Rotary seamer

a seamer and rotary technology, applied in the field of rotary seamers, can solve the problems of allowing high precision and strength, and achieve the effect of strong and precis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

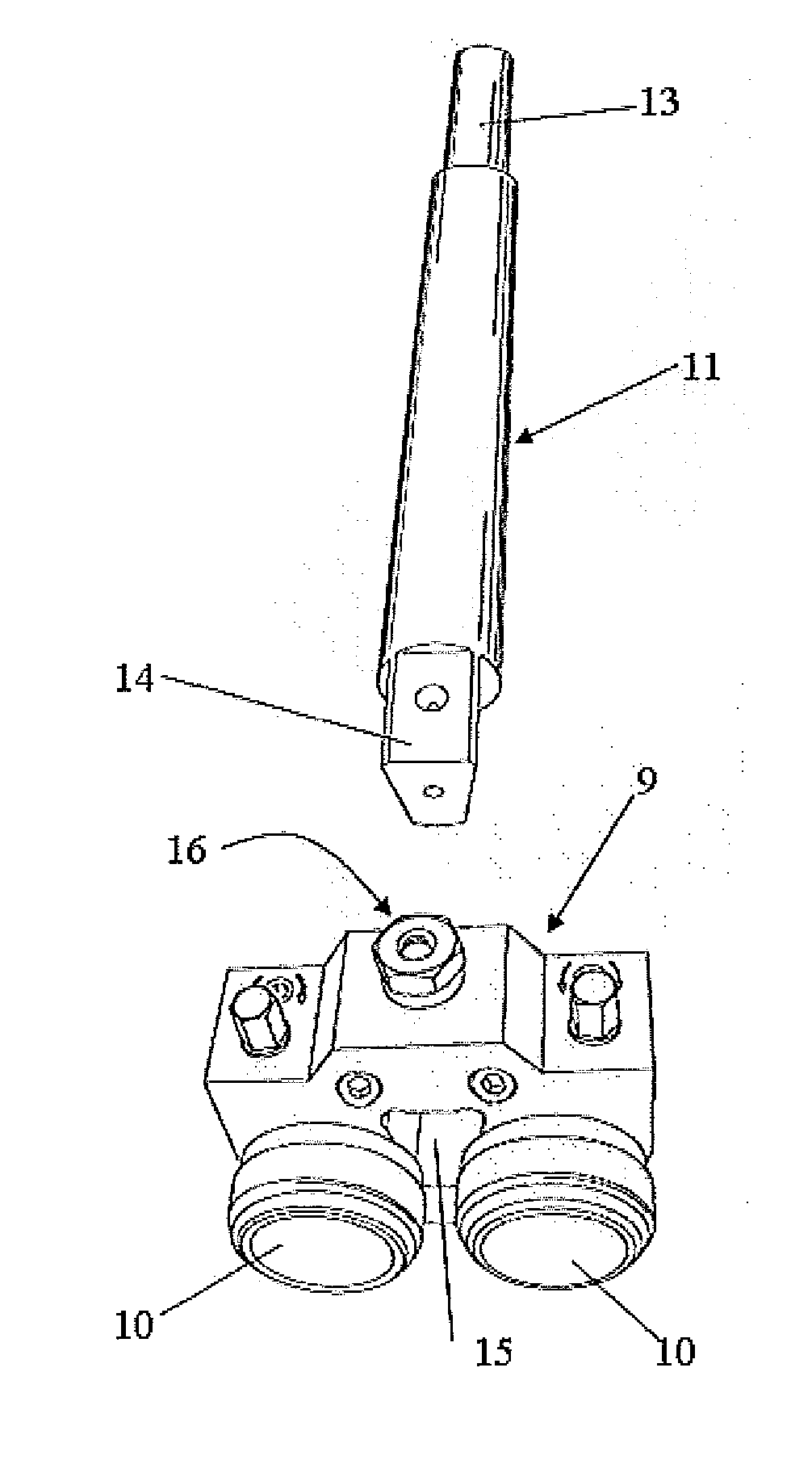

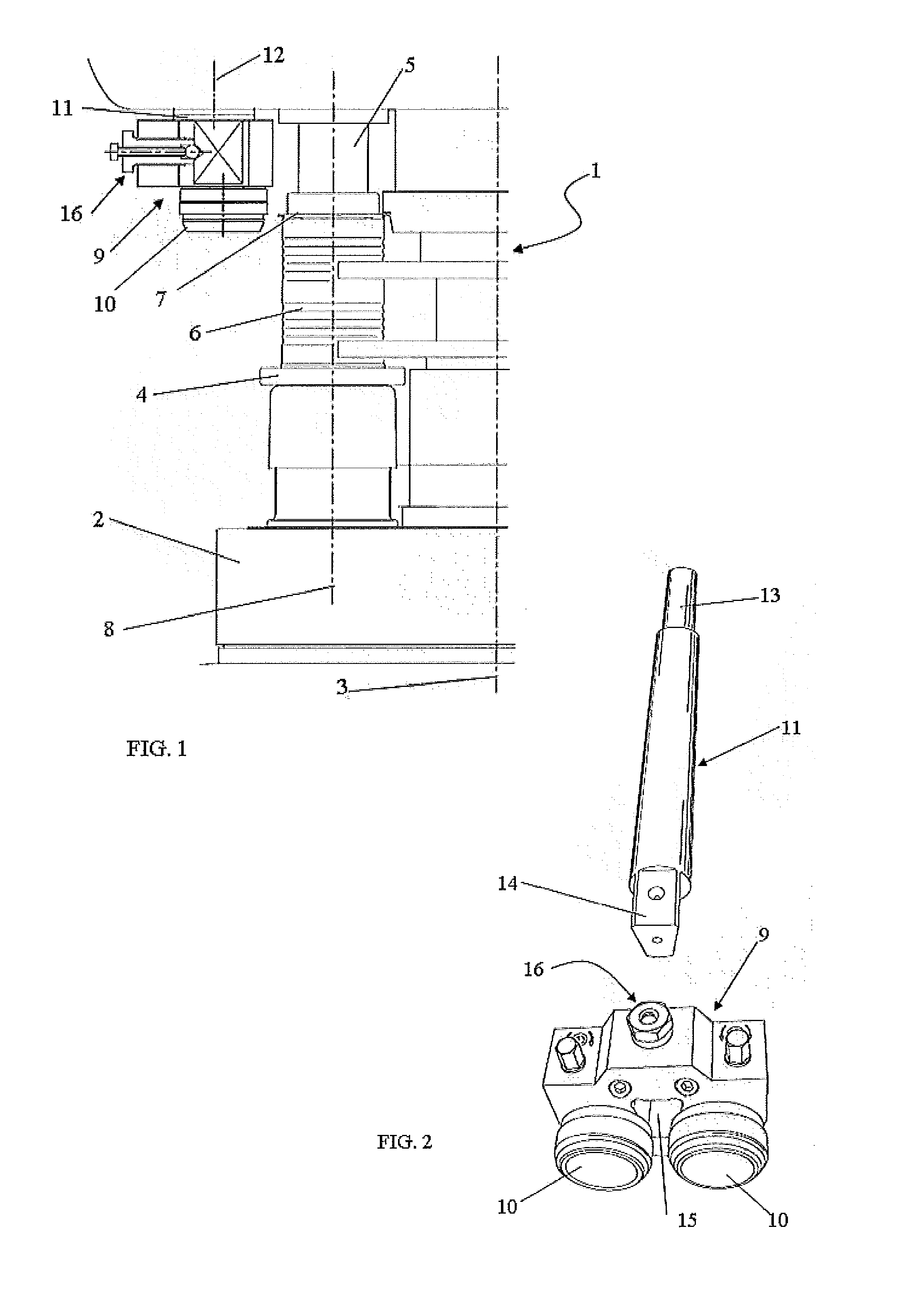

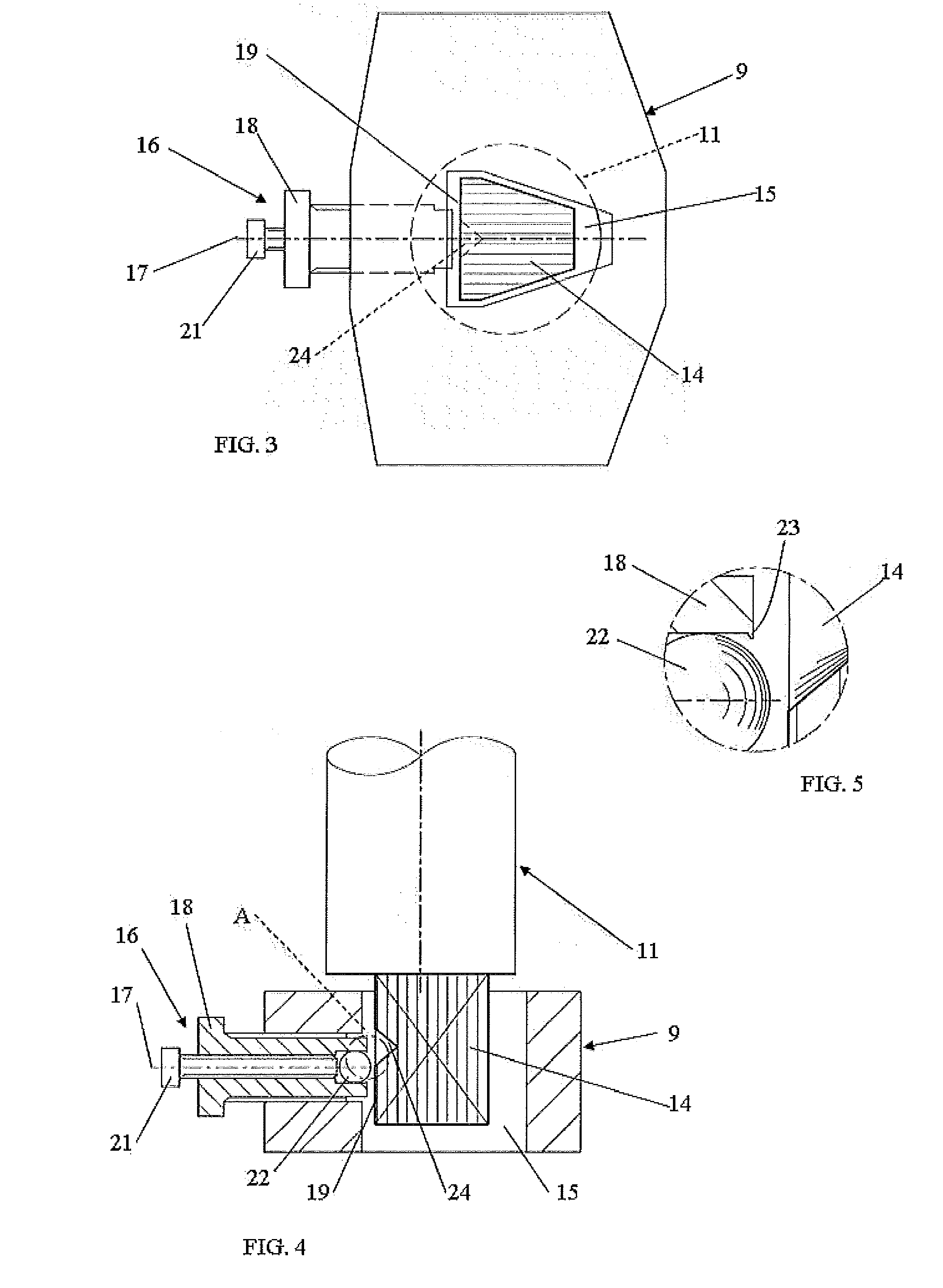

[0035]In FIG. 1, the reference number 1 designates a seamer according to the present invention, whereof is shown, in particular, a portion of a seaming turret 2 rotating around its own axis 3. To the seaming turret 2 are pivotally associated a pan 4 and a mandrel 5, which define a seaming site, to set a container 6 and a lid 7 in rotation around their own axis 8. The reference number 9 designates a seaming block provided with rotating idle pivots 10 (in particular a first and a second rotating pivot, but according to the seamer model there may be a single pivot per block and consequently the number of the blocks and of the pivots doubles). The seaming block 9 is anchored to a shaft 11 hinged on the seaming turret 2, such that it can rotate around its own axis 12.

[0036]FIG. 2 shows an exploded perspective view of the shaft 11 and of the seaming block 9. The shaft 11 has a first end 13, hinged in the seaming turret 2, and a second end 14.

[0037]The seaming block 9 internally defines a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com