Silver-bismuth superlattice nanowire array and preparation method and application thereof

A technology of nanowire arrays and silver nanowires, which is applied in nanotechnology, nanotechnology, and the preparation of test samples, can solve problems such as difficult to obtain accurate and controllable sizes, achieve melting test signal enhancement, scientific preparation methods, and eliminate The effect of mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The concrete steps of preparation are:

[0032] Step 1, first use the secondary anodic oxidation method to obtain a through-hole alumina template with a hole diameter of 55nm, and then plate a gold film on one side of the through-hole alumina template.

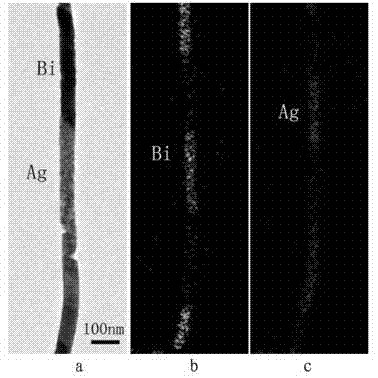

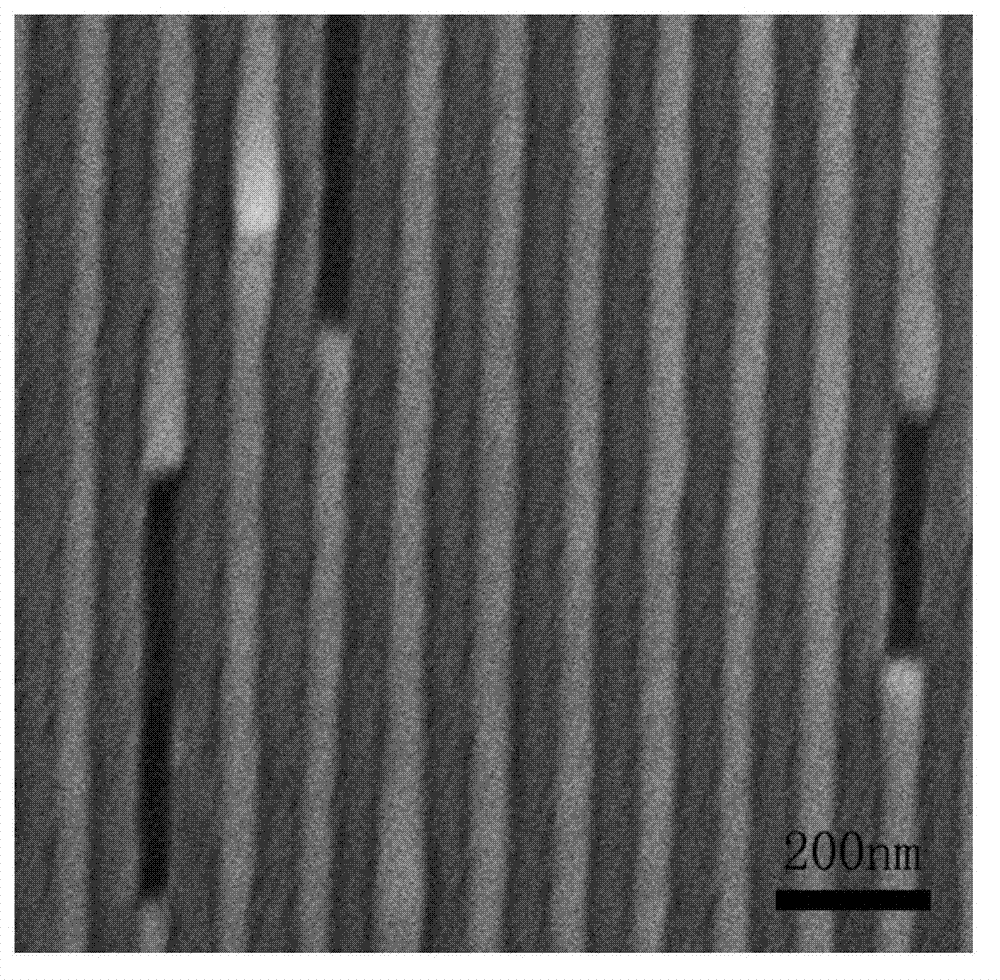

[0033] Step 2, first place the aluminum oxide template coated with a gold film on one side in the silver electrolyte, and after electrodeposition at a DC voltage of 0.4V for 35 seconds, soak and clean it in deionized water for 1 minute. Then it was placed in a bismuth electrolyte, and after being electrodeposited at a DC voltage of 0.9V for 600s, it was soaked and cleaned in deionized water for 1 min. Repeat the above steps to place the aluminum oxide templates coated with a gold film on one side in the silver electrolyte and bismuth electrolyte in turn for electrodeposition, and the number of cycles of immersion and cleaning in deionized water is 2 times, and the approximate figure 1 and figure 2 The silver-bismuth ...

Embodiment 2

[0035] The concrete steps of preparation are:

[0036] Step 1, first use the secondary anodic oxidation method to obtain a through-hole alumina template with a hole diameter of 58nm, and then plate a gold film on one side of the through-hole alumina template.

[0037] Step 2, first place the aluminum oxide template coated with a gold film on one side in the silver electrolyte, electrodeposit it at a DC voltage of 0.45V for 33s, then soak and clean it in deionized water for 2min. Then it was placed in a bismuth electrolyte, and after being electrodeposited at a DC voltage of 1.0 V for 460 s, it was soaked in deionized water and cleaned for 2 min. Repeat the above steps to place the aluminum oxide template coated with a gold film on one side in the silver electrolyte and bismuth electrolyte in turn for electrodeposition, and the number of cycles of immersion and cleaning in deionized water is 4 times. figure 1 and figure 2 The silver-bismuth superlattice nanowire array shown....

Embodiment 3

[0039] The concrete steps of preparation are:

[0040] Step 1, first use the secondary anodic oxidation method to obtain a through-hole alumina template with a hole diameter of 60nm, and then plate a gold film on one side of the through-hole alumina template.

[0041] Step 2, first place the aluminum oxide template coated with a gold film on one side in a silver electrolyte, and after electrodeposition at a DC voltage of 0.5V for 30 seconds, soak and clean it in deionized water for 3 minutes. Then it was placed in a bismuth electrolyte, and after being electrodeposited at a DC voltage of 1.1V for 320s, it was soaked and cleaned in deionized water for 3 minutes. Repeat the above steps to place the aluminum oxide templates coated with a gold film on one side in the silver electrolyte and bismuth electrolyte for electrodeposition, and place the number of cycles of immersion and cleaning in deionized water for 6 times to obtain the following: figure 1 and figure 2 The silver-bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com