from the resistive material in a pattern based on a predetermined approximate dimension and predetermined approximate resistance value. A first set of one or more conductive layers are formed on the portions of the resistive material exposed by the insulative coating to form a plurality of conductive pads on the resistive material between the patterned insulative material. The sets of conductive pads are probed to measure a preliminary resistance value between the sets of conductive pads. For one or more sets of conductive pads, a calculated amount of additional insulative material adjacent the respective conductive pads is removed based upon the preliminary resistance value between the corresponding set of conductive pads and a final resistance value to exposed additional portions of resistive material. The conductive pads and resistive material is cut at substantially the middle of each conductive pad to form pieces. A second set of one or more conductive layers are formed on the first set of one or more conductive layers at opposing ends of each piece, and the additionally exposed portions of the resistive material.

Owner:VISHAY DALE ELECTRONICS INC

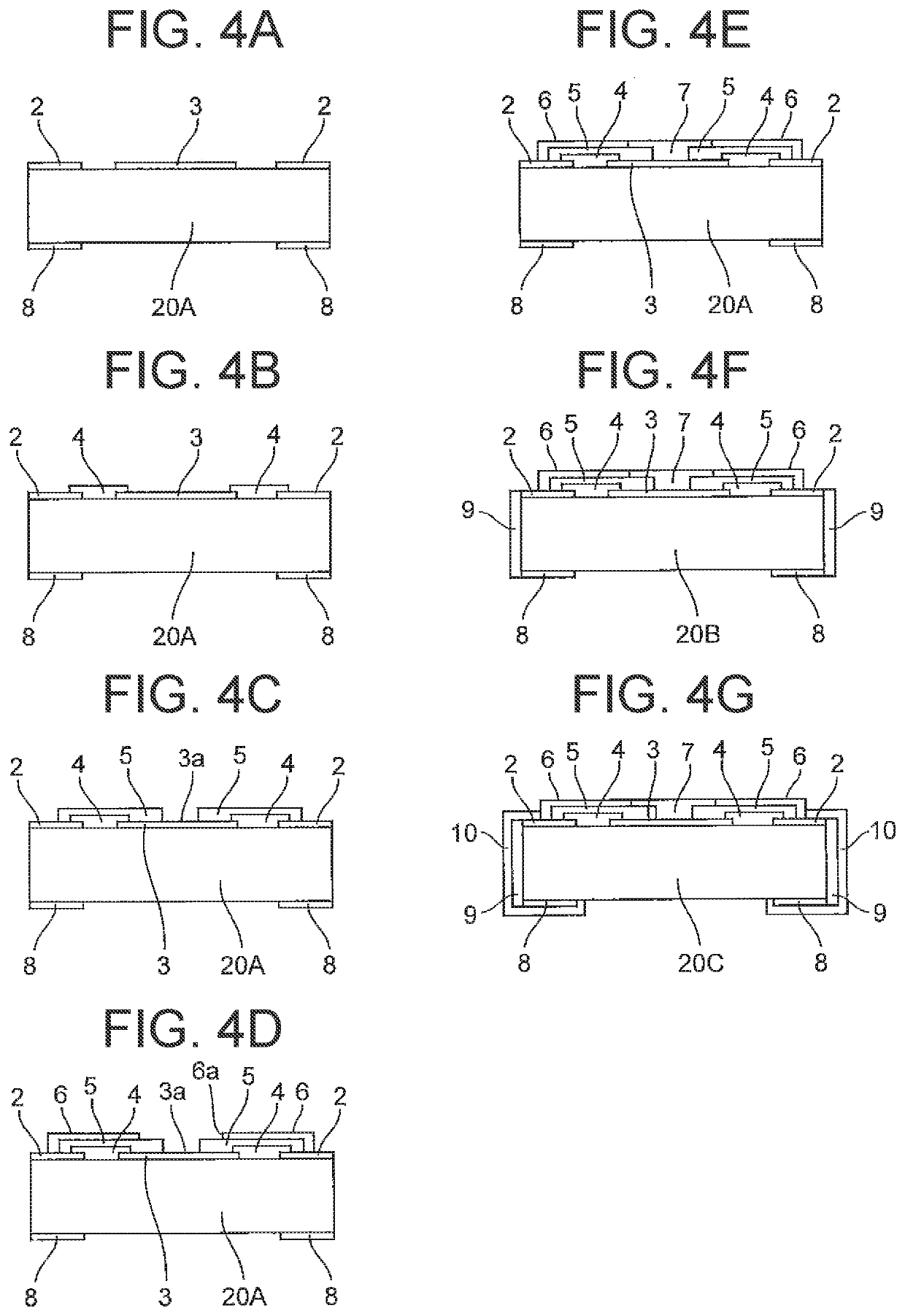

Chip resistor element and method for forming same

ActiveCN106960708AResistor chip manufactureMass resistorsProtection layerElectrical and Electronics engineering

Provided are a chip resistor element and a method for forming the same. The chip resistor element includes an insulating substrate, a resistor layer, first and second internal electrodes, a resistor protection layer, first and second electrode protection layers, and first and second external electrodes. The resistor layer is on the insulating substrate, the first and second internal electrodes are on respective sides of the resistor layer, and the resistor protection layer covers the resistor layer and extends onto portions of the internal electrodes. The first electrode protection layers are on the first and second internal electrodes so as to overlap with portions of the resistor protection layer and contain first conductive powder particles and resin, while the second electrode protection layers are disposed on the first electrode protection layers and contain second conductive powder particles and resin. A content of resin in the second electrode protection layer is lower than in the first electrode protection layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

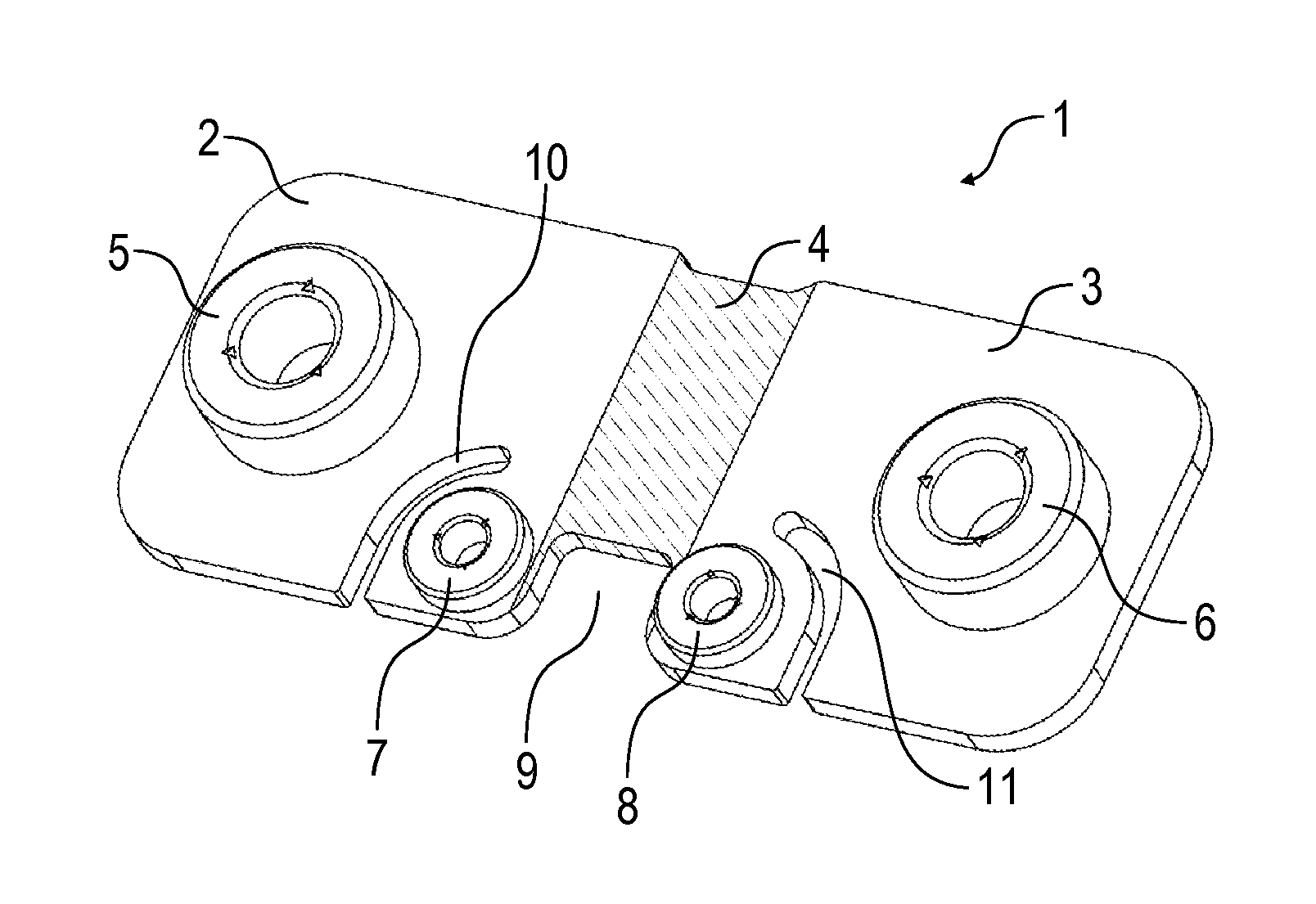

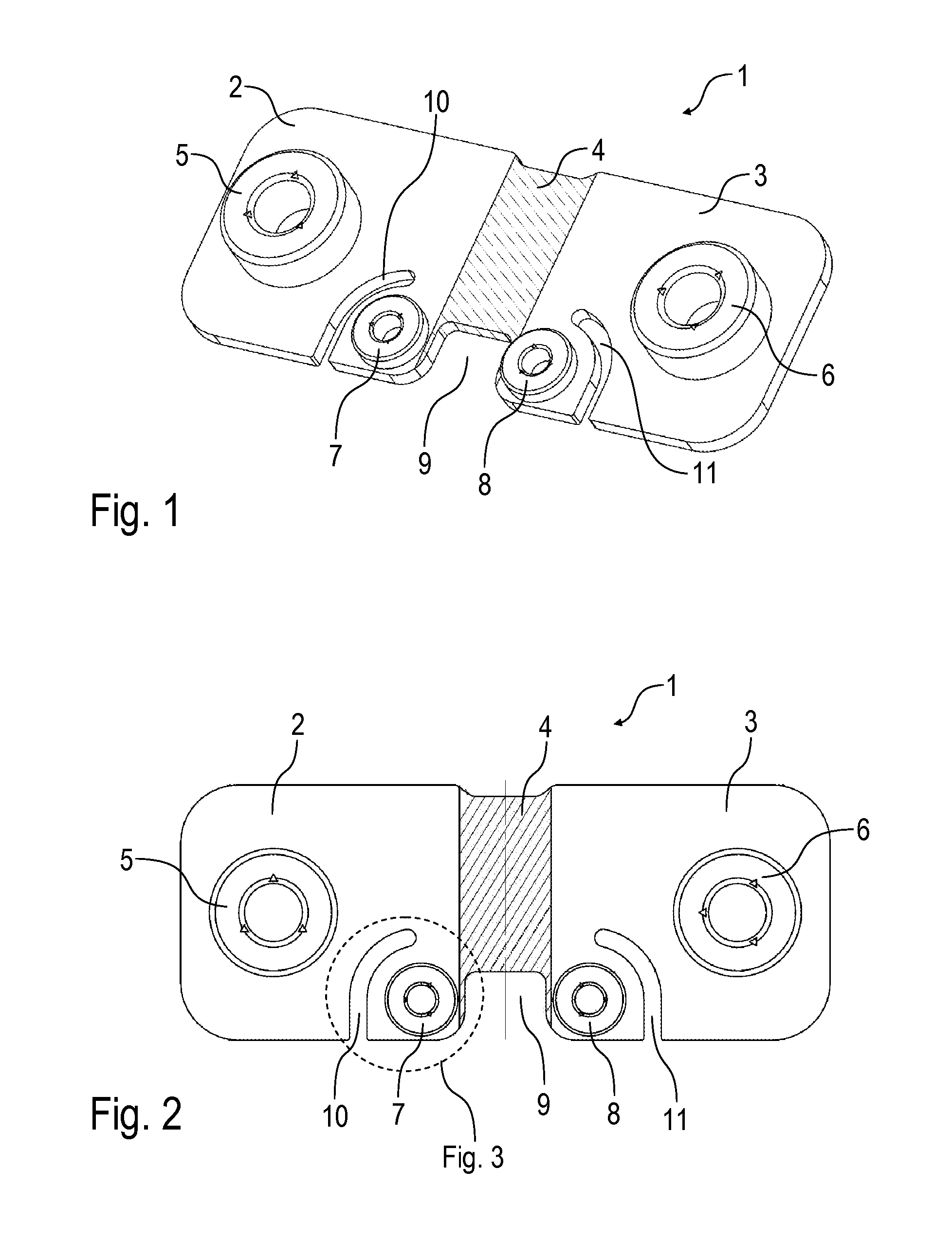

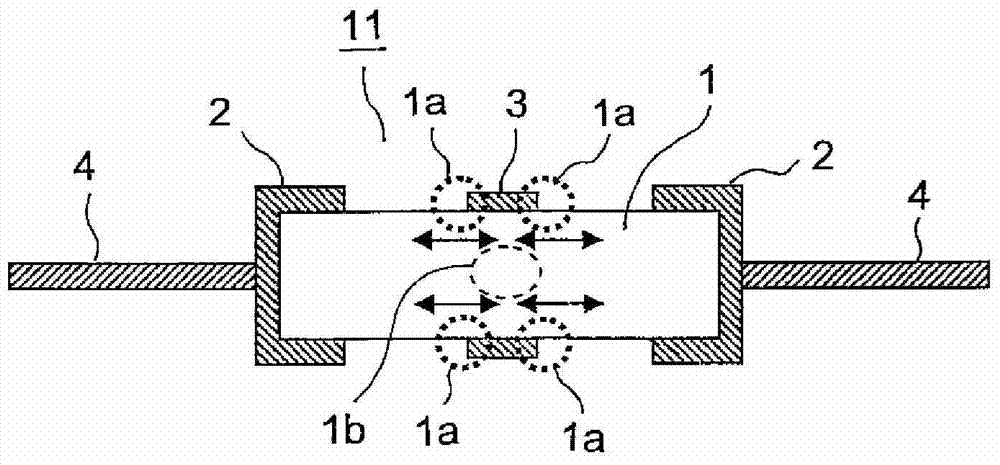

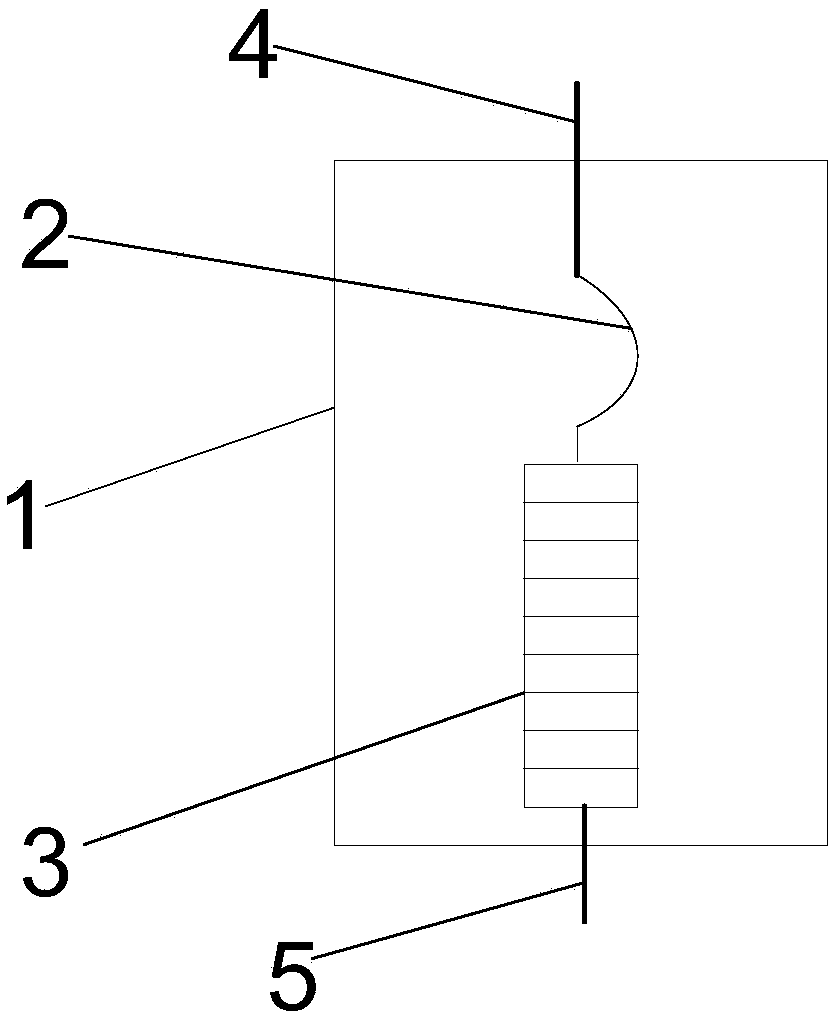

Current-sense resistor

ActiveUS8884733B2Low temperature dependenceMass resistorsCurrent/voltage measurementElectrical resistance and conductanceElectrical conductor

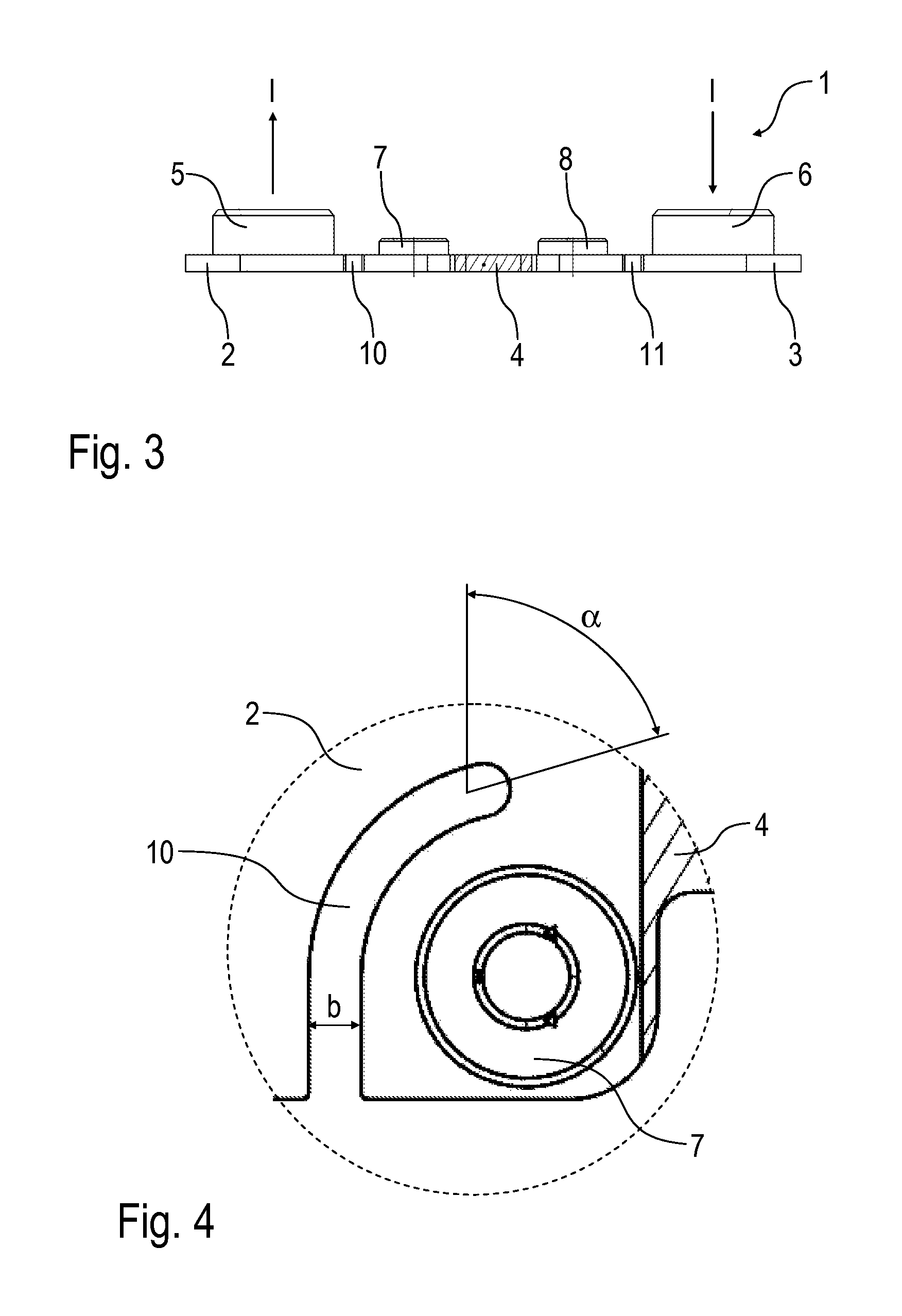

The invention relates to a current-sensing resistor (1) for measuring an electric current, in particular also for measuring a battery current in a vehicle power supply, having a plate-shaped first connecting part (3) for introducing the electrical current to be measured, wherein the plate-shaped first connecting part (3) consists of an electrically conductive conductor material; a plate-shaped second connecting part (2) for conducting away the electrical current to be measured, wherein the plate-shaped second connecting part (2) consists of an electrically conductive conductor material; and a plate-shaped resistance element (4), which is connected in the current path between the two connecting parts and through which the electrical current to be measured flows, wherein the resistance element (4) consists of a comparatively high-impedance resistance material. According to the invention an incision (10, 11) is arranged in the plate-shaped first connecting part (3) and / or in the plate-shaped second connecting part (2) in order to reduce the temperature dependency of the measurement and to eliminate the influence of the plate-shaped connecting parts (usually copper or aluminum).

Owner:ISABELLENHUTTE HEUSLER

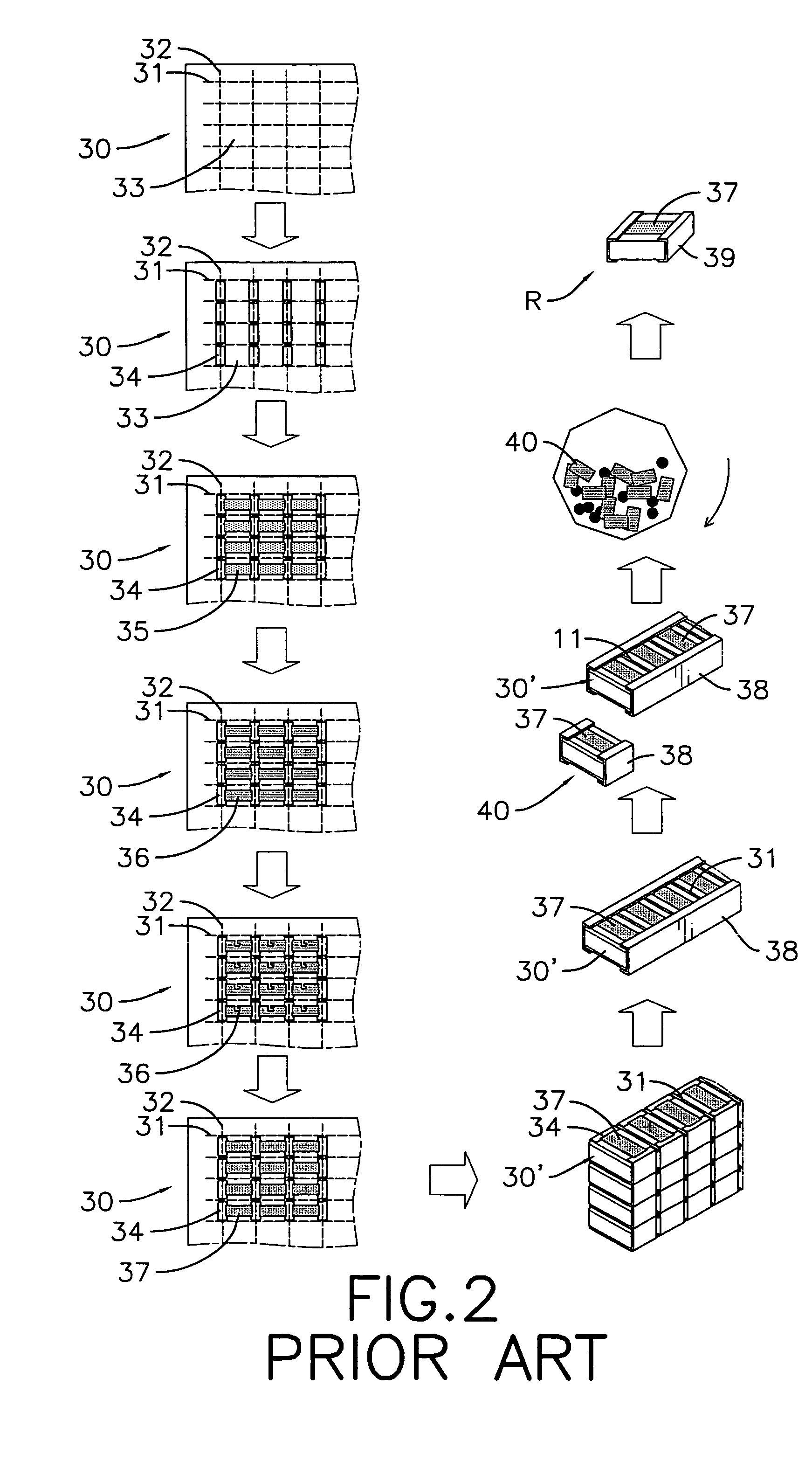

Electroplating method in the manufacture of the surface mount precision metal resistor

InactiveUS20070001802A1Improve throughputImprove productivityResistor chip manufactureMass resistorsSurface mountingCopper electrode

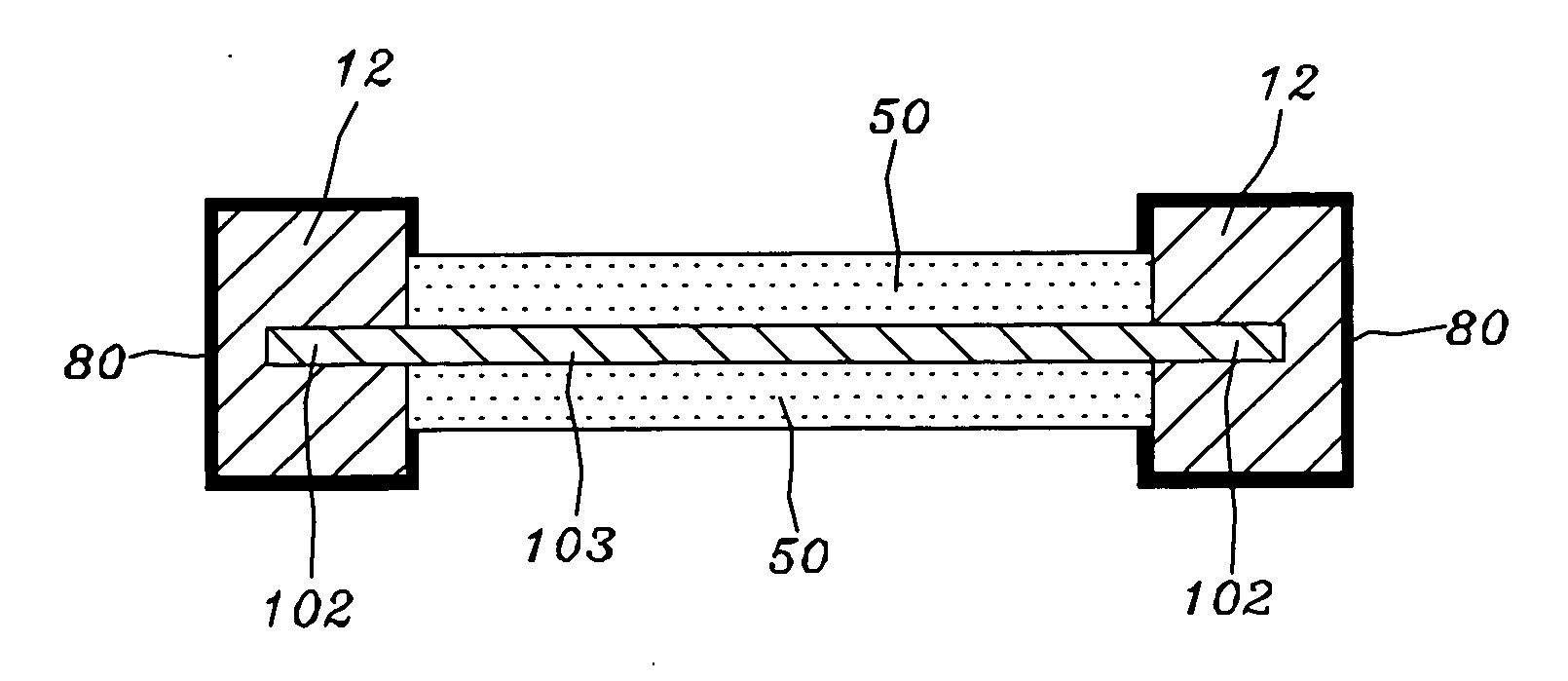

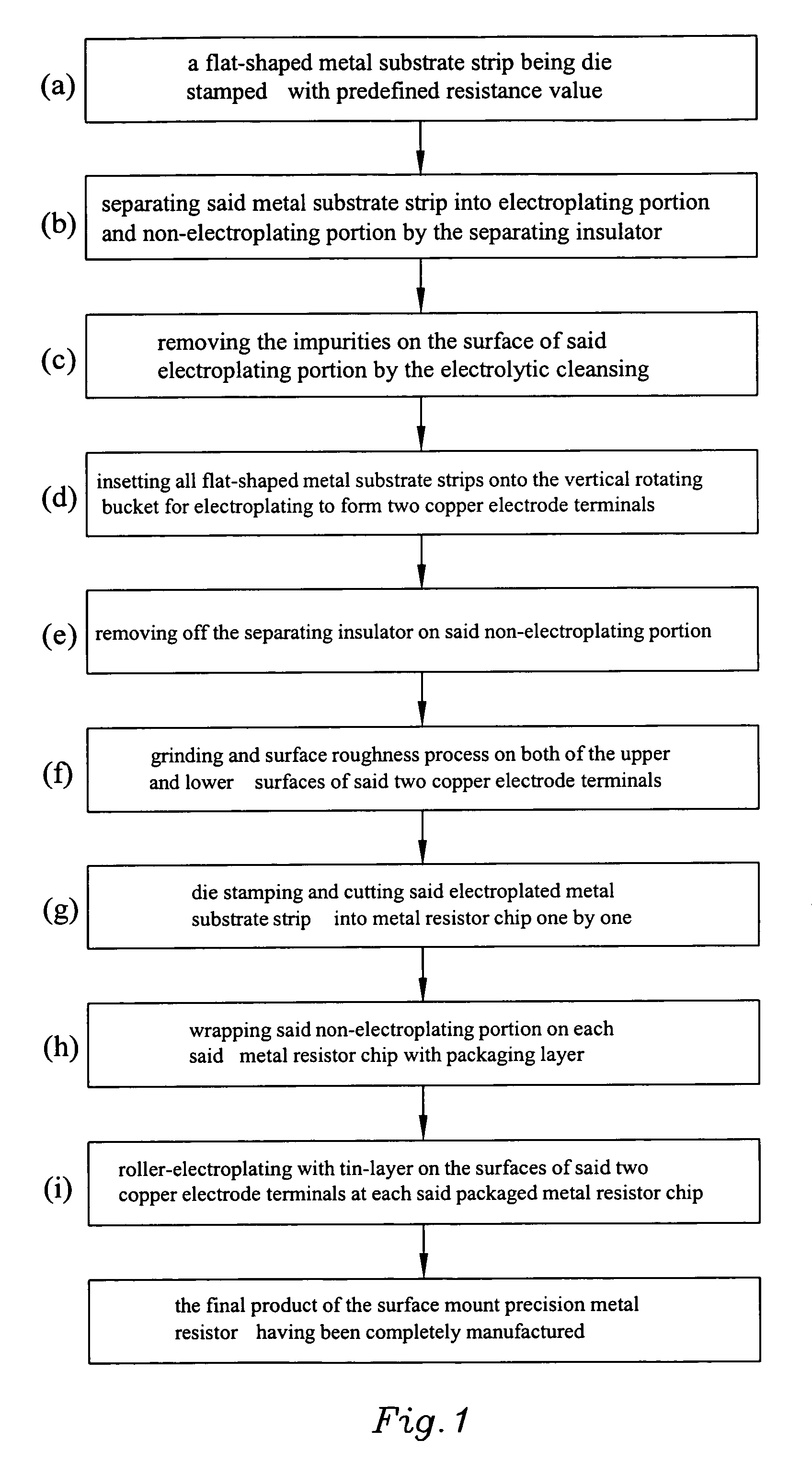

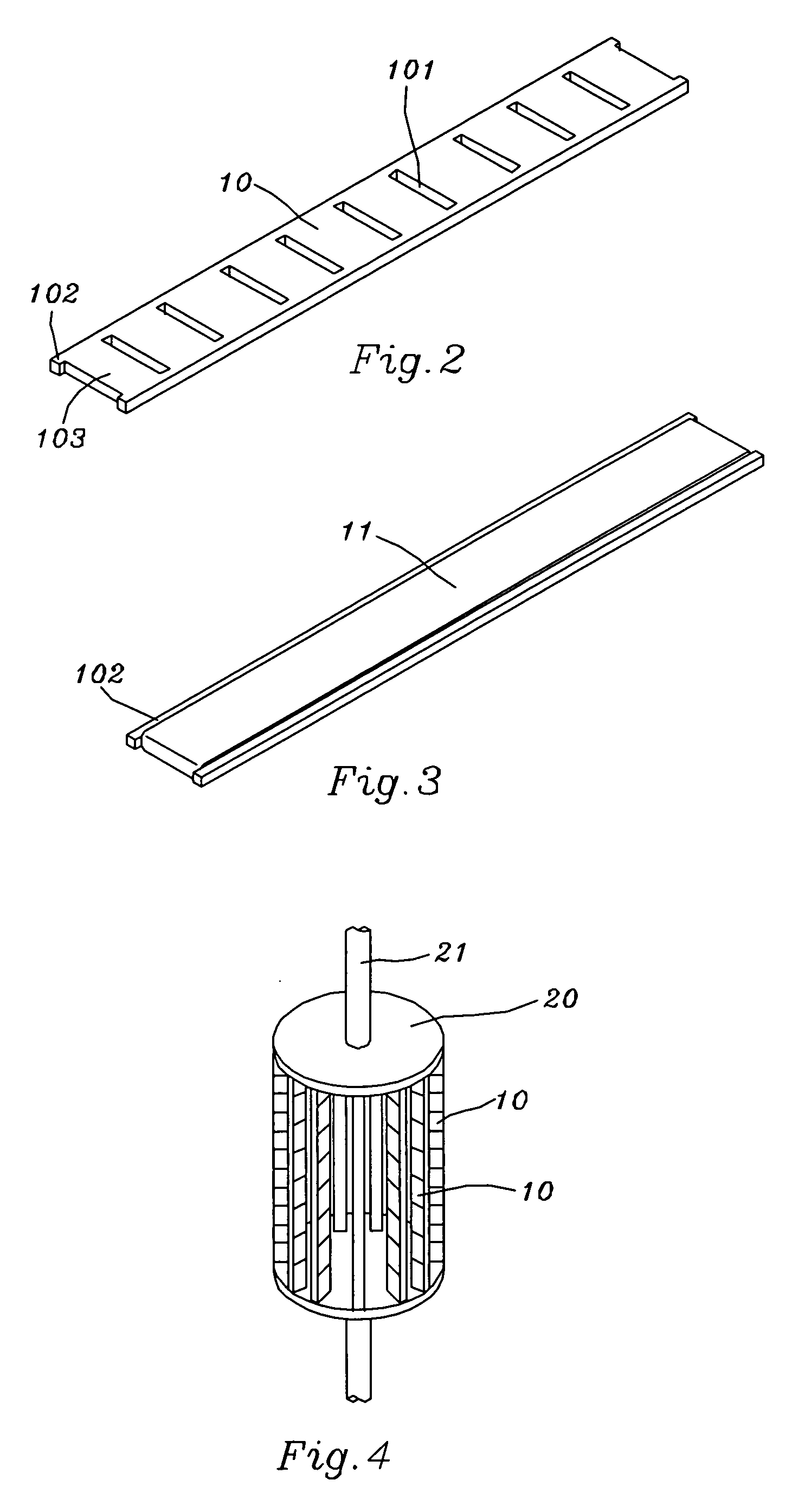

The present invention relates to an electroplating method in the manufacture of the surface mount precision metal resistor, the manufacturing steps are as below: a flat-shaped metal substrate strip being die stamped with predefined resistance value; separating said metal substrate strip into electroplating portion and non-electroplating portion by the separating insulator; removing the impurities on the surface of said electroplating portion by the electrolytic cleansing; insetting all flat-shaped metal substrate strips onto the vertical rotating bucket for electroplating to form two copper electrode terminals; removing off the separating insulator on said non-electroplating portion; grinding and surface roughness process on both of the upper and lower surfaces of said two copper electrode terminals; die stamping and cutting said electroplated metal substrate strip into metal resistor chip one by one; wrapping said non-electroplating portion on each said metal resistor chip with packaging layer; and roller-electroplating with tin-layer on the surfaces of said two copper electrode terminals at each said packaged metal resistor chip, thus the final product of the surface mount precision metal resistor having been completely manufactured.

Owner:HSIEH CHING HSIUNG

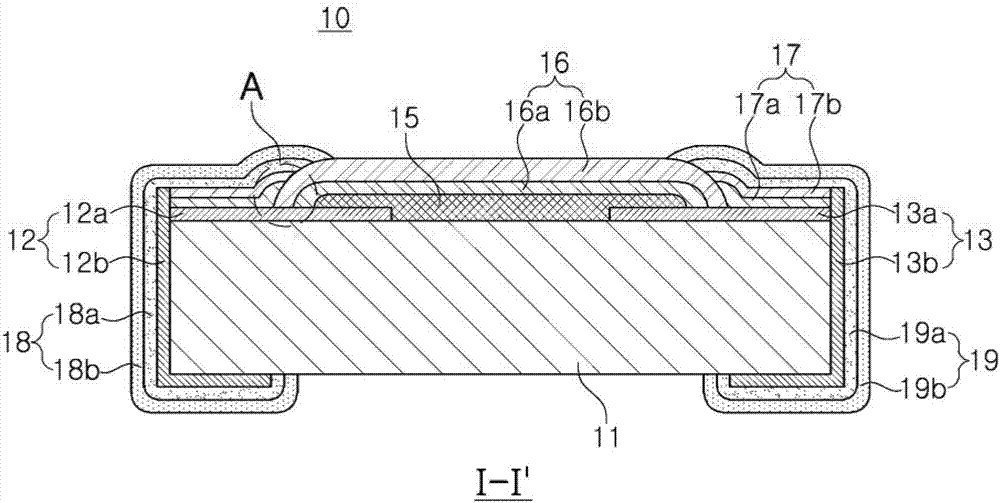

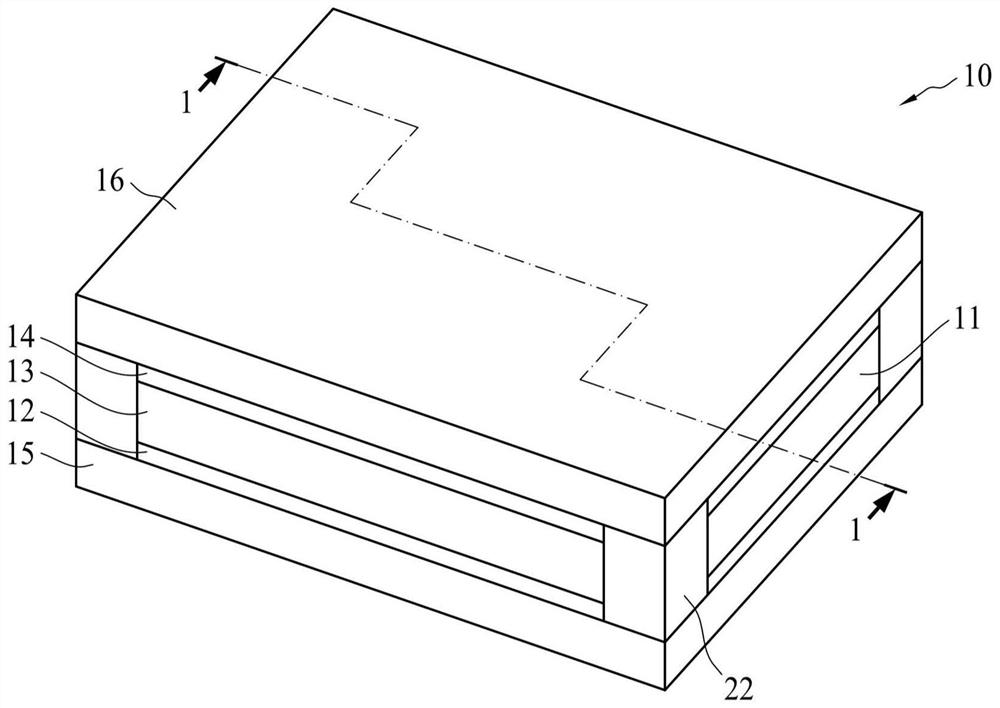

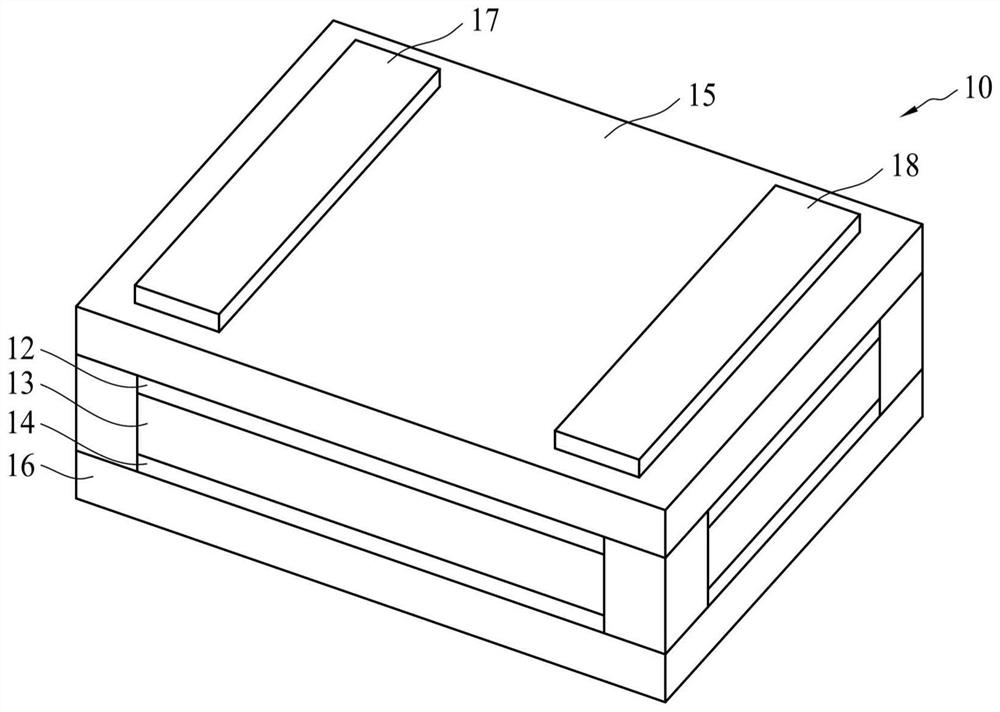

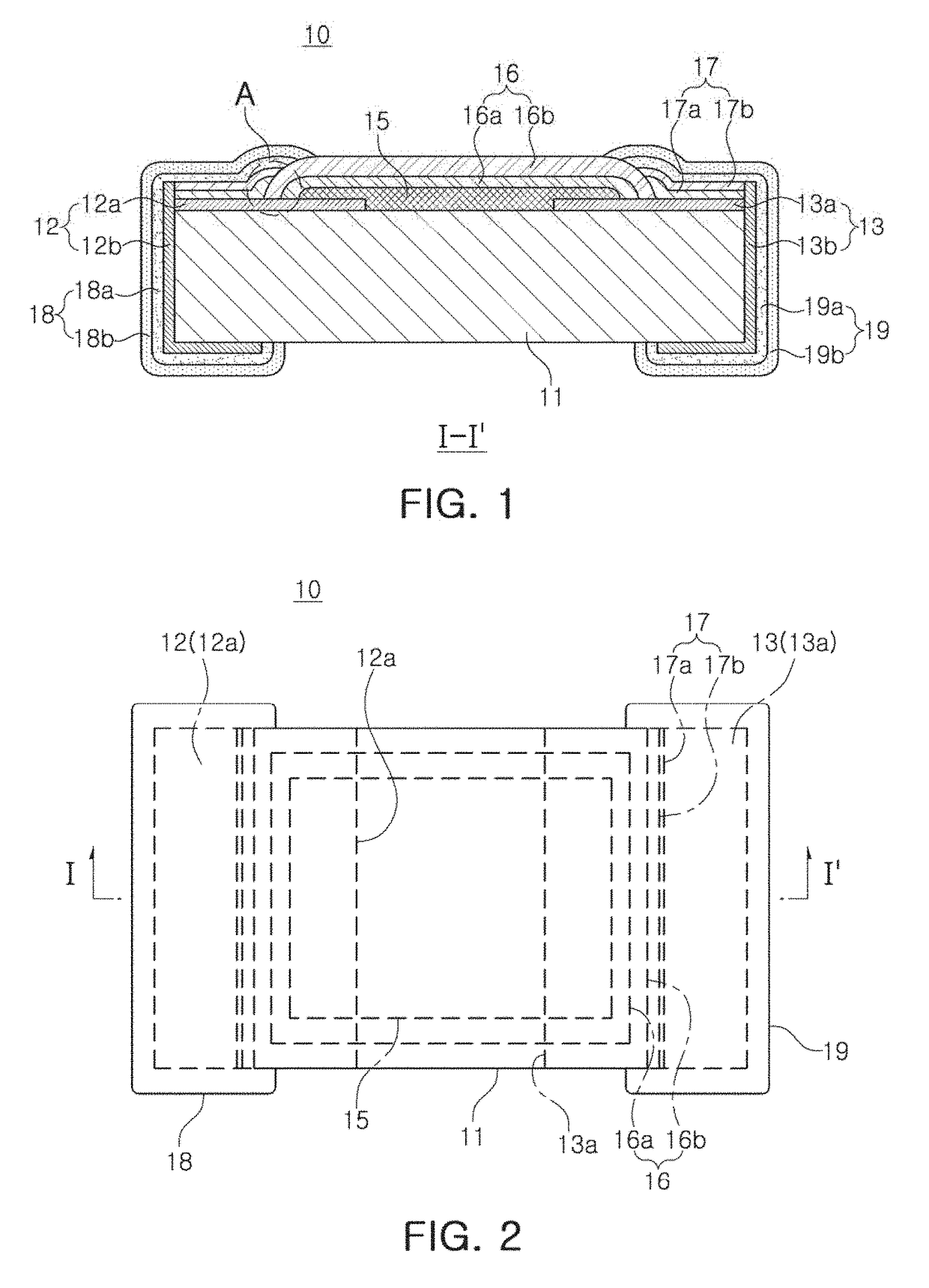

Chip resistor element

ActiveUS20170202089A1Improve the plating effectStrong adhesionResistor chip manufactureMass resistorsProtection layerElectrical and Electronics engineering

A chip resistor element includes an insulating substrate, a resistor layer, first and second internal electrodes, a resistor protection layer, first and second electrode protection layers, and first and second external electrodes. The resistor layer is on the insulating substrate, the first and second internal electrodes are on respective sides of the resistor layer, and the resistor protection layer covers the resistor layer and extends onto portions of the internal electrodes. The first electrode protection layers are on the first and second internal electrodes so as to overlap with portions of the resistor protection layer and contain first conductive powder particles and resin, while the second electrode protection layers are disposed on the first electrode protection layers and contain second conductive powder particles and resin. A content of resin in the second electrode protection layer is lower than in the first electrode protection layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Chip resistor and its manufacturing method

InactiveCN1989578AAvoid crackingPrevent electromigrationResistor chip manufactureMass resistorsEngineeringElectrical and Electronics engineering

A chip resistor comprises a pair of upper-face electrodes formed on two confronting side portions of a square substrate such that they are positioned on the sides opposed to each other with respect to the center line of the square substrate extending in the direction joining the two side portions, a resistor formed on the square substrate such that it is electrically connected with the paired upper-face electrodes, and a pair of end-face electrodes formed on the end faces of the two confronting side portions of the square substrate and electrically connected with the paired upper-face electrodes. The chip resistor further comprises dummy electrodes formed individually at the two confronting side portions of the square substrate such that they are positioned to correspond to the paired upper-face electrodes in the direction joining the two side portions.

Owner:PANASONIC CORP

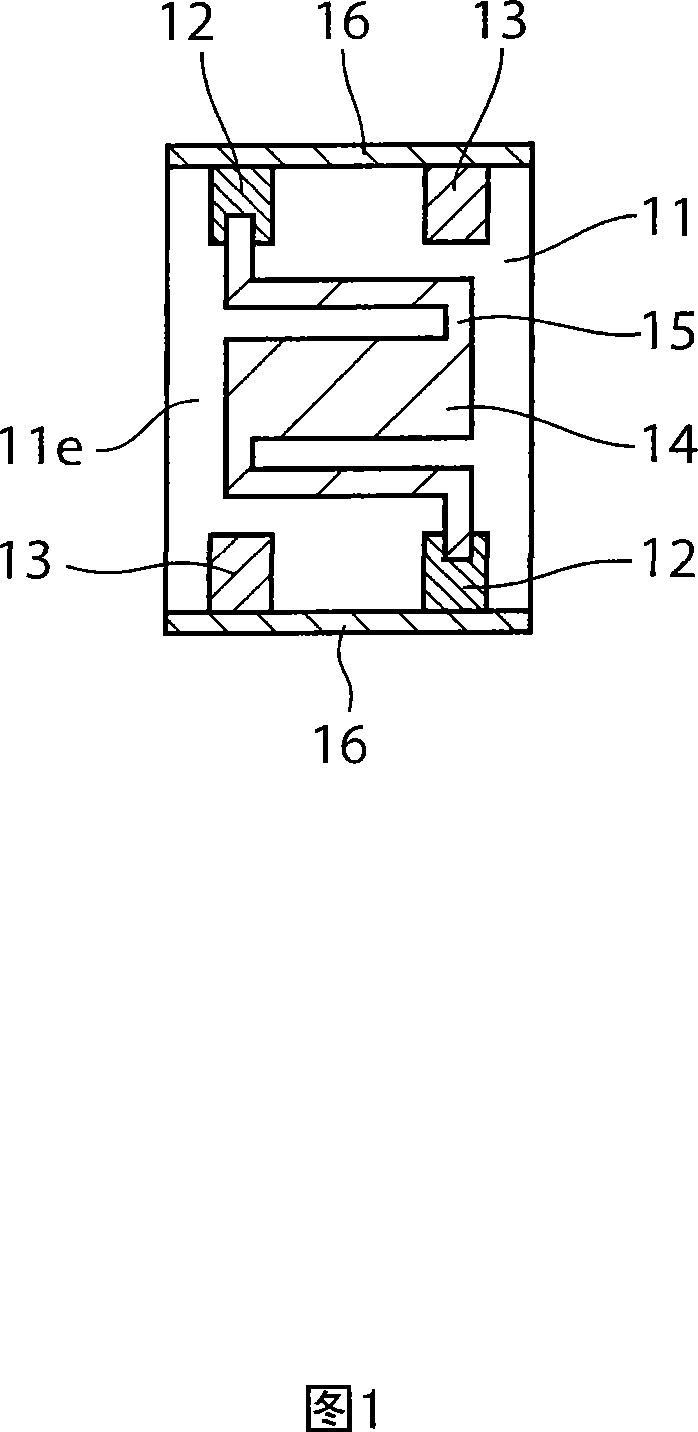

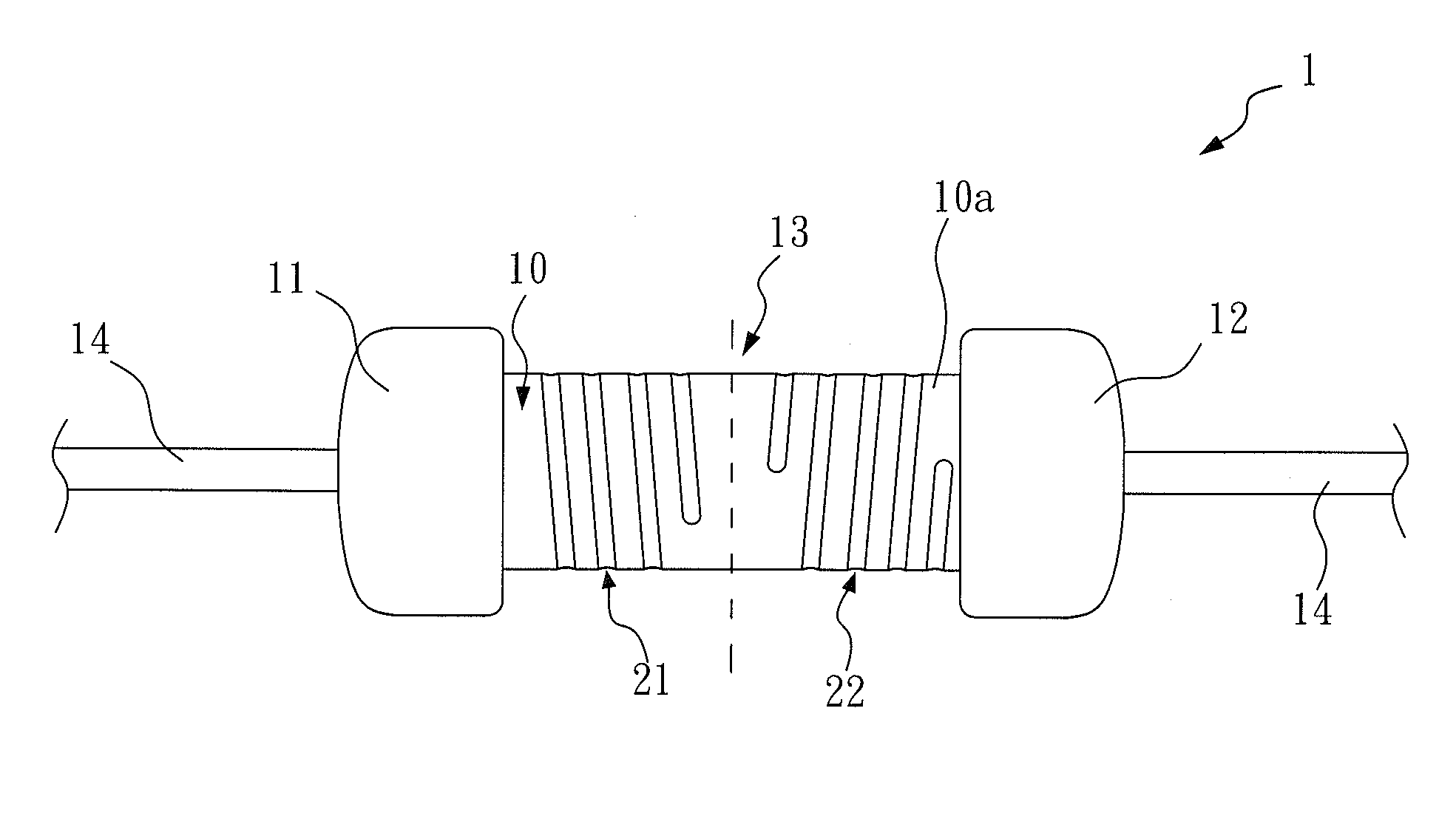

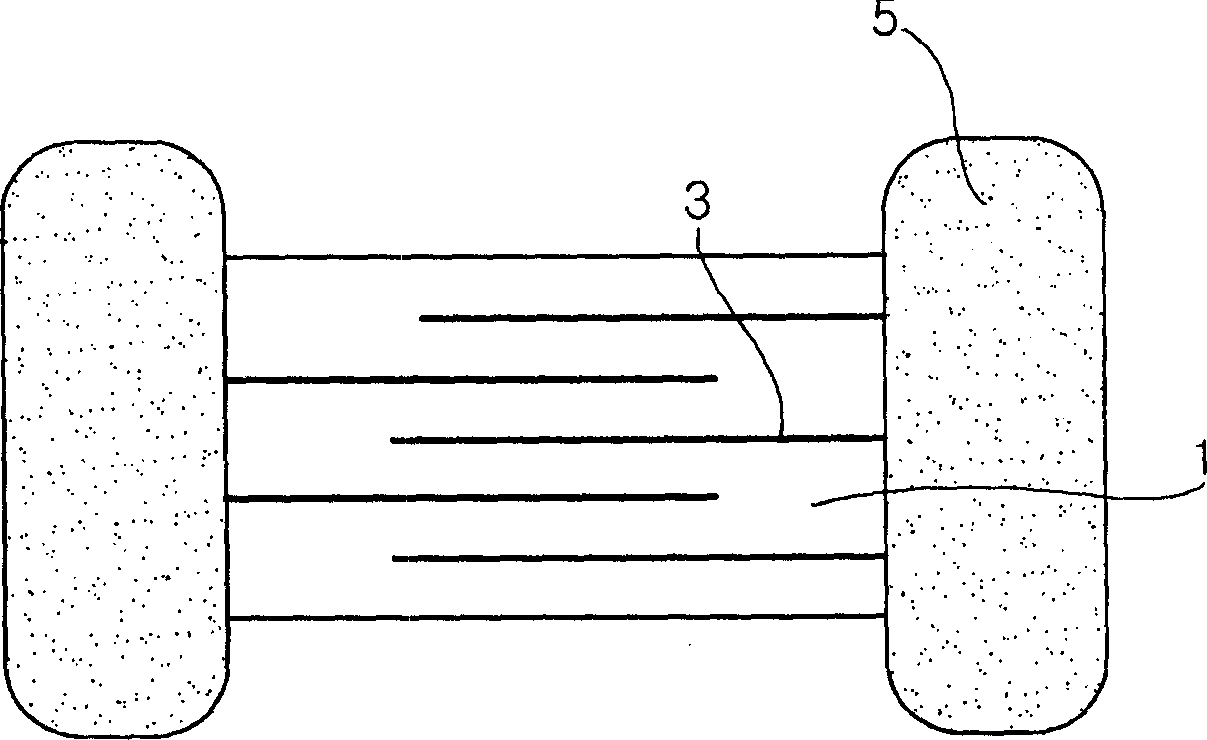

Metal plate low resistance chip resistor, and production method for the same

ActiveCN102326215AAvoid it happening againImprove reliabilityResistor chip manufactureMass resistorsMetalLow resistance

Provided is a metal plate low resistance chip resistor which has a resistance value of about 15 to 50 mO, high reliability, and a lower back. Also provided is a production method that can produce the metal plate low resistance chip resistor with a high degree of accuracy and at a high yield using a relatively simple process. A metal plate low resistance chip resistor (10) includes a metal resistance plate (11), electrode films (12) formed on both ends of the metal resistance plate, and a protective film (13) formed between the electrode films. Both sides (11a) of the rectangular metal resistance plate are cut off at predetermined positions to form the shape of the metal resistance plate. On both edge sections (11d) of the metal resistance plate, the electrode films (12) are formed near one edge side and the other edge side, respectively. An area where there is no electrode film on the metal resistance plate is provided as a resistance section. In the resistance section, there is a portion both sides of which remains without being cut off, and the portion serves as a resistance value adjustment section (11f). There is a portion both sides of which are cut off, and the portion serves as a resistance value fixed section (11e). The surface of the metal resistance plate is covered with the protective film. The protective film extends over both sides of the resistance value fixed section. Therefore, the width of the protective layer is the same as that of both edge sections.

Owner:KAMAYA ELECTRIC

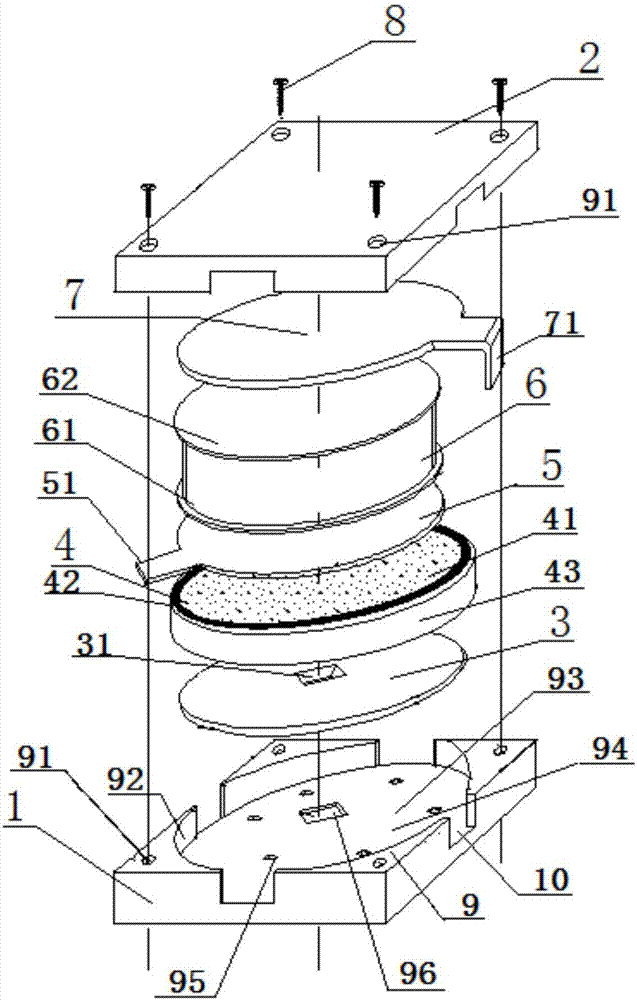

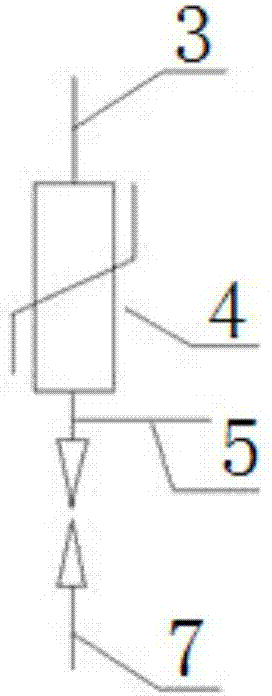

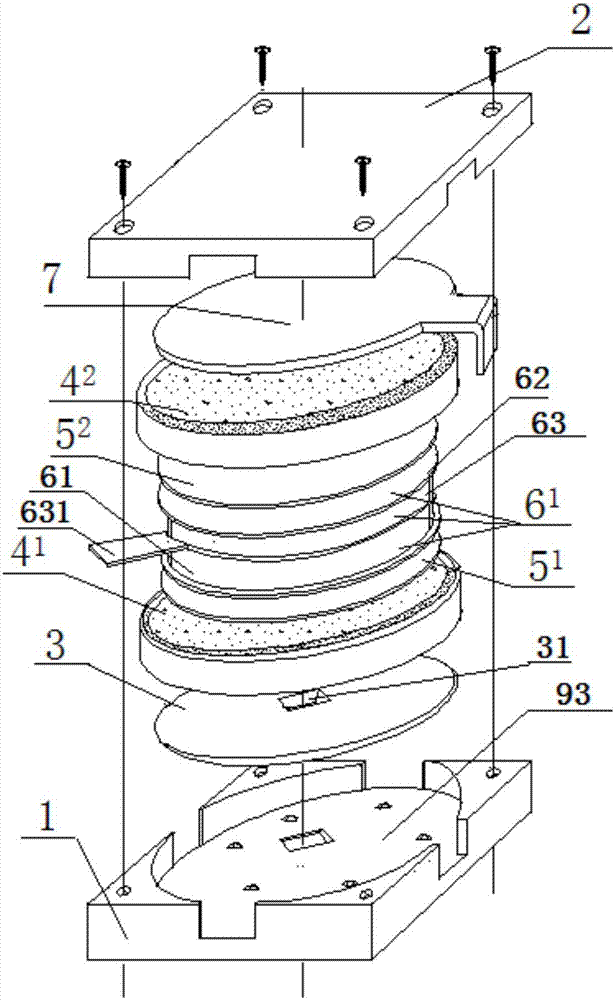

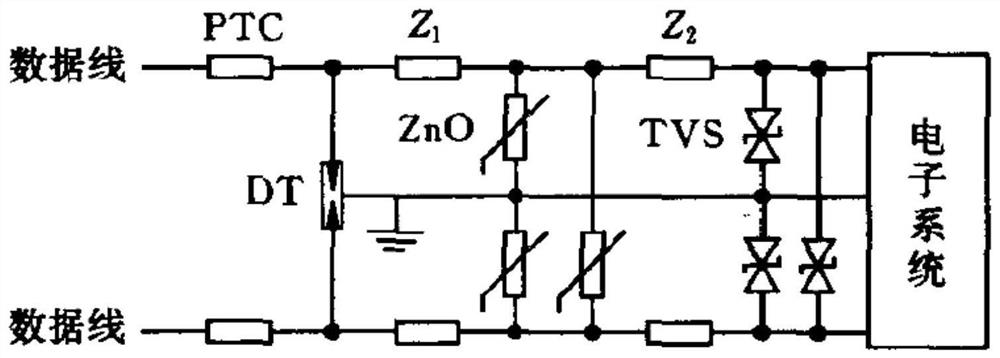

GDT (Gas discharge tube)-added composite MOV (Metal Oxide Varistor)

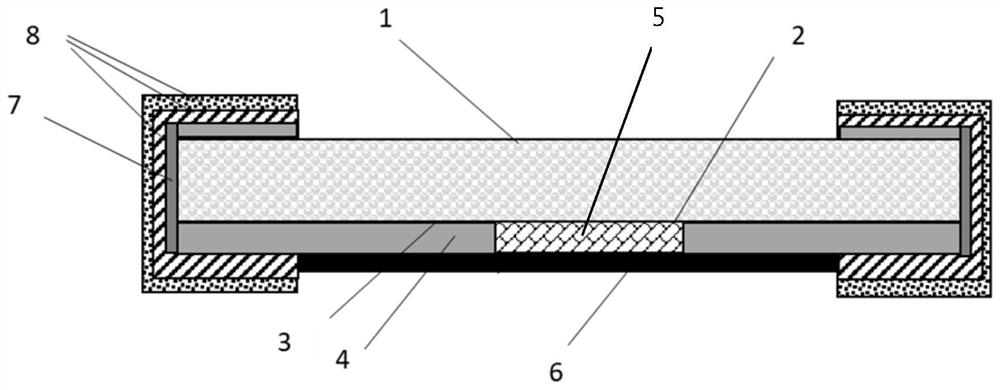

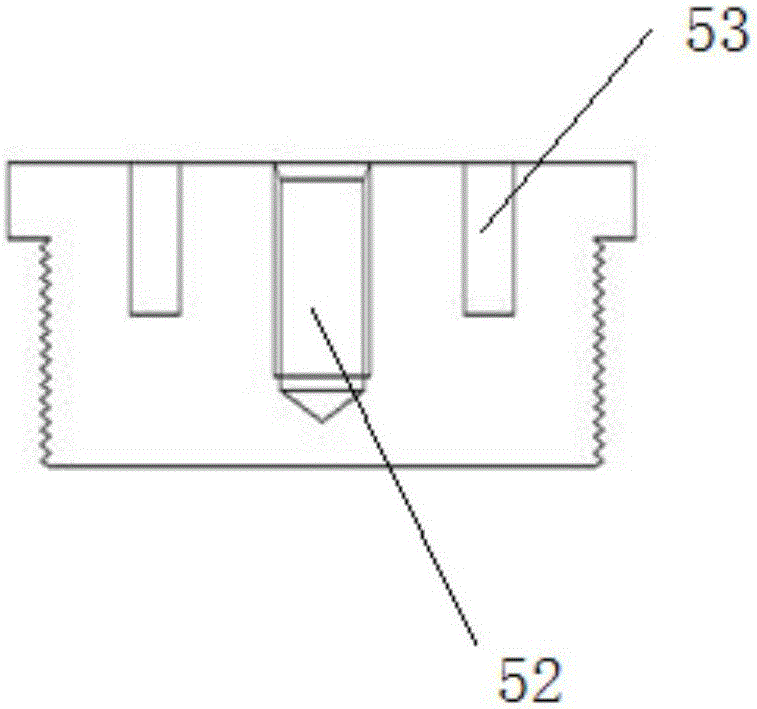

PendingCN107342145AFulfil requirementsDelay agingMass resistorsVaristor coresEngineeringMoisture barrier

The present invention relates to the technical field of design of a varistor composite component, and specifically discloses a GDT (Gas discharge tube)-added composite MOV (Metal Oxide Varistor), the GDT-added composite MOV is provided with an upper box body and a lower box body, is also provided with a lower extraction electrode embedded in the lower box body, a MOV chip, a middle extraction electrode, a GDT and an upper extraction electrode are successively stacked on the lower extraction electrode, or the MOV chip, the GDT and the upper extraction electrode are successively stacked on the lower extraction electrode. The independent separated MOV and GDT are combined into an integrated structure, can improve the electrical performance requirements, meanwhile is miniaturized, and can meet higher requirements of an electronic circuit and a signal channel; due to the gap isolation effect of the GDT, the MOV chip can normally work without bearing a working voltage, semiconductor grain aging speed is very slow, no current is leaked during working, the service life is improved, a damp proof layer and an anti-side flash cover are arranged on the edge, and the GDT-added composite MOV has longer service life, higher reliability and stronger weathering resistance.

Owner:LONGKE ELECTRONICS HUIYANG

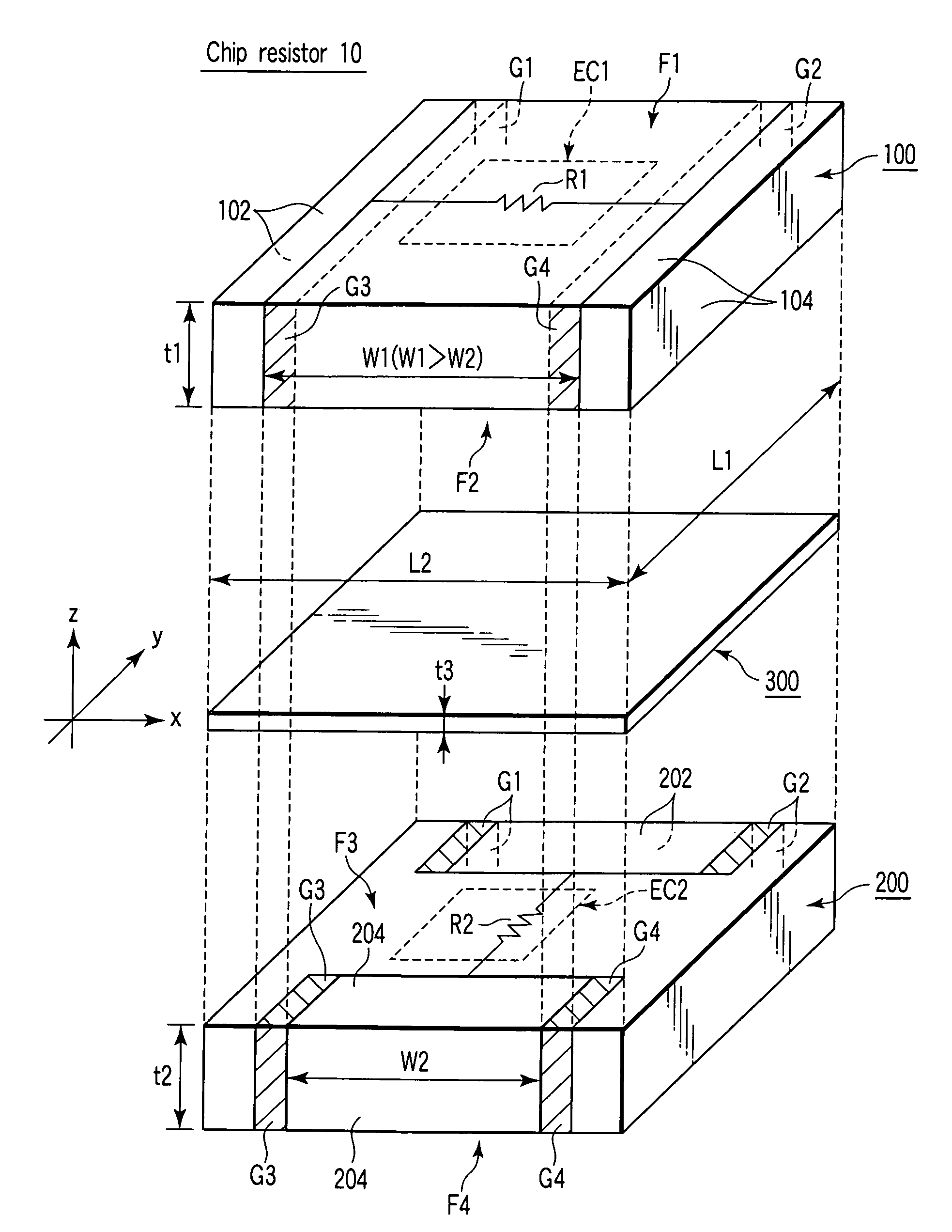

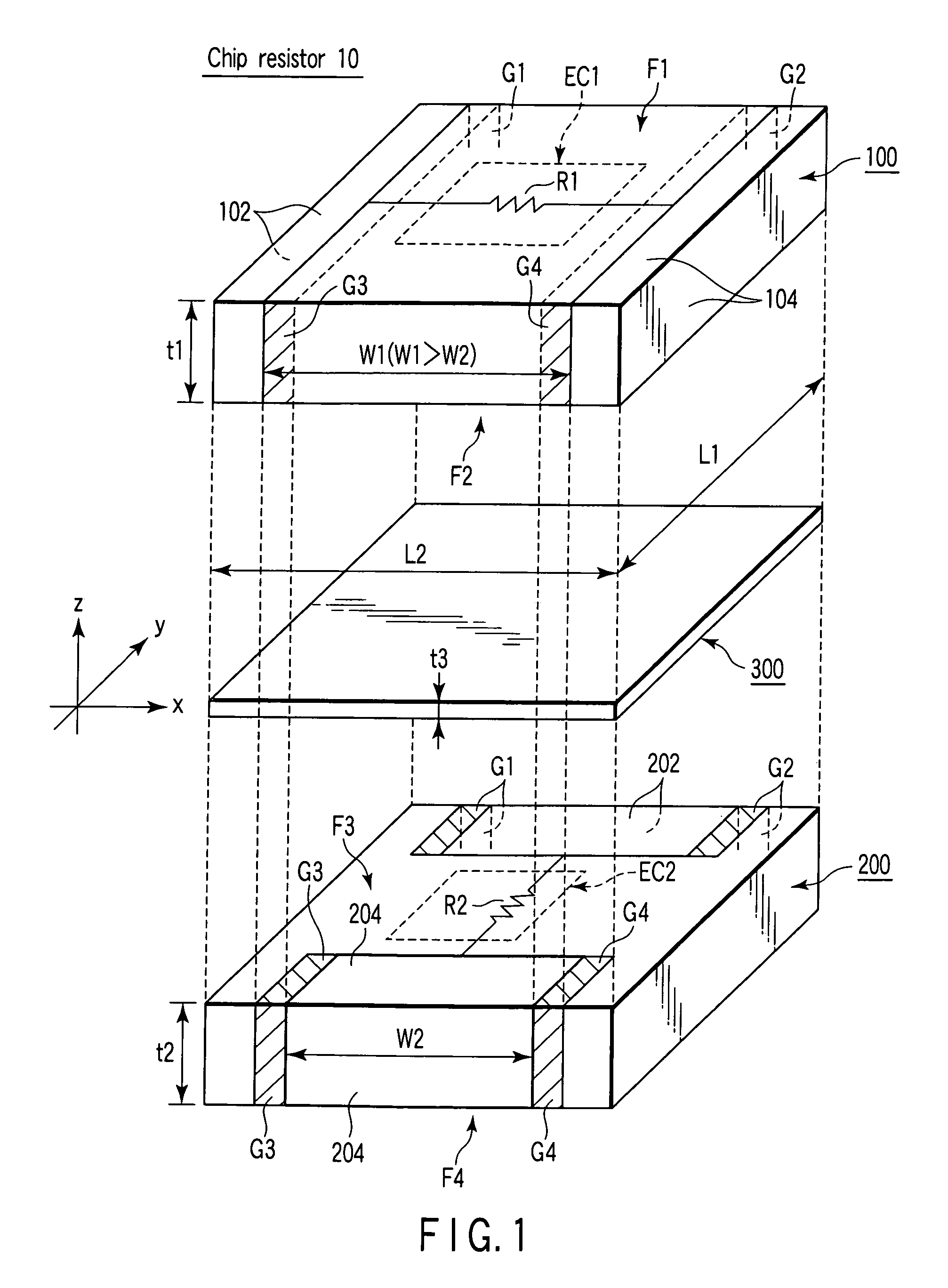

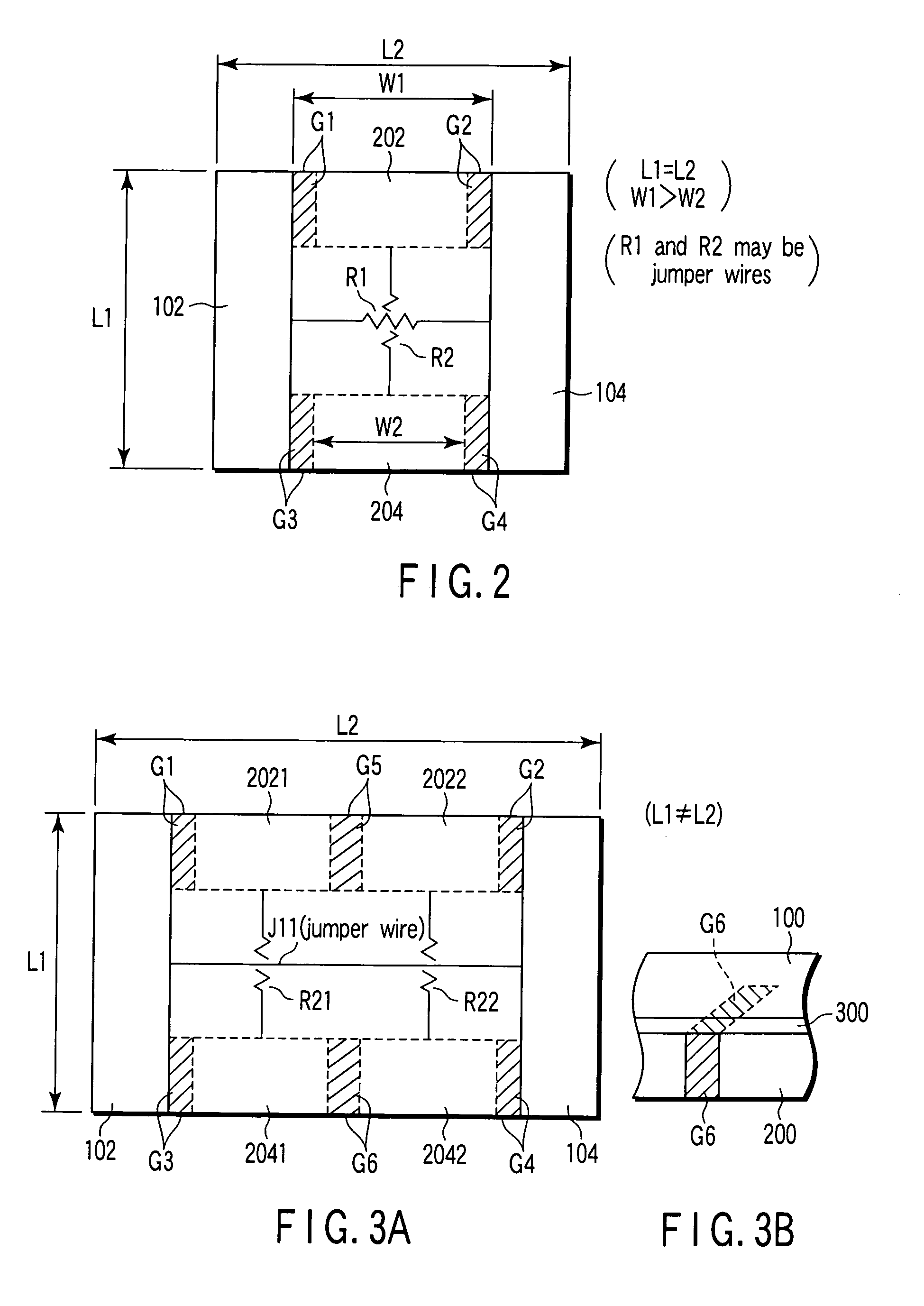

Chip resistor

Chip resistor includes the rectangular first substrate made of ceramics and having surfaces, the rectangular second substrate made of ceramics and having surfaces, and a joint layer interposed between the surfaces, and electrodes are formed on two opposing sides of the substrate and resistor is formed between the electrodes. Further, electrodes are formed on two opposing sides of the substrate and resistor is formed between the electrodes.

Owner:KK TOSHIBA

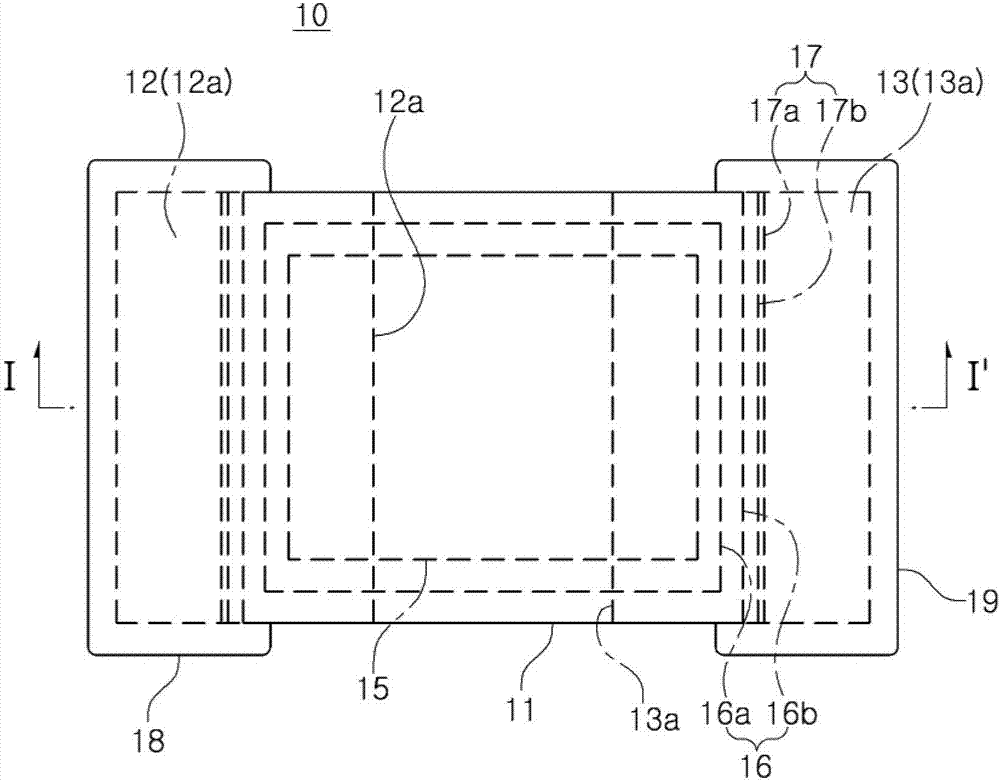

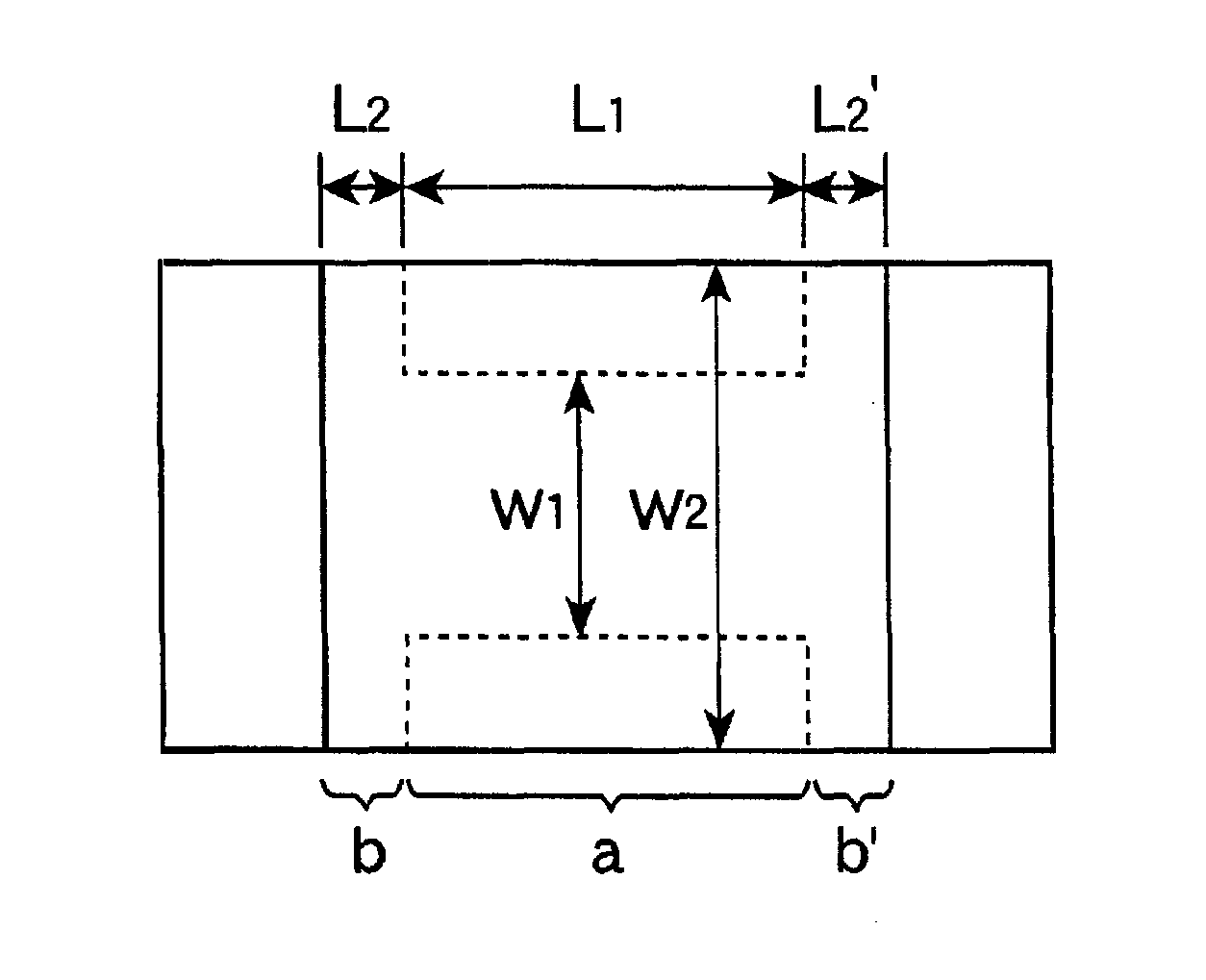

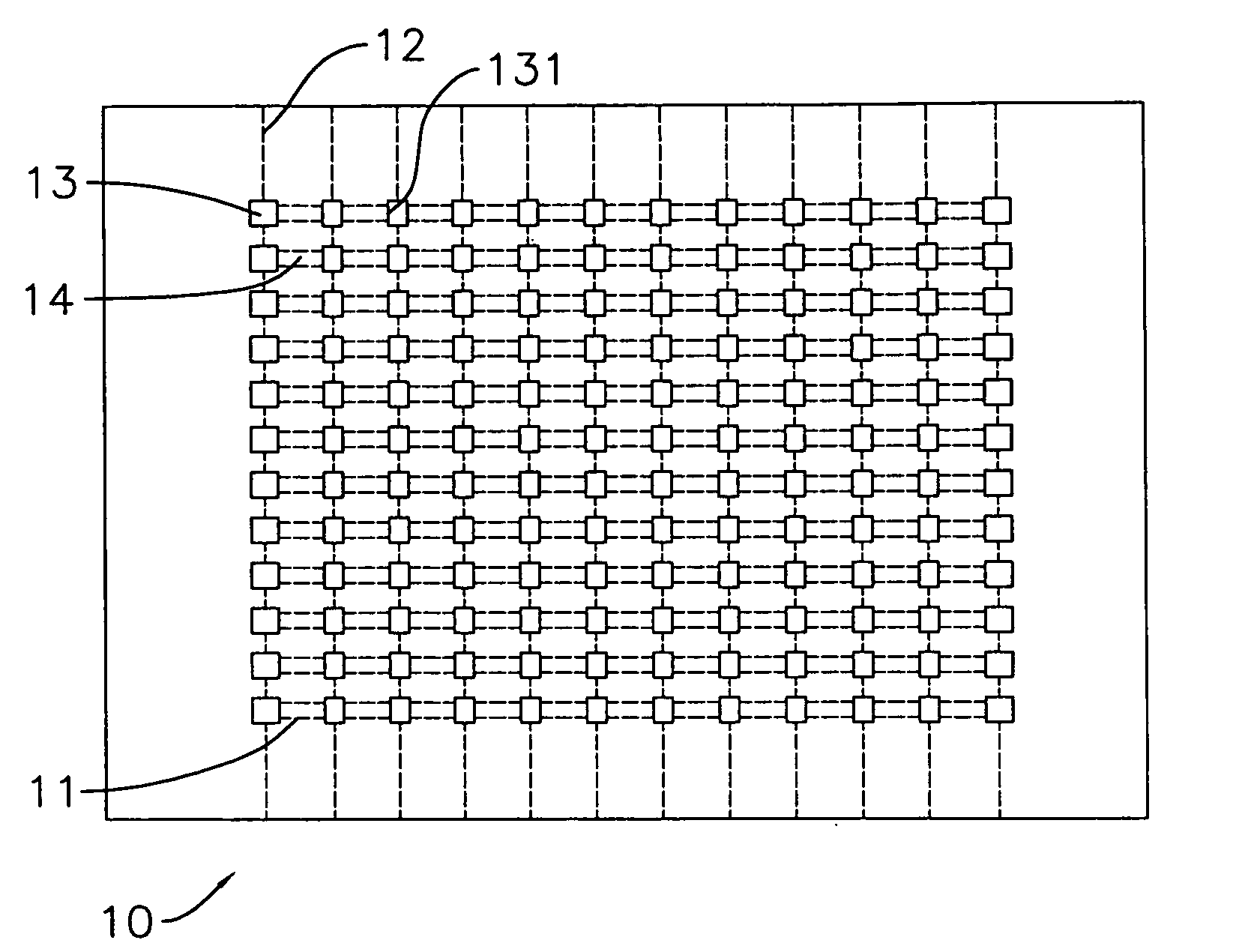

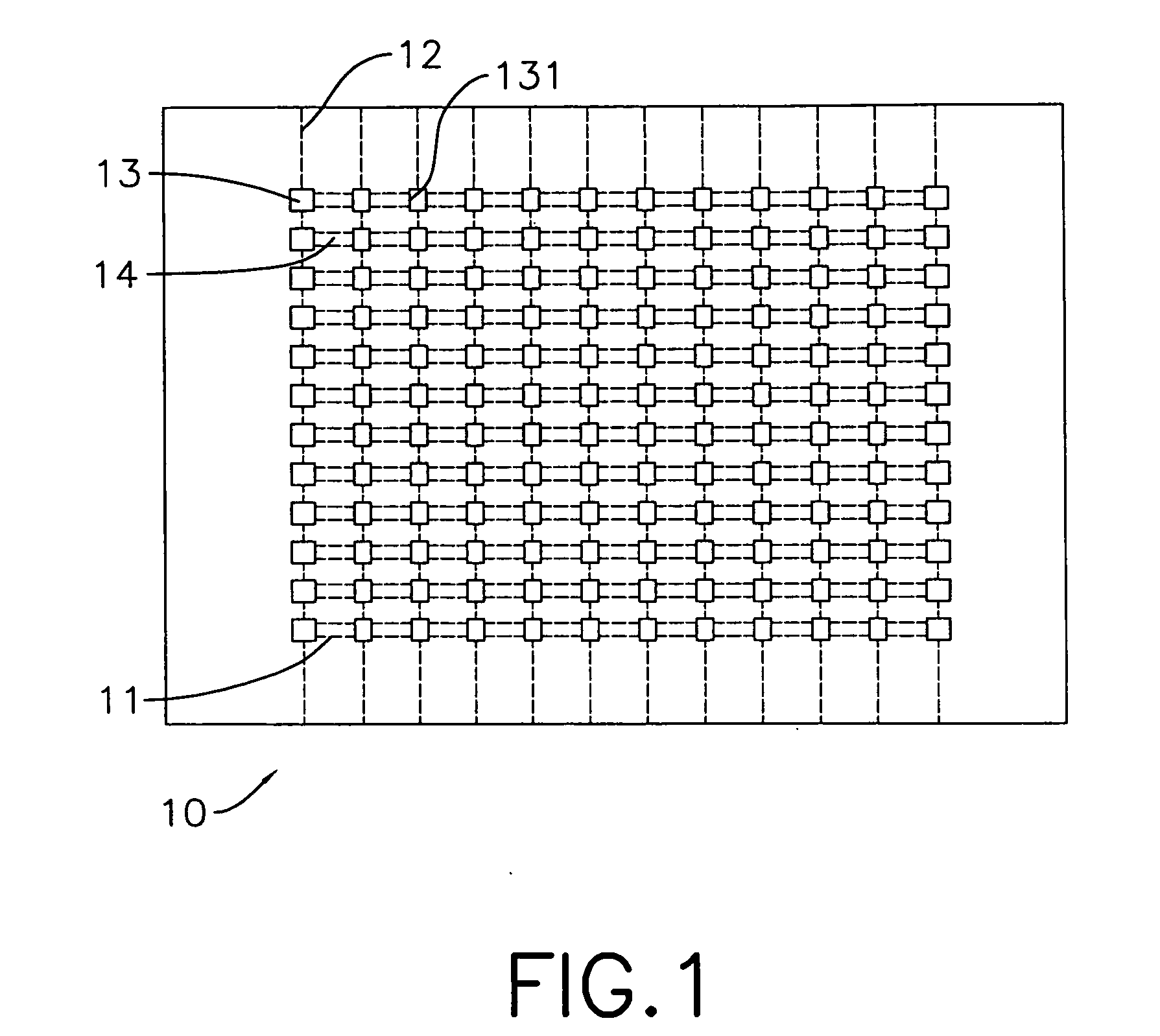

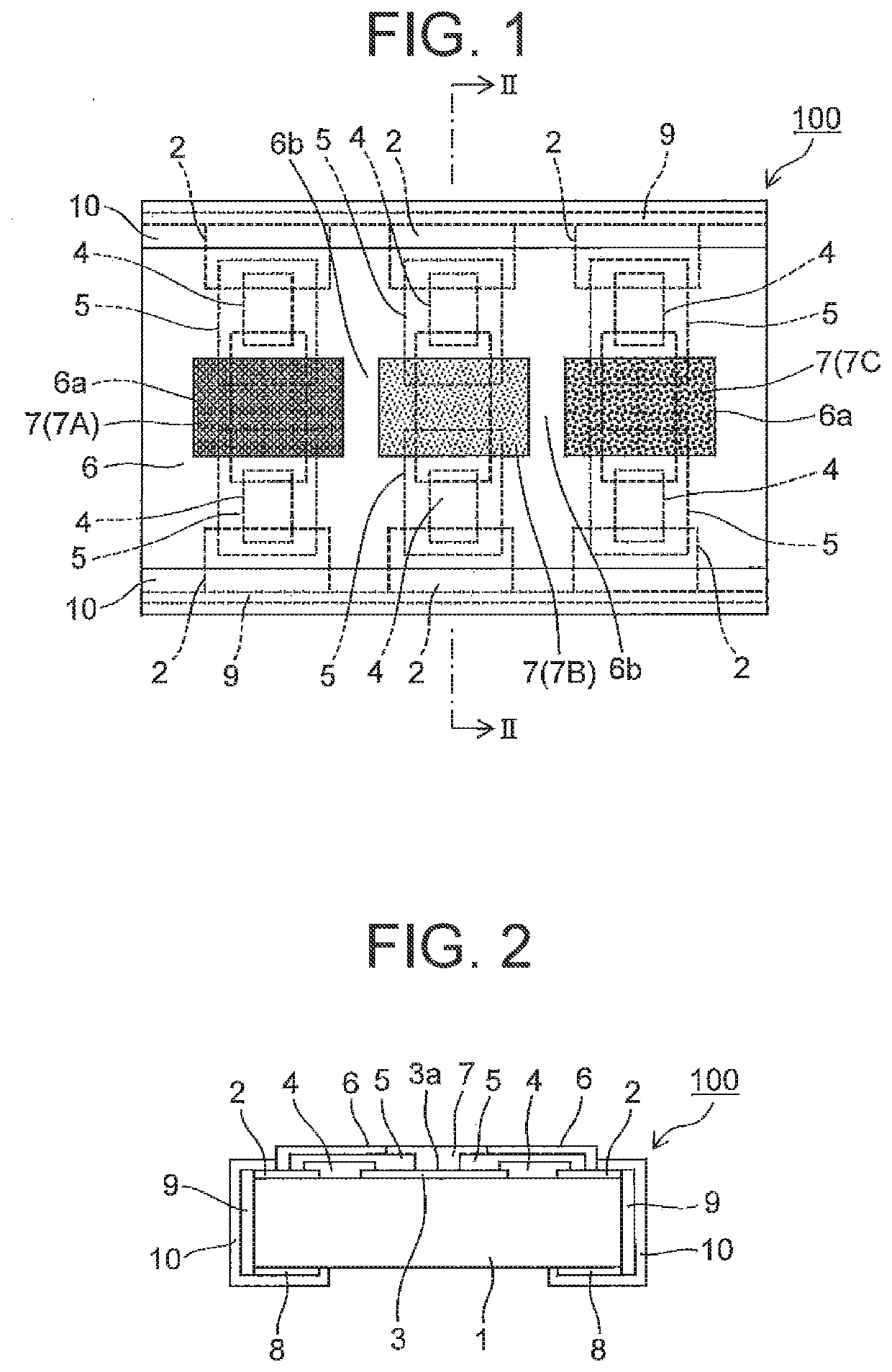

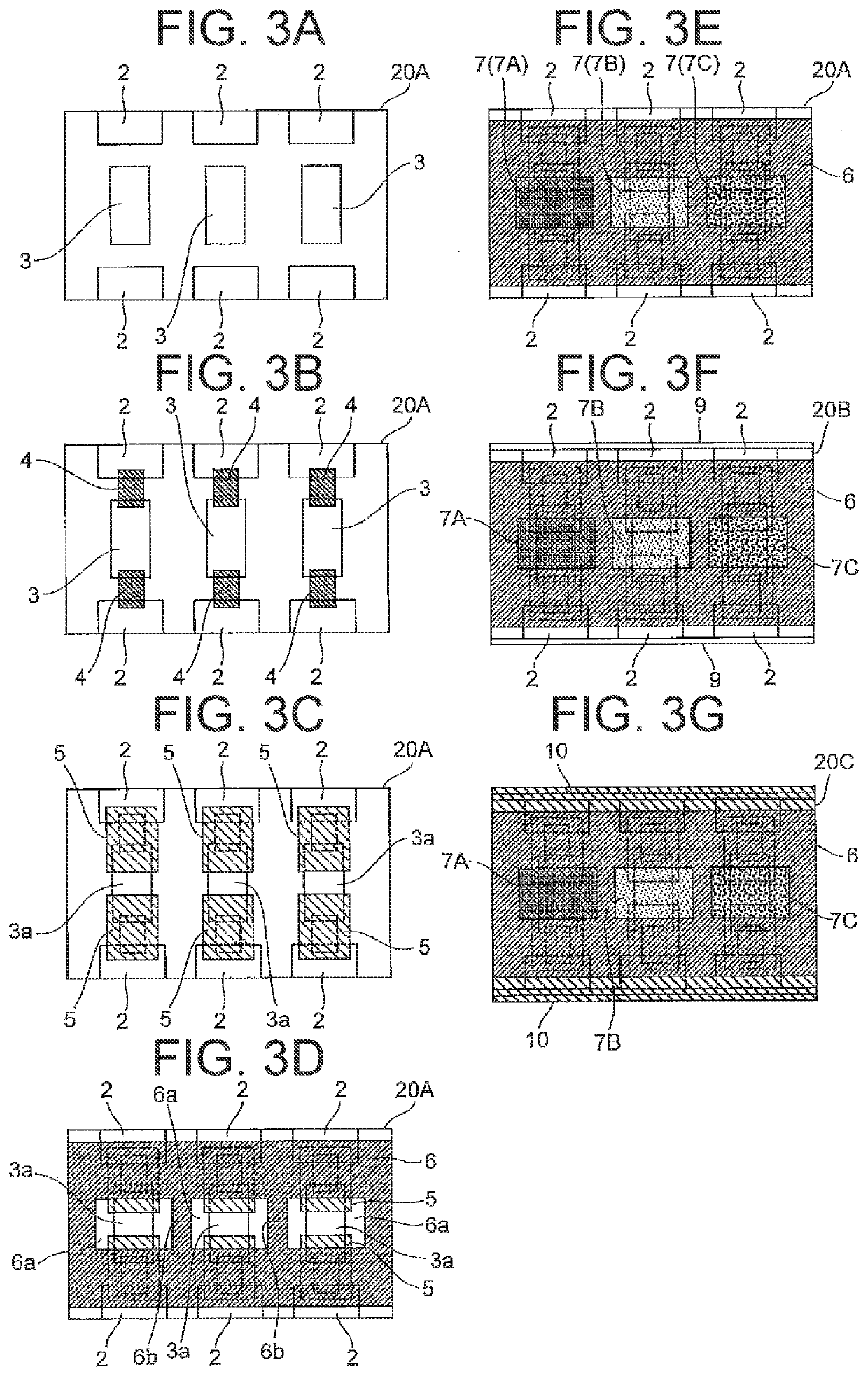

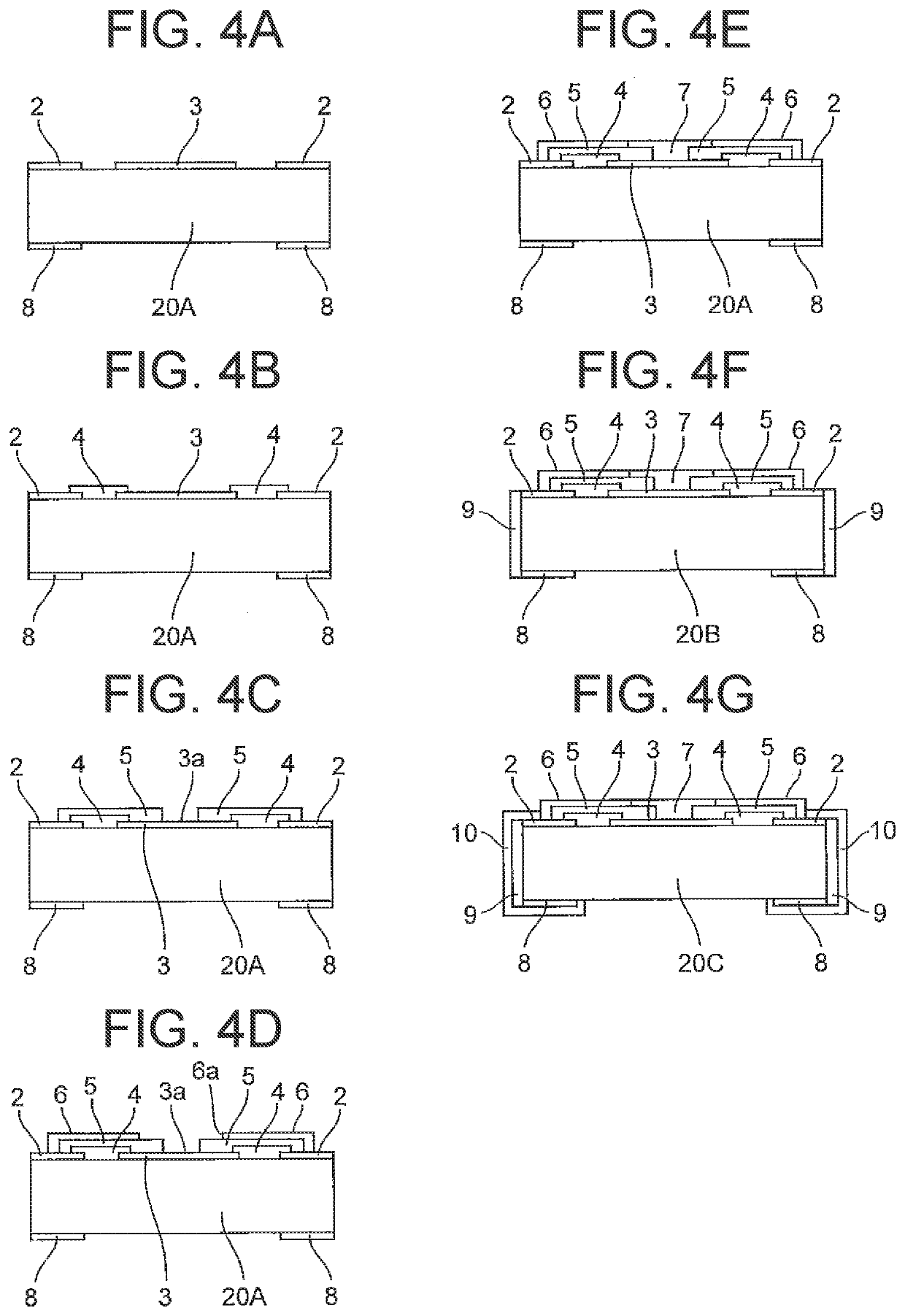

Collective substrate for resistor devices

ActiveUS9832877B2High yieldPreventing upsizingMass resistorsFinal product manufactureEngineeringResistor

A collective substrate for resistor devices includes a base, a first conductive pattern in a to-be-product region and a to-be-cut-away region of the base, and a resistive element in the to-be-product region of the base. The to-be-cut-away region includes a first region adjacent to the to-be-product region in a first direction, and a second region adjacent to the to-be-product region in a second direction. The first conductive pattern includes a first terminal portion connected to the resistive element and disposed in the to-be-product region, a first electrode portion disposed in the first region and larger in area than the first terminal portion, and a first interconnect portion extended from the first terminal portion toward the second region to be connected to the first electrode portion.

Owner:MURATA MFG CO LTD

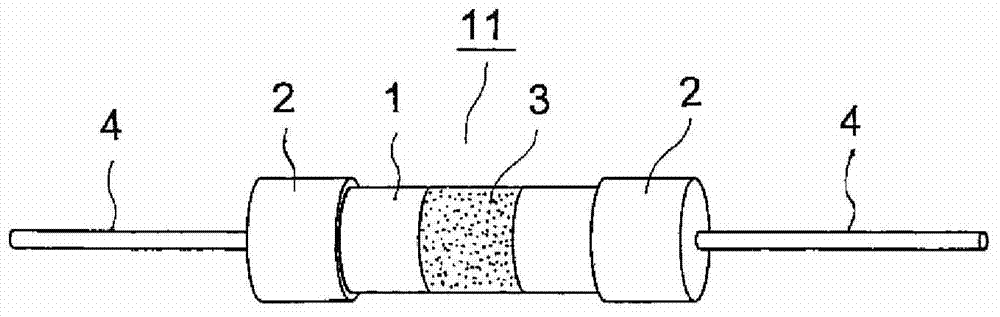

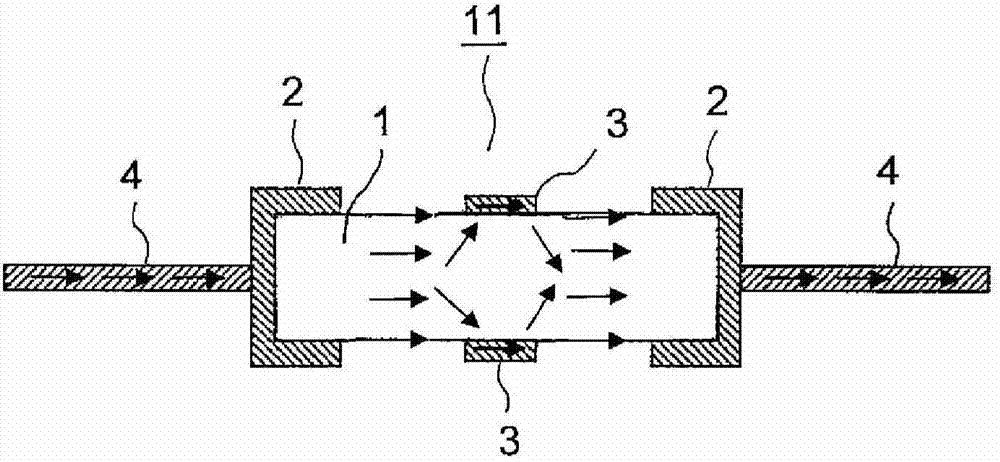

Ceramic resistor

ActiveCN103843078AConcentrated obviouslyWell formedMass resistorsResistor detailsElectrical resistance and conductanceConductive materials

Provided is a ceramic resistor that is capable of immediately shutting power off in the event of generation of abnormal heat in the resistor without requiring a thermal fuse to be added. The ceramic resistor (11) is provided with: a resistor body (1) which is created by means of sintering of a mixture of a conductive material and insulating ceramics; a pair of electrodes (2) which are fitted to either end of the resistor body (1) in the length direction; and lead terminals (4) which protrude outward from the respective electrodes (2). A conductive metal film (3) having a lower resistivity than that of the resistor body (1) is provided along the entire circumference of the outer peripheral surface of the resistor body (1) in a partial region away from the electrodes (2).

Owner:KAO CORP

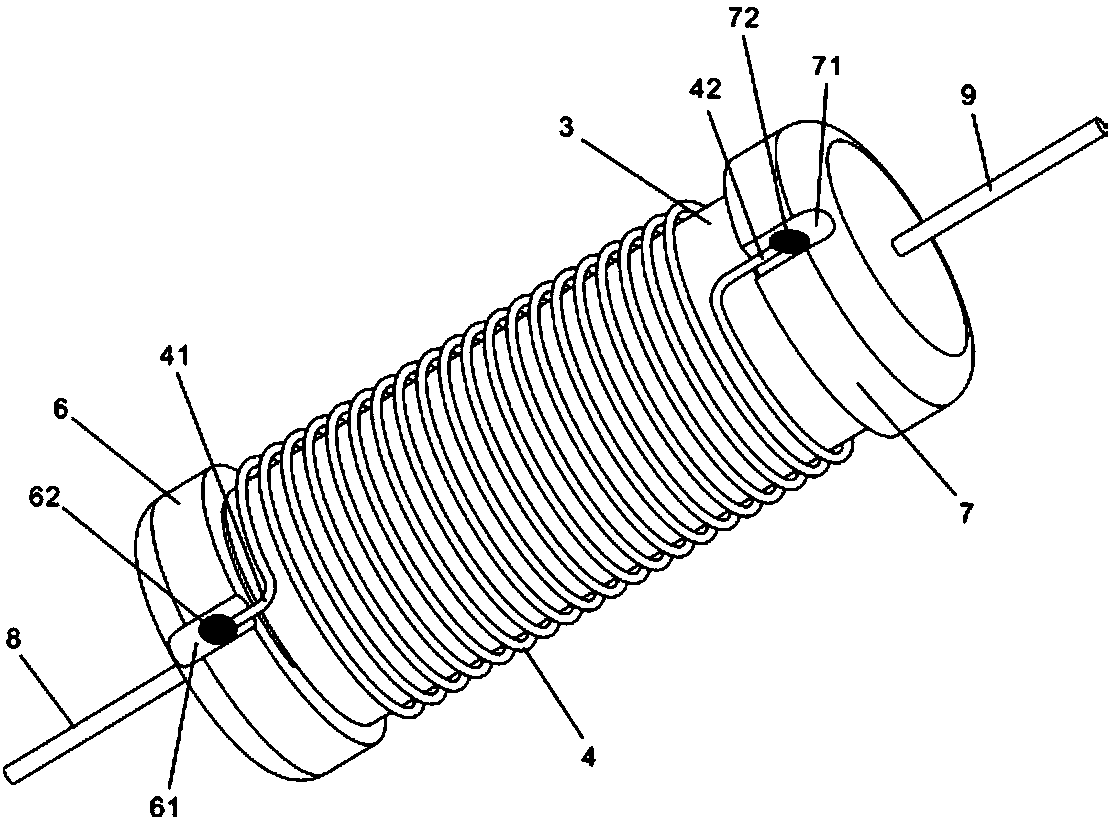

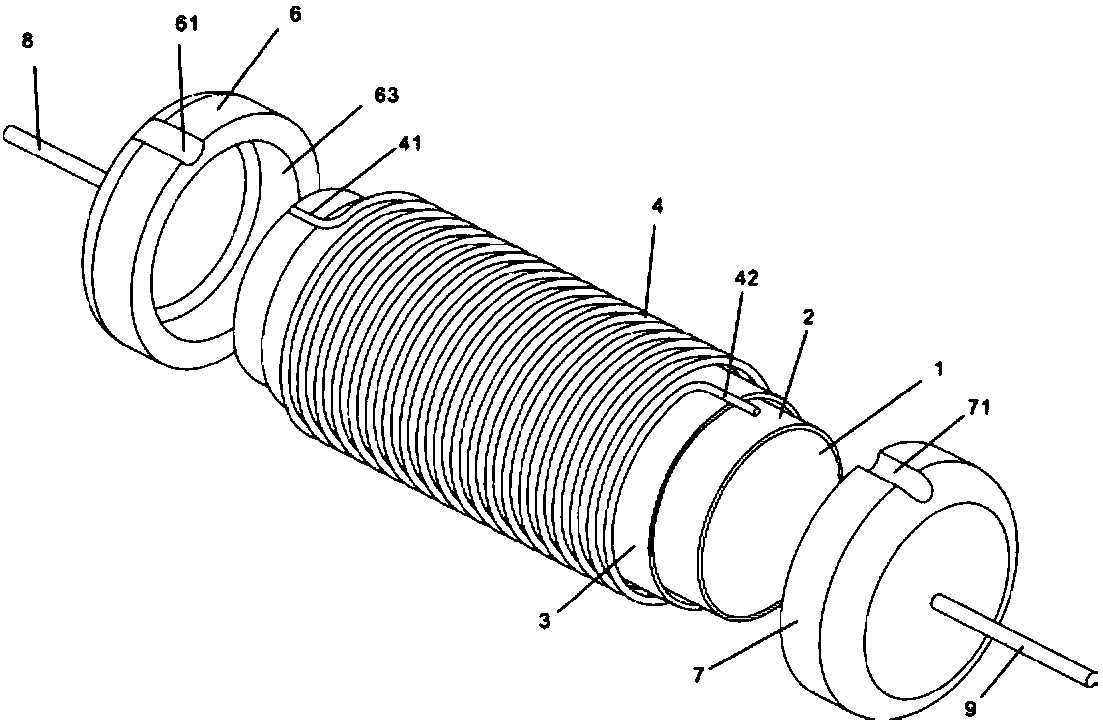

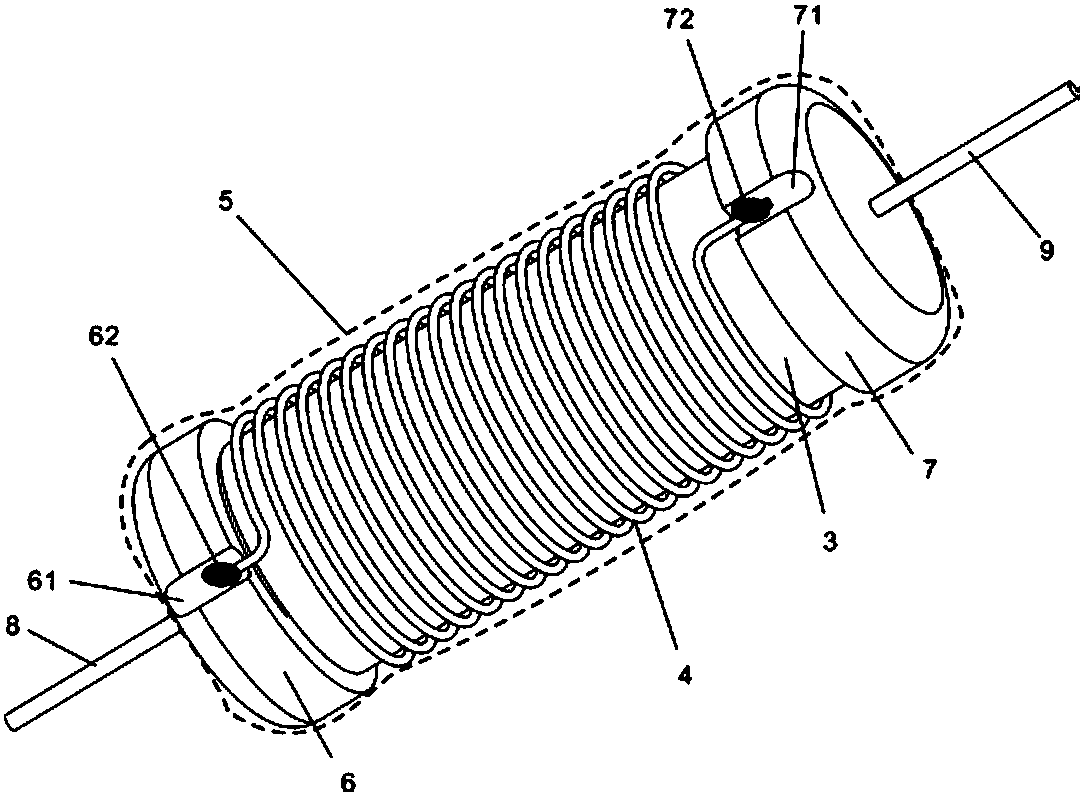

Wire winding type metal oxide film resistor and processing process

PendingCN108335810ACause some damagesIncrease powerOther resistor networksMass resistorsFilm resistanceSpace environment

The invention discloses a wire winding type metal oxide film resistor and a processing process. The wire winding type metal oxide film resistor is characterized in that the circumferential surface ofa ceramic core is coated with a metal oxide film resistance layer, the metal oxide film resistance layer is coated with an insulating layer, and a resistance wire winds the insulating layer; after theleft tip and left metal end cap of the resistance wire are welded at a left welding point and the right tip and right metal end cap of the resistance wire are welded at a right welding point, and theouter surfaces of the resistance wire, the left metal end cap and the right metal end cap are coated with an insulating wrapping layer. The wire winding type metal oxide film resistor and the processing process have the advantages that the power of the resistor is doubled as compared with that of a traditional wire winding type resistor which is identical with the resistor in volume; when the resistor meets with severe current overrun, the resistor only has disconnection when a resistor medium is burnt out due to the triple wrapping of the metal oxide film resistance layer, the insulating layer and the resistance wire, severe explosion can be avoided, damage to other devices is avoided, a space environment on a circuit board can be prevented from being polluted, and use and operation safety is enhanced greatly.

Owner:东莞市创嘉电子有限公司

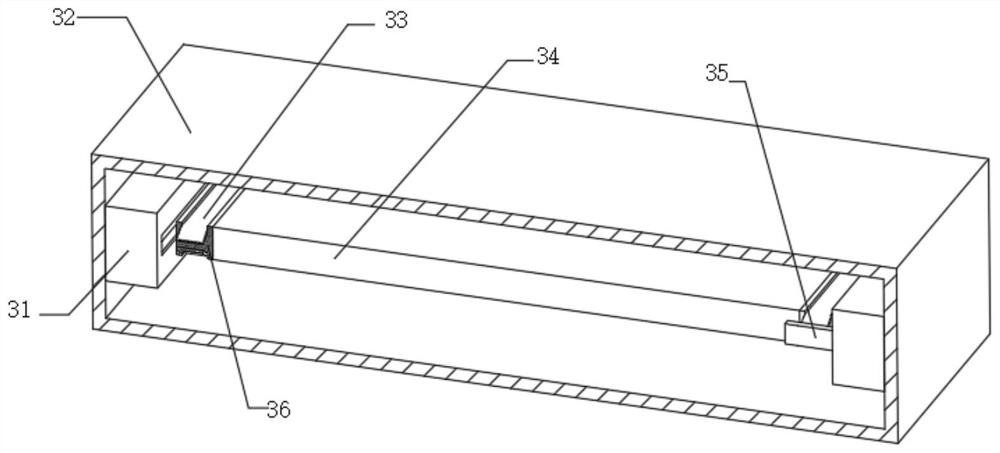

High-power alloy foil resistor and manufacturing method

ActiveCN113113199AImprove cooling effectUnobstructed diffusionMass resistorsResistor detailsMetallic materialsAlloy

The invention discloses a high-power alloy foil resistor which comprises a substrate, a resistor element attached to the substrate and electrodes connected to the two ends of the resistor element. The resistor element comprises an intermediate material piece and two resistor alloy pieces, the middle material piece is clamped between the two resistance alloy pieces and is connected with the two resistance alloy pieces at the same time, the two resistance alloy pieces are connected with the electrodes at the two ends respectively, and the intermediate material piece is made of a low-resistivity high-thermal-conductivity metal material. As the middle area of the resistance element is replaced by the low-resistivity high-thermal-conductivity material, a heat accumulation area is divided into two parts. The heat accumulation points of the resistor element can be segmented, and a heat transmission path is shortened, so that the heat dissipation capability of the whole resistor is improved, and the service power of a product is improved. Meanwhile, the middle part of the resistor element is replaced by the low-resistivity metal, so that the designed length of the resistor element is reduced, and the resistor with a lower resistance value can be designed and produced.

Owner:NANJING SART SCI & TECH DEV

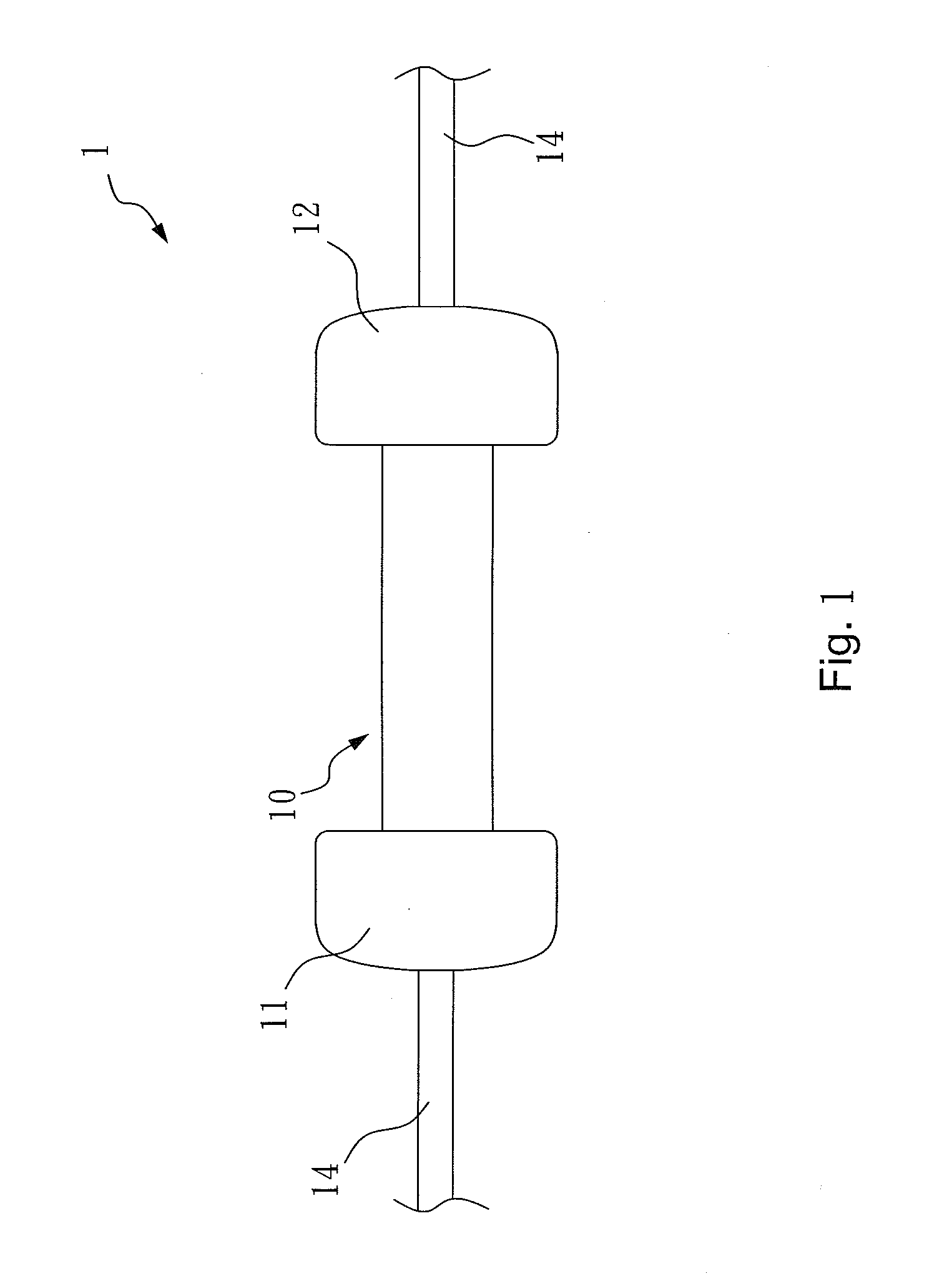

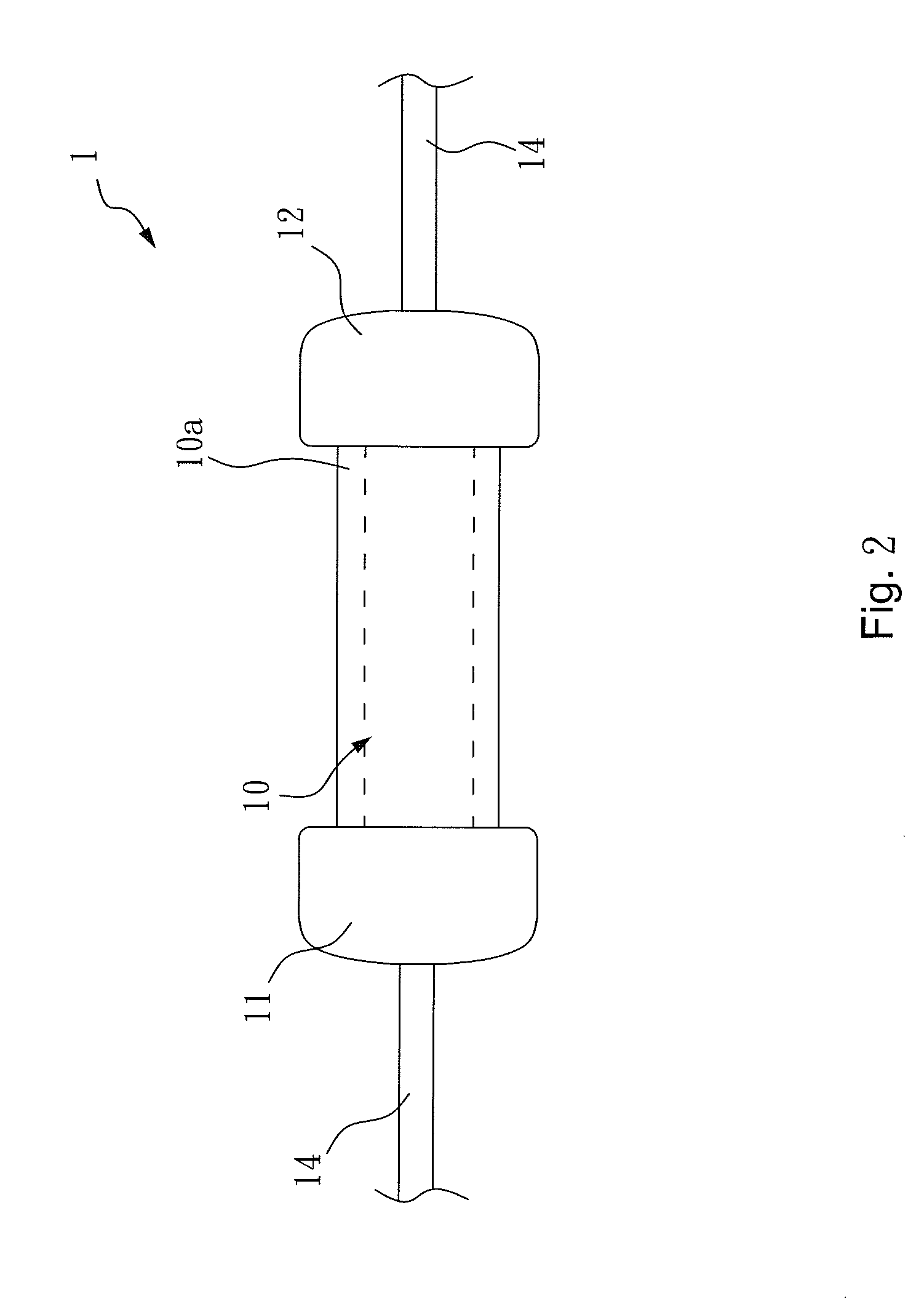

Non-Inductive Resistor and the Manufacturing Method Thereof

A non-inductive resistor and a method of manufacturing a non-inductive resistor are disclosed. The non-inductive resistor comprises a resistance rod, a conductive layer, a clockwise cut mark, and a counterclockwise cut mark. The resistance rod comprises a first end and a second end, and a cutting center is established between the first end and the second end. The conductive layer is used for covering the resistance rod between the first end and the second end. The clockwise cut mark is situated on the conductive layer between the first end and the cutting center. The counterclockwise cut mark is situated on the conductive layer between the second end and the cutting center, wherein the clockwise cut mark and counterclockwise cut mark are used for counteracting an inductance effect of the non-inductive resistor.

Owner:FUTABA ELECTRIC

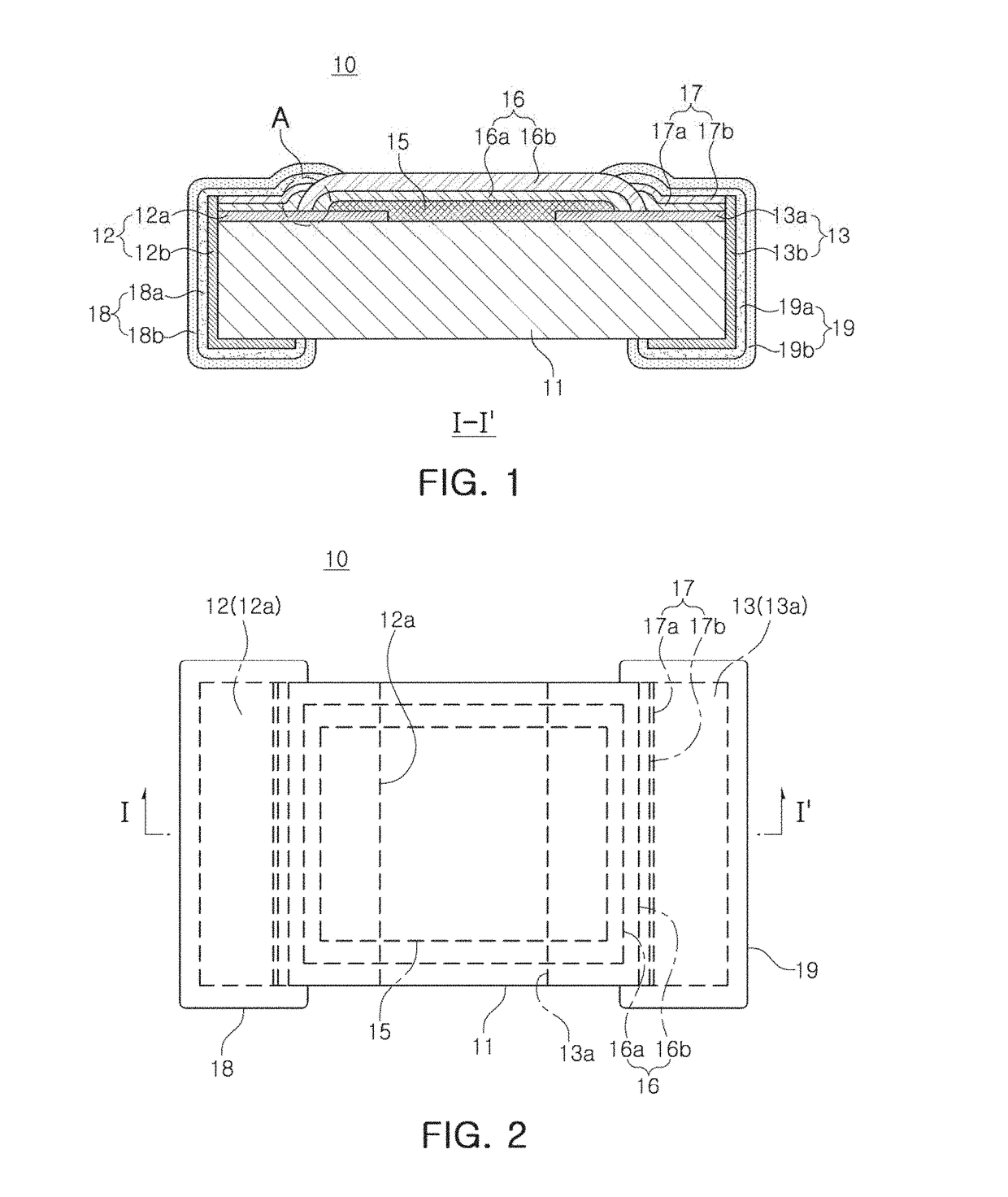

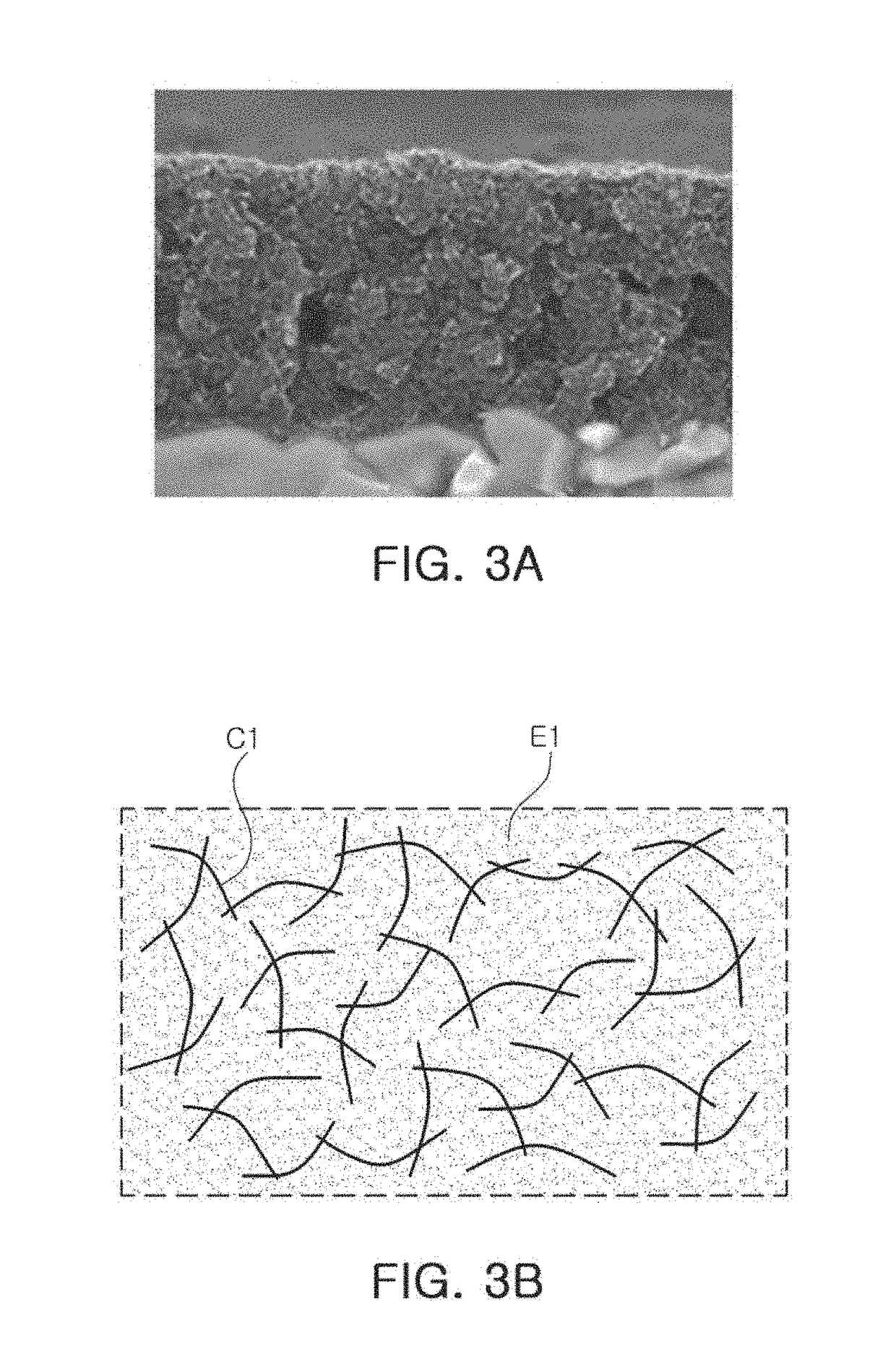

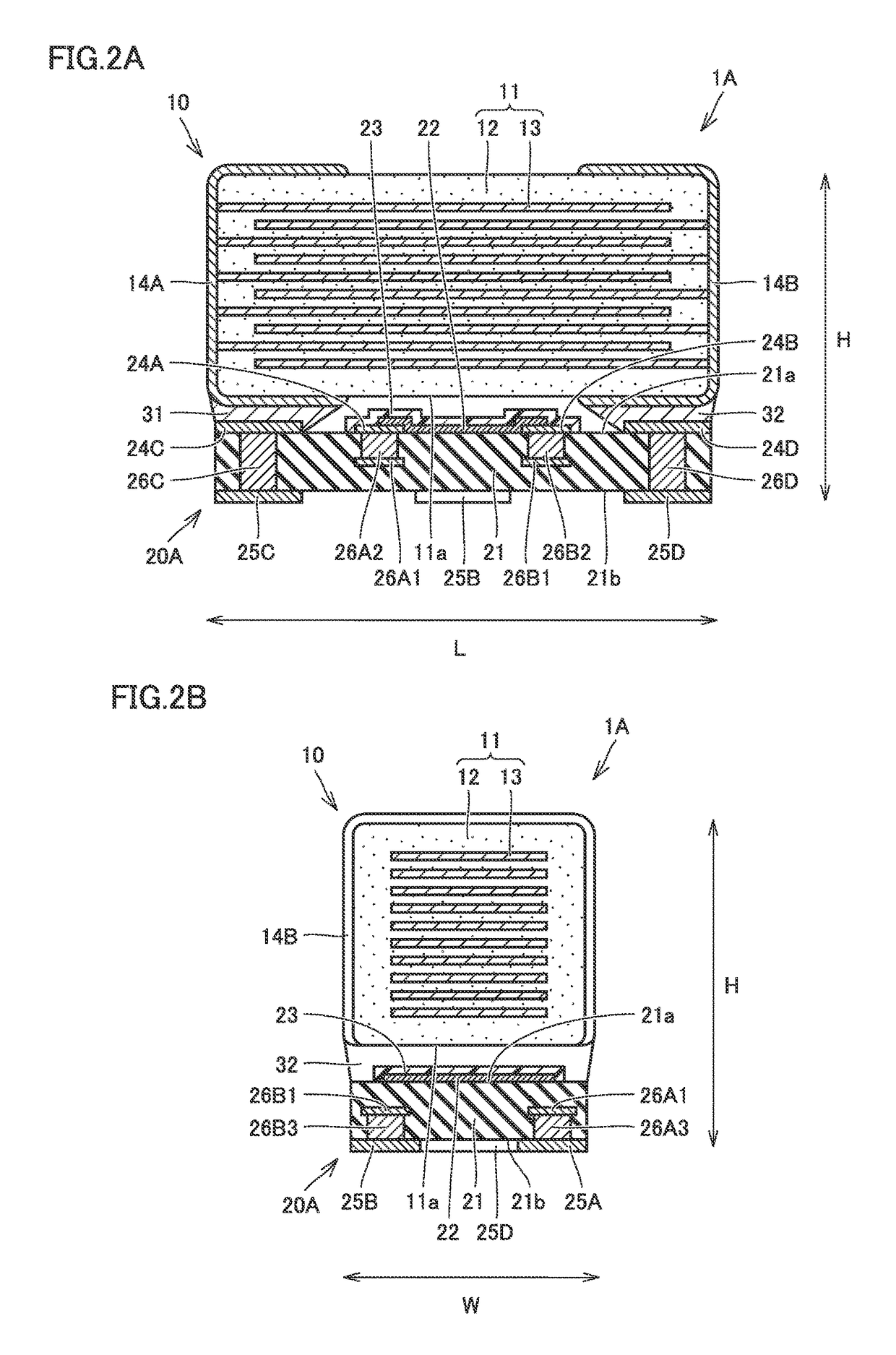

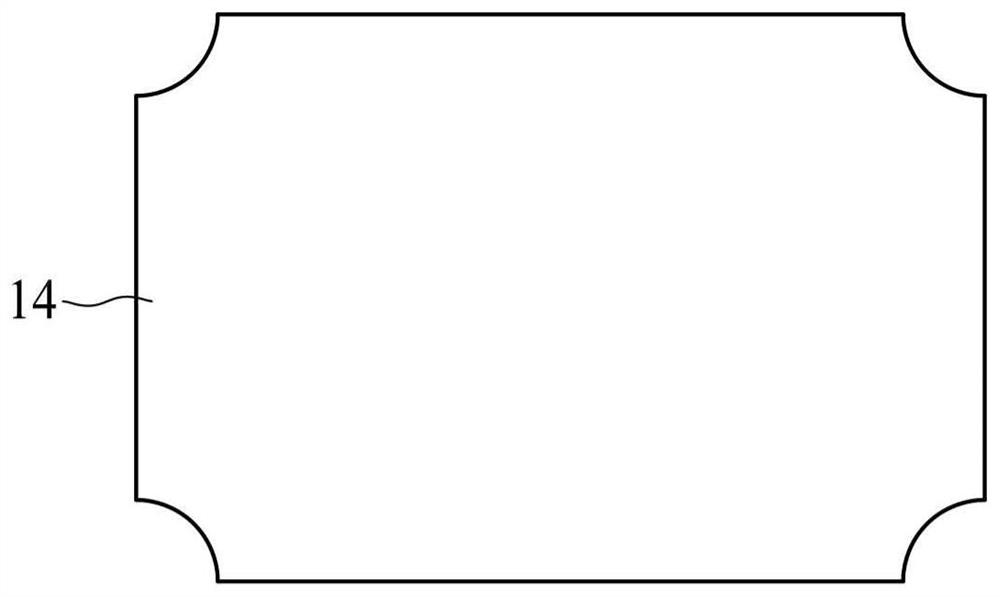

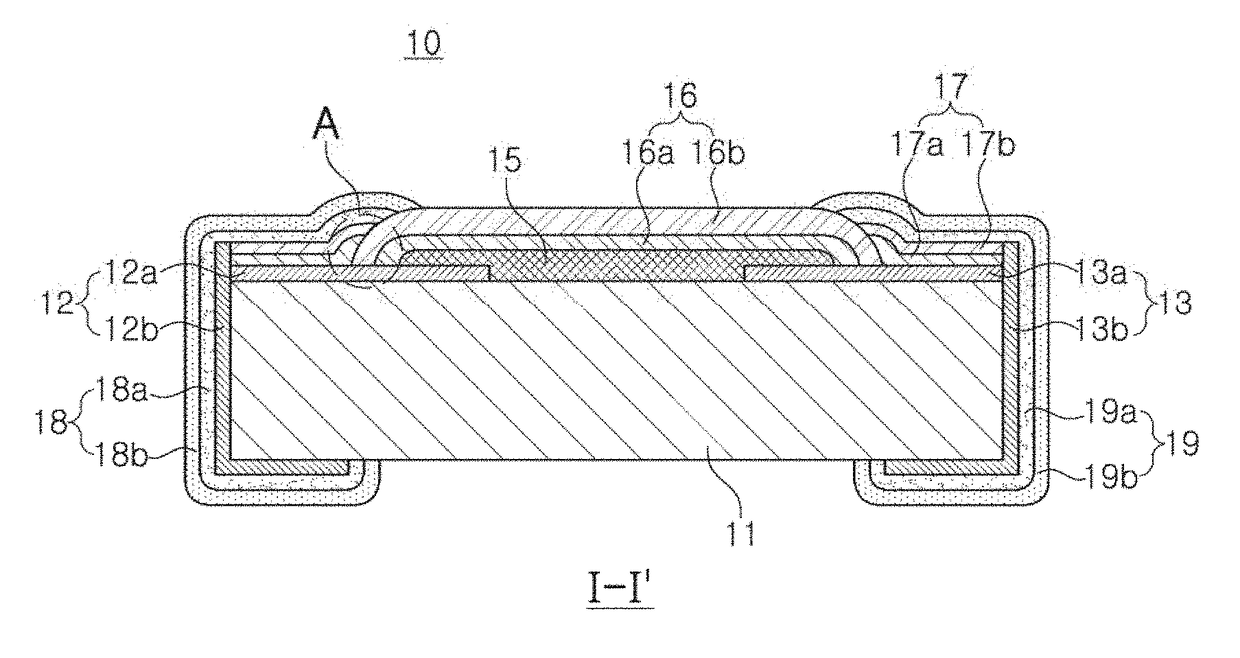

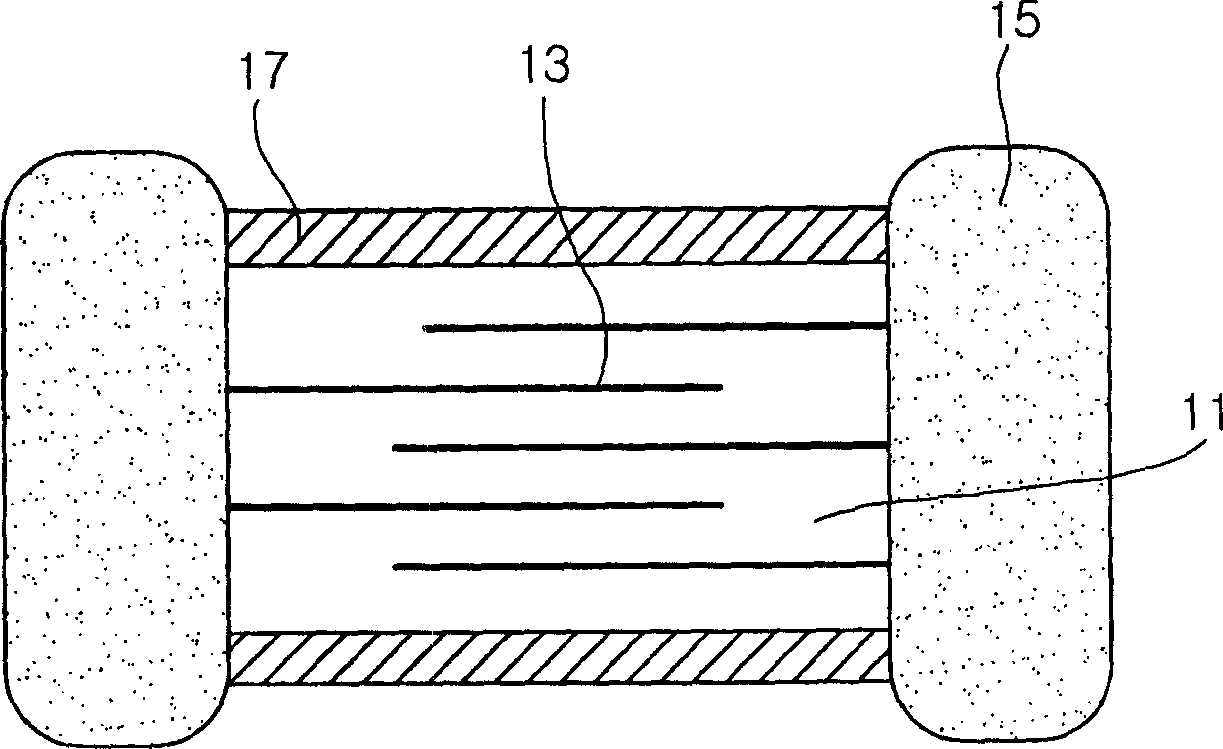

Chip resistor and method for producing same

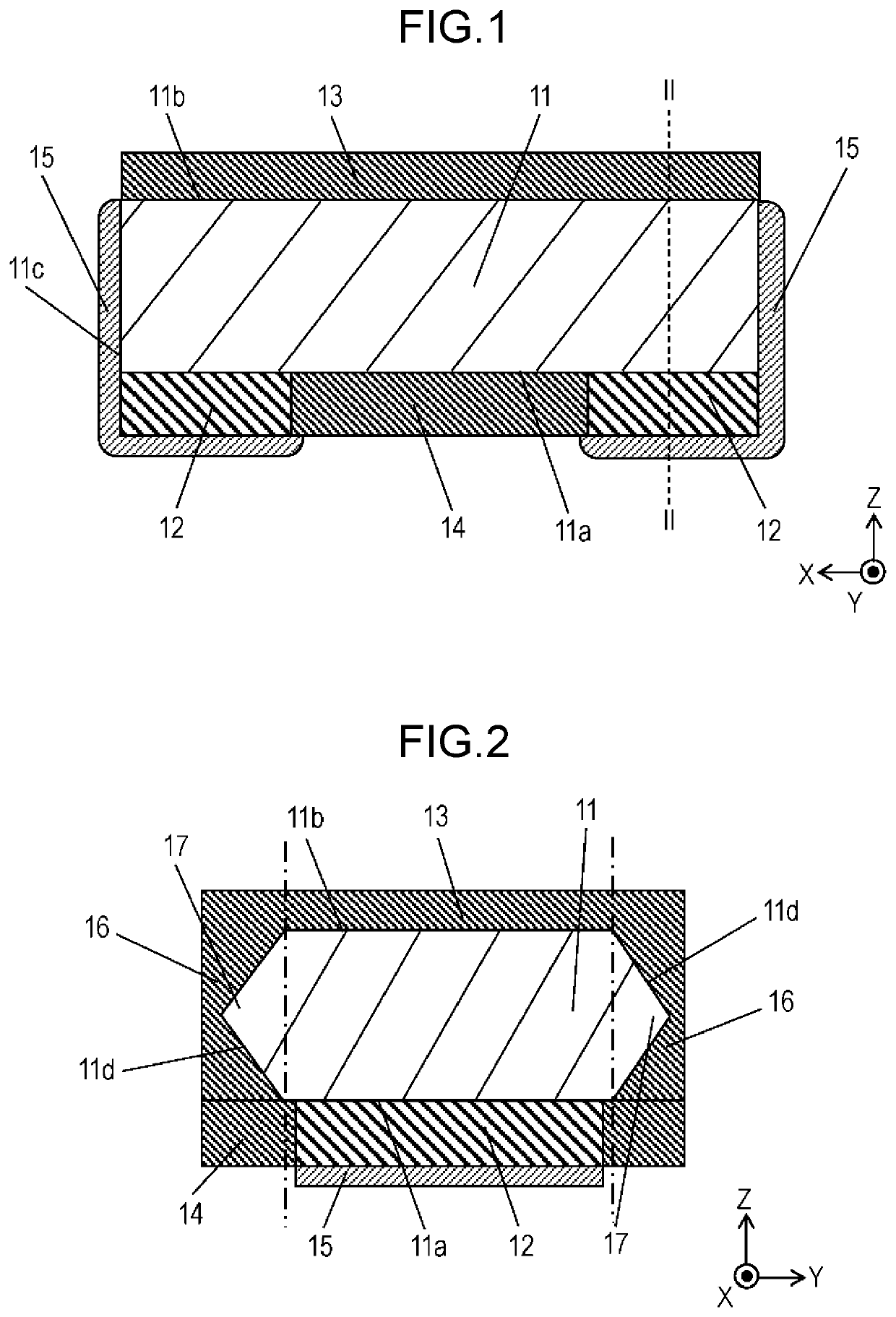

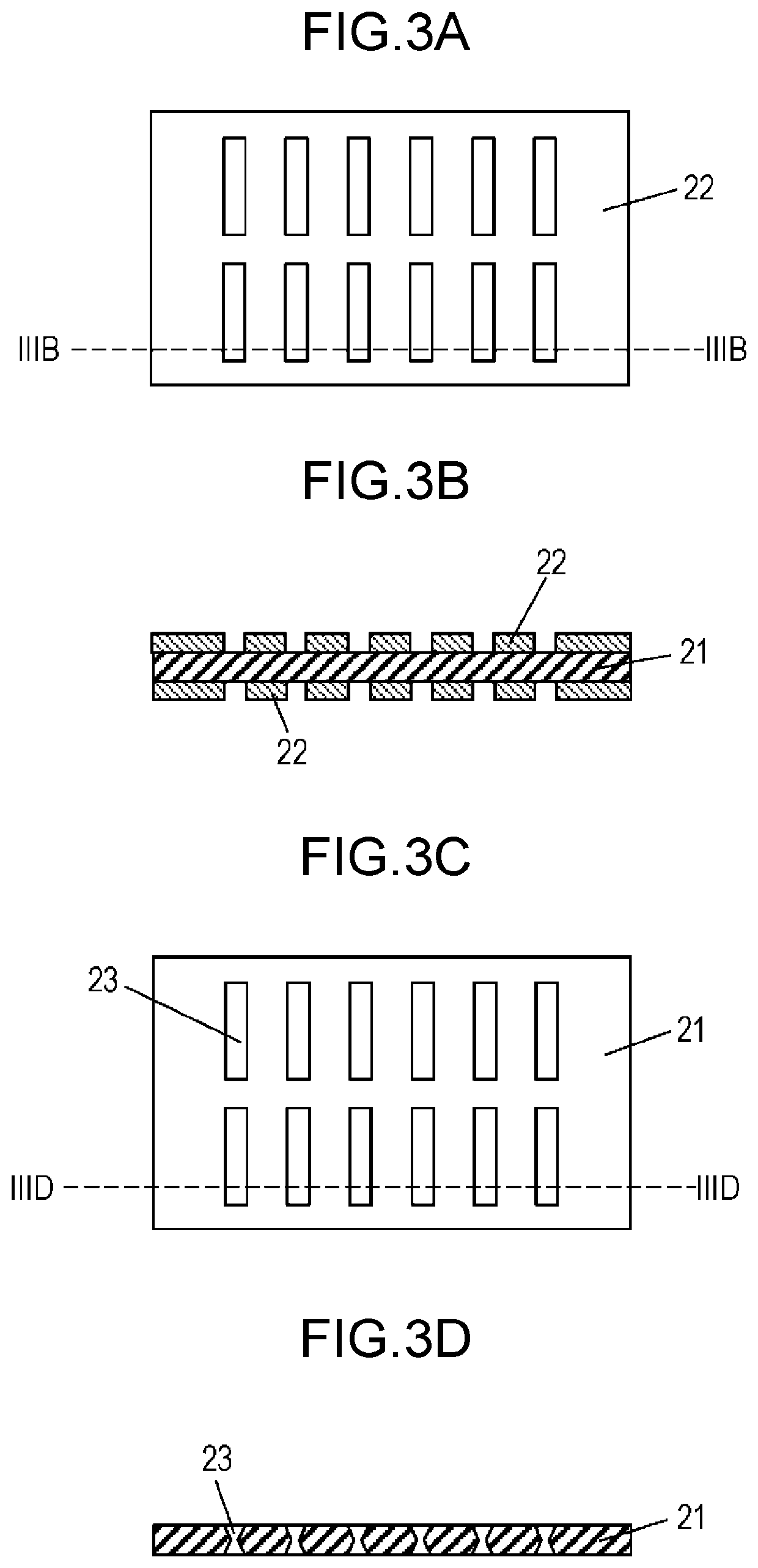

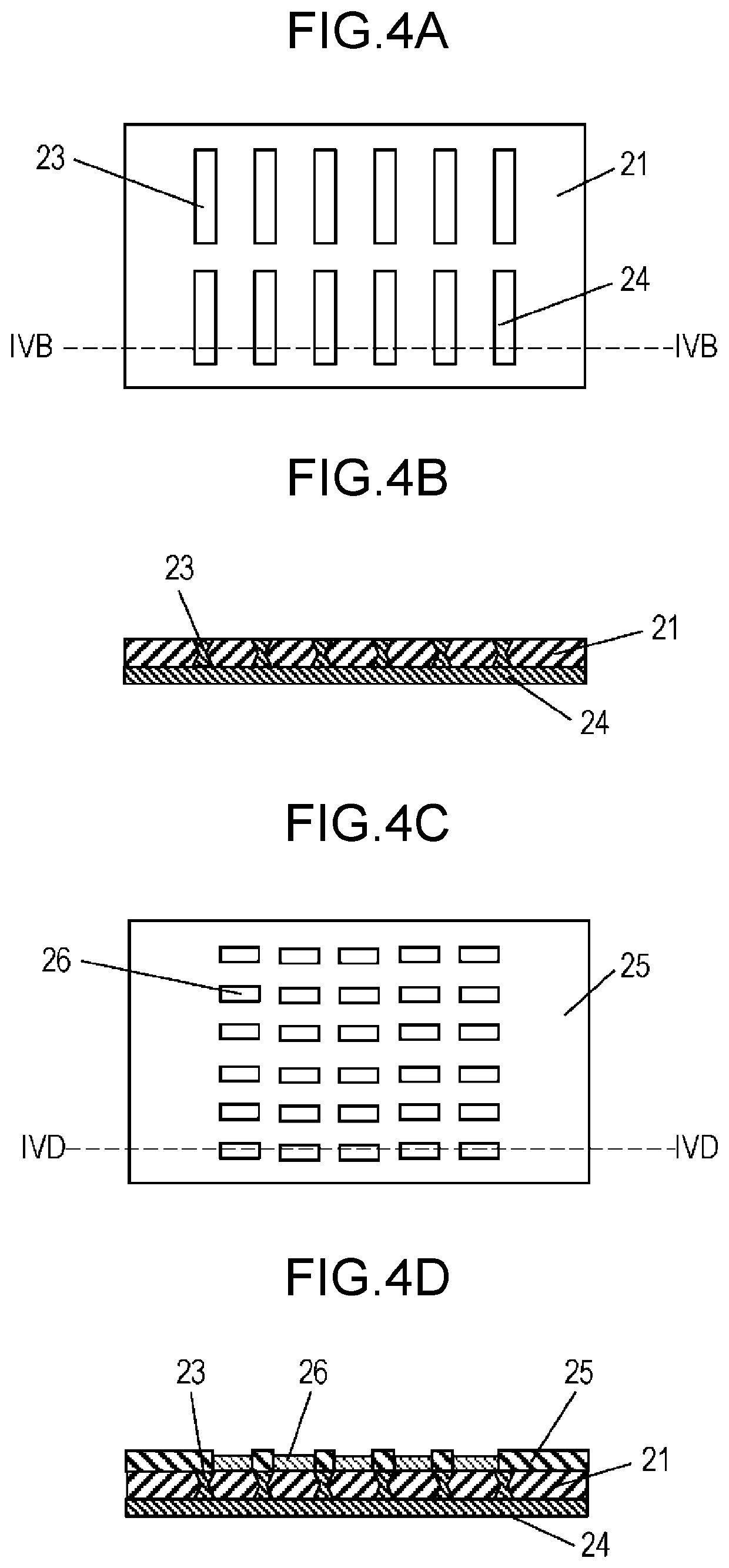

ActiveUS20200051716A1Increase contact areaExcellent effect of maintaining long-term reliabilityResistor chip manufactureMass resistorsElectrical resistance and conductanceElectric current flow

An object of the present disclosure is to provide a chip resistor capable of suppressing degradation of long-term reliability, and a method for producing the chip resistor. The chip resistor of the present disclosure includes resistance member (11) formed of metal, and a pair of electrodes (12) respectively formed on both ends of first main surface (11a) of resistance member (11). The chip resistor further includes first protective film (13) formed on second main surface (11b) located on a rear side of first main surface (11a) of resistance member (11), second protective film (14) formed on first main surface (11a) of resistance member (11) and between the pair of electrodes (12), and a third protective film formed on a side surface parallel to a direction of a current flowing between the pair of electrodes (12) of resistance member (11). The side surface of resistance member (11) is provided with a protrusion that protrudes outward when viewed along the current flowing direction.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

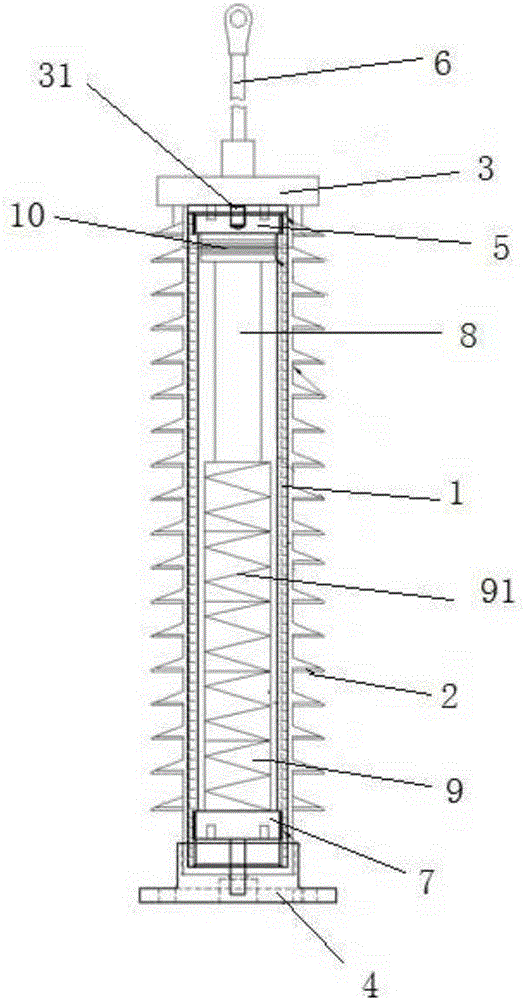

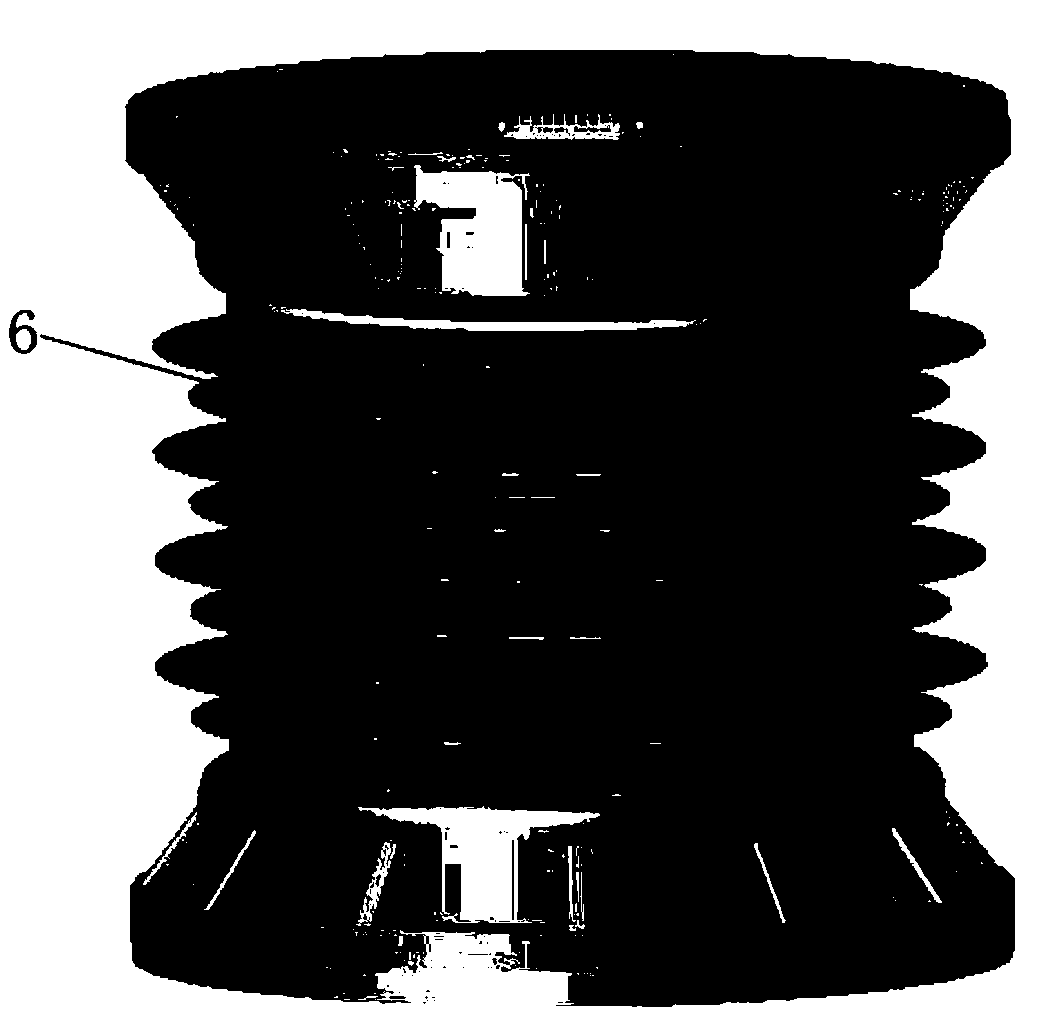

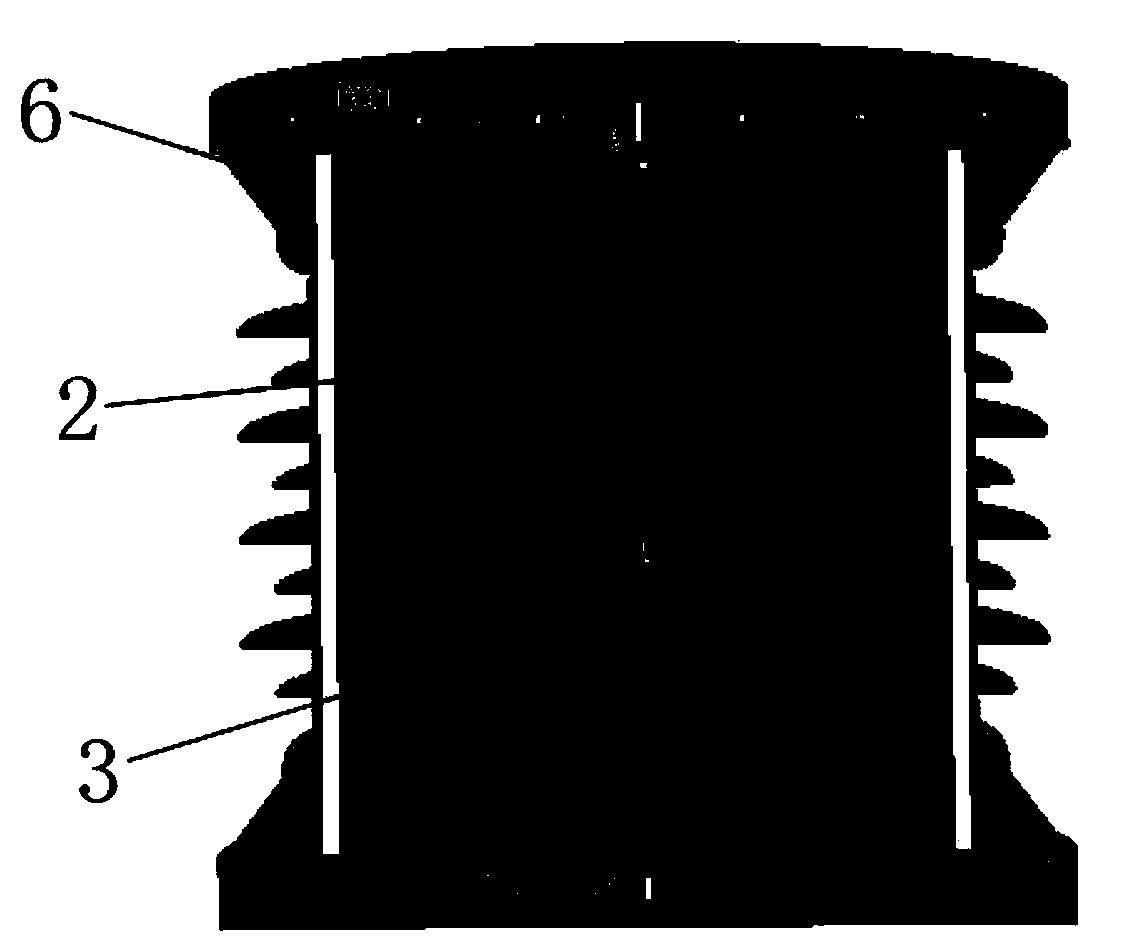

Outdoor alternating-current anti-explosion 35-kV lightning arrester

InactiveCN105825986AWith explosion-proof functionImprove protectionMass resistorsResistor terminals/electrodesEpoxyEngineering

The invention relates to an outdoor alternating-current anti-explosion 35-kV lightning arrester. The lightning arrester comprises a hollow cylindrical epoxy pipe framework and a rubber outer sleeve arranged outside the epoxy pipe framework in a sleeving mode, the upper end of the epoxy pipe framework is provided with a nylon cock cover, and the lower end of the epoxy pipe framework is provided with a metal part; a lightning arrester core is arranged in the middle of the epoxy pipe framework, the inner side of the nylon cock cover is provided with an upper electrode connected with the lightning arrester core, the outer side of the nylon cock cover is provided with a cable connected with the upper electrode, and the inner side of the metal part is provided with a lower electrode connected with the lightning arrester core. The outdoor alternating-current anti-explosion 35-kV lightning arrester is small in size and weight, easy and convenient to install, good in protecting performance and high in mechanical strength; by adopting the composite insulated outer sleeve and a high-voltage cable outer-introduced structure, the product is high in sealing property, large in creepage distance and capable of being used in high-altitude and heavy-pollution areas; meanwhile, the lightning arrester has the anti-explosion function, and when the lightning arrester is damaged by any reasons, a disconnector can effectively avoid short-circuit accidents caused by lightning arrester explosion.

Owner:ANHUI SHANGTU ELECTRIC PROTECTION EQUIP CO LTD

Device and method for manufacturing the same

ActiveUS7537963B2Small dimensionResistor chip manufactureMass resistorsConductive materialsEngineering

Owner:SENSOTHERM TEMPERATURSENSORIK

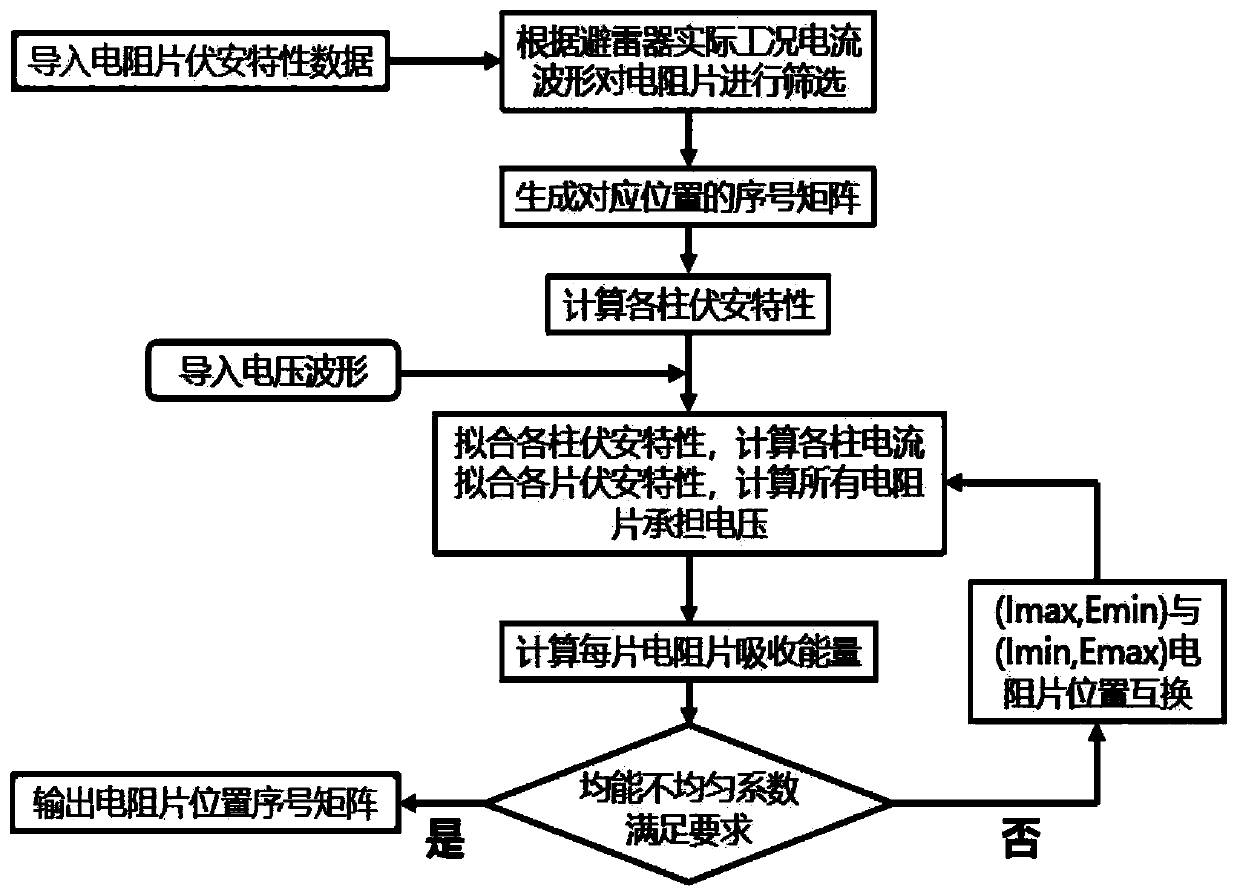

Zinc oxide resistor disc energy equalization matching method

ActiveCN111508674AReduce the difference in volt-ampere characteristicsImprove protectionMass resistorsResistor manufactureElectrical resistance and conductanceElectric power system

The invention belongs to the technical field of power systems, and particularly relates to a zinc oxide resistor disc energy equalization matching method, which comprises the processes of zinc oxide valve disc static volt-ampere characteristic normal distribution characteristic construction, zinc oxide valve disc energy distribution characteristic construction and zinc oxide valve disc energy equalization matching based on a normal distribution rule. Firstly, a zinc oxide valve plate static volt-ampere characteristic normal distribution rule is provided; secondly, a zinc oxide valve plate energy equalization principle is provided; and finally, a zinc oxide valve plate energy equalization matching method based on the normal distribution rule is proposed. The resistor disc with the maximum energy absorption difference in two lightning arresters with the maximum energy absorption difference are exchanged; multiple iteration is carried out; the current non-uniform coefficient of each lightning arrester column of the lightning arrester group is minimal, uniform energy distribution is realized, the current non-uniform coefficient of the lightning arrester group can be effectively reduced, parallel energy equalization of multi-column zinc oxide lightning arresters can be achieved, and the operation reliability of the lightning arrester group is improved.

Owner:厦门中高智能电器科学研究院有限公司 +1

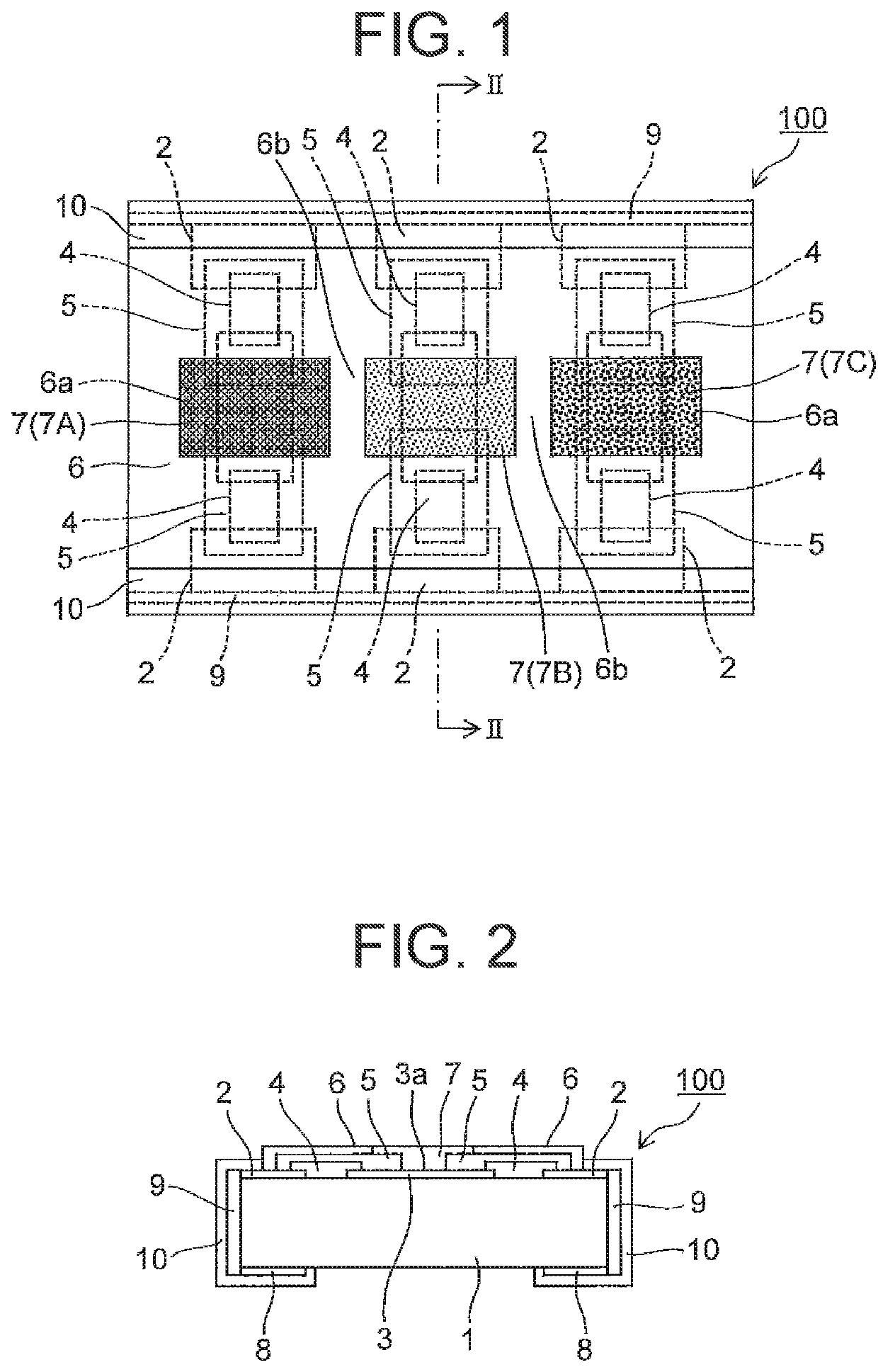

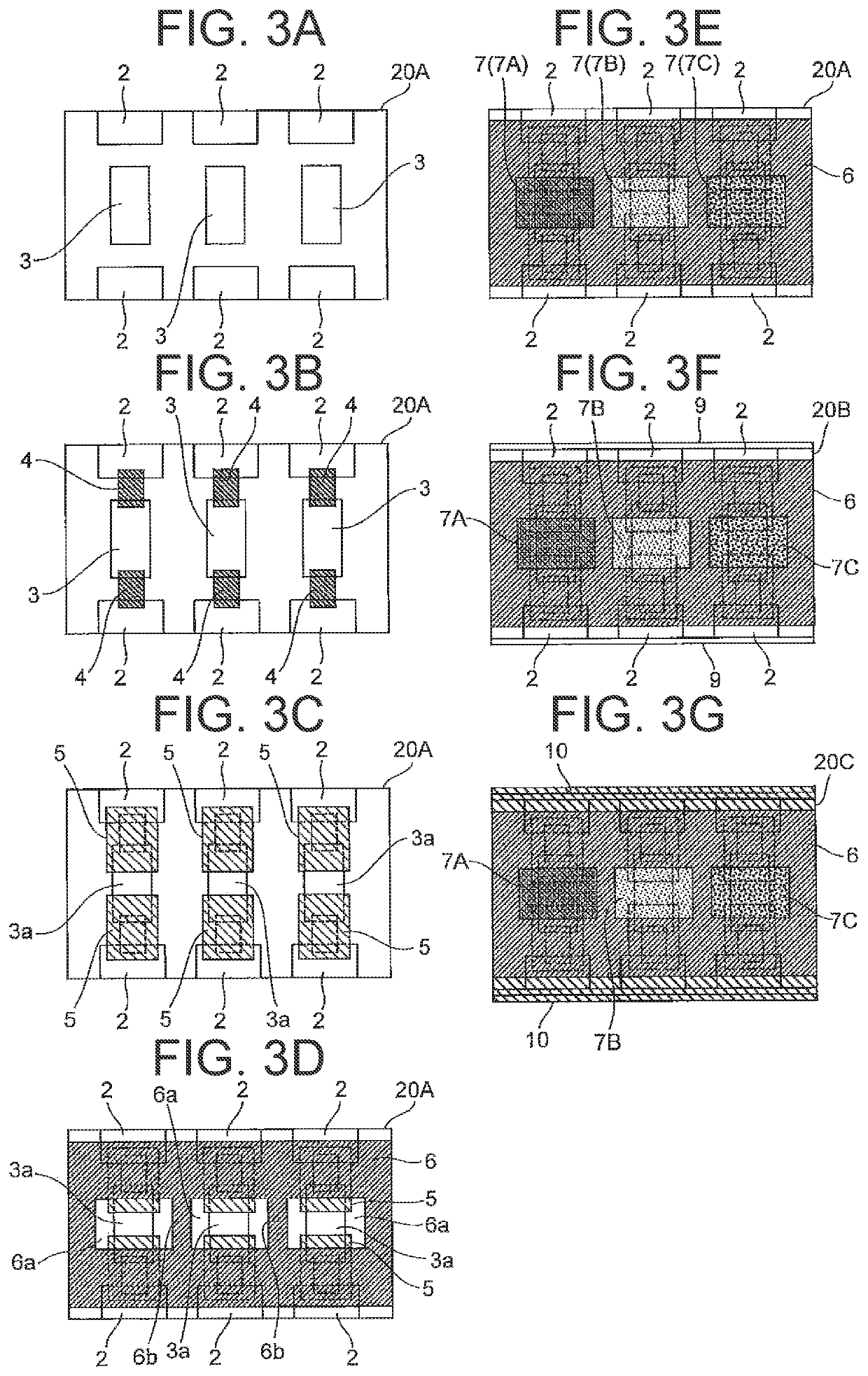

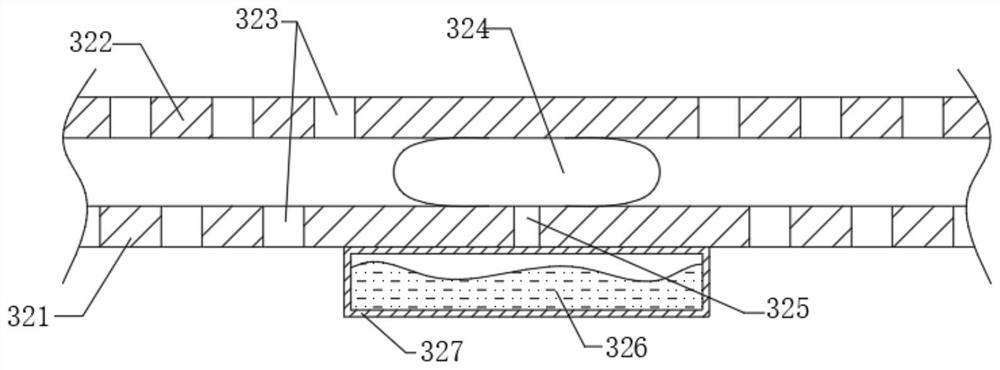

Sulfurization detection resistor

ActiveUS11506594B2High-precision detectionMass resistorsWeather/light/corrosion resistanceElectrical conductorAcrylic resin

A sulfurization detection resistor includes: a rectangle-shaped insulating substrate; pair of front electrodes formed at both ends facing each other on a surface of the insulating substrate; plurality of sulfurization detection conductors arranged in parallel between the paired front electrodes; plurality of resistors connected between the ends of each of the sulfurization detection conductors and the paired front electrodes; and sulfide gas impermeable protective film that covers all of the resistors and some of the sulfurization detection conductors, wherein each of the sulfurization detection conductors has a sulfurization detection unit exposed from a window hole in the protective film; and by covering the sulfurization detection units with different types of sulfurization rate adjustment layers formed of an acrylic resin, a silicon resin, and the like, timing of disconnection is set so as to vary in response to a cumulative amount of sulfurization in each of the sulfurization detection units.

Owner:KOA CORP

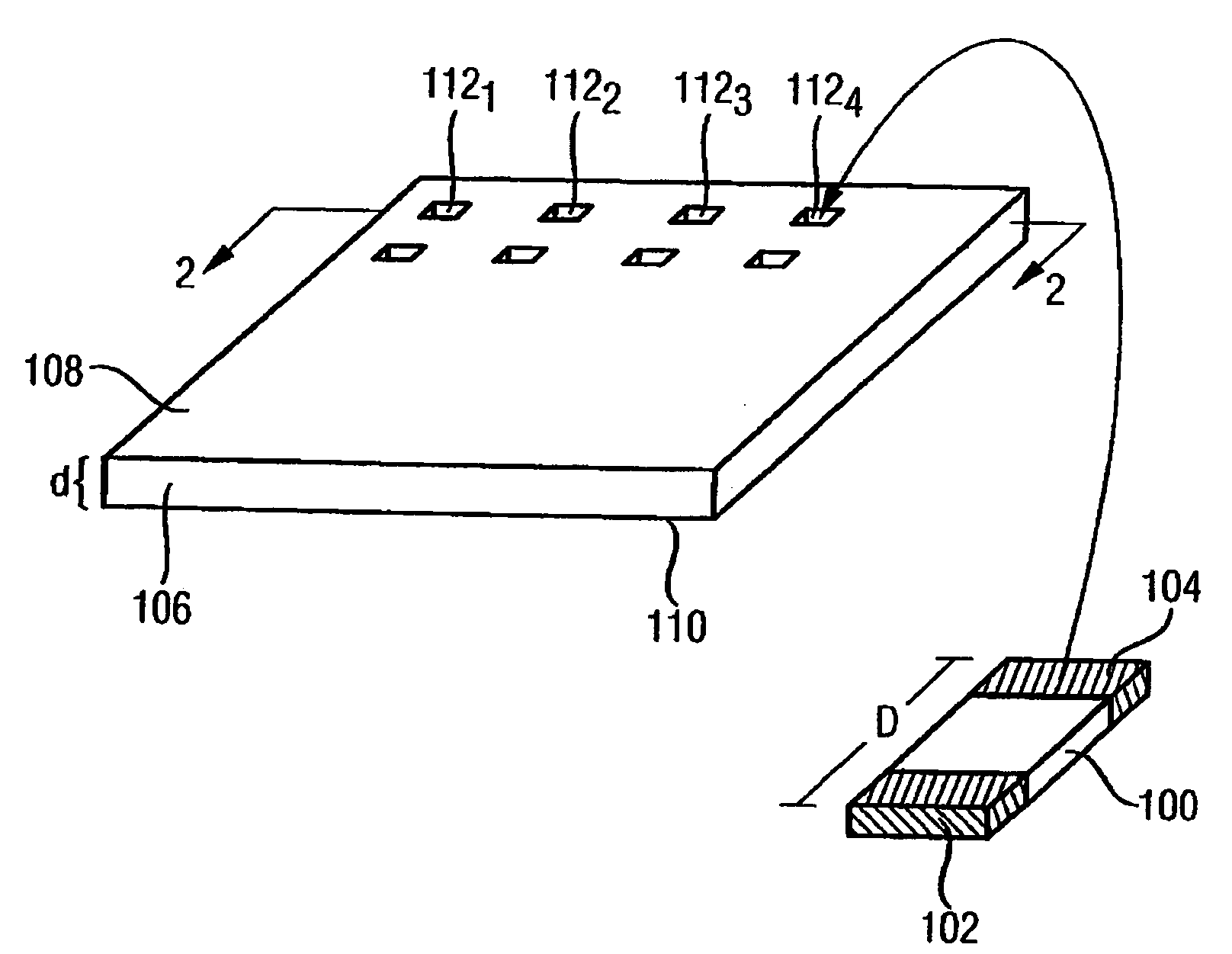

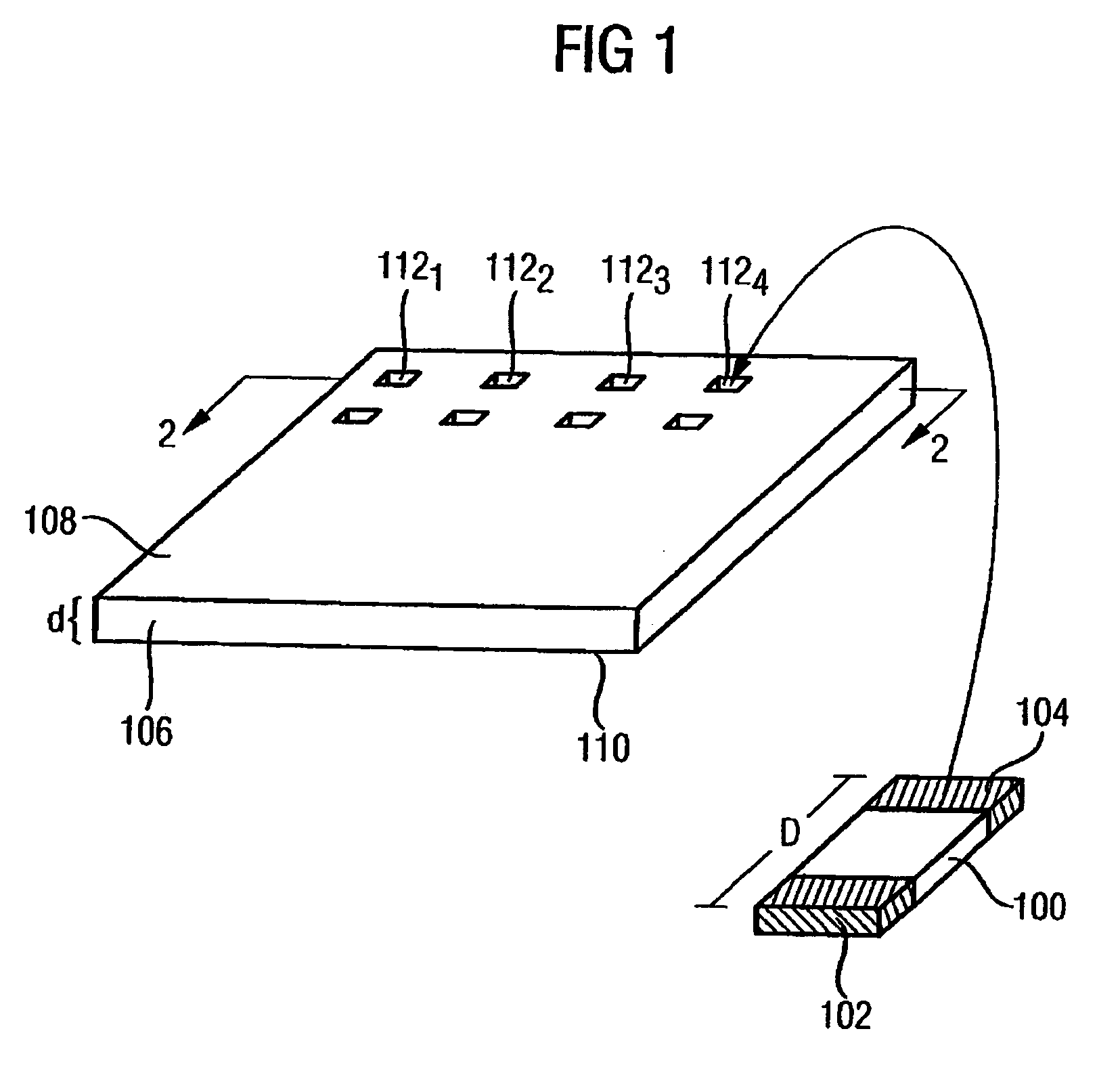

Substrate for forming passive elements in chip type

InactiveUS20070196051A1Resistor chip manufactureMass resistorsEngineeringElectrical and Electronics engineering

A substrate for forming passive elements in chip type has a top surface, a thickness, multiple parallel grooves, multiple through holes and multiple chip regions. The parallel grooves are formed on the top surface of the substrate. The through holes are formed between and across two adjacent parallel grooves, and each through hole is separated from other through holes and has smooth inner walls. The chip regions are defined between adjacent through holes and parallel grooves and are arranged in a matrix.

Owner:WALSIN TECHNOLOGY CORPORATION

Overcurrent protection element

ActiveCN111696738AImprove structural strengthOther resistor networksMass resistorsOvercurrentStructural engineering

An overcurrent protection element has a hexahedral structure including upper and lower surfaces and four side surfaces. The overcurrent protection element comprises a PTC element, a first insulating layer, a first electrode layer and a second electrode layer. The PTC element comprises a first conductive layer, a second conductive layer and a PTC material layer. The first conducting layer is arranged on the first surface of the PTC material layer, the second conducting layer is arranged on the second surface of the PTC material layer, and the second surface is located on the opposite side of the first surface. The first conductive layer is separated into a first conductive block and a second conductive block by at least one interval. The first insulating layer is arranged on the surface ofthe first conductive layer. The first electrode layer is arranged on the surface of the first insulating layer and is electrically connected with the first conductive block. The second electrode layeris arranged on the surface of the first insulating layer and is electrically connected with the second conductive block. The gap includes a major portion that is not parallel to a longitudinal direction of the first electrode layer and the second electrode layer.

Owner:POLYTRONICS TECH

Chip resistor element

ActiveUS10104776B2Improve the plating effectStrong adhesionPrinted circuit assemblingResistor chip manufactureEngineeringProtection layer

A chip resistor element includes an insulating substrate, a resistor layer, first and second internal electrodes, a resistor protection layer, first and second electrode protection layers, and first and second external electrodes. The resistor layer is on the insulating substrate, the first and second internal electrodes are on respective sides of the resistor layer, and the resistor protection layer covers the resistor layer and extends onto portions of the internal electrodes. The first electrode protection layers are on the first and second internal electrodes so as to overlap with portions of the resistor protection layer and contain first conductive powder particles and resin, while the second electrode protection layers are disposed on the first electrode protection layers and contain second conductive powder particles and resin. A content of resin in the second electrode protection layer is lower than in the first electrode protection layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

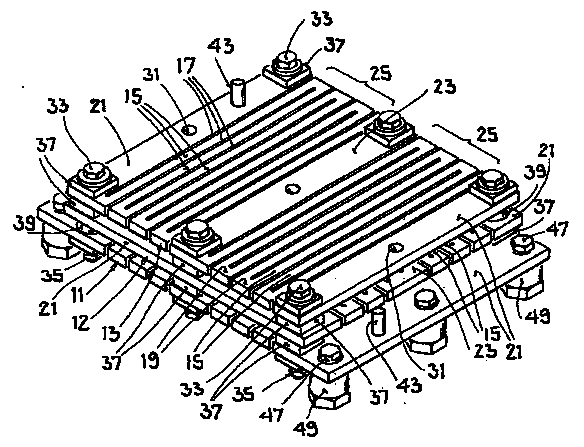

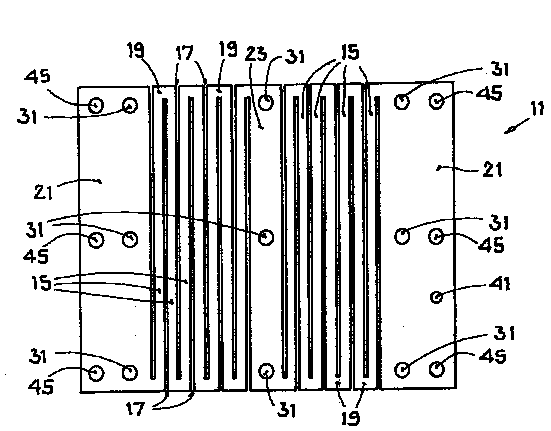

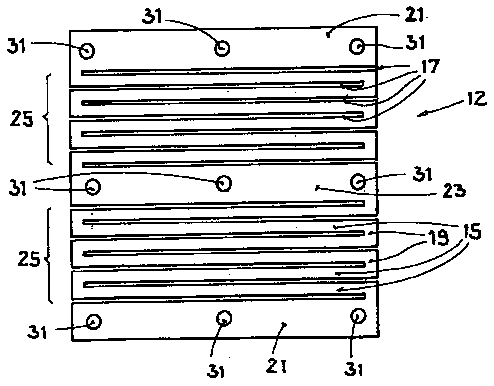

Electrical power resistor

ActiveCN103262181AReduce manufacturing costMass resistorsResistor detailsResistorElectrical and Electronics engineering

The invention relates to an electrical power resistor, comprising a stack of a plurality of resistor plates made of metal. Each resistor plate has at least one serpentine structure which is formed by a plurality of crosspieces alternately connected to one another. Successive resistor plates in the stacking direction are rotated by 90 DEG relative to one another.

Owner:VISHAY ELECTRONICS

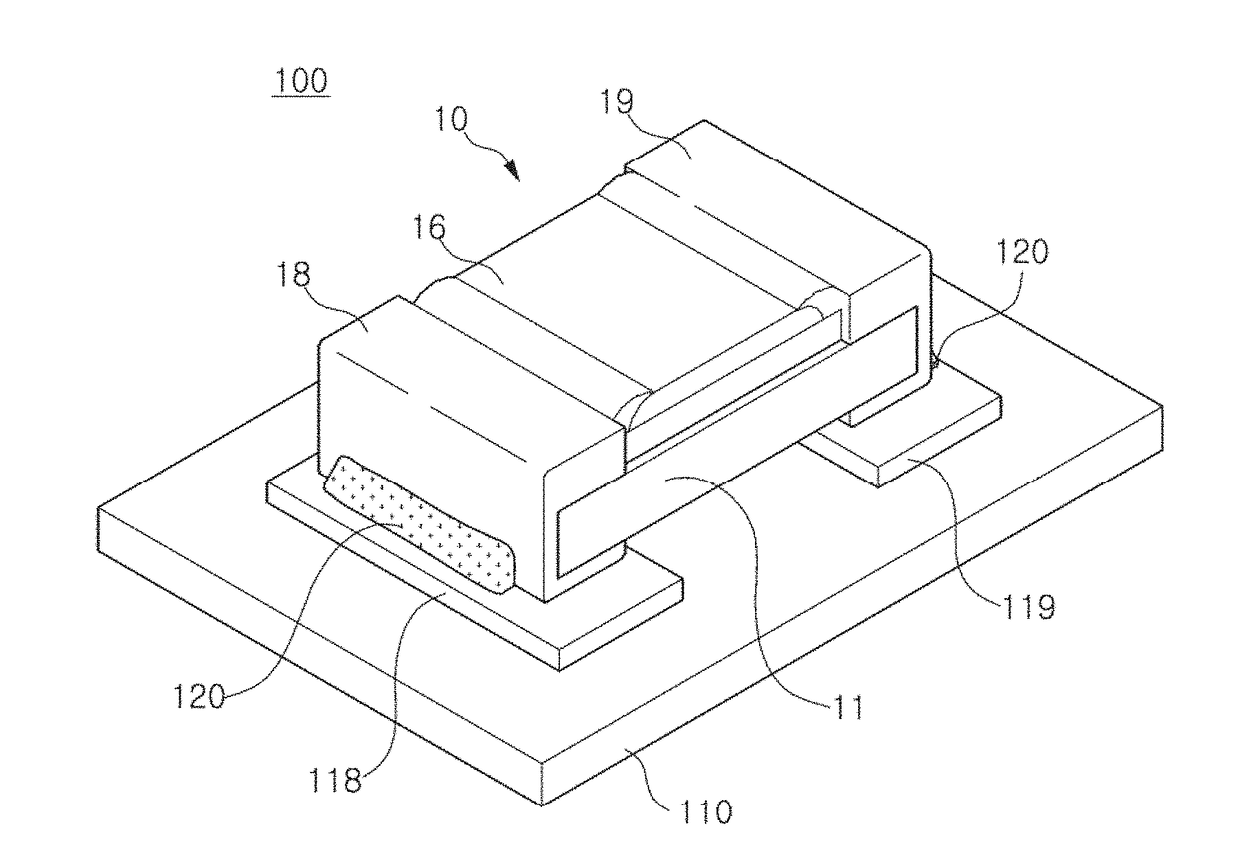

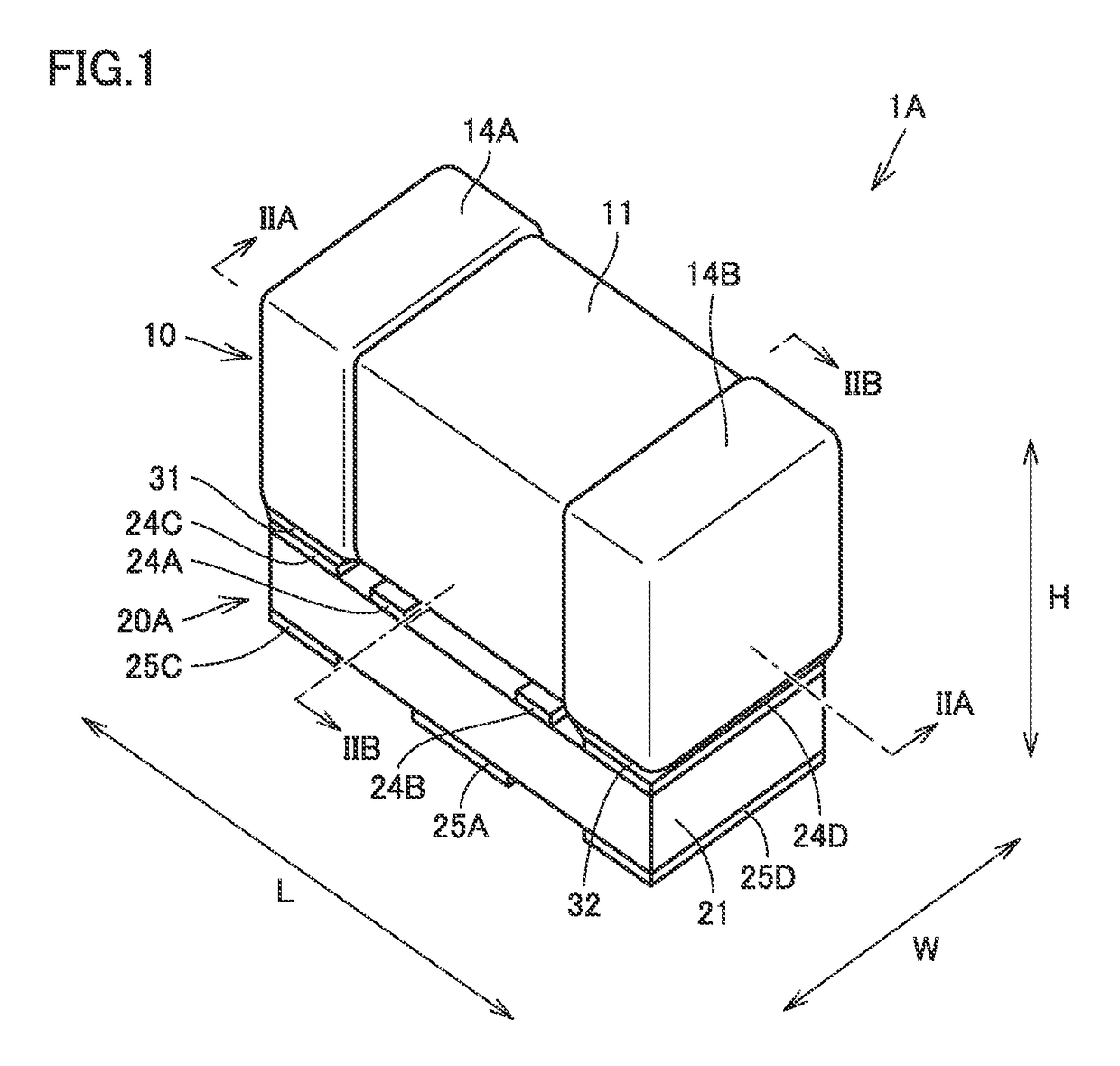

Chip resistor and mounting structure thereof

InactiveCN113571273AChange the size of the resistorThe temperature of the working environment is stableMass resistorsResistor terminals/electrodesElectrical resistance and conductanceStructural engineering

The invention discloses a chip resistor and a mounting structure thereof. The chip resistor comprises a resistor main body, wherein a first electrode and a second electrode are arranged on the outer walls of the two ends of the resistor body respectively, connecting boxes are arranged on the outer walls of one ends of the first electrode and the second electrode, mounting grooves are formed in the connecting boxes, an insertion box is fixedly connected to one side of each connecting box, a rotating shaft is rotatably connected to the top of the mounting groove, a knob is arranged at the top of the rotating shaft, a second bevel gear is fixedly connected to the outer wall of the bottom of the rotating shaft, a first bevel gear is meshed with one side of the second bevel gear, a first threaded rod is fixedly connected to the outer wall of one side of the first bevel gear, and the first threaded rod is rotatably connected to the joint of the connecting box and the insertion box. By arranging the insertion box, an arc-shaped reed, a clamping column, a half gear, the threaded rod I, the clamping groove, the clamping groove and the arc-shaped reed clamping groove, a plurality of resistor main bodies can be connected in series, and the resistance of the resistor can be changed, so that the application range of the resistor is greatly widened.

Owner:南京翰洋电子有限公司

Sulfurization detection resistor

ActiveUS20210199562A1High precisionIncrease variation timingMass resistorsWeather/light/corrosion resistanceElectrical conductorAcrylic resin

A sulfurization detection resistor includes: a rectangle-shaped insulating substrate; pair of front electrodes formed at both ends facing each other on a surface of the insulating substrate; plurality of sulfurization detection conductors arranged in parallel between the paired front electrodes; plurality of resistors connected between the ends of each of the sulfurization detection conductors and the paired front electrodes; and sulfide gas impermeable protective film that covers all of the resistors and some of the sulfurization detection conductors, wherein each of the sulfurization detection conductors has a sulfurization detection unit exposed from a window hole in the protective film; and by covering the sulfurization detection units with different types of sulfurization rate adjustment layers formed of an acrylic resin, a silicon resin, and the like, timing of disconnection is set so as to vary in response to a cumulative amount of sulfurization in each of the sulfurization detection units.

Owner:KOA CORP

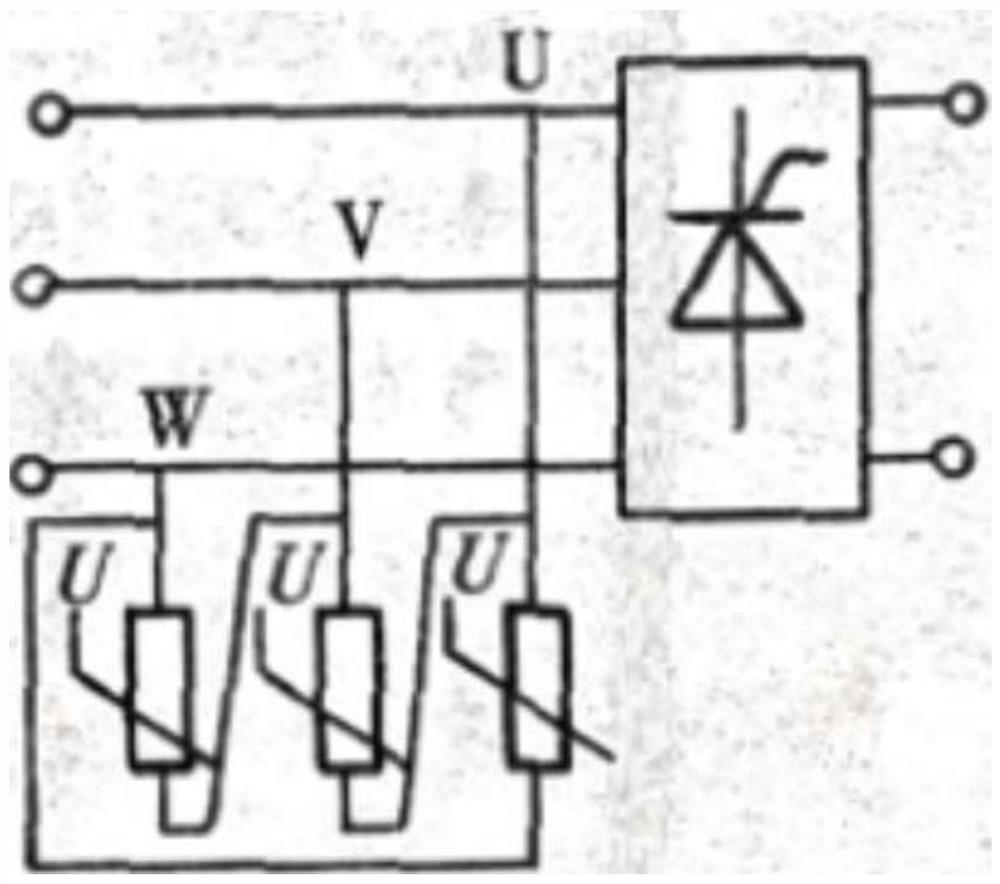

High-voltage fuse type DC lightning arrester

InactiveCN108766693ASolve the problem of characteristic failure breakdownMeet application needsMass resistorsOvervoltage protection resistorsHigh pressureZinc

The invention relates to a high-voltage fuse type DC lightning arrester, which comprises a single-column fuse type DC lightning arrester, wherein the single-column fuse type DC lightning arrester comprises a zinc oxide valve piece unit and a fuse, which are connected in series; and the zinc oxide valve piece unit and the fuse are packaged through an epoxy tube to form the single-column fuse type DC lightning arrester. A plurality of single-column fuse type DC lightning arresters are packaged in parallel to form a single lightning arrester; and a plurality of single lightning arresters are connected in parallel to form a lightning arrester group. The fuse type DC lightning arrester group of the invention adopts a multi-column multi-branch parallel operation scheme; the fuse of the faulty column can be automatically blown before the single-column fuse-type DC lightning arrester is broken down due to characteristic failure and the structure is not damaged; when being broken down due to failure, the single-column fuse type DC lightning arrester is automatically blown and isolated from the whole set of lightning arresters; the remaining DC lightning arrester group can continue to operate, thereby ensuring that the DC system is not shut and improving the reliability of the DC transmission system.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST +1

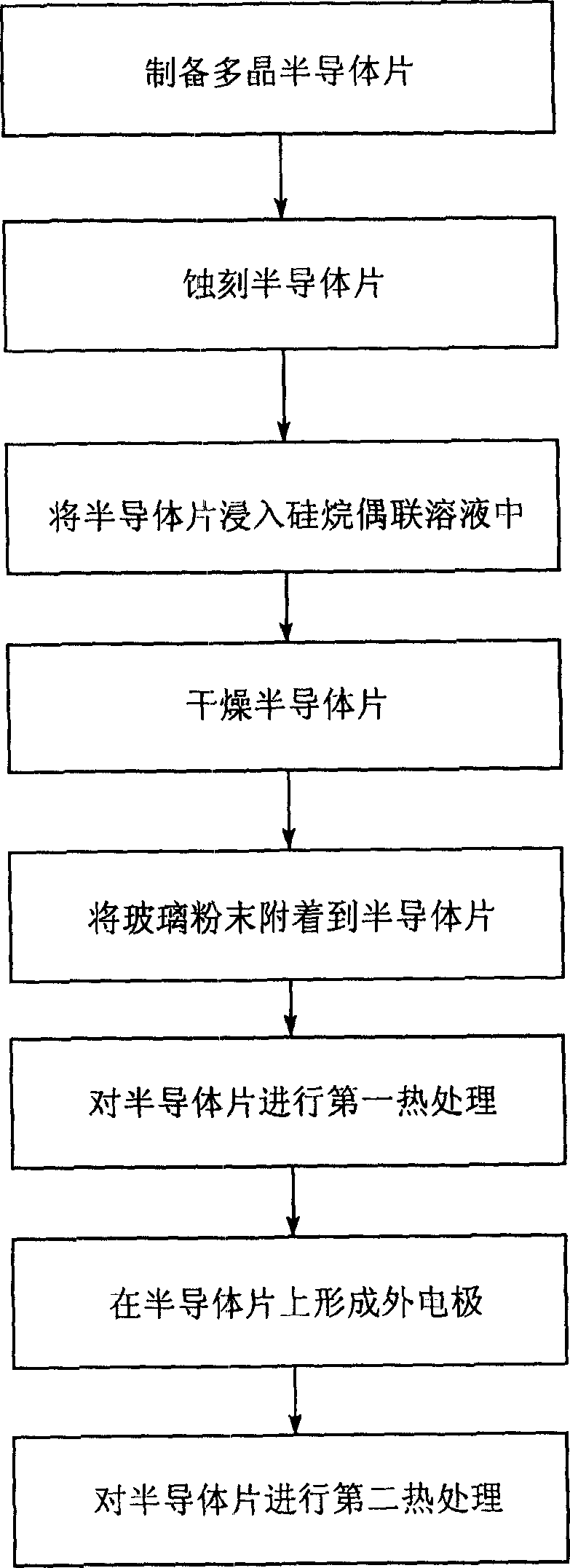

Semiconductive chip device having insulating coating layer and method of manufacturing the same

InactiveCN1822249ASimple preparation processGood reproducibilityMass resistorsEnvelope/housing resistor manufactureFused glassHeat treating

Disclosed herein is a semiconductive chip device having an insulating coating layer, which includes a multi-crystalline semiconductive chip requiring surface insulation properties, outer electrodes formed at both ends of the semiconductive chip, and an insulating coating layer formed by fusing glass powder to a silane coupling agent on the surface of the semiconductive chip. In addition, a method of manufacturing the semiconductive chip device having an insulating coating layer is provided, which comprises: preparing a multi-crystalline semiconductive chip requiring surface insulation properties, and etching the multi-crystalline semiconductive chip; dipping the etched semiconductive chip into a silane coupling solution, and removing the aqueous component from the solution attached to the surface of the semiconductive chip; attaching glass powder to the surface of the semiconductive chip having no aqueous component, and primarily heat treating the semiconductive chip; and forming outer electrodes on the primarily heat treated semiconductive chip, and, secondarily heat treating the semiconductive chip, thereby forming the insulating coating layer on the surface of the semiconductive chip.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

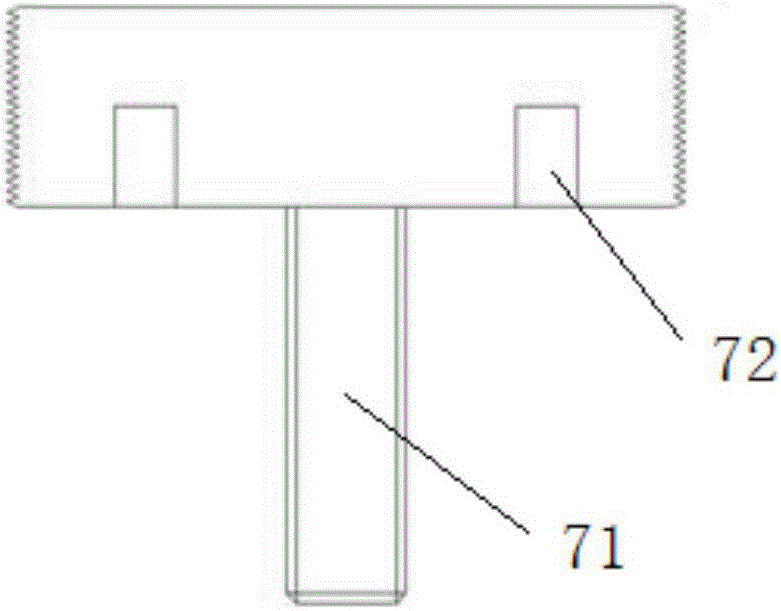

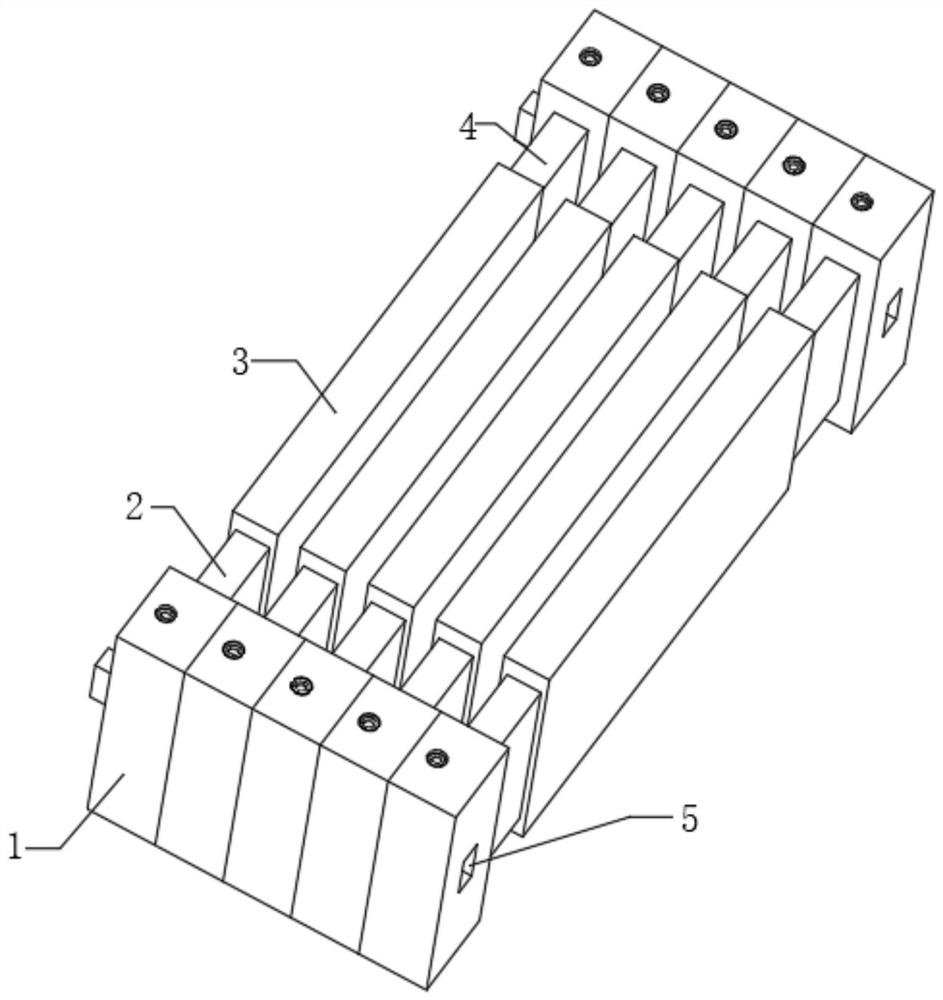

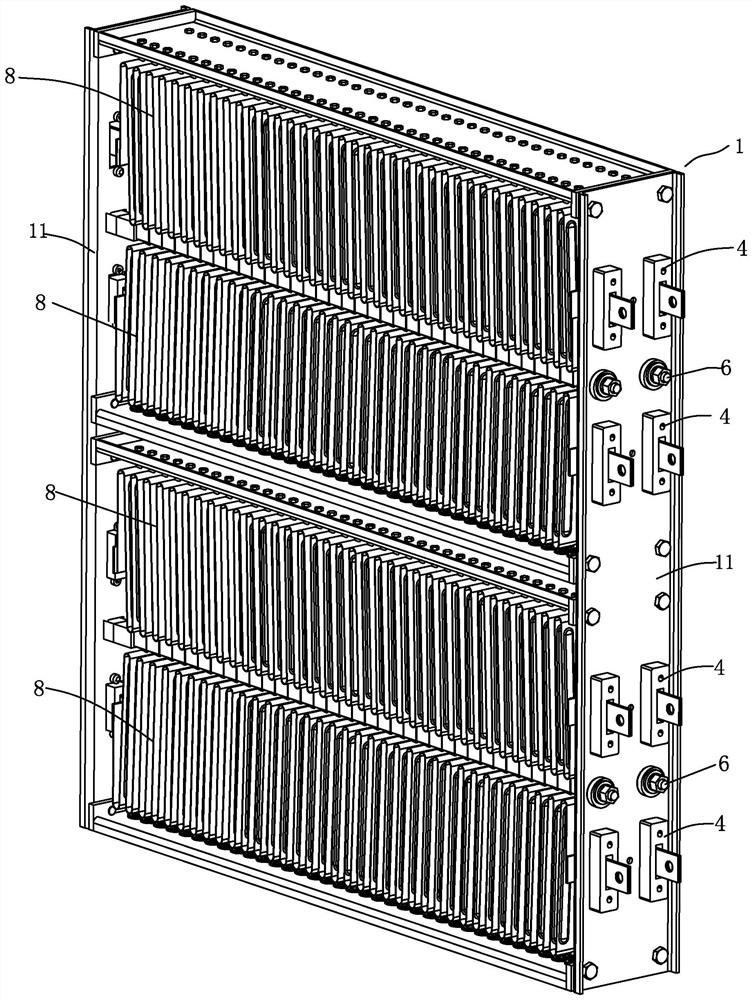

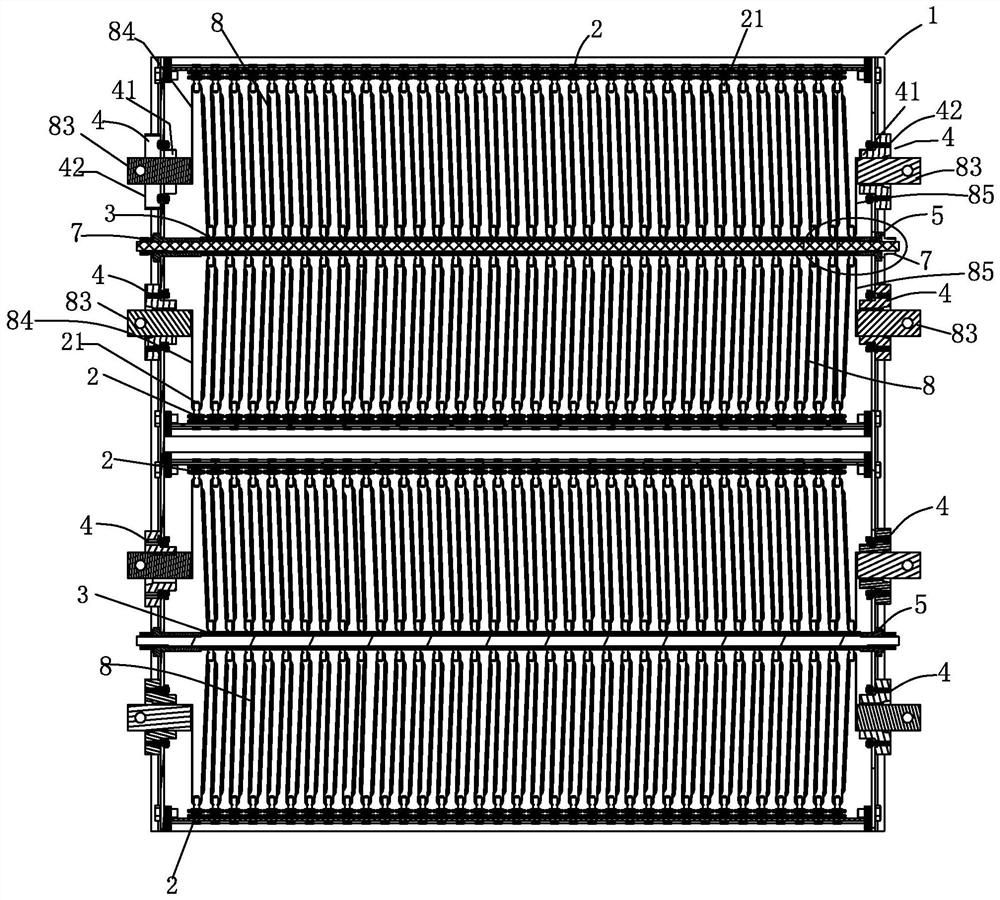

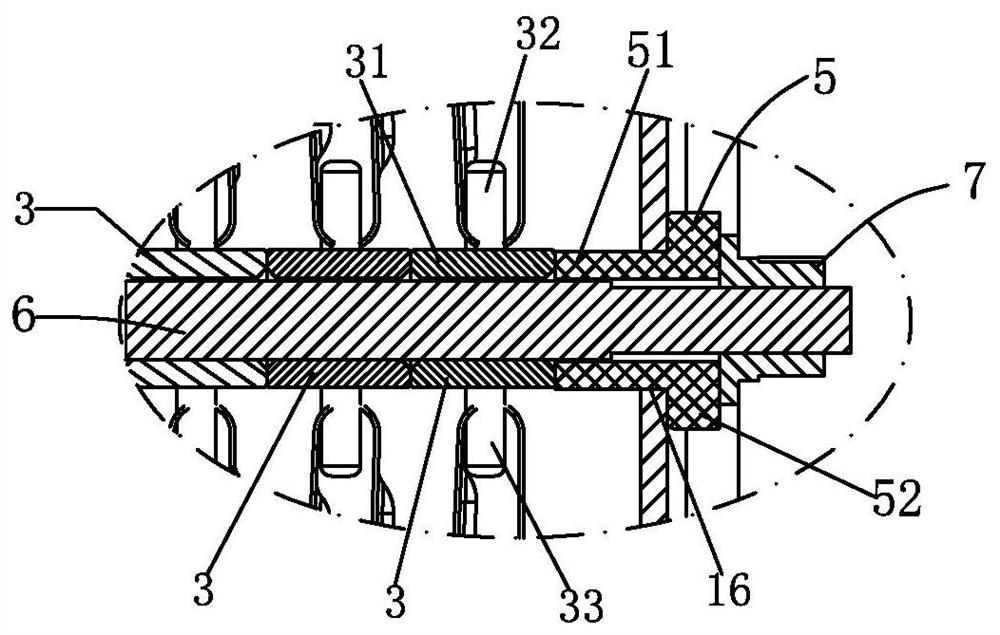

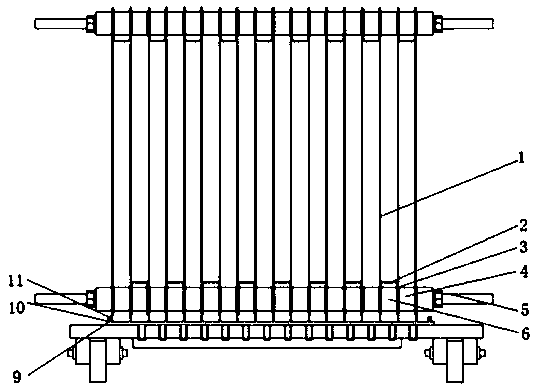

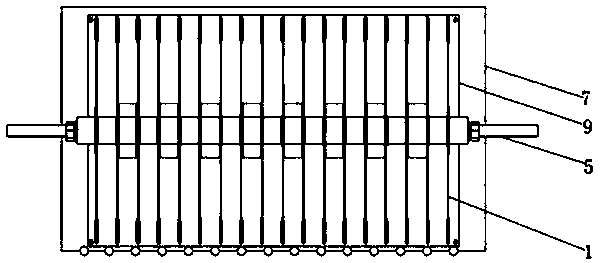

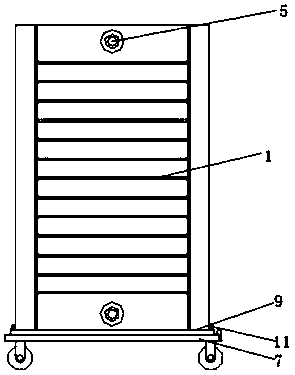

Resistor with resistor monomers capable of being connected in series or in parallel

PendingCN112086251AReduce volumeImprove cooling effectMass resistorsResistor terminals/electrodesEngineeringMechanical engineering

The invention relates to a resistor with resistor monomers capable of being connected in series or in parallel, and the resistor comprises a square frame-shaped seat frame, an insulating seat, a middle insulating seat, a terminal insulating seat, an insulating connecting seat, a square connecting rod with screw rods at two ends, a nut and a plurality of resistor monomers, wherein a resistor groupis disposed between a top transverse frame plate and the square connecting rod; the pin columns of the insulating seats on the top transverse frame plate are inserted into the wave crest holes of theresistor single bodies, and the upper pin bodies of the middle insulating seats are inserted into the wave trough holes; the other resistor group is arranged between the square connecting rod and thebottom transverse frame plate, the lower pin body is inserted into the trough hole of the resistor monomer, and the pin body of the insulating seat on the bottom transverse frame plate is inserted into the crest hole; a terminal plate of the resistor monomer extends out of a terminal plate hole of the terminal insulating seat; and the resistor monomers are distributed in rows and columns. Due to the adoption of the structure, the resistor single bodies adopt the distribution mode, the size is reduced, and the resistor single bodies are formed by bending the battens, so the heat dissipation performance is good; one row of resistor monomers can be connected in parallel, and the same column of resistor monomers can be connected in series.

Owner:山东大通电阻器科技有限公司

Improved alloy resistor

ActiveCN110690017AEasy to installImprove portabilityMass resistorsResistor mounting/supportingElectrical resistance and conductanceEngineering

The invention relates to the field of resistance devices, and discloses an improved alloy resistor, which achieves installation and fixation of a plurality of resistor discs through mutual cooperativeuse of a U-shaped conductive sheet, a mica gasket, a porcelain piece I, a screw rod and a porcelain piece II, and solves the defects of time and labor waste due to adoption of iron sheet welding in atraditional connection mode. Europium-doped silane mica is adopted in the europium-doped silane mica modified resistor disc to facilitate dispersion of various components, improve the microstructureof the resistor discs and prolong the service life of the resistor discs under a high current. The improved alloy resistor disclosed in the invention is convenient to install, good in portability, simple to operate, low in production cost and convenient to popularize and use.

Owner:浦江召日电器有限公司

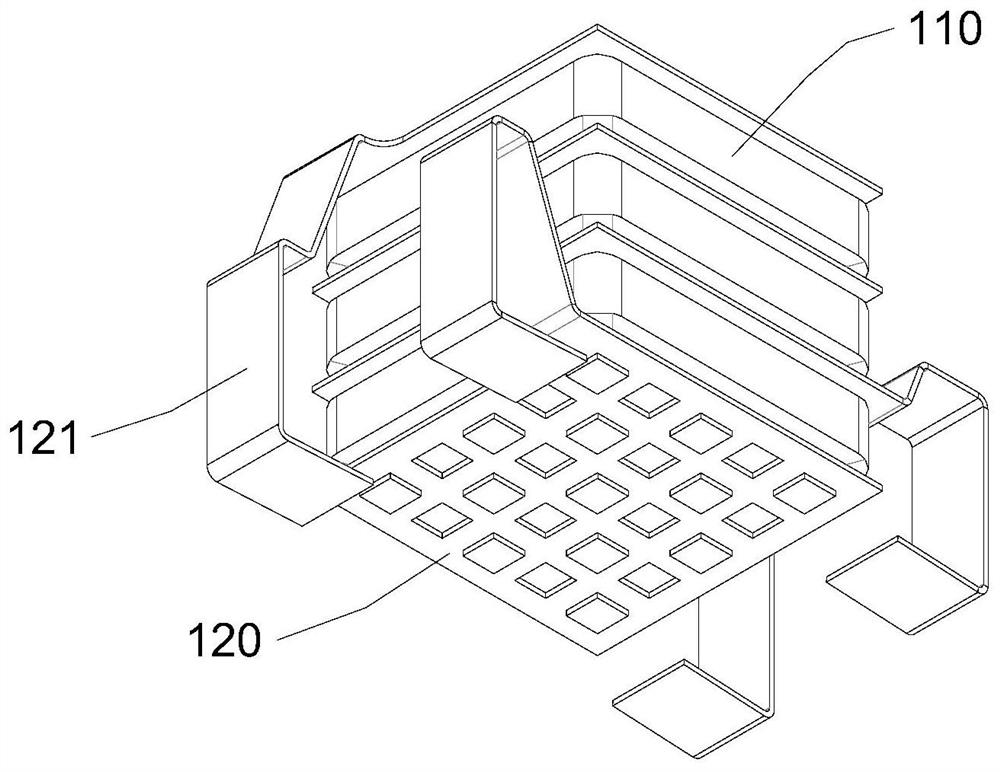

Pressure-sensitive component, pressure-sensitive component manufacturing method and overvoltage protection circuit

ActiveCN113363036AMiniaturizationImprove consistencyMass resistorsEnvelope/housing resistor manufactureOvervoltagePlastic packaging

The invention provides a pressure-sensitive component, a pressure-sensitive component manufacturing method and an overvoltage protection circuit, and relates to the field of plastic packaging. The pressure-sensitive component comprises at least three pressure-sensitive resistor chips; four electrode plates, wherein the at least three piezoresistor chips and the four electrode plates are arranged in a layered manner, at least one piezoresistor chip is arranged between every two adjacent electrode plates, each electrode plate is electrically connected with the adjacent piezoresistor chip, and each electrode plate comprises a pin; and a plastic package body, wherein the at least three piezoresistor chips and the four electrode plates are packaged in the plastic package body, and the pin of each electrode plate is exposed out of the plastic package body. The voltage-sensitive component, the voltage-sensitive component manufacturing method and the overvoltage protection circuit provided by the invention have the advantages of smaller size, lower cost and better consistency between devices.

Owner:捷捷半导体有限公司

Popular searches

Resistors adapted for applying terminals Resistive material coating Printed circuit aspects Printed circuit manufacture Thick film resistors Base element modifications Adjustable resistors Printed circuit non-printed electric components association Semiconductor/solid-state device details Solid-state devices

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com