GDT (Gas discharge tube)-added composite MOV (Metal Oxide Varistor)

A composite, added technology, applied in resistor sets, resistor components, varistor cores, etc., to achieve the effects of improved heat dissipation, no leakage current, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

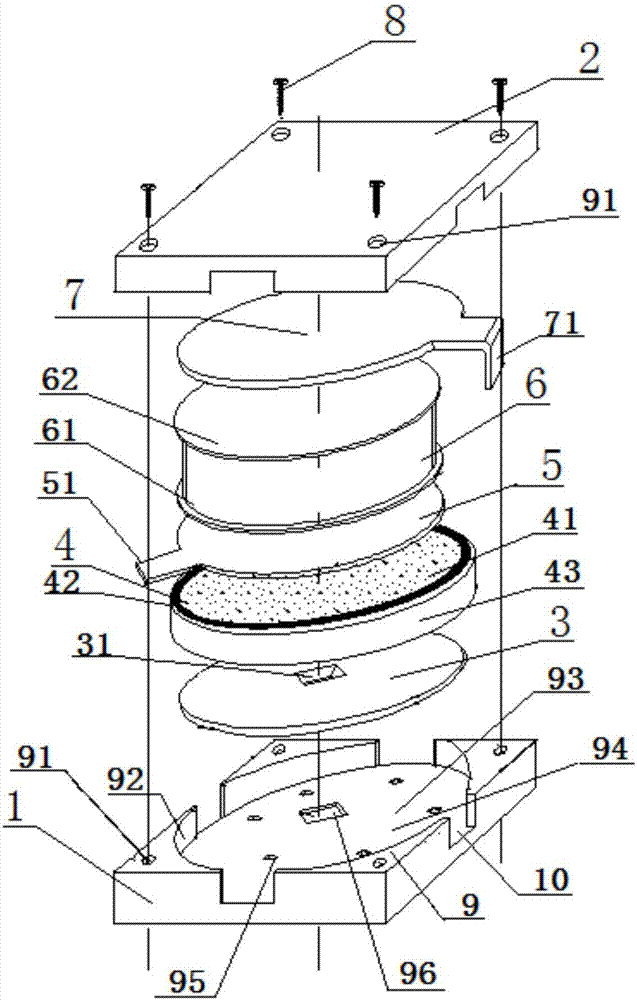

[0026] This embodiment provides a compound MOV with GDT added, such as figure 1 As shown, a lower case body 1 is provided with an upper case body 2, and a lower lead-out electrode 3 embedded in the lower case body 1 is also provided. On the lower lead-out electrode 3, MOV chips 4, middle lead-out Electrode 5, two-pole GDT6 (including lower discharge electrode 61 and upper discharge electrode 62), upper lead-out electrode 7; the upper box body 2 is covered on the upper lead-out electrode 7, and the lower The box body 1 is fastened as a whole, and the lower lead-out electrode 3 , the MOV chip 4 , the middle lead-out electrode 5 , the diode GDT 6 , and the upper lead-out electrode 7 are tightly pressed and fixed.

[0027] Wherein, the four corners of the upper box body 2 and the lower box body 1 are provided with bosses 9 (in figure 1 Among them, one is marked in the upper box body 2 and one in the lower box body 1, and the other same structures are not marked, and the same stru...

Embodiment 2

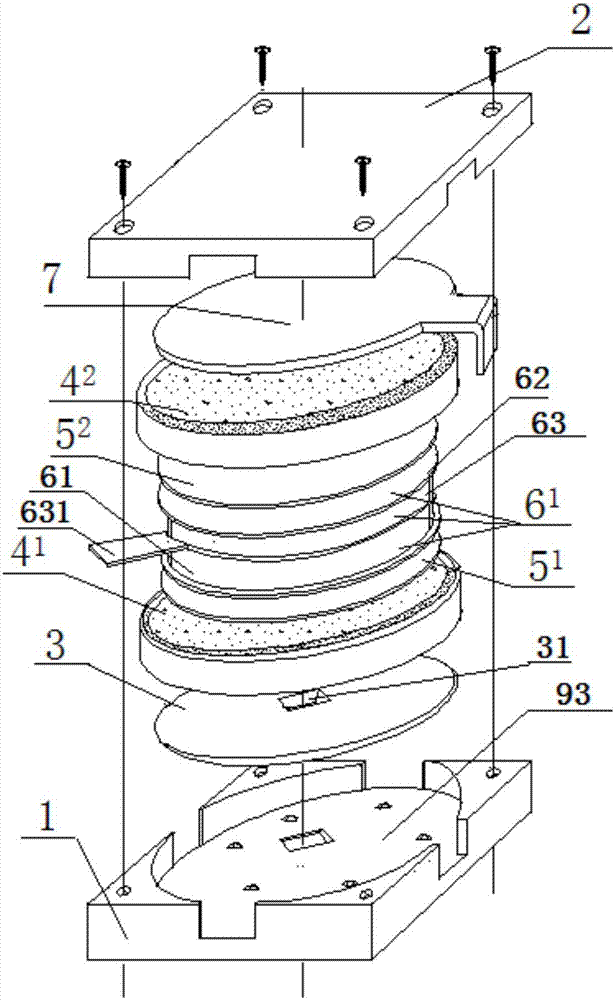

[0036] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 lies in that the first MOV chip 4 is sequentially stacked on the lower lead-out electrode 3 1 , the first metal gasket 5 1 , three-pole GDT6 1 , the second metal gasket 5 2 , the second MOV chip 4 2 , The upper lead-out electrode 7, that is: replace the middle lead-out electrode 5 with a circular or rectangular metal gasket 5 1 and 5 2 , and the three-pole GDT6 1 A triode gas discharge tube comprising a lower discharge tube 61 and an upper discharge tube 62 with an intermediate electrode 63 is adopted, and the MOV chip 4 in Embodiment 1 is retained, named as the first MOV chip 4 in this embodiment 1 , and then add one of the first MOV chip 4 in the triode GDT61 and the upper lead-out electrode 7 1 same MOV chip, named as the second MOV chip 4 2 . At this time, the cylindrical accommodation space 93 composed of the lower box body 1 and the upper box body 2 accommodates the lower l...

Embodiment 3

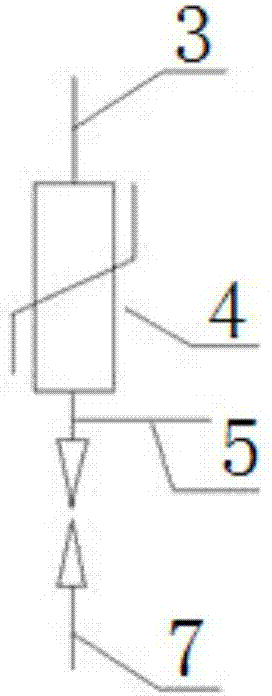

[0039] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that: in the case where the contact surface between the MOV chip 4 and the bipolar GDT6 is flat, the middle lead-out electrode 5 can also be omitted, that is, the bottom lead-out electrode 5 can be omitted. The MOV chip 4 , the bipolar GDT 6 , and the upper lead-out electrode 7 are sequentially stacked on the electrode 3 . That is: the middle lead-out electrode 5 is removed, and the cylindrical accommodation space 93 composed of the lower box body 1 and the upper box body 2 accommodates the lower lead-out electrode 3, the MOV chip 4, the bipolar GDT6, and the upper lead-out electrode. Electrode 7. If the one provided by this embodiment is added to the composite MOV access circuit of GDT, because compared with embodiment 1, the middle lead-out electrode 5 is omitted, as Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com