A preparing method of a metal-based polyvinylpyrrolidone ionic liquid-grafted attapulgite clay composite flocculating agent and applications of the composite flocculating agent

A technology based on vinylpyrrolidone and vinylpyrrolidone, which is applied in the field of preparation of polymerized metal-based vinylpyrrolidone ionic liquid grafted attapulgite composite flocculants, can solve problems such as troublesome separation process, achieve fast settling speed, simple preparation method, and flocculation effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

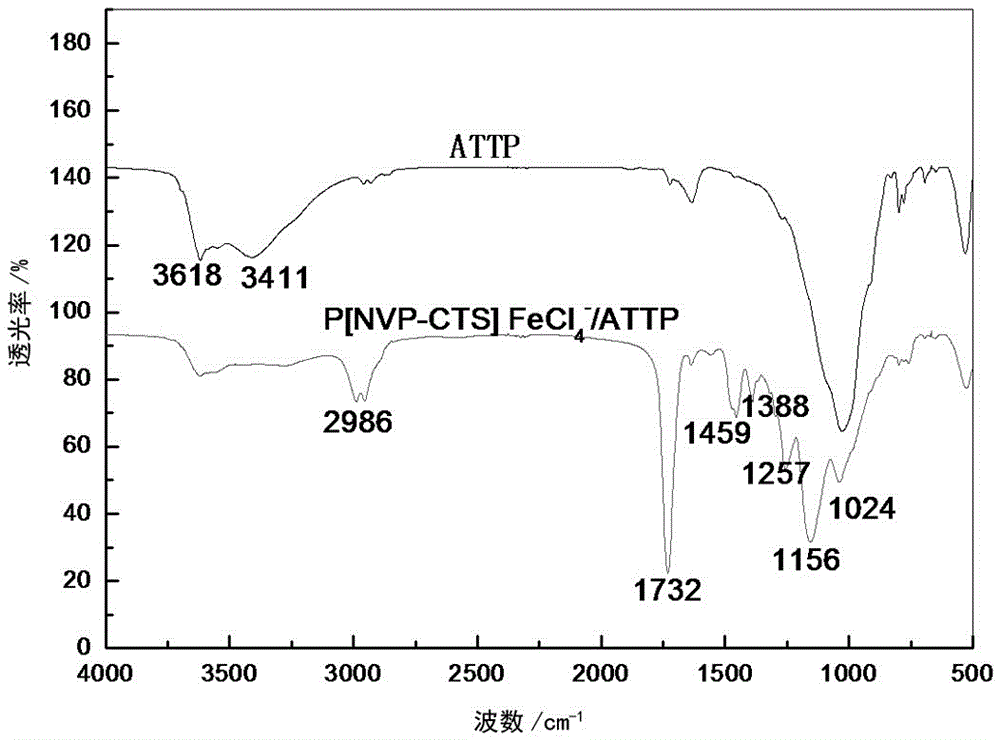

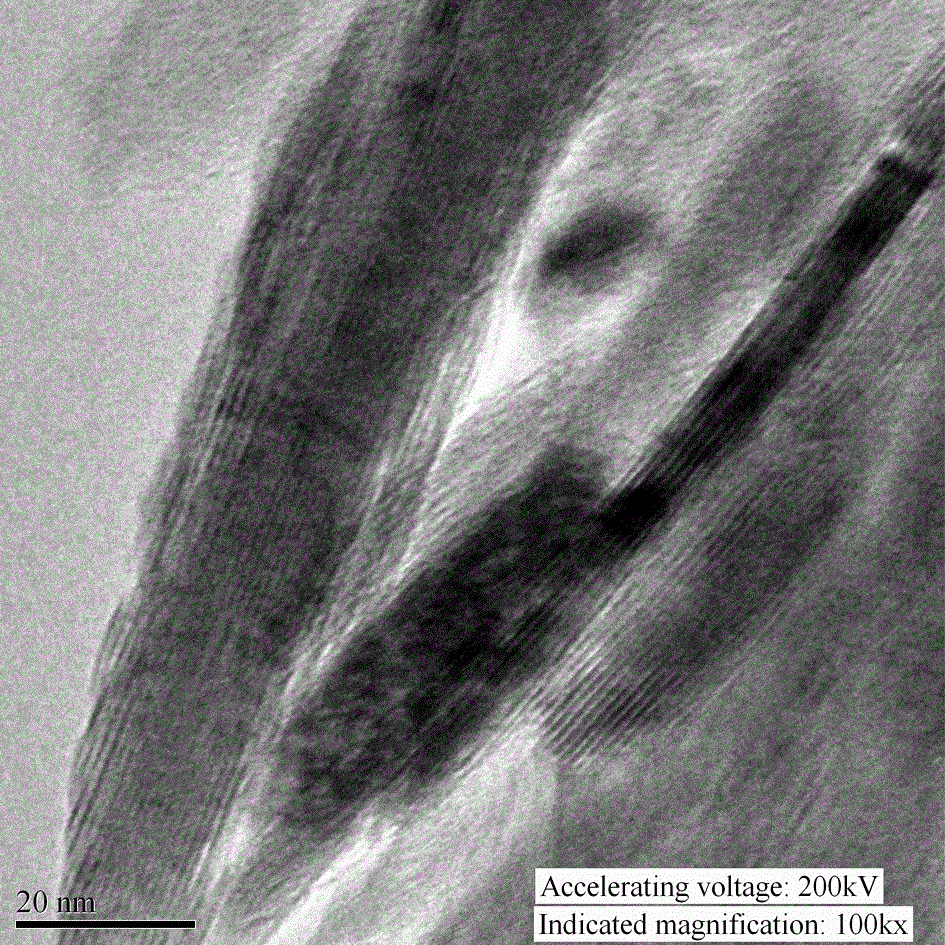

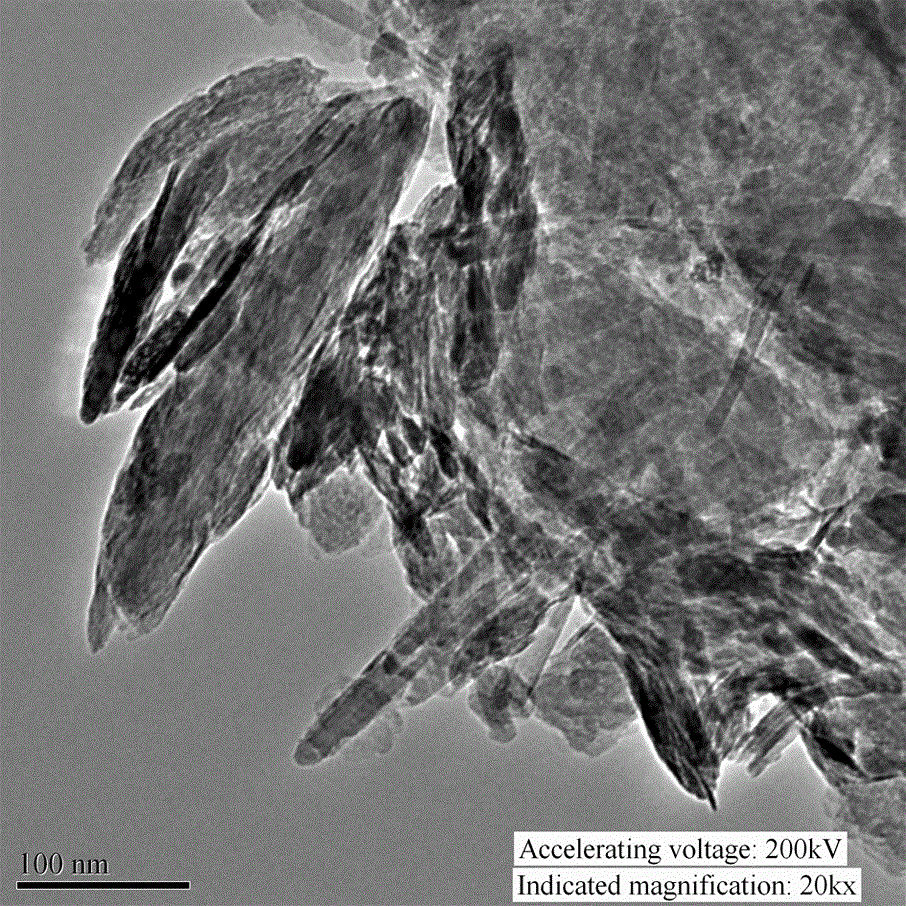

[0027] This embodiment specifically relates to a preparation method and application of a polymerized metal-based vinylpyrrolidone ionic liquid grafted attapulgite composite flocculant, which specifically includes the following steps:

[0028] (1) Preparation of functionalized ionic liquid monomer:

[0029] In a 500 ml three-necked flask, add 11.1g (0.1mol) of vinylpyrrolidone (NVP), 24g (0.1mol) of 3-chloropropyltriethoxysilane (3-CTS) and 20ml of ethanol solvent for stirring , under the protection of nitrogen and the temperature of 80 ° C, the reaction was refluxed for 24 h; then the ethanol solvent was evaporated by rotary evaporation, and ethyl acetate and methanol were washed in sequence, and vacuum dried to obtain 28 g of yellow transparent functionalized ionic liquid ([NVP-CTS ] Cl - ), the yield is 80%, and the reaction principle is as follows:

[0030]

[0031] Put 28g of functionalized ionic liquid ([NVP-CTS]Cl - ) into a 250ml beaker, weigh 13g of ferric chlori...

Embodiment 2

[0041] This embodiment specifically relates to a preparation method and application of a polymerized metal-based vinylpyrrolidone ionic liquid grafted attapulgite composite flocculant, which specifically includes the following steps:

[0042] (1) Preparation of functionalized ionic liquid monomer:

[0043] In a 500 ml three-necked flask, add 11.1g (0.1mol) of vinylpyrrolidone (NVP), 24g (0.1mol) of 3-chloropropyltriethoxysilane (3-CTS) and 20ml of ethanol solvent for stirring , under the protection of nitrogen and the temperature of 80 ° C, the reaction was refluxed for 24 h; then the ethanol solvent was evaporated by rotary evaporation, and ethyl acetate and methanol were washed in sequence, and vacuum dried to obtain 28 g of yellow transparent functionalized ionic liquid ([NVP-CTS ] Cl - ), the yield is 80%:

[0044] Put 28g of functionalized ionic liquid ([NVP-CTS]Cl - ) into a 250ml beaker, weigh 13g of ferric chloride (FeCl 3 ) was slowly added to the liquid in the be...

Embodiment 3

[0050] This embodiment specifically relates to a preparation method and application of a polymerized metal-based vinylpyrrolidone ionic liquid grafted attapulgite composite flocculant, which specifically includes the following steps:

[0051] (1) Preparation of functionalized ionic liquid monomer:

[0052] In a 500 ml three-necked flask, add 11.1g (0.1mol) of vinylpyrrolidone (NVP), 24g (0.1mol) of 3-chloropropyltriethoxysilane (3-CTS) and 20ml of ethanol solvent for stirring , under the protection of nitrogen and the temperature of 80 ° C, the reaction was refluxed for 24 h; then the ethanol solvent was evaporated by rotary evaporation, and ethyl acetate and methanol were washed in sequence, and vacuum dried to obtain 28 g of yellow transparent functionalized ionic liquid ([NVP-CTS ] Cl - ), the yield is 80%:

[0053] Put 28g of functionalized ionic liquid ([NVP-CTS]Cl - ) into a 250ml beaker, weigh 13g of ferric chloride (FeCl 3 ) was slowly added to the liquid in the be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com