Method for producing ultra-high purity aluminium sulfate from fly ash

An ultra-high-purity, fly ash technology is applied in the field of ultra-high-purity aluminum sulfate and fly ash to produce ultra-high-purity aluminum sulfate. The effect of high iron efficiency, simple operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

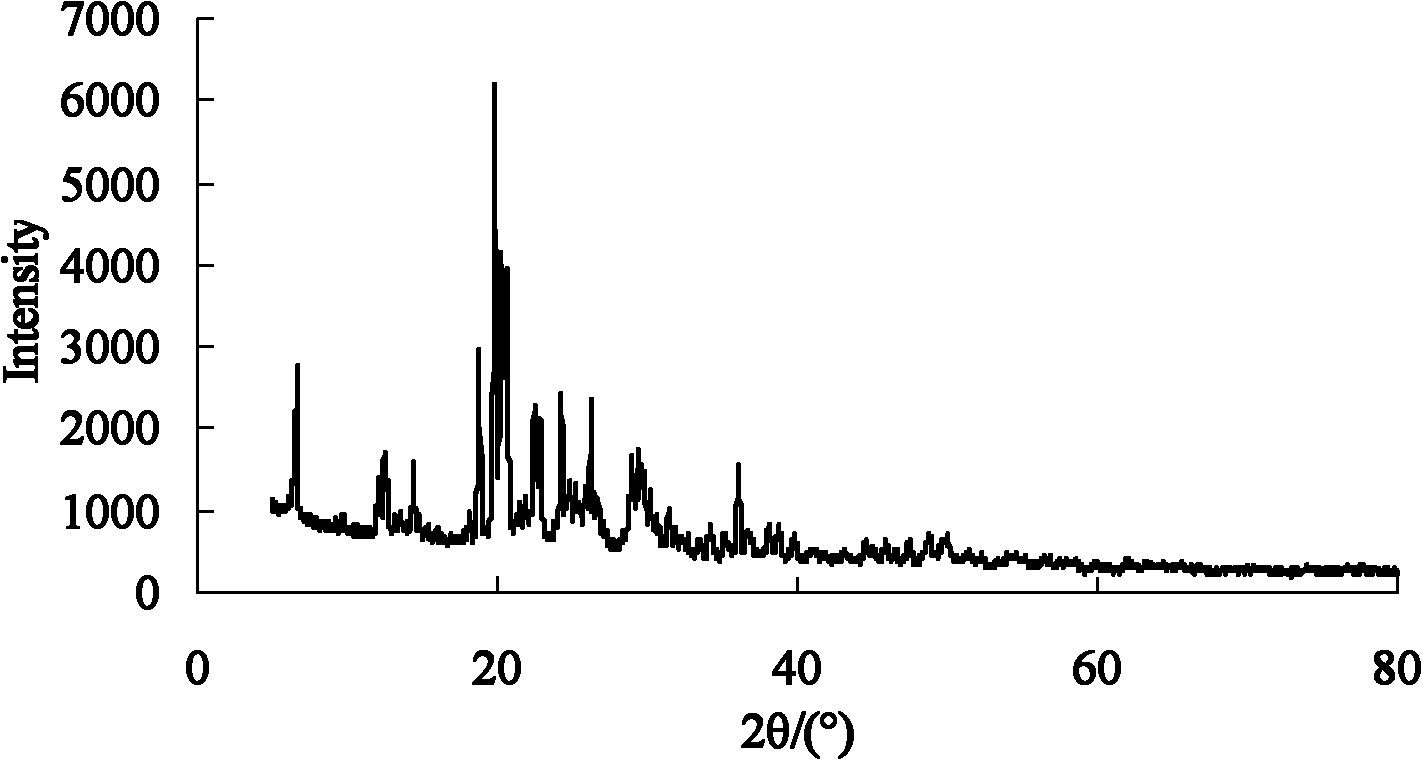

Image

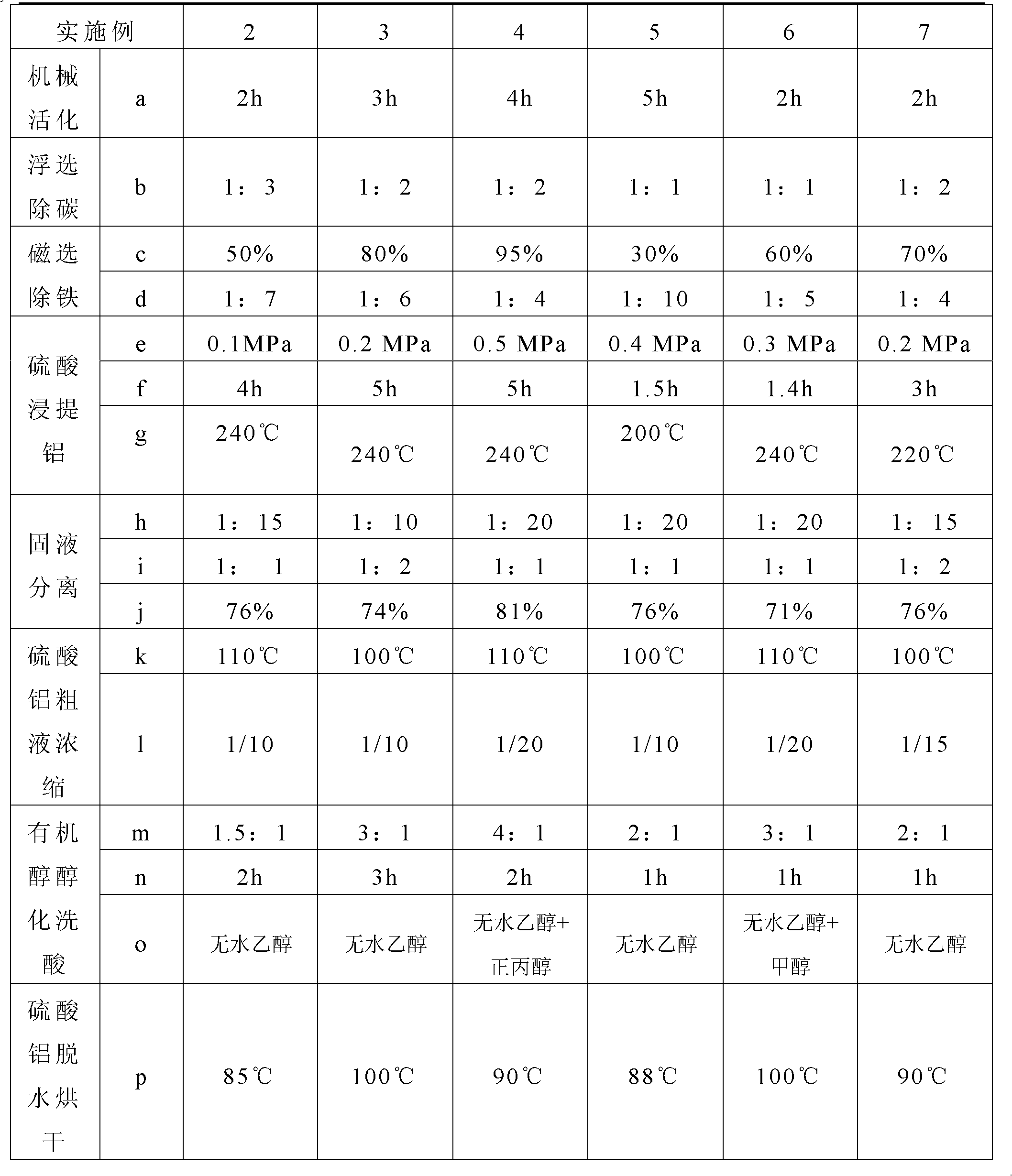

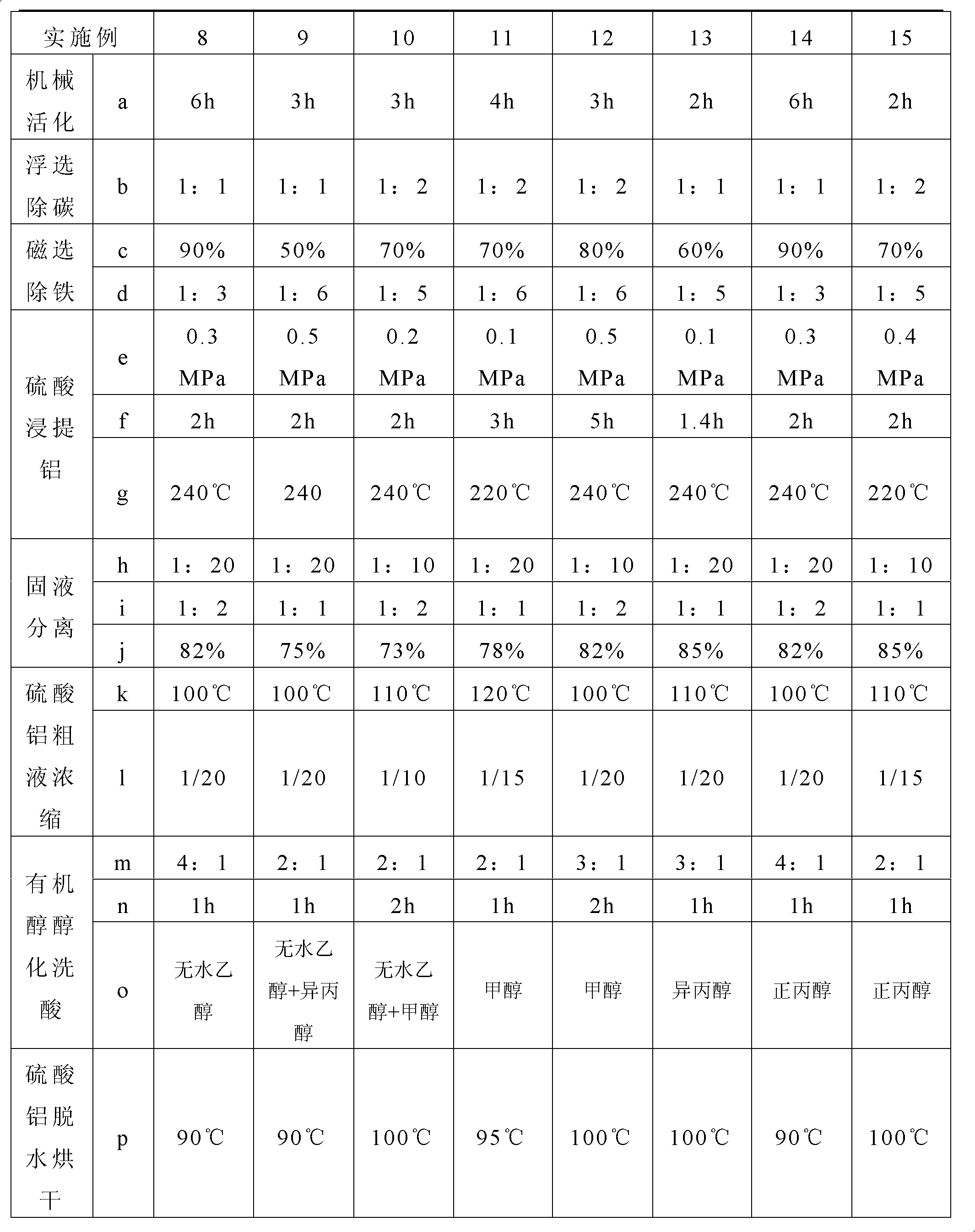

Examples

Embodiment 1

[0049] Example 1: Taking raw material 1 as the research object

[0050] The fly ash is ball milled in a ball mill for 1 hour for mechanical activation; add water according to the mass ratio of fly ash to water of 1:3, stir thoroughly, and remove the unburned carbon black after flotation. The unburned carbon black can be used It is used to produce carbon black or directly burned to produce heat; then through magnetic separation to remove iron oxide, the magnetite powder obtained through wet magnetic separation is used to produce cement, make iron black pigments or iron making; The fly ash residue after iron separation is mixed with concentrated sulfuric acid to form a mixed solution with a sulfuric acid mass concentration of 40%. The solid-liquid ratio of the fly ash and the mixed solution is controlled to be 1:8, and the heating and pressure reaction is carried out in the acid-resistant reaction equipment 3h, the highest temperature of the reaction is 240℃, the pressure is 0.5MPa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com