Method for synthesizing nickel sulfide nanorods through solid-liquid phase reaction and prepared nanorods

A nickel sulfide and nanorod technology, applied in nickel sulfide, nanotechnology and other directions, can solve the problems of uneven product morphology and complex preparation process, and achieve the effects of short reaction time, simple reaction system and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In a clean 250 mL ground-necked three-neck flask, add 0.25 g Ni(acac) 2 Solid, 2.4 mL of n-dodecylmercaptan and 5 mL of octadecene were heated in a sand bath to 6 o C / min rate of heating up to 250 o C, after reacting for 45 min, cool down to room temperature naturally. To obtain a black solution, add n-heptane to disperse, then add ethanol to precipitate, centrifuge to separate the solid, remove the upper colored solvent, and obtain a black solid precipitate. The black precipitate was repeatedly washed 4-5 times with n-heptane and absolute ethanol, and then vacuum-dried at room temperature for 4 hours for analysis and characterization.

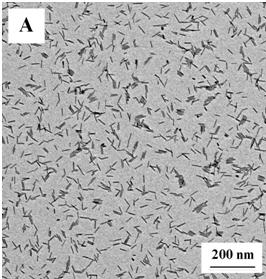

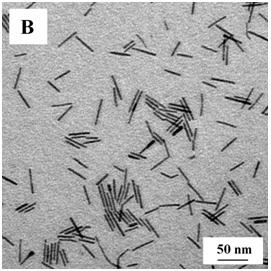

[0034] Its morphology and structure were observed with a transmission electron microscope (TEM) (Figure 1). The results showed that the obtained NiS was a rod-like nanostructure with an average diameter of 4 nm, a length of 27-50 nm, and an aspect ratio of 7-12.

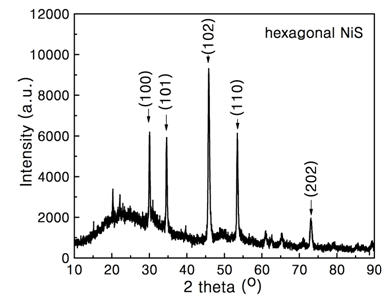

[0035] Its composition and phase structure were analyzed by X-Ray pow...

Embodiment 2

[0038] In a clean 250 mL ground-necked three-neck flask, add 0.50 g Ni(acac) 2 The solid, 4.8 mL of n-dodecylmercaptan and 8 mL of octadecene were heated in a sand bath, and the temperature was raised to 250 °C at a rate of 6 °C / min. After reacting for 45 min, it was naturally cooled to room temperature. To obtain a black solution, add n-heptane to disperse, then add ethanol to precipitate, centrifuge to separate the solid, remove the upper colored solvent, and obtain a black solid precipitate. The black precipitate was repeatedly washed 4-5 times with n-heptane and absolute ethanol, and then vacuum-dried at room temperature for 4 hours for analysis and characterization.

[0039] The morphology and structure were observed with a transmission electron microscope (TEM). The results showed that most of the obtained NiS were rod-like nanostructures. The average diameter of the rods was 5 nm, the length was 30-70 nm, and the aspect ratio was 6-12.

[0040] XRD result is identical...

Embodiment 3

[0042] In a clean 250 mL ground-necked three-neck flask, add 0.25 g Ni(acac) 2 Solid, 4.8 mL of n-dodecylmercaptan and 8 mL of octadecene were heated in a sand bath to 6 o C / min rate of heating to 280 o C, after reacting for 30 min, cool down to room temperature naturally. To obtain a black solution, add n-heptane to disperse, then add ethanol to precipitate, centrifuge to separate the solid, remove the upper colored solvent, and obtain a black solid precipitate. The black precipitate was repeatedly washed 4-5 times with n-heptane and absolute ethanol, and then vacuum-dried at room temperature for 4 hours for analysis and characterization.

[0043] The morphology and structure of the obtained NiS were observed with a transmission electron microscope (TEM). The results showed that the obtained NiS part was a rod-like nanostructure with an average diameter of 5 nm, a length of 25-40 nm, and an aspect ratio of 5-8.

[0044] XRD result is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com