Amidoxime-group-modified cyclodextrin/sodium alginate gel ball composite adsorption material as well as preparation method and application thereof

A composite adsorption material, sodium alginate technology, applied in the fields of chemistry and environment, can solve the problems of low mechanical strength, poor uranium absorption ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to solve the above technical problems, the present invention is achieved through the following technical solutions:

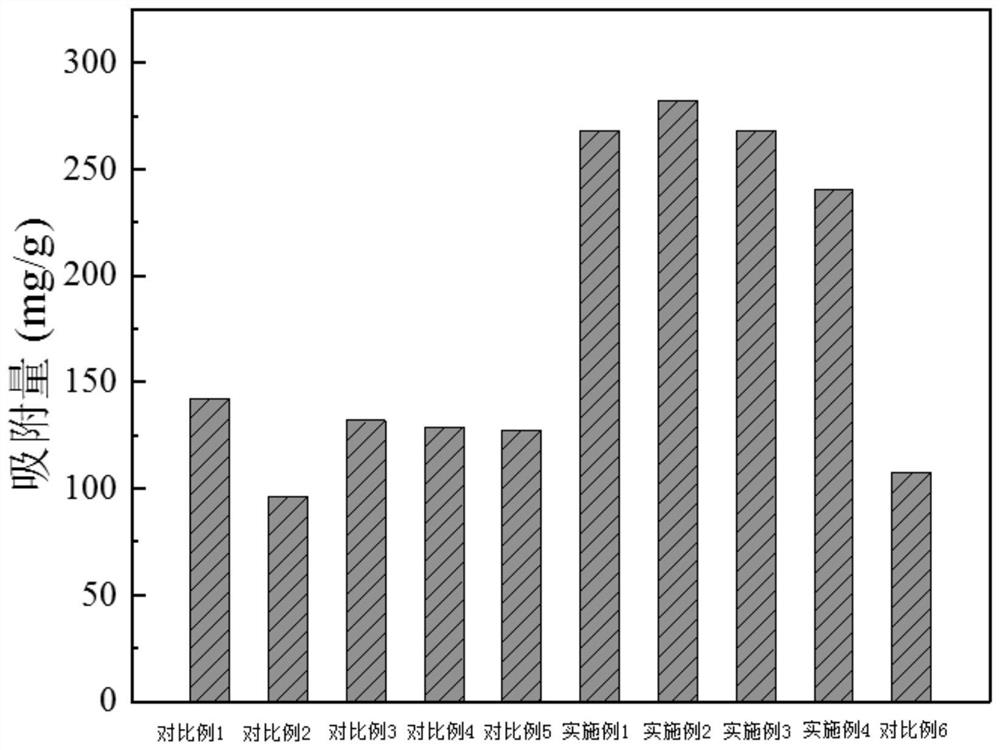

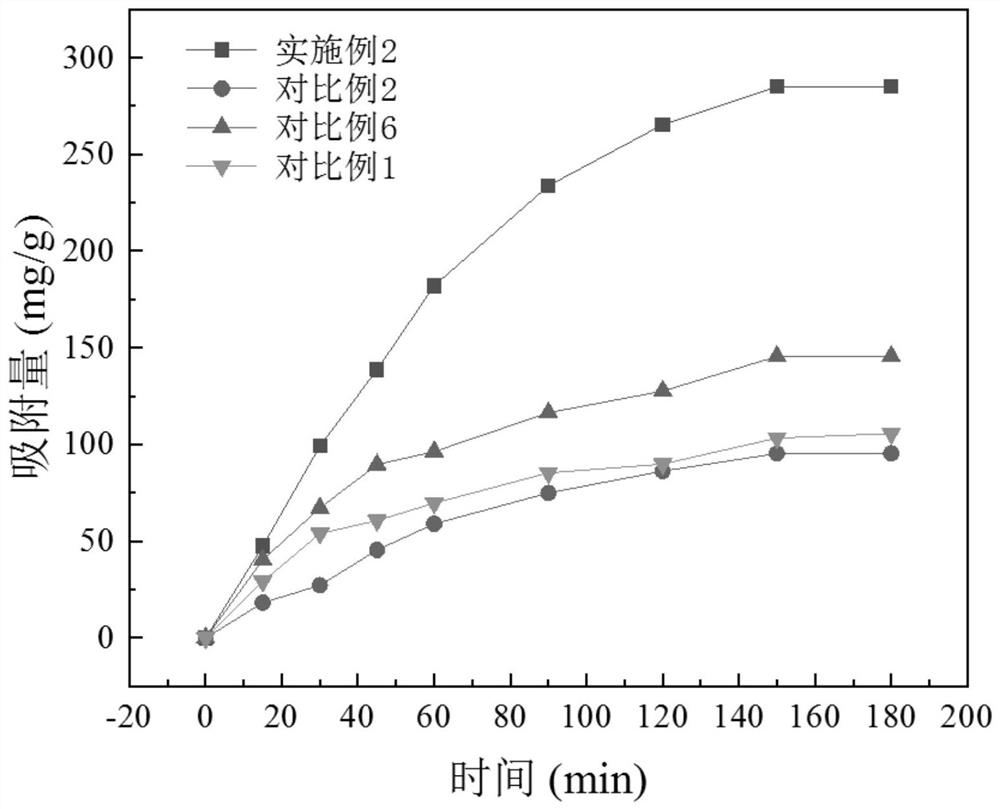

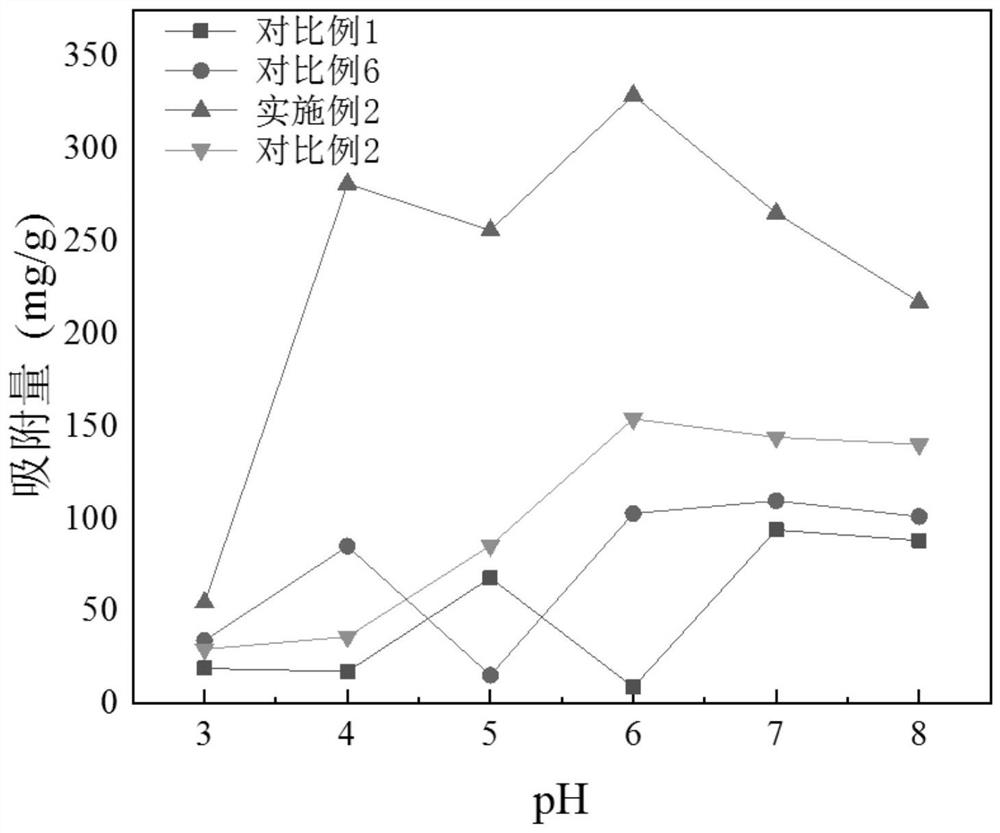

[0010] A cyclodextrin / sodium alginate gel ball composite adsorption material modified by amidoxime group, the composite adsorption material is a gel ball with uniform size, which is cyclodextrin, amidoximated diaminohormones It is obtained by mixing and cross-linking maleonitrile and sodium alginate in one step, and the amino group of amidoximated diaminomaleonitrile is combined with the oxygen-containing functional group of sodium alginate and the oxygen-containing functional group of cyclodextrin.

[0011] A preparation method of amidoxime-modified cyclodextrin / sodium alginate gel ball composite adsorption material, comprising the following steps:

[0012] Add sodium alginate, β-cyclodextrin and amidoximated diaminomaleonitrile into deionized water, stir at constant temperature to dissolve completely to obtain a mixed solution, and drop the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com