Ceramic resistor

A technology of ceramic resistors and ceramics, applied in the direction of resistors, resistor assemblies, resistor components, etc., can solve problems such as short circuit of wiring patterns, fire of resin components, etc., and achieve the effect of ensuring safety and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

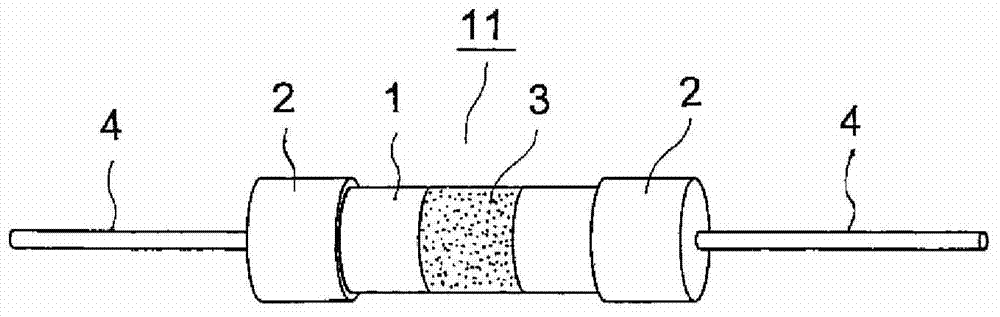

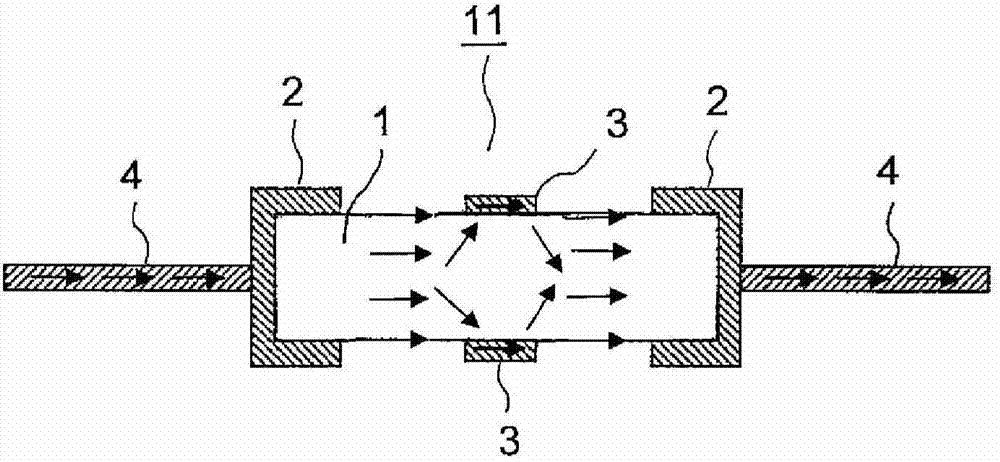

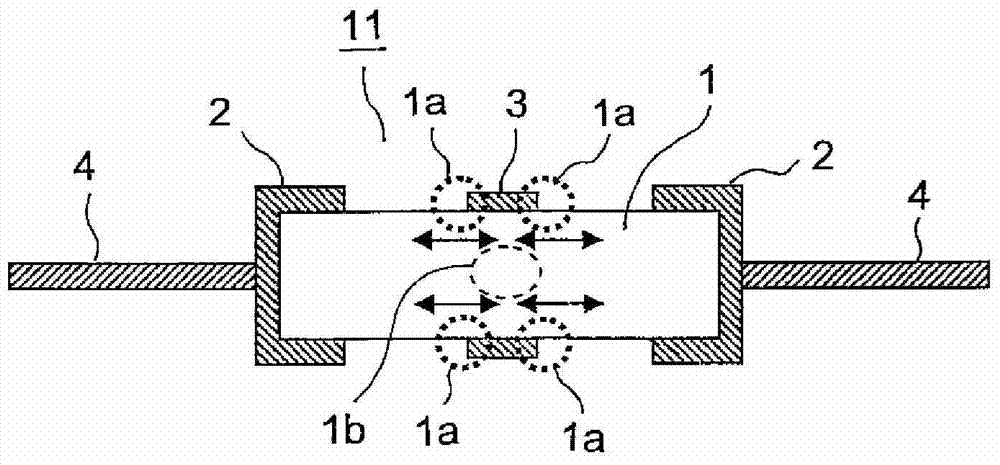

[0026] Hereinafter, embodiments of the present invention will be described with reference to the drawings. First, use Figure 1 ~ Figure 4 A ceramic resistor according to a first embodiment of the present invention will be described.

[0027] Such as figure 1 as well as figure 2 As shown, the ceramic resistor 11 of the first embodiment of the present invention mainly includes: a cylindrical resistor body 1; a pair of electrodes 2 embedded in the two ends of the length direction of the resistor body 1; A conductive metal film 3 on a part of the outer peripheral surface of the resistor 1 ; and lead terminals 4 protruding outward from the pair of electrodes 2 . The ceramic resistor 11 is mounted on a printed circuit board (not shown), and the electrodes 2 are soldered to through holes of the printed circuit board.

[0028] The structure of the ceramic resistor 11 will be described in detail. The resistor body 1 is made of insulating ceramics mixed with SnO 2 It is sintered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com