Magnetic separation type composite adsorbing material and preparation method thereof

A composite adsorption material, magnetic separation technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problem of reaction mechanism analysis, solvent recovery and waste liquid treatment difficulties, unable to meet actual production and large-scale applications, solvents and various Auxiliaries are not common in price and other problems, and achieve the effects of good external magnetic field reaction ability, lower synthesis cost, and simple and easy preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation steps of the present invention are as follows:

[0028] 1. Activated carbon fiber pretreatment

[0029] Activated carbon fiber (ACF) is a PAN (polyacrylonitrile)-based, 1.5mm thick industrial activated carbon fiber felt product purchased directly, with a specific surface area of 1402m 2 / g. First cut the carbon felt into small pieces of 5×15 cm, then impregnate it with a certain volume of 67% concentrated nitric acid (according to the submerged ACF), seal it and let it stand for more than 12 hours, take it out and rinse it with deionized water until the pH value is 6.5, Dry it thoroughly in an oven at 150°C, and store it in an oven at 120°C for future use.

[0030] 2. Nano Fe 3 o 4 One-step solvothermal synthesis of composites with ACF fibers

[0031] Accurately weigh 1.25g Fe(acac)3 (iron acetylacetonate) into a 150ml thoroughly dried Erlenmeyer flask with a stopper, accurately measure 70ml of organic solvent with a measuring cylinder, add it in...

Embodiment 1

[0034] (1) Preparation of nano Fe3O4 and ACF composite fiber adsorption material by solvothermal in situ reduction reaction with ethanol as solvent

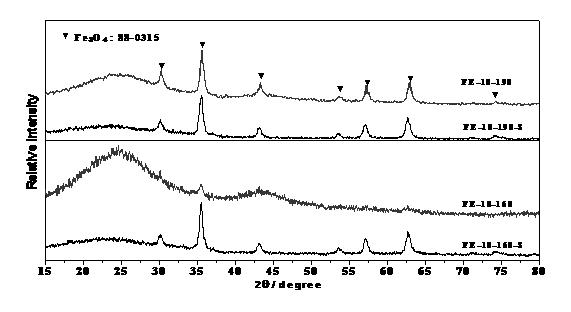

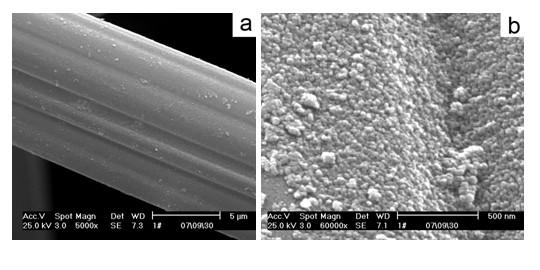

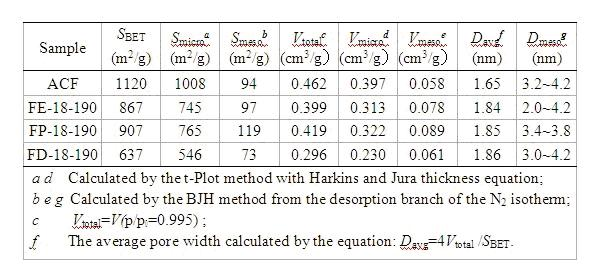

[0035] The synthesis steps are equivalent to the preparation steps in the specific embodiments of the invention above, using ethanol as the organic solvent, and the reaction temperatures are 160°C and 190°C respectively. Such as figure 1 According to the XRD spectrum, the composition of oxides in the products synthesized at two temperatures is Fe3O4, and the crystal phase is perfect. However, it can be seen from the XRD spectrum that the product loading at 160°C is much less than that of the sample at 190°C. The particle sizes of the oxide crystal phase in FE-18-160 (composite sample obtained after 18h reaction at 160°C) and FE-18-190 (composite sample obtained after 190°C reaction for 18h) were estimated to be 18.2 nm and 17.1 nm, respectively nm. FESEM image of FE-18-160 ( figure 2 ) in the distribution of the oxide partic...

Embodiment 2

[0044] The concrete steps of the preparation method of a kind of magnetic separation type composite adsorption material are:

[0045] 1) Activated carbon fiber pretreatment

[0046] Impregnate the activated carbon fiber ACF with 75% concentrated nitric acid, subject to the immersion of the ACF, seal it and let it stand for 48 hours, take it out and rinse it with deionized water until the pH value is 6, then dry it thoroughly in an oven at 100°C, and put it in an oven at 120°C Save for later.

[0047] 2) Nano Fe 3 o 4 One-step solvothermal synthesis of composites with ACF fibers

[0048] Accurately weigh 4g of iron acetylacetonate and put it into a 500mL thoroughly dried Erlenmeyer flask with a stopper, add 150ml of acetone to it with a measuring cylinder, seal it, and ultrasonically disperse it for 45 minutes to obtain nano-Fe 3 o 4 . Take 2g of ACF treated in step 1) and immerse in the prepared solution, seal it, and ultrasonically degas it for 120 minutes, then mov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com