Chip resistor element and method for forming same

A technology for resistors and resistor layers, applied in the direction of resistor parts, resistors, electrical components, etc., can solve problems such as lowering of plating characteristics, delamination, and inability to form properly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

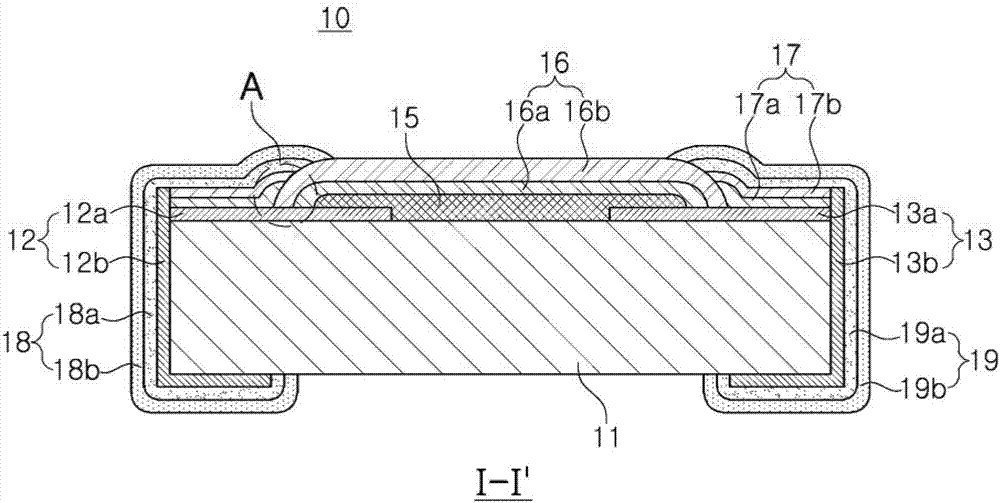

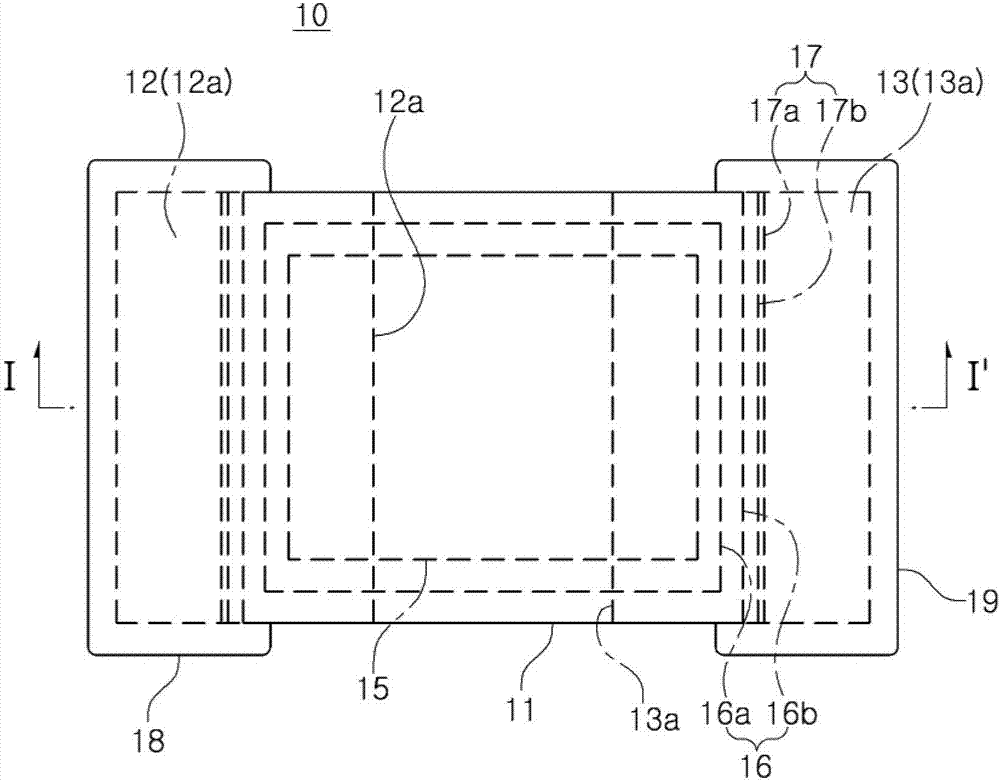

[0066] Based on the conditions of this disclosure, with figure 1 The first electrode protection layer and the second electrode protection layer (for example, 17a and 17b) were fabricated in a chip resistor element similar to the chip resistor element shown in .

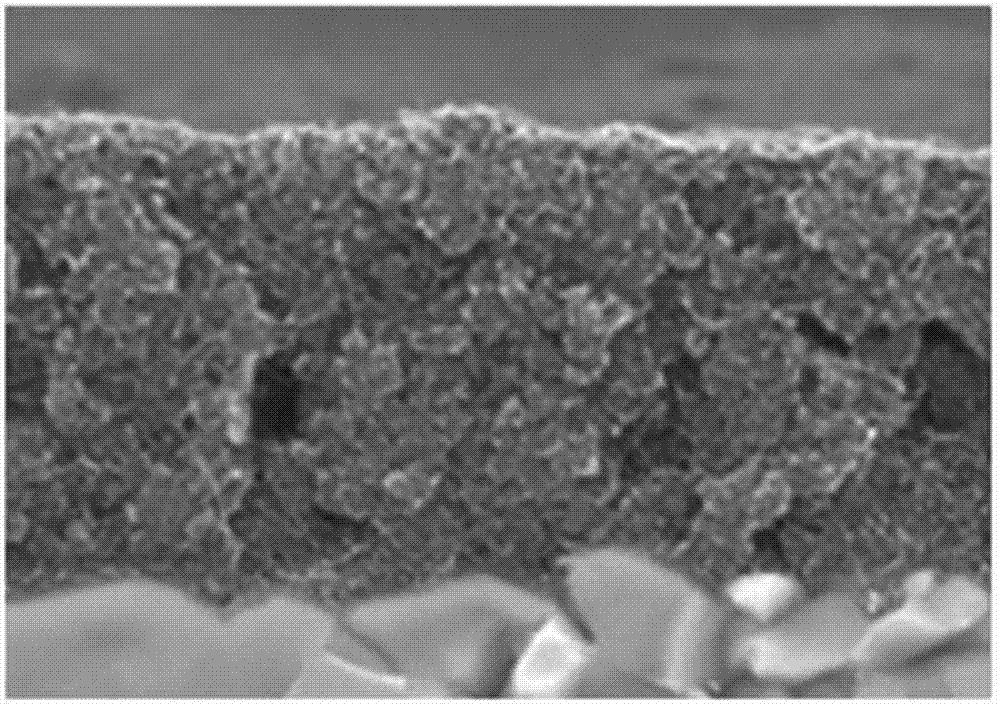

[0067] First, upper electrodes (for example, 12a and 13a) are formed using a paste containing Ag as a main component. A paste in which carbon nanotubes and epoxy resin are mixed with each other at a weight ratio of 3:97 is used to form the first electrode protective layer (for example, 17a). A product having a diameter of about 8 nm and a length of 10 μm to 15 μm was used as the carbon nanotube. Use the paste of CuNi alloy (Ni: 70wt%), carbon nanotube and epoxy resin to mix each other according to the ratio of 94:1:5 to form the second electrode protection layer (for example, 17a) on the first electrode protection layer (for example, 17a). , 17b). Then, external electrodes (for example, 18, 19) are formed by succes...

example 2

[0078] Invention example 2: Evaluation of CuNi alloy

[0079] The evaluation of the CuNi alloy effectively employed in this exemplary embodiment was performed. While changing the ratio of Cu to Ni (Ni content: 0wt%, 20wt%, 45wt%, 80wt%, 100wt%), the anti-sulfidation characteristics and specific resistance values of the alloy powder particles of the respective samples were measured. An electrode protective layer (for example, 17 ) was manufactured by mixing 90 wt % of alloy powder particles having a composition based on the conditions described above with 10 wt % of epoxy resin. The electrode protection layer prepared in this experiment may be the second electrode protection layer (for example, 17b).

[0080] First, an alloy ratio-based FoS test was performed on each sample. The FoS test is performed by the same method as described above. In addition, the change in the specific resistance value of each sample based on the amount of carbon nanotubes added was also measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com