Track with rotating bushings for track-type vehicles

A track and flange technology, applied in the field of track with rotating bushing, can solve the problems of short working life and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

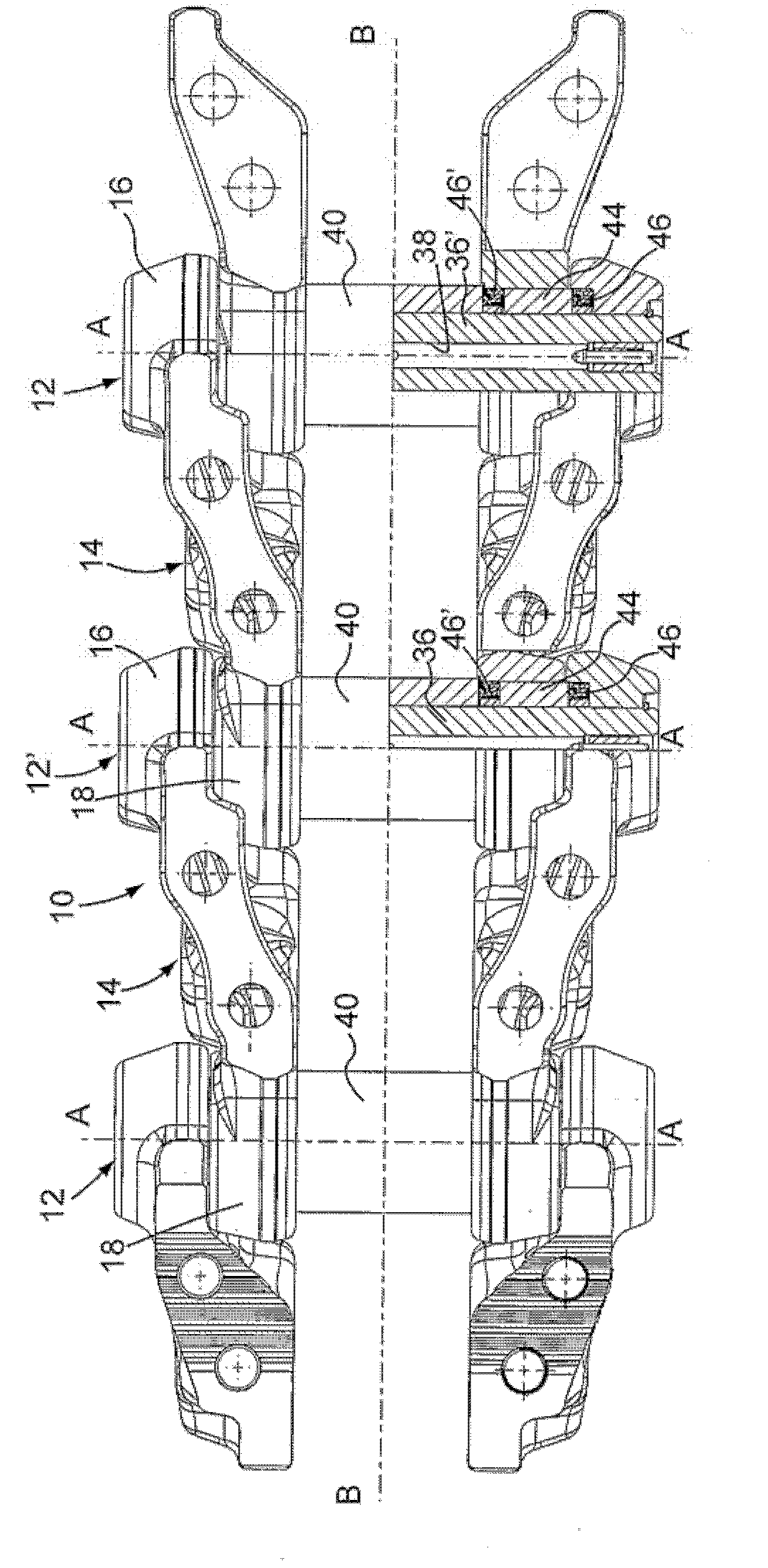

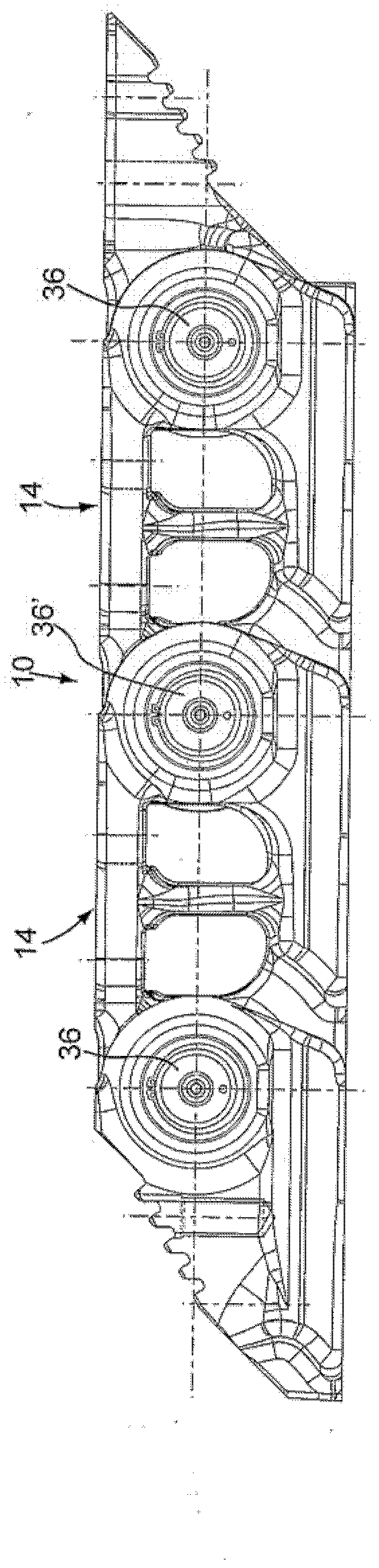

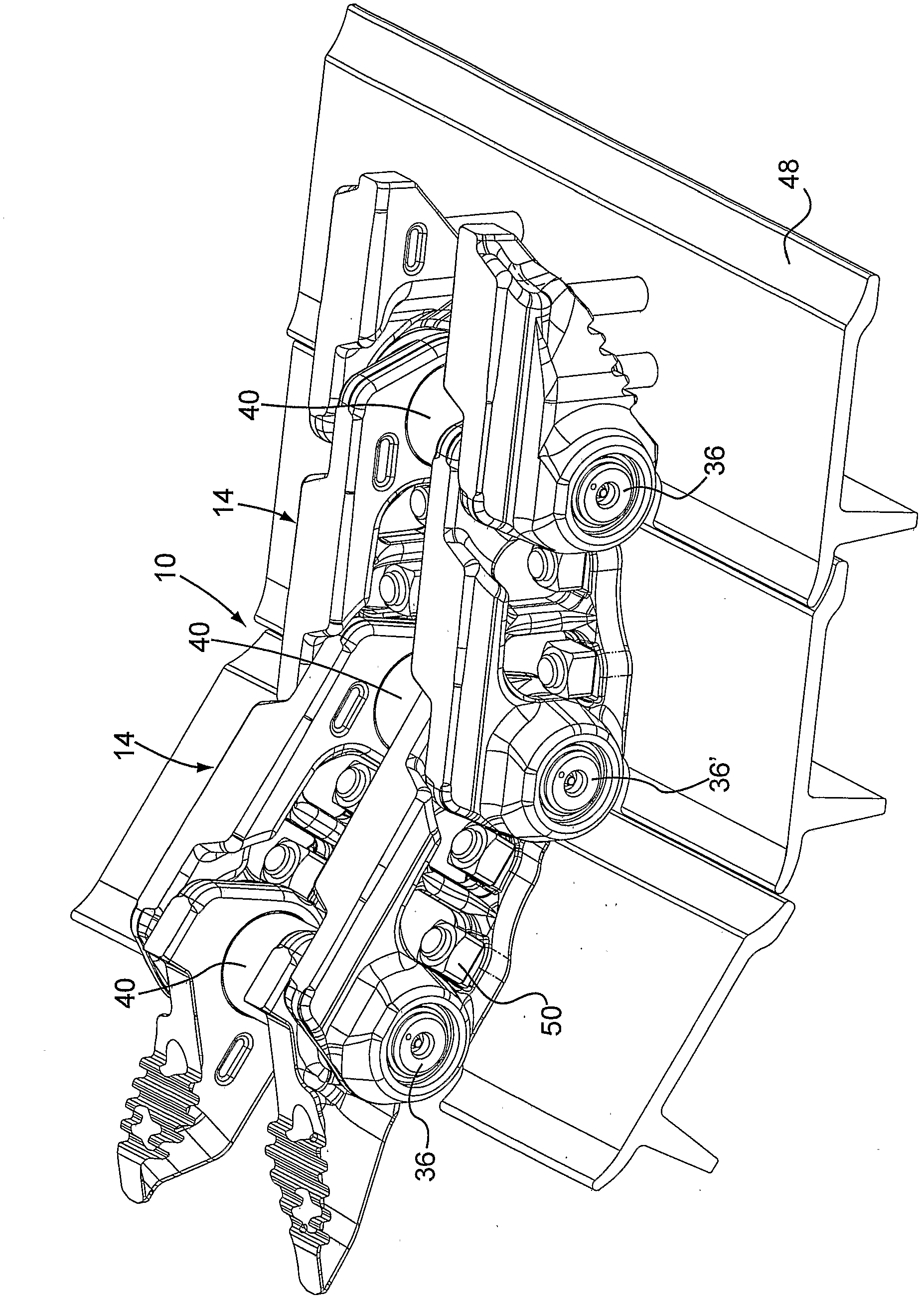

[0025] Referring to the drawings, there is shown a portion of a track generally indicated by the reference numeral 10 having rotating bushings in accordance with the present invention.

[0026] The track 10 essentially consists of a continuous series of articulated connections 12 , 12 ′ of the hinge type oriented according to an axis A-A substantially perpendicular to the central longitudinal extension axis B-B of the track 10 . The articulated connections 12 , 12 ′ are interconnected and held at a constant distance by a pair of links 14 having a longitudinal extension, arranged transversely and symmetrically with respect to the longitudinal center axis B-B of the track 10 .

[0027] Each link 14 is of the asymmetric type, that is to say provided with a first end flange 16 facing the outside of the track 10 if seen with reference to the longitudinal center axis B-B and with a second end flange facing the inside of the track 10 18 (or in other words, facing the longitudinal cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com