Copious cooling pulverizer and working method thereof

A pulverizer and cryogenic technology, applied in the field of low-temperature crushing, can solve problems such as the inability to guarantee low energy consumption operation, the inability to ensure the economical recycling of liquid nitrogen, and the inability to guarantee the brittleness of materials, so as to facilitate collection, reduce energy consumption, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with accompanying drawing of description and specific embodiment:

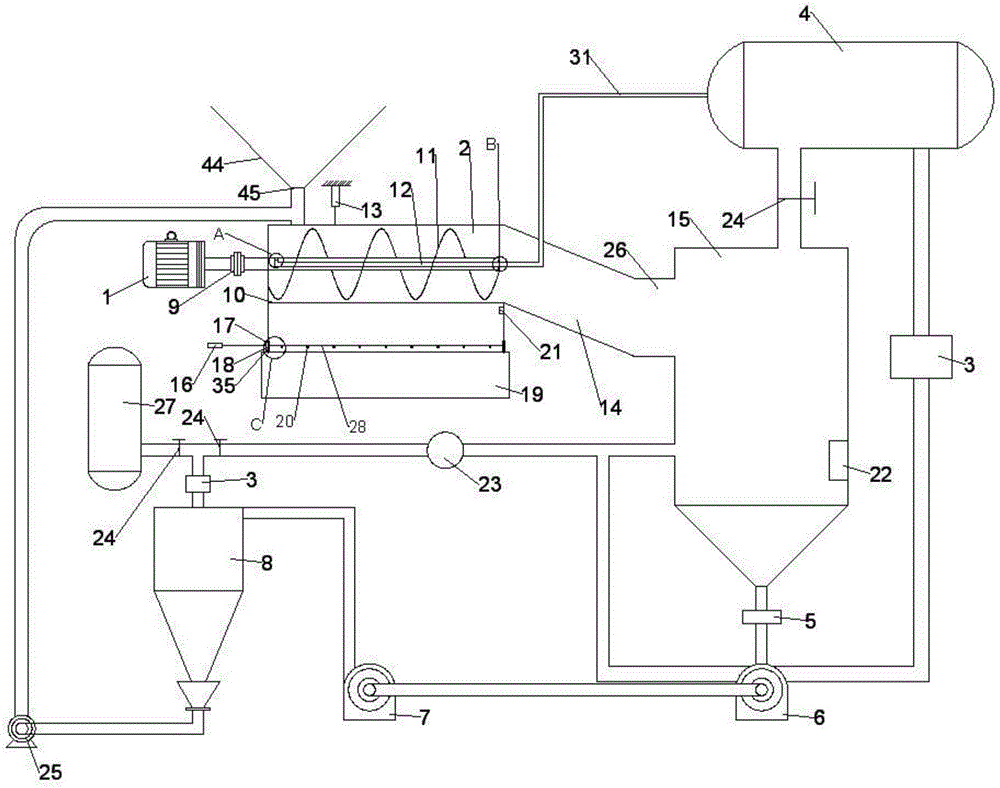

[0055] Such as figure 1 , a cryogenic pulverizer, comprising a motor 1, a hopper 44, a material precooling chamber 2, a material freezing chamber 15, a cryogenic mill 6, an induced draft fan 7, a cyclone separator 7, a bag filter 3, a liquid nitrogen tank 4 and compressor 23;

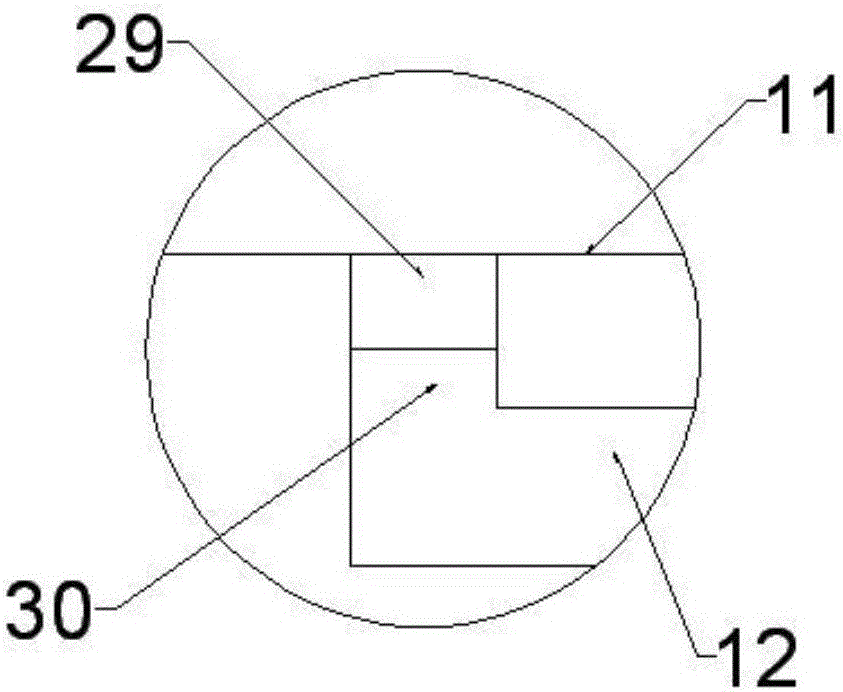

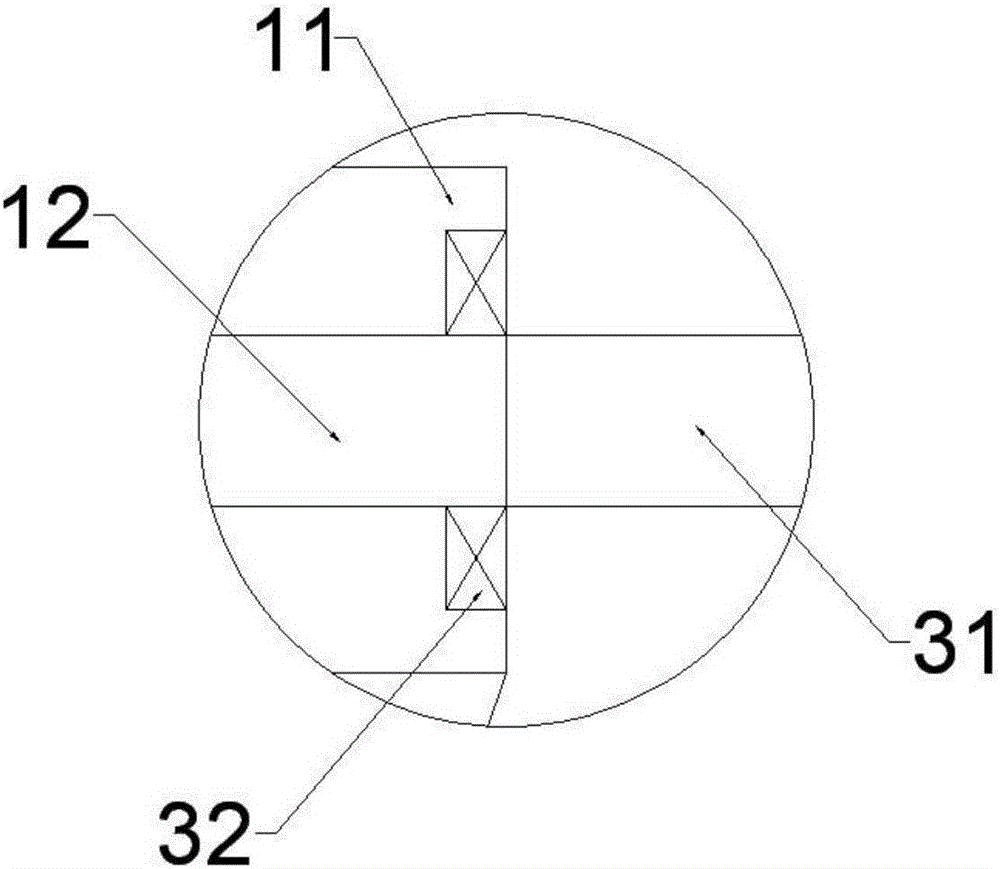

[0056] A sieve 10 is set in the middle of the material pre-cooling chamber 2, and the sieve 10 divides the material pre-cooling chamber 2 into an upper cavity and a lower cavity. The rotating shafts are connected, and the cooling blind hole 12 along the axial direction is arranged in the screw shaft 11;

[0057] The closed end of the cooling blind hole 12 is provided with a nitrogen nozzle 29 embedded in the screw shaft 11. The nitrogen nozzle 29 communicates with the cooling blind hole 12 through the nitrogen nozzle installation hole 30, and the other end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com