Infrared detector with micro-bridge structure and manufacturing method thereof

A technology of infrared detector and microbridge structure, which is applied in the field of micro-electromechanical, can solve the problems that affect the overall performance of infrared detectors, high resistivity, and easy electromigration, etc., to improve processing and manufacturing capabilities, improve effective area, and improve process The effect of compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047]The present invention will be further described below in conjunction with accompanying drawing:

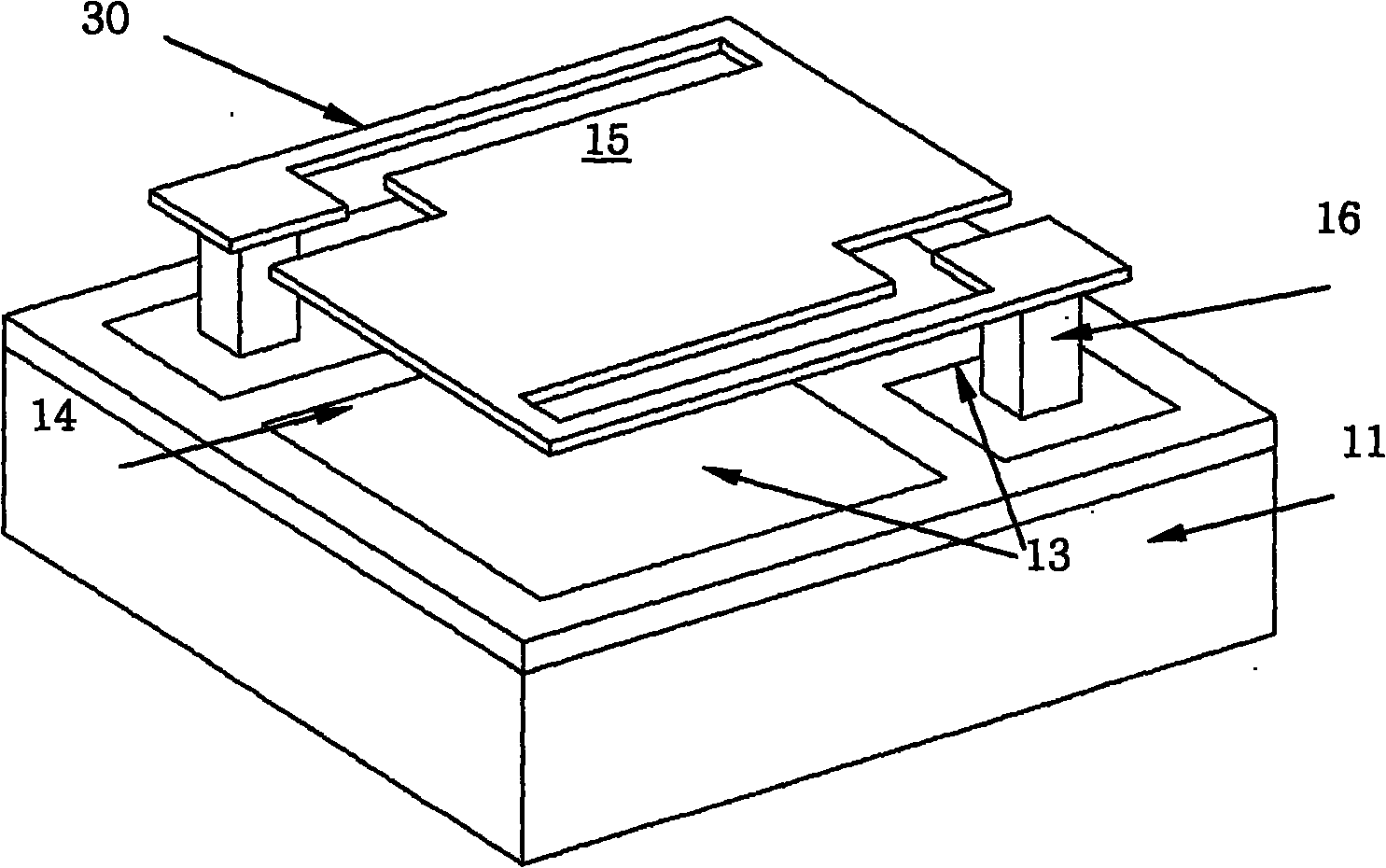

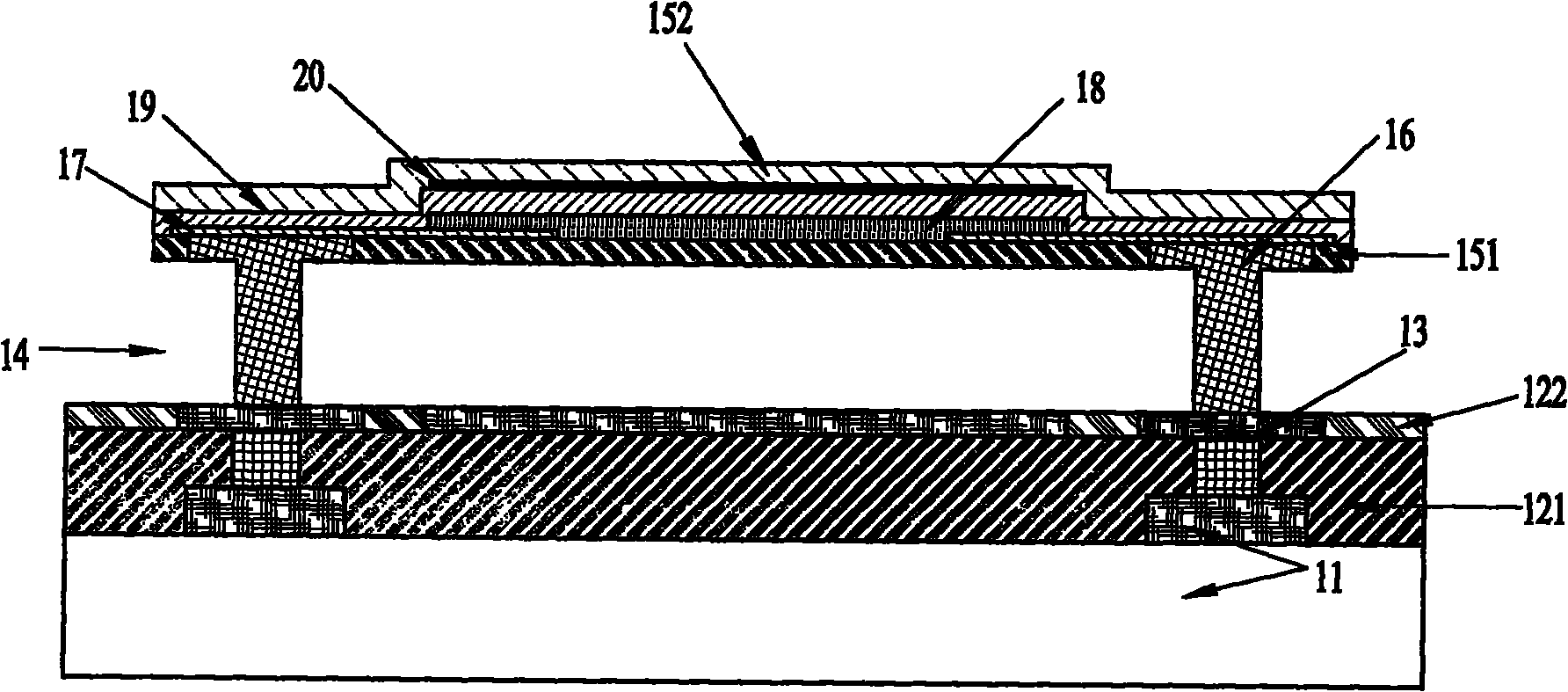

[0048] Please see figure 1 and figure 2 , This embodiment proposes an infrared detector, which is applicable to places such as power network security detection, forest fire detection, and human body temperature detection. The inventive microbridge structure can be widely used in micro-electromechanical systems and devices such as uncooled infrared detectors, gas detectors, micro-heating platforms, and infrared radiation source devices.

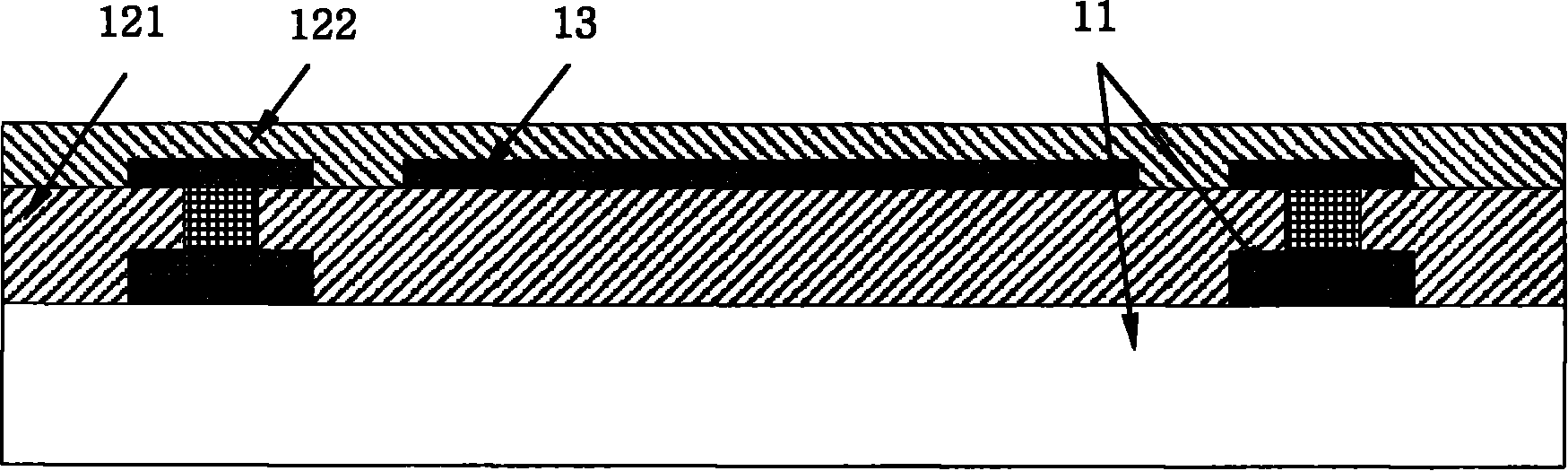

[0049] The infrared detector sequentially includes a readout circuit 11, a first dielectric layer 121, a metal reflection layer 13, a second dielectric layer 122, a sacrificial layer 14, a copper pillar 16, a first release protection layer 151, a metal electrode 17, and a sensitive material detection layer 18. A dielectric insulating layer 19, an infrared absorbing layer 20, and a second release protection layer 152.

[0050] The silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com