Wave-absorbing lightweight aggregate and preparation method

A lightweight aggregate and raw material technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve problems such as high water absorption, affecting the mechanical properties of cement-based wave-absorbing materials, and consuming natural resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

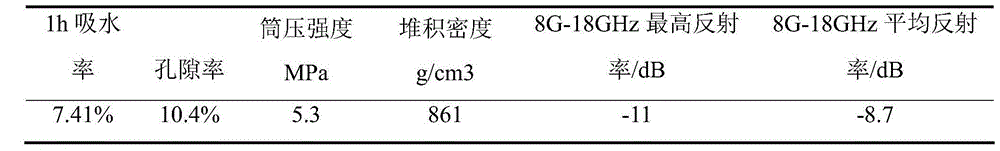

Embodiment 1

[0039]A preparation method of light absorbing aggregate, which comprises the steps of:

[0040] 1) Selection of raw materials: water, shale, municipal domestic sludge and fly ash are used as raw materials, and mixed according to the ratio to obtain raw meal. Each gram of raw meal contains 0.23g of water, 0.615g of shale, and 0.154g of municipal domestic sludge. Fly ash is 0.001g;

[0041] 2) One-time forming: using anhydrous roll forming to form the raw material into raw material balls, and control the diameter of the raw material balls to 5mm-12mm;

[0042] 3) Primary pre-burning and roasting: Air-dry the raw meal balls for 24 hours, then heat them to 450°C under carbonaceous fuel for the first pre-burning, and the pre-burning time is 15 minutes; then place the pre-fired raw meal balls on carbon As for the high-quality fuel, it is roasted in a high-temperature furnace, the roasting temperature is about 1180 ° C, and the roasting time is 15 minutes. The pre-burning and roasti...

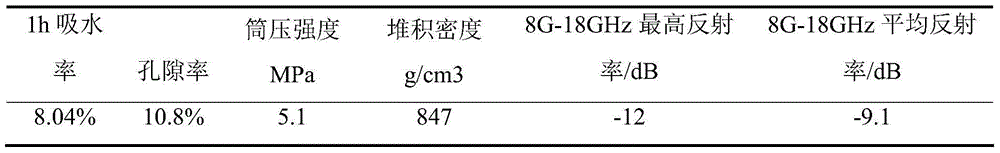

Embodiment 2

[0052] A preparation method of light absorbing aggregate, which comprises the steps of:

[0053] 1) Select raw materials: use water, shale, and municipal domestic sludge as raw materials, and mix them according to the ratio to obtain raw meal. Each gram of raw meal contains 0.13g of water, 0.696g of shale, and 0.174g of municipal domestic sludge;

[0054] 2) One-time molding: Use a disc granulator to turn the raw meal into raw meal balls, add water at 15% of the mass of the raw meal, and control the diameter of the raw meal balls to 5mm-12mm, air-dry the raw meal balls for 24 hours per gram of raw meal The water content of the ball is below 0.05g;

[0055] 3) Primary pre-burning and roasting: ,, and then heated to 500°C under carbonaceous fuel for the first pre-burning, the pre-burning time is 20min; then place the pre-burned raw pellets on the carbonaceous fuel, Roasting in a high temperature furnace, the calcination temperature is about 1200°C, the calcination time is 20min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Average reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com