Recycling method of waste zinc-manganese battery

A zinc-manganese battery, recycling technology, applied in the direction of battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of short process flow, complex process flow, high recovery efficiency, etc., achieve high economic and social value, separate Good effect and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

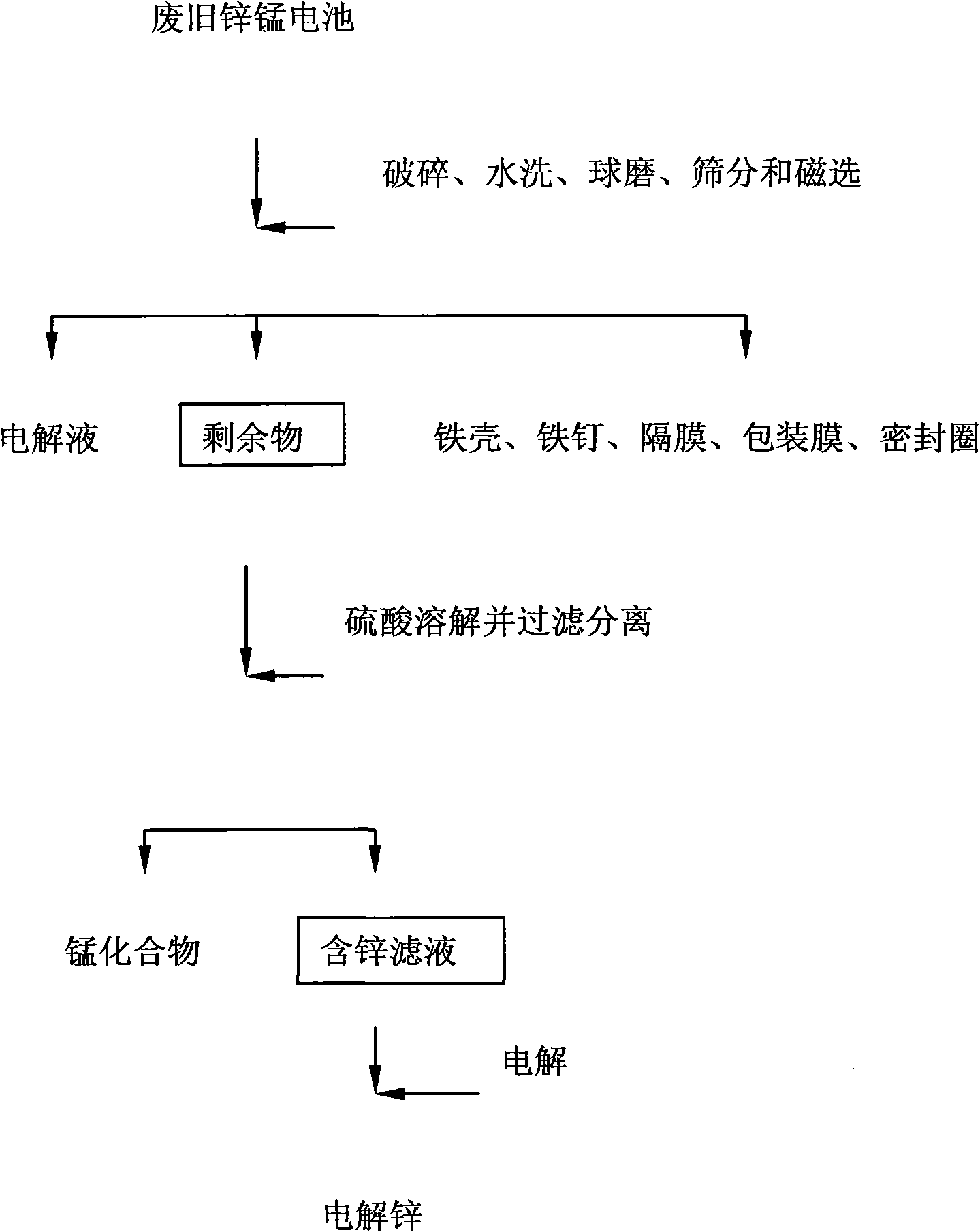

[0026] The flow chart of the present invention is as figure 1 Shown, the recovery processing method of waste zinc-manganese battery of the present invention, it comprises the following steps:

[0027] 1) The battery is broken and the electrolyte is recovered;

[0028] 2) Separating iron and organic components from the water-washed crushed product;

[0029] 3) acid dissolves and separates the residue;

[0030] 4) Zinc is recovered from the filtrate.

[0031] In the above step 1), the shell of the used battery is opened, and then the electrolyte is separated by washing with water.

[0032] In the above step 1), the shell of the battery is first broken and opened, and the pole core material can fall off from the shell in the subsequent ball milling process, and the electrolyte is recovered by filtering after adding water to the broken material for soaking.

[0033] In the above step 2), the method including ball milling, sieving and magnetic separation is used to separate the...

Embodiment 2

[0046] The recycling method of this embodiment is the same as that of Embodiment 1, the difference is that the battery to be recycled is a waste zinc-manganese dry battery, and in step 1) a cutting machine is used to break the battery, and in step 3) the sulfuric acid concentration of the broken battery is dissolved 6mol / L, in step 4), the electrolysis uses a titanium plate as the electrode material of the electrolytic cell.

Embodiment 3

[0048] The recovery method of this embodiment is the same as that of Example 1, the difference is that the batteries recovered are all alkaline zinc-manganese batteries, and the concentration of sulfuric acid for dissolving the broken battery in step 3) is 0.5mol / L, and in step 4) , Electrolysis uses titanium plates as the electrode material of the electrolytic cell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com