Semiconductive chip device having insulating coating layer and method of manufacturing the same

An insulating coating, semiconductor technology, applied in the direction of semiconductor devices, semiconductor devices, semiconductor/solid-state device components of light-emitting elements, etc., can solve the problems of complex technical process and unsuitable application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

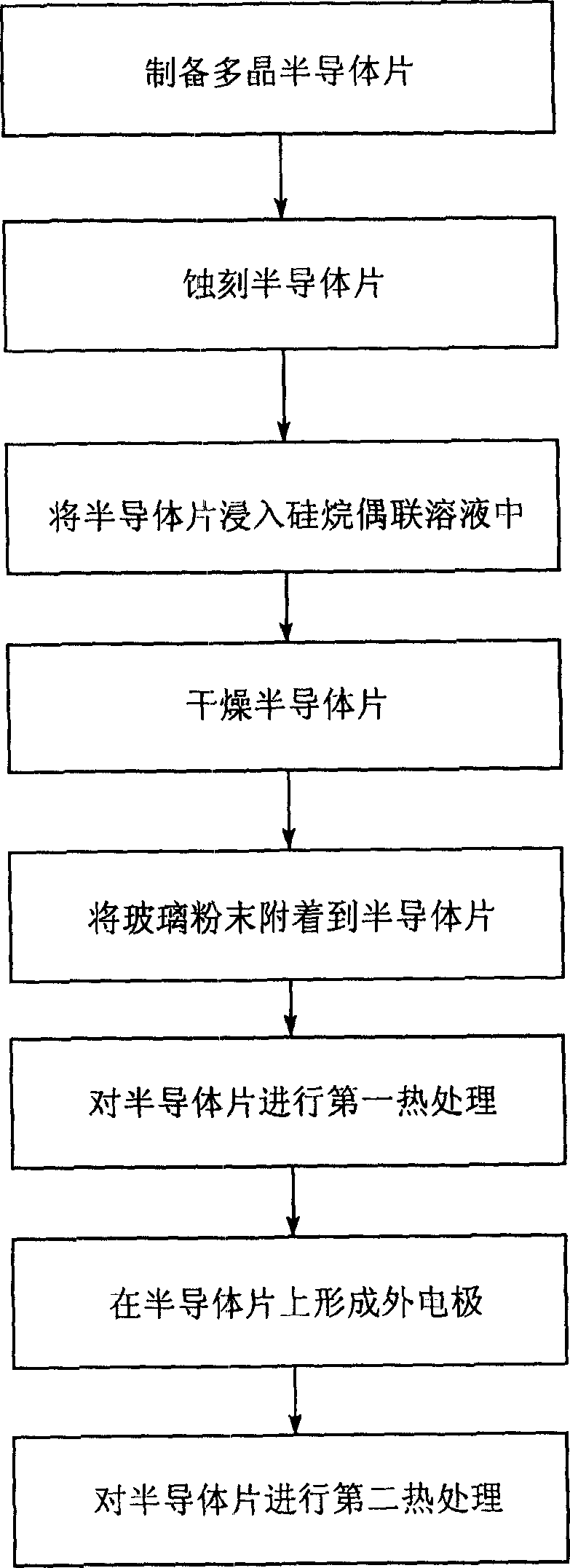

[0022] The present invention will be described in detail below with reference to the accompanying drawings.

[0023] figure 2 The view in the figure shows the process of manufacturing a semiconductor chip device according to the present invention. Such as figure 2 As shown, a polycrystalline semiconductor wafer that requires surface insulation properties is first prepared. Polycrystalline semiconductor chips requiring surface insulating properties are applied to chip varistors, such as PTCR and MTCR, etc., but not limited to these.

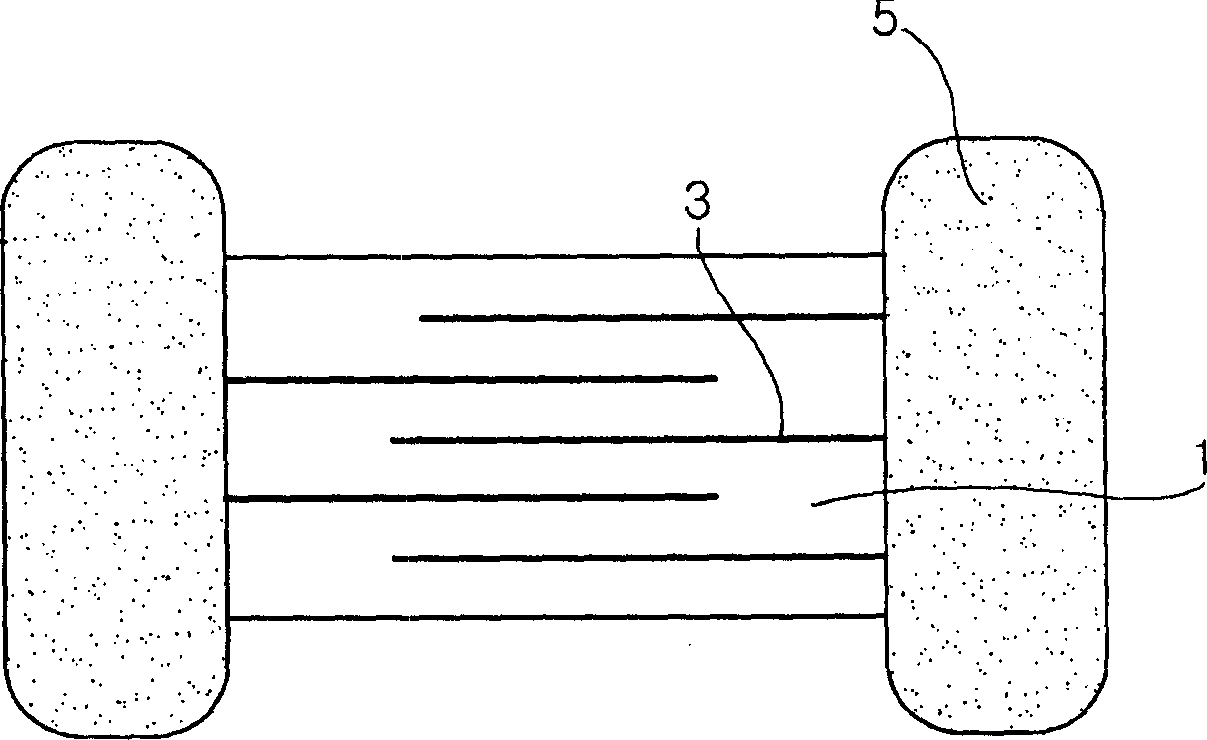

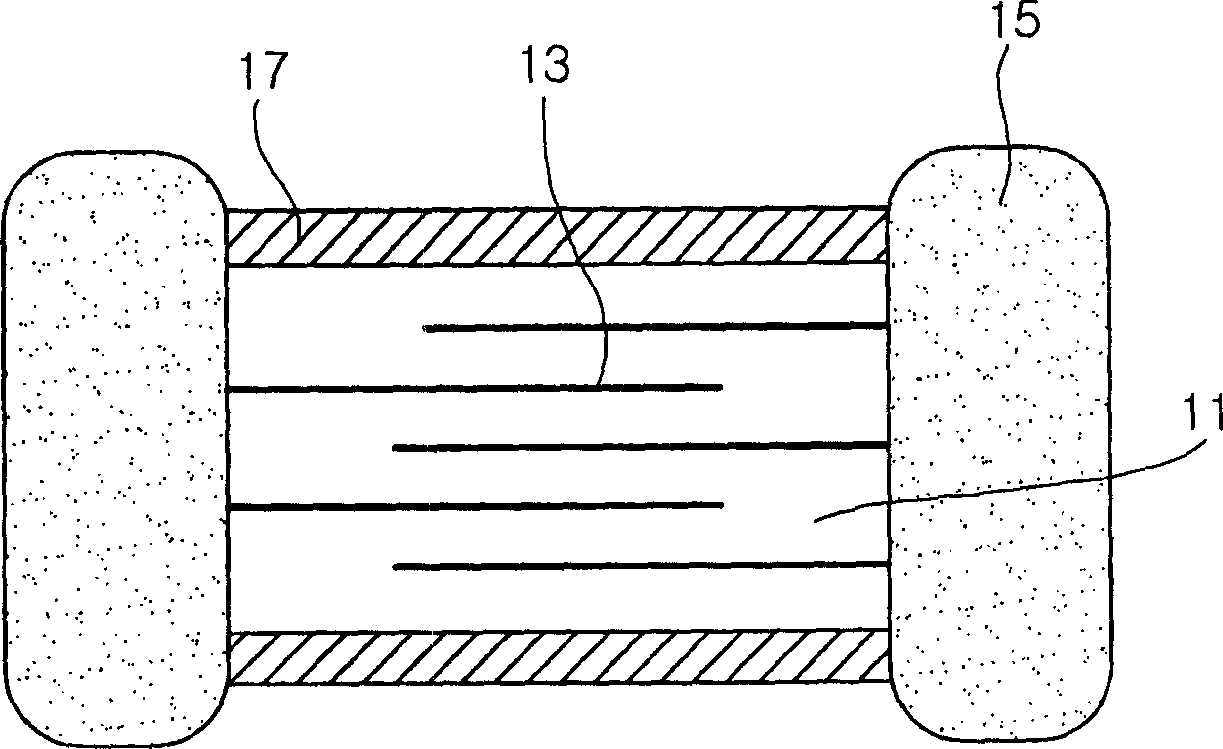

[0024] Polycrystalline semiconductor wafers are mainly classified into a laminated type and a disk type, each of which can be used in the present invention. see Figure 1b , the laminated semiconductor chip is formed as a semiconducting ceramic laminate, including dielectric layers 11 and internal electrodes 13 sandwiched between the dielectric layers 11 and alternately connected to both ends of the dielectric layer 11 . At this time, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com