Method for separation and recovery of metal and nonmetal in waste printed circuit board

A technology for separating and recycling waste circuit boards, which is applied in the fields of electronic waste recycling, recycling technology, and solid waste removal. Reduce the difficulty of separation and recovery and avoid the effect of destructive crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

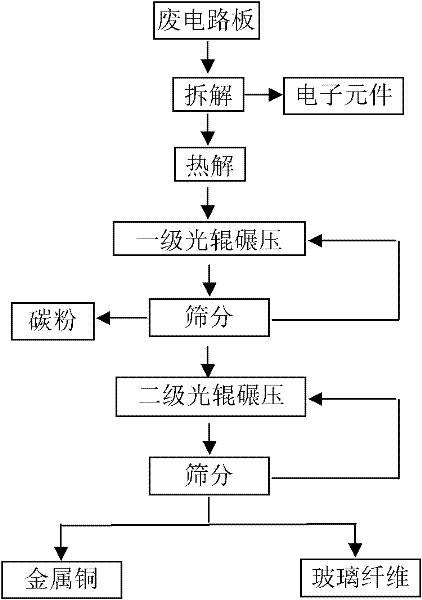

[0016] Embodiments of the invention employ the following steps:

[0017] (1) The waste circuit board with electrical components removed is pyrolyzed at 800°C, and the resin bonded between the glass fiber cloth and the metal layer is pyrolyzed and carbonized at high temperature, and the bonding strength between the glass fiber cloth and the metal layer is greatly reduced ;

[0018] (2) Send the waste circuit board pyrolysis residue collected in step (1) to the first-level double smooth roller rolling equipment for rolling, so that the resin pyrolytic carbon between the glass fiber layer and the glass fiber layer and the metal layer will fall off , the glass fiber cloth is completely separated from the metal layer in sheet form;

[0019] (3) The mixture of glass fiber sheet, metal sheet and carbon powder in step (2) is separated into carbon powder by vibrating screening equipment; First-level rolling equipment, rolling and sieving again until the material is completely dissoci...

Embodiment 2

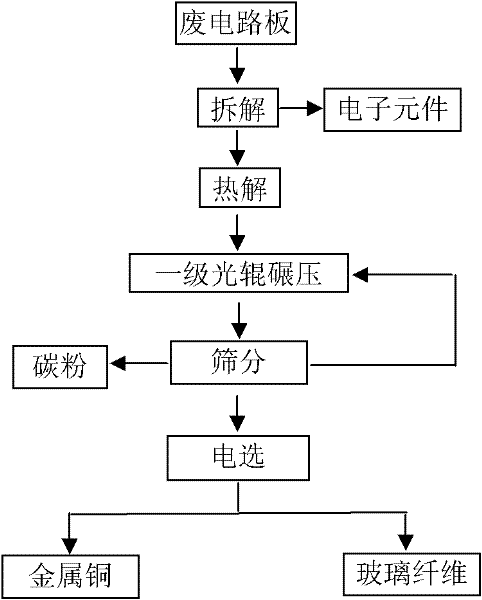

[0023] Embodiments of the invention employ the following steps:

[0024] (1) The waste circuit board with electrical components removed is pyrolyzed at 800°C, and the resin bonded between the glass fiber cloth and the metal layer is pyrolyzed and carbonized at high temperature, and the bonding strength between the glass fiber cloth and the metal layer is greatly reduced ;

[0025] (2) Send the waste circuit board pyrolysis residue collected in step (1) to the first-level double smooth roller rolling equipment for rolling, so that the resin pyrolytic carbon between the glass fiber layer and the glass fiber layer and the metal layer will fall off , the glass fiber cloth is completely separated from the metal layer in sheet form;

[0026] (3) The mixture of glass fiber sheet, metal sheet and carbon powder in step (2) is separated into carbon powder by vibrating screening equipment; First-level rolling equipment, rolling and sieving again until the material is completely dissoci...

Embodiment 3

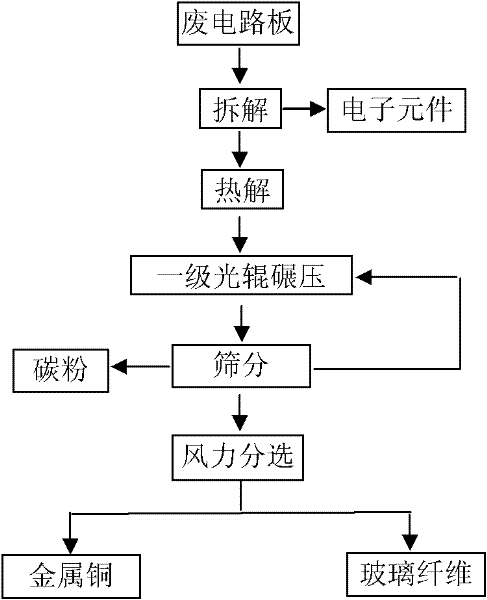

[0029] Embodiments of the invention employ the following steps:

[0030] (1) The waste circuit board with electrical components removed is pyrolyzed at 800°C, and the resin bonded between the glass fiber cloth and the metal layer is pyrolyzed and carbonized at high temperature, and the bonding strength between the glass fiber cloth and the metal layer is greatly reduced ;

[0031] (2) Send the waste circuit board pyrolysis residue collected in step (1) to the first-level double smooth roller rolling equipment for rolling, so that the resin pyrolytic carbon between the glass fiber layer and the glass fiber layer and the metal layer will fall off , the glass fiber cloth is completely separated from the metal layer in sheet form;

[0032] (3) The mixture of glass fiber sheet, metal sheet and carbon powder in step (2) is separated into carbon powder by vibrating screening equipment; First-level rolling equipment, rolling and sieving again until the material is completely dissoci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com