Ecologically safe composite efficient flocculant

A composite flocculant, an ecologically safe technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of poor flocculation effect of the initial material of pure natural polysaccharides, achieve good flocculation effect, wide applicability, and flocculation performance high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

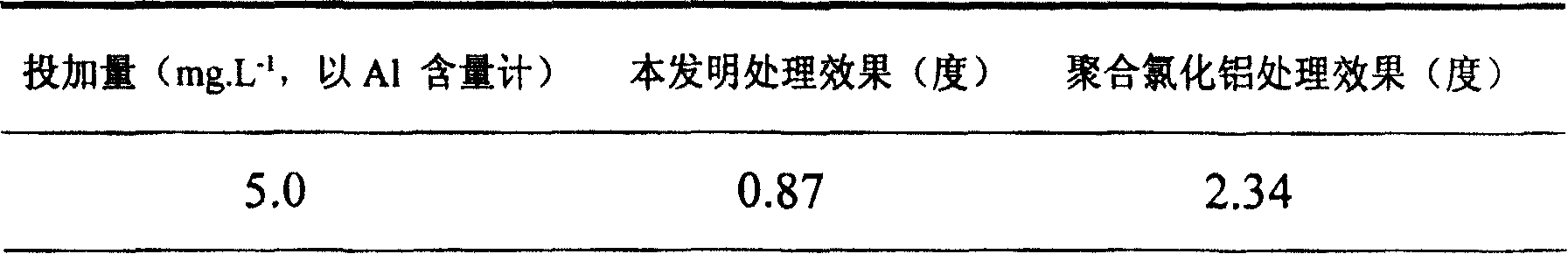

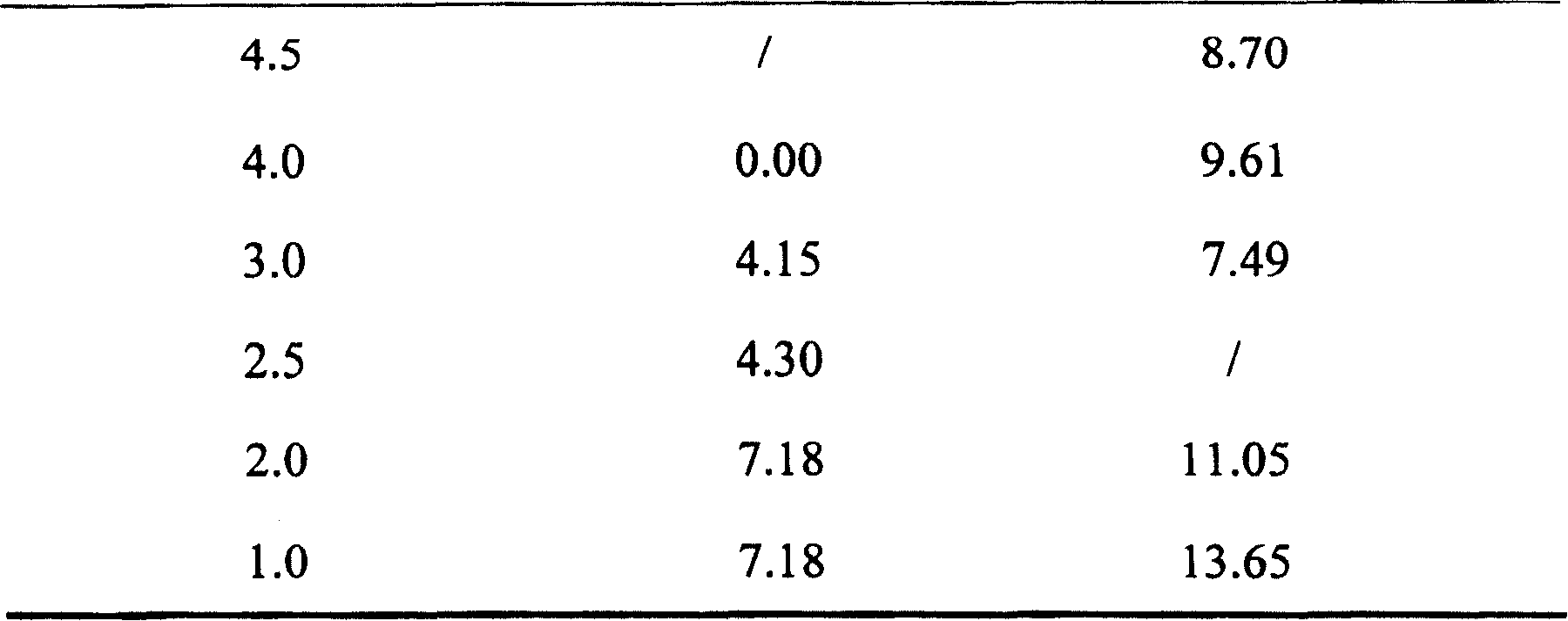

Examples

Embodiment 1

[0029] The present invention takes aluminum salt, cornstarch, dehydrated alcohol, sodium hydroxide (NaOH) as raw material, wherein: aluminum salt (AlCl 3 ), corn starch is the main component, absolute ethanol is used as the reaction solvent, and sodium hydroxide is used for the modification of corn starch; AlCl 3 The mass ratio of aluminum to cornstarch is 1:18;

[0030] Its preparation method is: (1) Preparation of aluminum salt: take 1 gram of aluminum powder according to the mass ratio and mix it with 20% HCl until it is completely dissolved to form AlCl 3 Solution; (2) modification of starch: get 18 grams of cornstarch and dissolve completely with absolute ethanol, slowly add 20mL 20%NaOH in a water bath at 55°C and slowly stir for modification reaction for 1 hour; (3) composite reaction: modify The final starch was made into a solution by adding water at a volume ratio of 1:3, and the pH was adjusted to 3.0 with 0.1N HCl solution, and the AlCl 3 The solution and the mod...

Embodiment 2

[0033] The difference from Example 1 is that the mass ratio of aluminum in the aluminum salt in the raw material of this example to cornstarch is 1: 100; its preparation method is: (1) the preparation of aluminum salt: 1 gram of aluminum powder with 20% HCl until completely dissolved to form AlCl 3 Solution; (2) modification of starch: get 100 grams of cornstarch and dissolve completely with absolute ethanol, slowly add 100mL 20% NaOH in a 75°C water bath and slowly stir for modification reaction for 10 hours; (3) compound reaction: modify The final starch was made into a solution by adding water at a volume ratio of 1:5, and the pH was adjusted to 5.0 with 0.1N HCl solution, and the AlCl 3 The solution was stirred and mixed with the modified starch and reacted in a 75°C water bath for 24 hours to obtain a white milky product, which is the product flocculant.

[0034] In this embodiment, the sewage to be treated is alkaline (pH=9), and the proportion of starch is increased to...

Embodiment 3

[0036] The difference from Example 1 is that the mass ratio of aluminum to cornstarch in the aluminum salt in the raw material of this example is 1:5; the preparation method is: (1) take commercially available AlCl 3 Make a solution, wherein: the aluminum content in the aluminum salt is 1 gram, (2) modification of starch: take 5 grams of corn starch and dissolve it completely with absolute ethanol, slowly add 5 mL of 20% NaOH in a water bath at 40 ° C and slowly stir for modification React for 30 minutes; (3) Composite reaction: add water to the modified starch in a volume ratio of 1:1 to form a solution, and then add AlCl 3 Stir and mix the solution with the modified starch, then adjust the pH to 6.0 with 0.1N HCl solution, and react in a 40°C water bath for 30 minutes to obtain a white milky product, and then wash the white milky product alternately with absolute ethanol and water Take off 3 times, filter, dry, and pulverize to obtain a white powder product.

[0037] The ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com