High-power alloy foil resistor and manufacturing method

A manufacturing method and alloy foil technology, applied in the direction of resistance manufacturing, non-adjustable metal resistors, resistors, etc., can solve the problems of accelerating product failure and increasing heat accumulation, so as to achieve a smooth path for heat diffusion, improve heat overflow, The effect of ensuring firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment is an embodiment of a resistor.

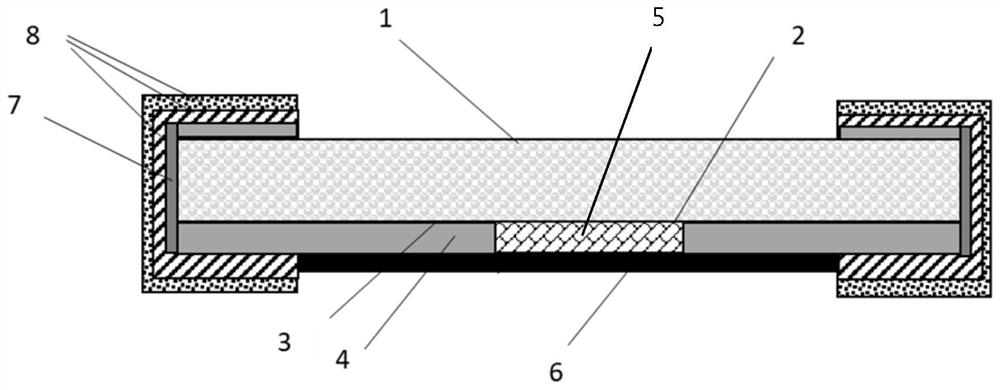

[0033] refer to figure 1 As shown, this embodiment provides a high-power alloy foil resistor, which is suitable for automobiles, industrial control and other precision electronic products or equipment.

[0034] The high-power alloy foil resistor includes: a substrate 1, a metal layer 2, an adhesive layer 3, a resistance element 4, an intermediate material 5, a protective layer 6, a side metal bottom layer 7 and an electrode terminal 8. The substrate 1 can be Soft insulating and heat-conducting materials such as alumina or aluminum nitride ceramics or polyimide after pre-cutting, the metal layer 2 can be a material that can be used for film growth processes such as deposition and sputtering, such as copper alloy, nickel-chromium alloy , one of titanium-tungsten alloys, the adhesive 3 can be applied on the surface of the substrate 1 by pressing, coating, etc. and combined with the resistance element, and the resistance el...

Embodiment 2

[0036] This embodiment is an embodiment of the manufacturing method for manufacturing the resistor in the first embodiment.

[0037] The manufacturing method of this resistor comprises the following steps:

[0038] Paste the glue 3 on the surface of soft insulating and heat-conducting materials 1 such as aluminum oxide or aluminum nitride ceramics or polyimide with cutting grooves, such as figure 2 As shown; in this step, the substrate is cut by laser to form a cutting groove on the substrate, the cutting depth is 30% to 60% of the thickness of the substrate, the laser power is 200 to 400W, the cutting speed is 500 to 1500mm / s, and the laser frequency is 40% to 90%. The width of the cutting blade used is 0.05-0.3 mm, the rotation speed of the cutting blade is 500-1800 rpm, and the material of the blade can be diamond or other hard alloy materials. Then stick the adhesive layer on the substrate with the cutting groove.

[0039] The resistance alloy piece and the intermediat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com