Preparation method of cuprous oxide hollow nanometer cubes

A hollow nanometer, cuprous oxide technology, applied in copper oxide/copper hydroxide, nanotechnology and other directions, can solve the problems of affecting the product, inconvenient cleaning of the product, affecting the purity of the final product, etc., and achieve a simple reaction system and simple production equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

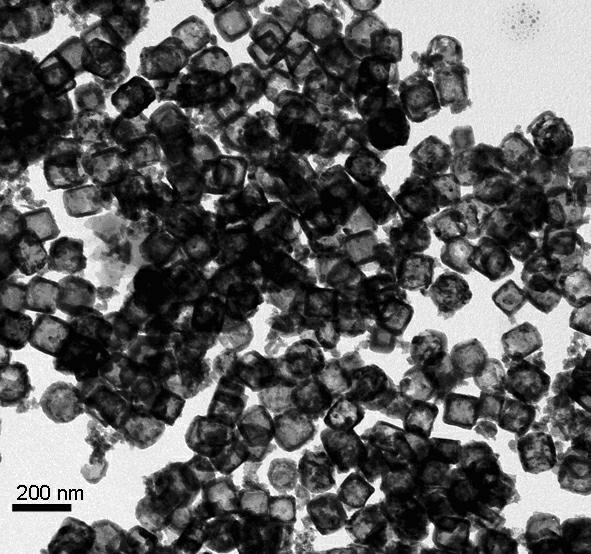

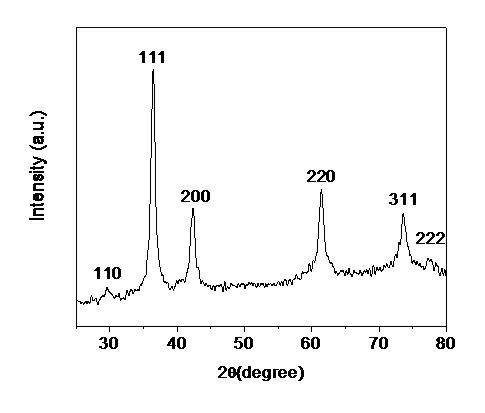

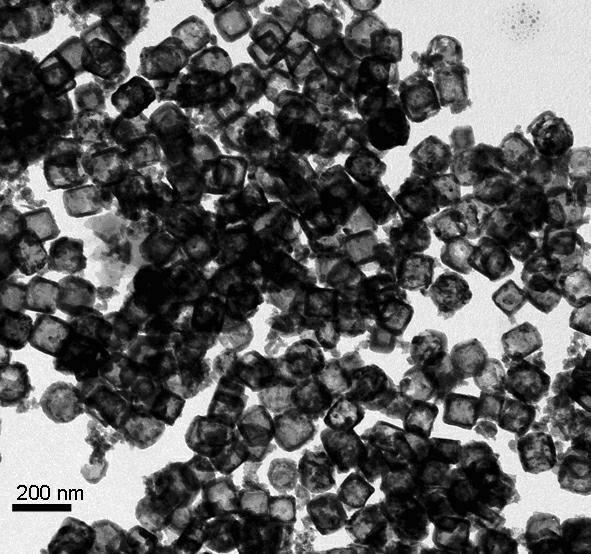

[0019] Embodiment 1: Prepare cuprous oxide hollow nanocubes according to the following steps

[0020] (1) Add copper acetylacetonate to the polyol, and raise the temperature to the reaction temperature at a certain heating rate under the stirring condition of 1000 rpm, wherein the weight ratio of the polyol to copper acetylacetonate is 1:0.0005; wherein, The polyol is ethylene glycol; wherein, the heating rate is 2°C / sec; wherein, the reaction temperature is 180°C;

[0021] (2) After reacting for 6 hours, the above solution was left to cool to room temperature, and the product was washed several times with ethanol and deionized water to obtain a light yellow precipitate, which was dried at 70°C to obtain a cuprous oxide hollow nanometer cube.

Embodiment 2

[0022] Embodiment 2: Prepare cuprous oxide hollow nanocubes according to the following steps

[0023] (1) Add copper acetylacetonate to the polyol, and raise the temperature to the reaction temperature at a certain heating rate under the stirring condition of 1100 rpm, wherein the weight ratio of the polyol to copper acetylacetonate is 1:0.001; wherein, The polyol is sorbitol; wherein, the heating rate is 3°C / sec; wherein, the reaction temperature is 200°C;

[0024] (2) After reacting for 5 hours, the above solution was left to cool to room temperature, and the product was washed several times with ethanol and deionized water to obtain a light yellow precipitate, which was dried at 70°C to obtain hollow cuprous oxide nanoparticles cube.

Embodiment 3

[0025] Embodiment 3: Prepare cuprous oxide hollow nanocubes according to the following steps

[0026] (1) Add copper acetylacetonate to the polyol, and raise the temperature to the reaction temperature at a certain heating rate under the stirring condition of 1250 rpm, wherein the weight ratio of the polyol to copper acetylacetonate is 1:0.01; wherein, Polyhydric alcohol is glycerol; Wherein, described heating rate is 4 ℃ degree / second; Wherein, described reaction temperature is 220 ℃ degree;

[0027] (2) After reacting for 3 hours, the above solution was left to cool to room temperature, and the product was washed several times with ethanol and deionized water to obtain a light yellow precipitate, which was dried at 70°C to obtain a cuprous oxide hollow nanometer cube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com