Resistor with resistor monomers capable of being connected in series or in parallel

A technology of resistors and resistors, applied in the direction of non-adjustable metal resistors, resistors, resistor sets, etc., can solve the problems of poor heat dissipation, unstable mechanical strength structure, and large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

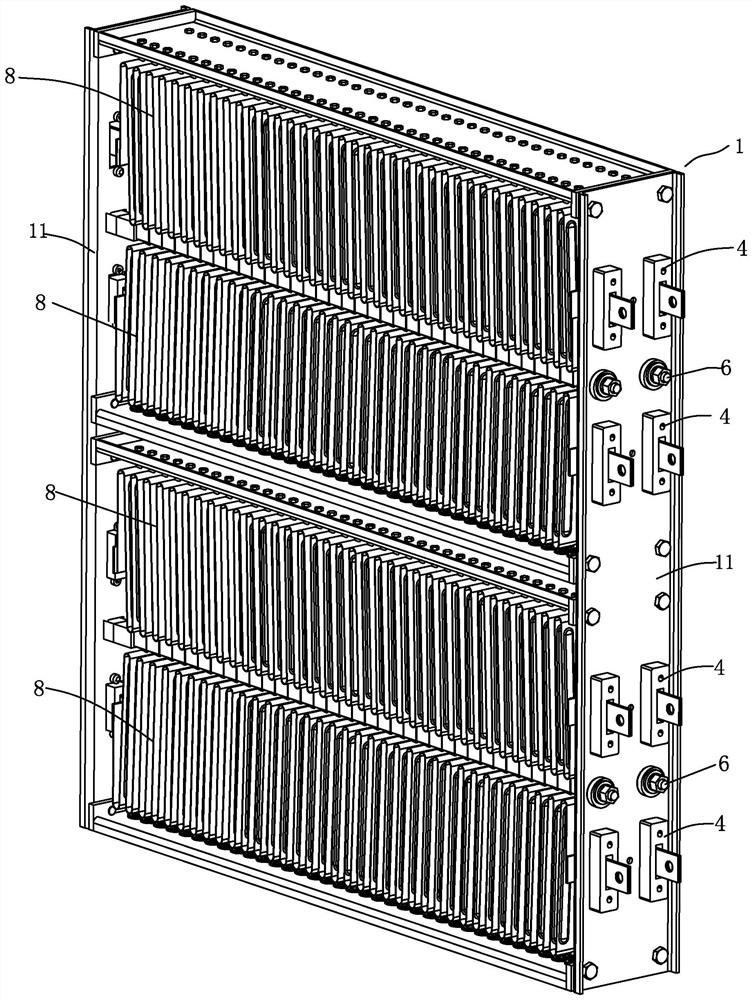

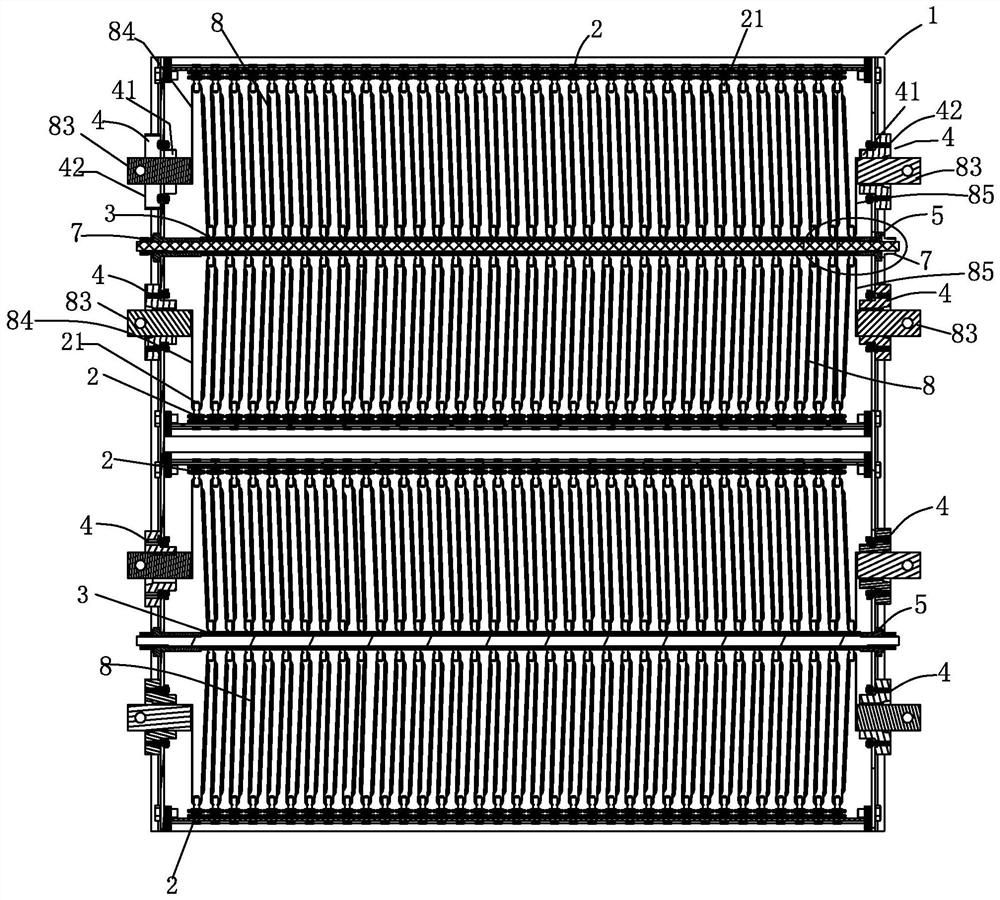

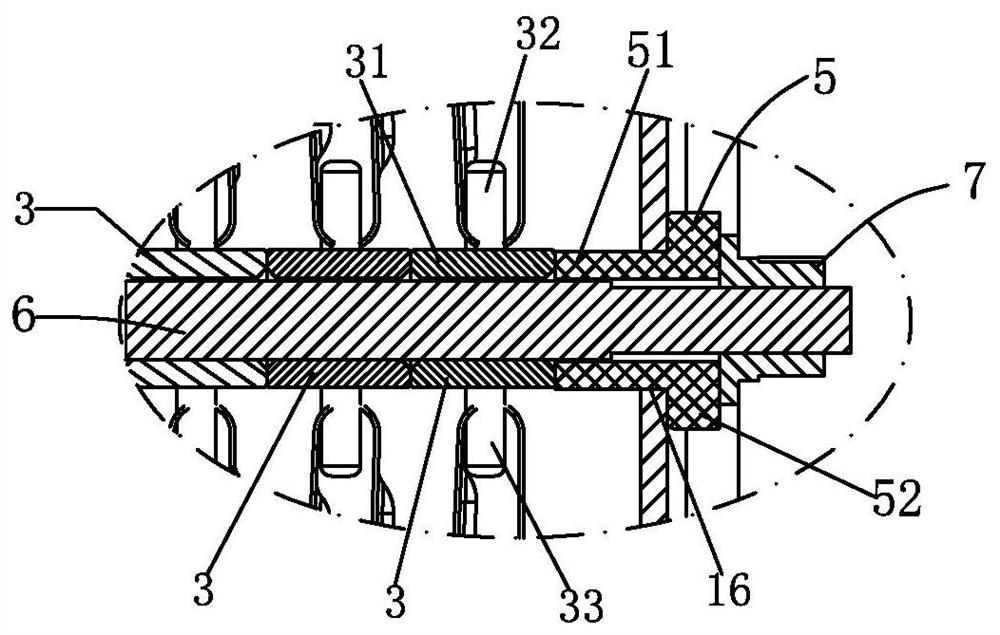

[0031] Such as figure 1 As shown, a resistor whose resistance monomers can be connected in series or in parallel, it includes a square frame-shaped frame 1, an insulating seat 2, an intermediate insulating seat 3, a terminal insulating seat 4, an insulating connecting seat 5, and screw rods at both ends The square connecting rod 6, the nut 7 and several resistor monomers 8,

[0032] Seat frame 1 comprises side frame plate 11, top horizontal frame plate 12 and bottom horizontal frame plate 13, top horizontal frame plate 12 and bottom horizontal frame plate 13 constitute frame plate group; Side frame plate 11 is provided with top connection hole 14, rectangular Terminal seat holes 15, square seat holes 16 and bottom connection holes 17, the top connection hole 14 is a hole for fixing the top horizontal frame plate 12, and the bottom connection hole 17 is a hole for fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com