Porous membrane and preparation method thereof

A technology of porous membrane and pore-forming agent, applied in the field of porous membrane and its preparation, can solve the problems of low mechanical strength of polyimide porous membrane, easy collapse of pore structure, etc. Source-rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

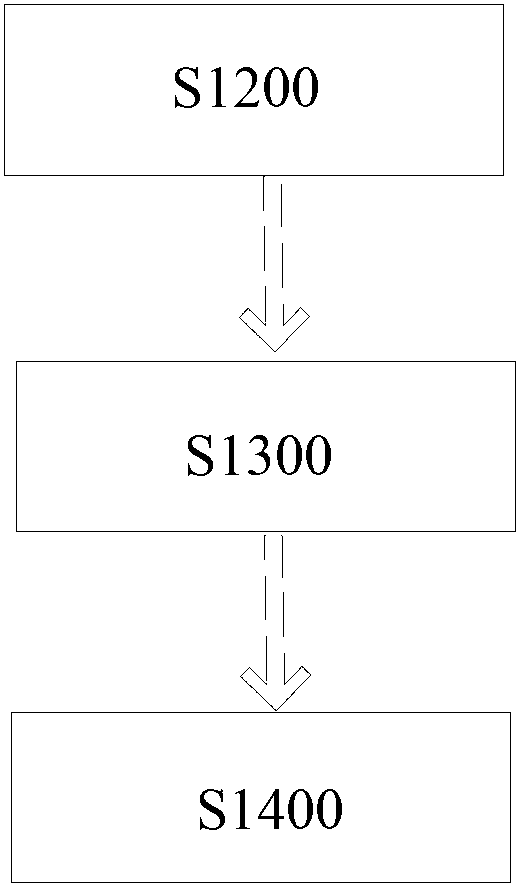

[0048] figure 1 A method for producing a porous membrane according to the present invention is shown. According to this method, first enter the S1200 step to prepare polyimide acid containing nanocellulose; then enter the S1300 step to make the polyimide acid into a polyimide film; finally enter the S1400 step to remove the polyimide film Inorganic pore forming agent to obtain polyimide porous membrane. In the present invention, the nano cellulose is used as the reinforcing material of the polyimide porous membrane, which can significantly improve the mechanical properties of the polyimide porous membrane.

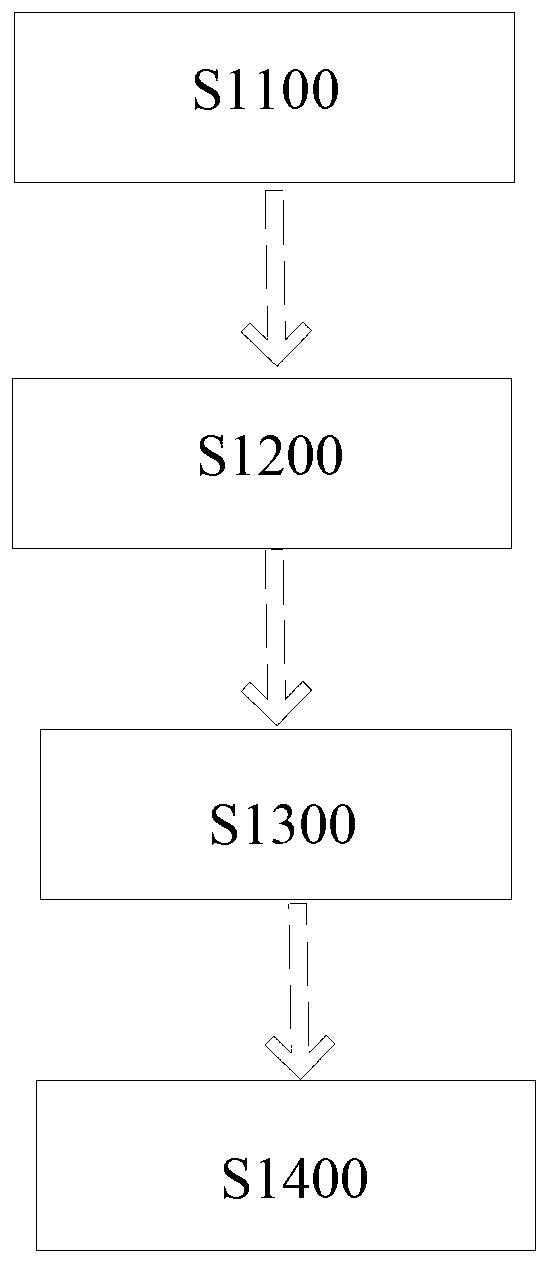

[0049] In order to further optimize the preparation method of the present invention to obtain a porous membrane with better performance, the present invention preferably adds the S1100 step before the S1200 step, such as figure 2 Shown: first enter the S1100 nanocellulose and the inorganic pore-forming agent surface modification step, nanocellulose and the inorganic por...

Embodiment 1

[0053] Such as figure 2 The preparation method first enters step S1100 to modify the surfaces of the nanocellulose and the inorganic pore-forming agent respectively. Weigh 3 parts by weight of nanocellulose (wherein the nanocrystalline cellulose accounts for 49% by mass of the nanocellulose), add 5 parts by weight of deionized water and 90 parts by weight of absolute ethanol, and magnetically stir Stir with a mixer or a stirring paddle at a speed of 20-200 rpm for 24 hours, add 2 parts by weight of aminopropyltriethoxysilane, stir at 60°C for 3 hours, and mix the reaction product with a speed of 1500 rpm After centrifugation, the obtained product is vacuum-dried to finally obtain surface-modified nanocellulose. The surface modification method of the inorganic pore-forming agent is the same as that of nanocellulose, so it will not be described in detail. Further, the surface modification method of nanocellulose and inorganic pore-forming agent in the following examples is th...

Embodiment 2

[0058] Such as figure 2 The preparation method first enters step S1100 to modify the surfaces of the nanocellulose and the inorganic pore-forming agent respectively. Secondly, enter the step S1200 to prepare polyimide acid containing nanocellulose: weigh 1 part by weight of modified nanocellulose powder in a dry 250ml three-necked flask, and 20 parts by weight of modified nanometer calcium carbonate powder, add 50ml In N,N-dimethylformamide (DMF), stir with a stirring blade at 100 rpm for 30 minutes, add 38 parts by weight of 4,4'-diaminodiphenyl ether, after fully dissolving, Under the conditions of ice-water bath and stirring, 41 parts by weight of pyromellitic dianhydride was added to the reaction system three times within 24 hours, until the reaction system was obviously viscous and then continued to stir for 3 hours.

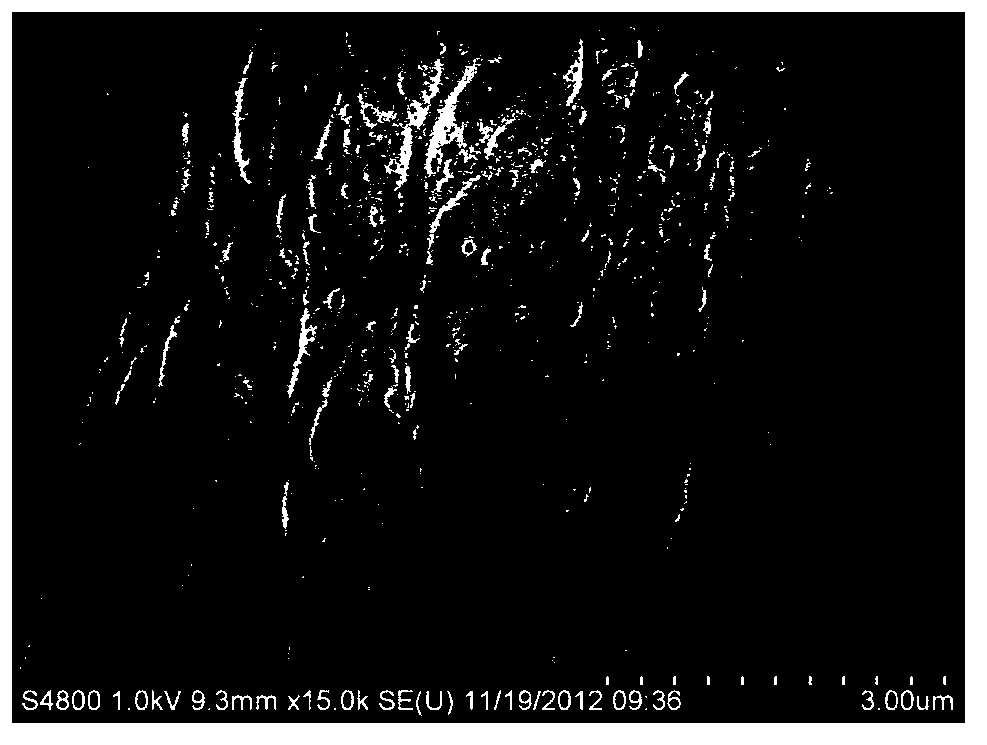

[0059] Next enter step S1300 to make polyimide acid into polyimide film: drop 0.3 g of the above polyimide acid solution on a 30mm×50mm glass slide, plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com