Crosslinked polystyrene-polypropenyl hydroximic acid inter-penetrating network resin and preparation method and application thereof

A technology of polypropylene-based hydroxamic acid and cross-linked polystyrene, which is applied in chemical instruments and methods, ion exchange, and other chemical processes, and can solve problems such as poor mechanical properties, restrictions on the application of adsorption and separation technology, and small adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Preparation of spherical crosslinked polystyrene macroporous resin:

[0072] Add 10 parts of styrene, 1 part of divinylbenzene, and 0.1 part of benzoyl peroxide into the reactor, add 6.5 parts of liquid paraffin, 6.5 parts of toluene and 0.2 parts of polyvinyl alcohol under stirring, and 65 parts of water as a solvent to control the reaction The temperature was 80°C, reacted for 4 hours, then raised the temperature to 90°C, reacted for 2 hours, filtered, extracted with petroleum ether to remove the porogen, and dried to obtain a white spherical cross-linked polystyrene macroporous resin (referred to as PS resin).

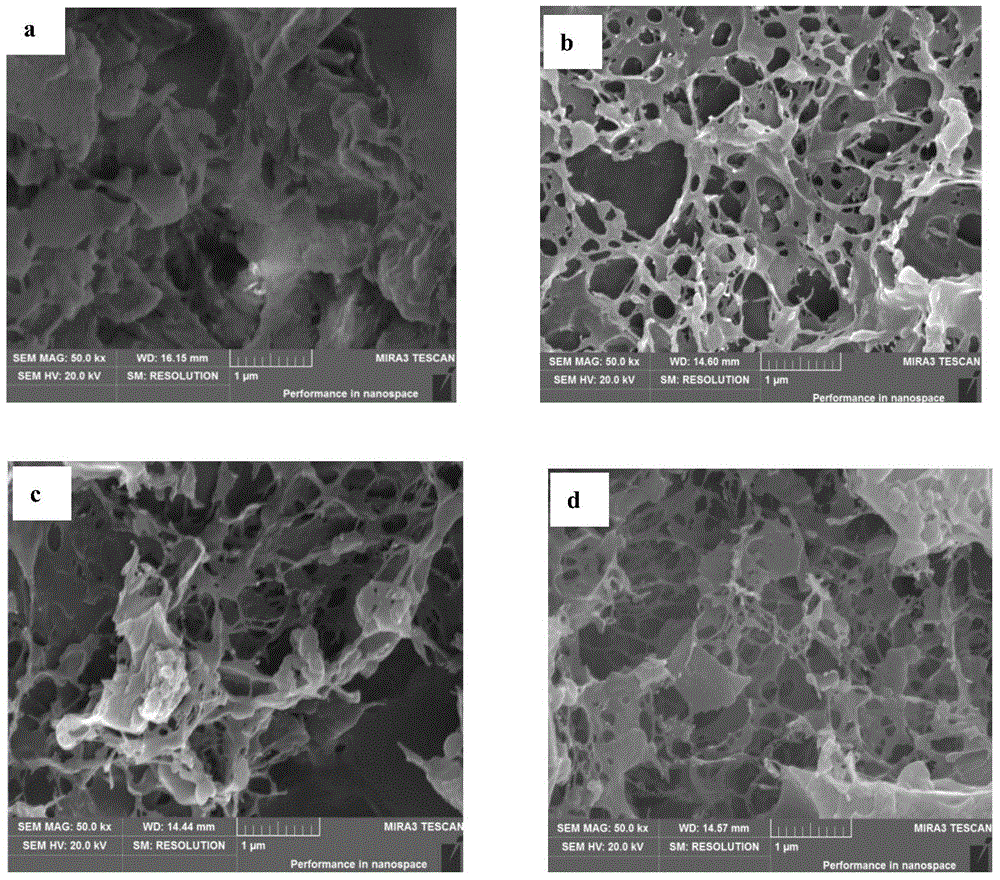

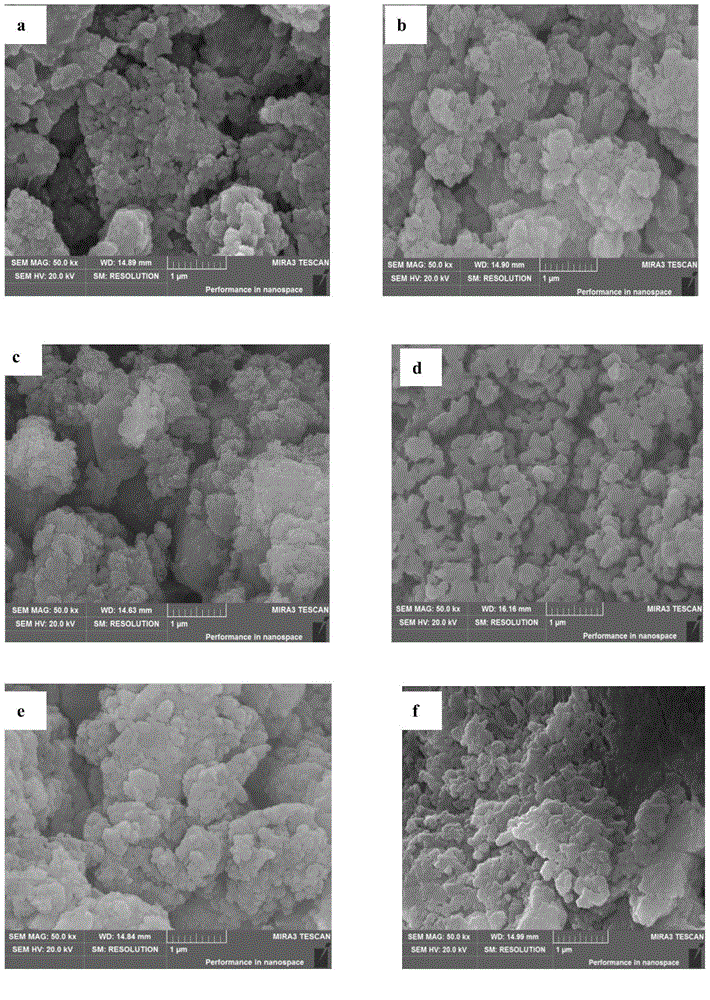

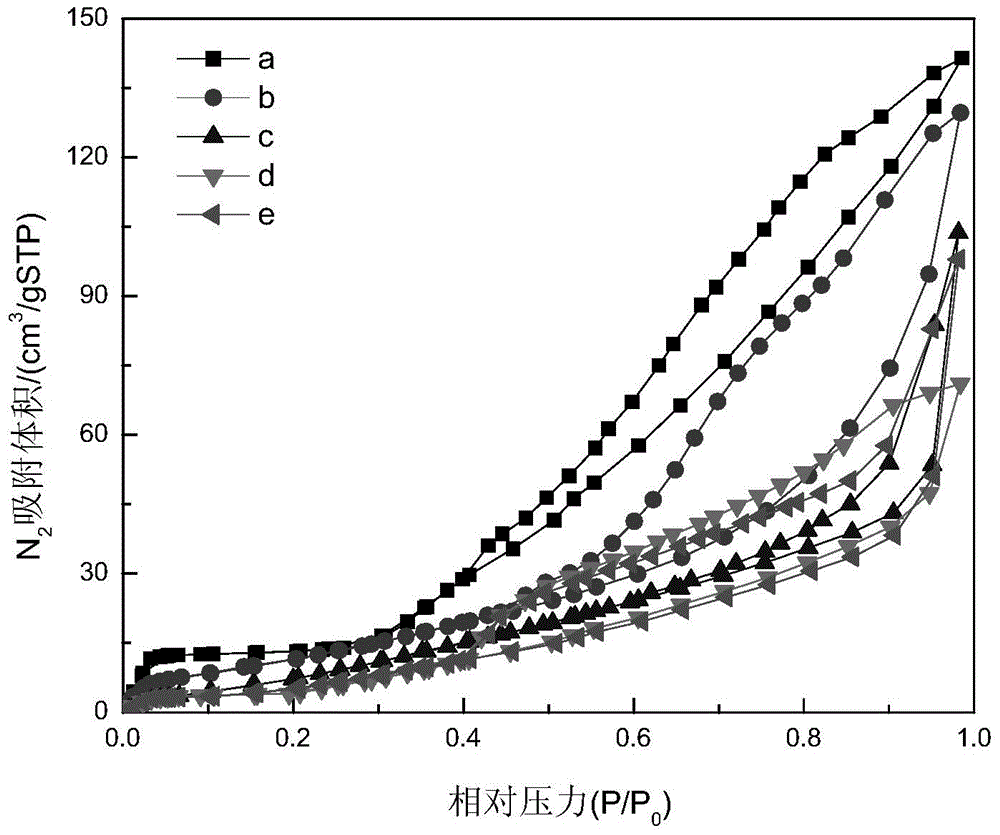

[0073] The specific surface area and pore size test results of PS resin are as follows: figure 1 , figure 2 As shown, the average particle size of the resin is 0.89mm, and the specific surface area is 141.1m 2 / g, the average pore diameter is 8.57nm, and the pore volume is 0.5472cm 3 / g.

Embodiment 2

[0075] Preparation of crosslinked polystyrene-polypropylene hydroxamic acid interpenetrating network resin:

[0076] Add 7.64 parts of hydroxylamine hydrochloride with a purity of 99% and 9.6 parts of sodium hydroxide with a purity of 99% into the reactor, add 43.5 parts of methanol water with a mass ratio of 1:4 as a solvent, and add 17.8 parts of methyl acrylate under stirring, Control the temperature at 35°C, react for 4 hours, acidify, filter, rotary evaporate, and purify to obtain a reddish-brown viscous liquid. Then add 5 parts of swollen PS resin (prepared in Example 1) into the reactor and stir and impregnate with 5 parts of propenyl hydroxamic acid and 0.8 part of divinylbenzene for 2 hours, filter, take out the resin, and mix the resin with 0.6 Add 50 parts of benzoyl peroxide to the above-mentioned reactor, add 50 parts of water containing 0.15 parts of polyvinyl alcohol as a solvent, control the pH of the solution to 6, heat up to 85 ° C for 2 hours, and continue t...

Embodiment 3

[0079] Preparation of cross-linked polystyrene-lanthanum ion imprinted polypropylene hydroxamic acid interpenetrating network resin:

[0080] Add 7.64 parts of hydroxylamine hydrochloride with a purity of 99% and 9.6 parts of sodium hydroxide with a purity of 99% into the reactor, add 43.5 parts of methanol water with a mass ratio of 1:4 as a solvent, and add 17.8 parts of methyl acrylate under stirring, Control the temperature at 35°C, react for 4 hours, acidify, filter, rotary evaporate, and purify to obtain a reddish-brown viscous liquid. 8.7 parts of propenyl hydroxamic acid and 16.25 parts of lanthanum nitrate were reacted in a solution with a pH value of 4 to generate propenyl hydroxamic acid assembled with lanthanum ions. Then add 5 parts of swollen PS resin (prepared in Example 1) into the reactor, stir and impregnate with 5 parts of propenylhydroxamic acid and 0.8 part of divinylbenzene assembled with lanthanum ions for 2 hours, filter, and take out the resin , add r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com