Track with rotating bushings for track-type vehicles with improved sliding bearing

A sliding bearing, crawler type technology, applied in the direction of crawler vehicles, motor vehicles, bearing components, etc., can solve the problem of short service life and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

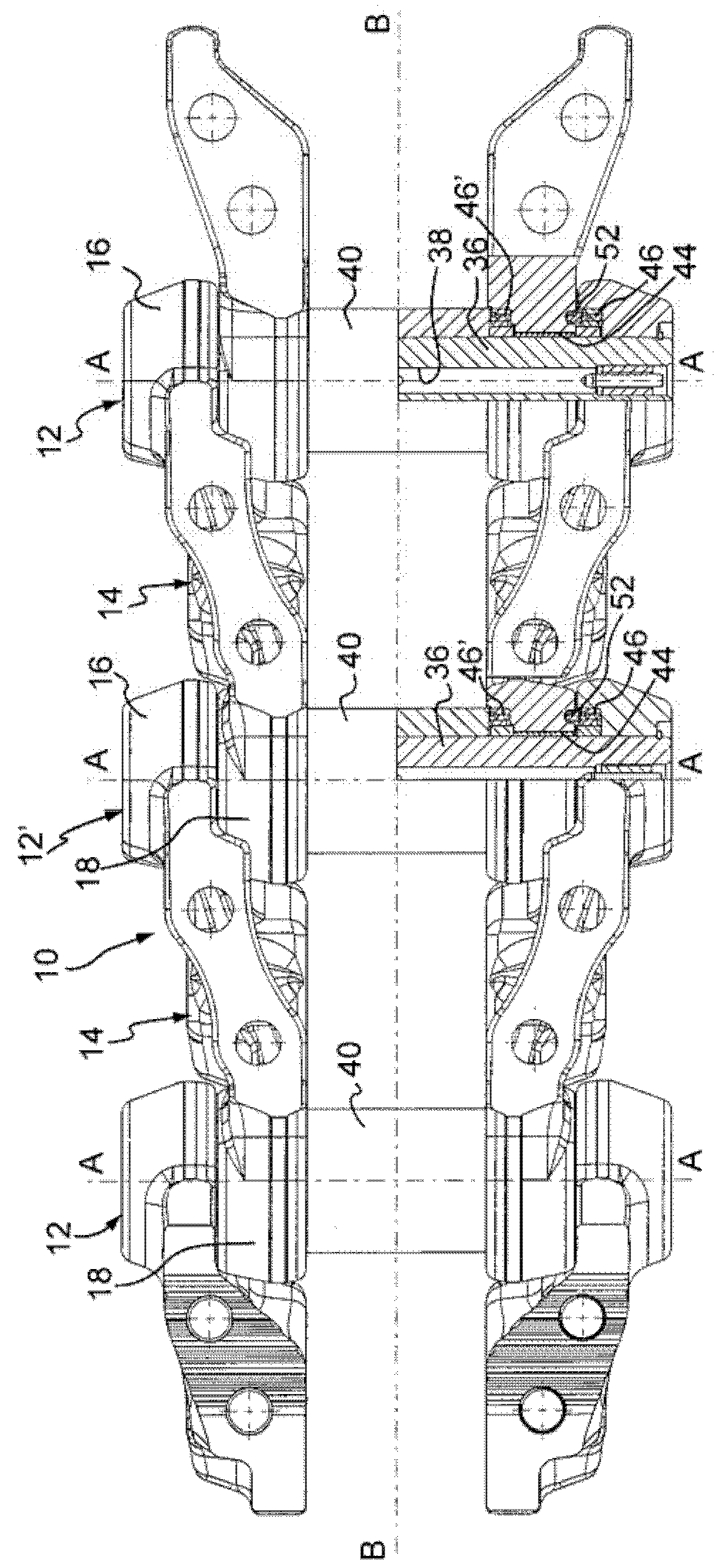

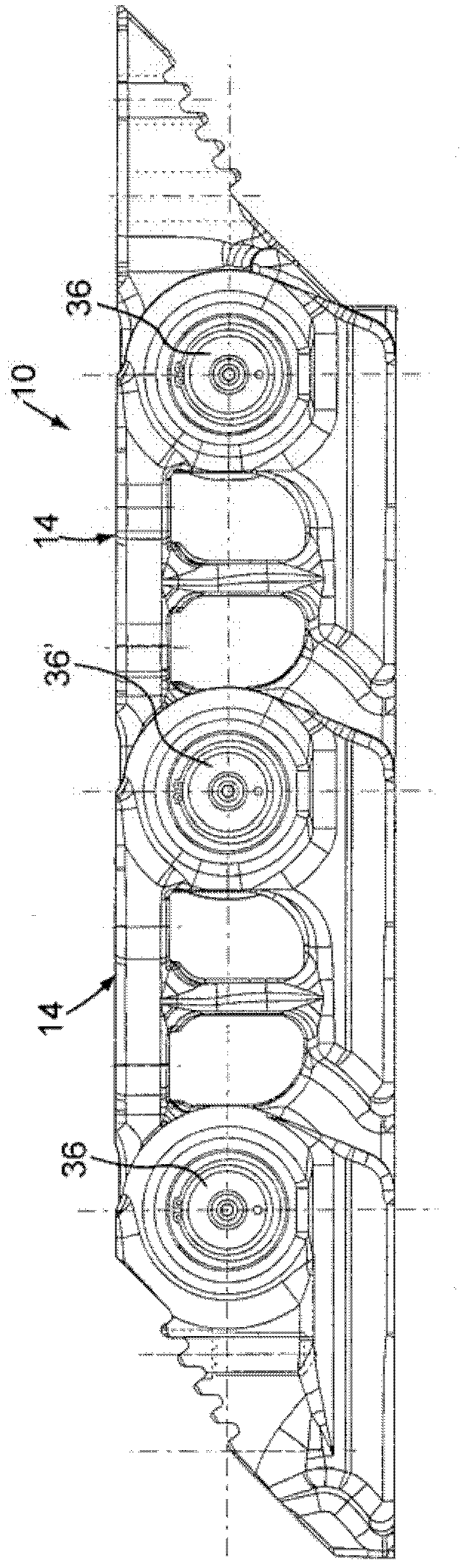

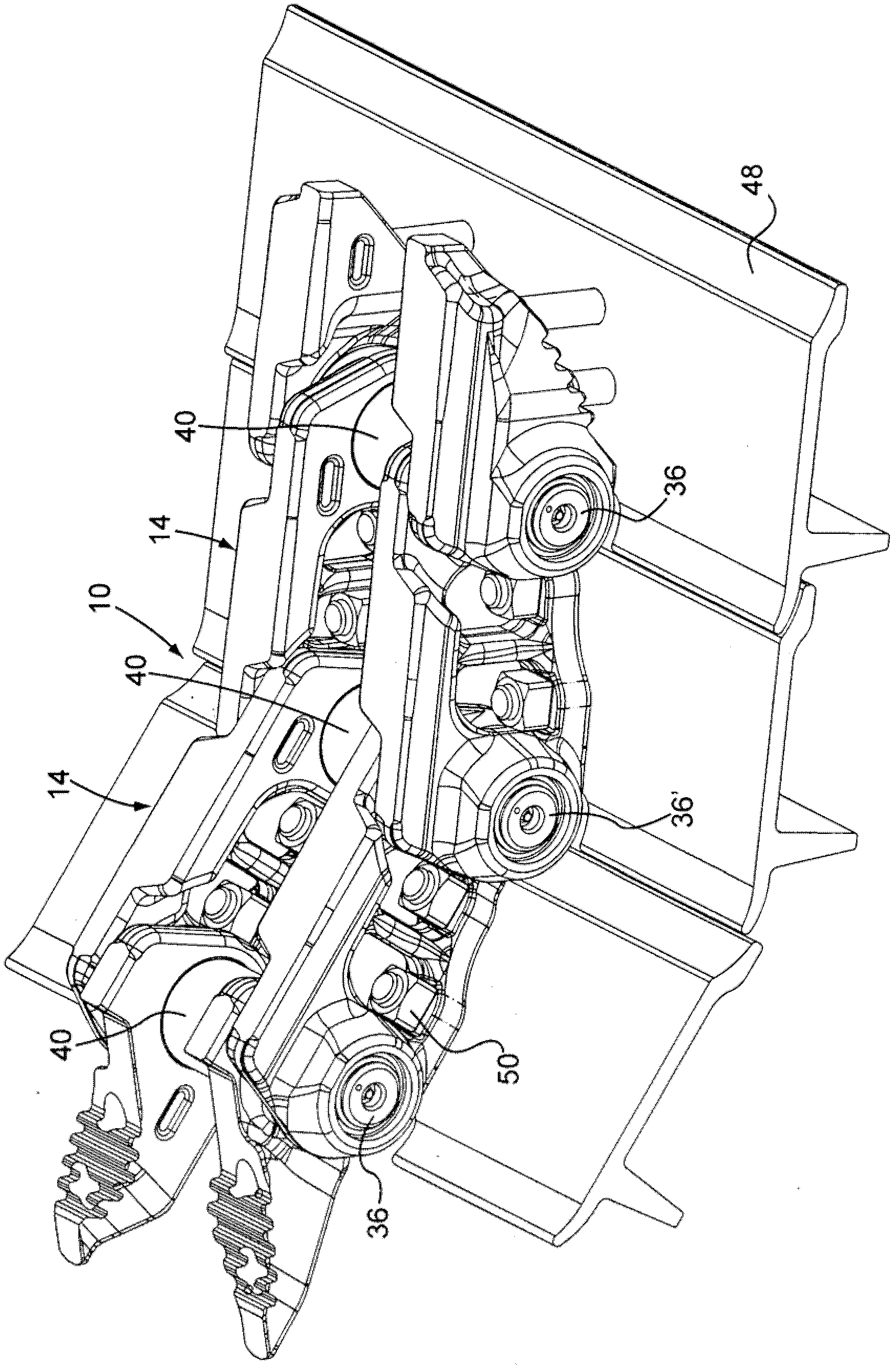

[0020] With reference to these figures, there is shown a part of a crawler track, generally indicated by the reference numeral 10, having a rotating bushing according to the invention. The crawler track 10 essentially consists of a continuous array of articulated articulation links 12, 12' oriented according to an axis A-A substantially perpendicular to the central longitudinal extension axis B-B of the track 10. The articulated connections 12, 12' are connected to each other and kept at a constant distance by a pair of links 14 having a longitudinal extension arranged symmetrically transversely with respect to the longitudinal center axis B-B of the track 10.

[0021] Each link 14 is of asymmetrical form, i.e. it is provided with a first end flange 16 facing the outside of the track 10 as seen with reference to the longitudinal central axis B-B, and is provided with a first end flange 16 facing the inside of the track 10, i.e. facing the longitudinal central axis B-B of the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com