Copolymerization reaction method for styrene/maleic anhydride

A technology for maleic anhydride and copolymerization, which is applied in the field of styrene/maleic anhydride copolymerization and achieves the effects of fast reaction rate, easy process control and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

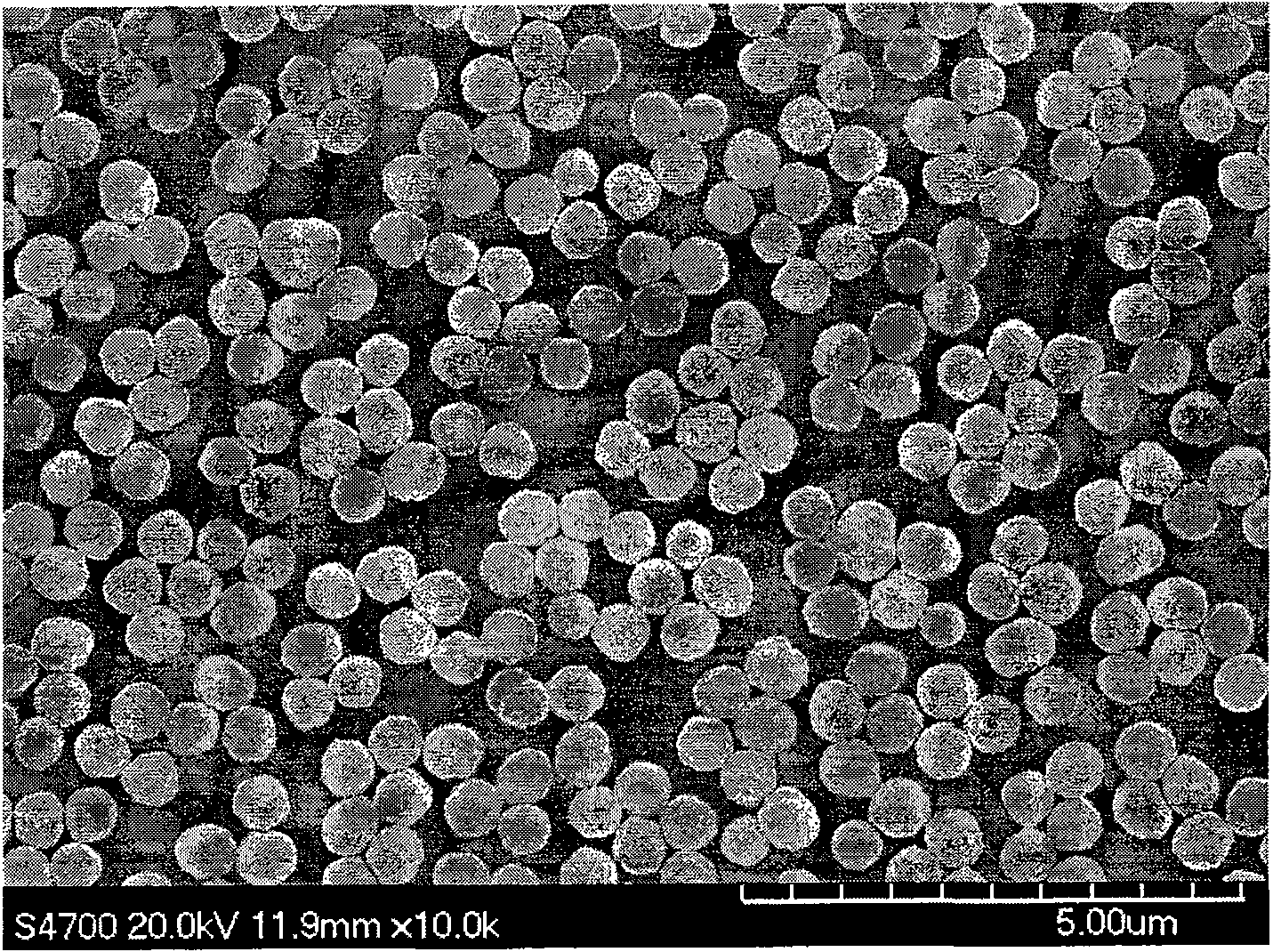

Embodiment 1

[0048] The molar ratio of MAn and St is 1:1, wherein MAn is 0.3065g and St is 0.325g; the initiator is azobisisobutyronitrile AIBN, 0.05g; the medium is isoamyl acetate, 45mL. Heating in a water bath and reacting at a temperature of 70° C. for 6 hours to obtain PMS microspheres of maleic anhydride / styrene alternating copolymer. Average particle size (Dn), dispersion coefficient (U) and polymerization yield (C p ), and the number average molecular weight (Mn) results of the polymer are shown in Table 1.

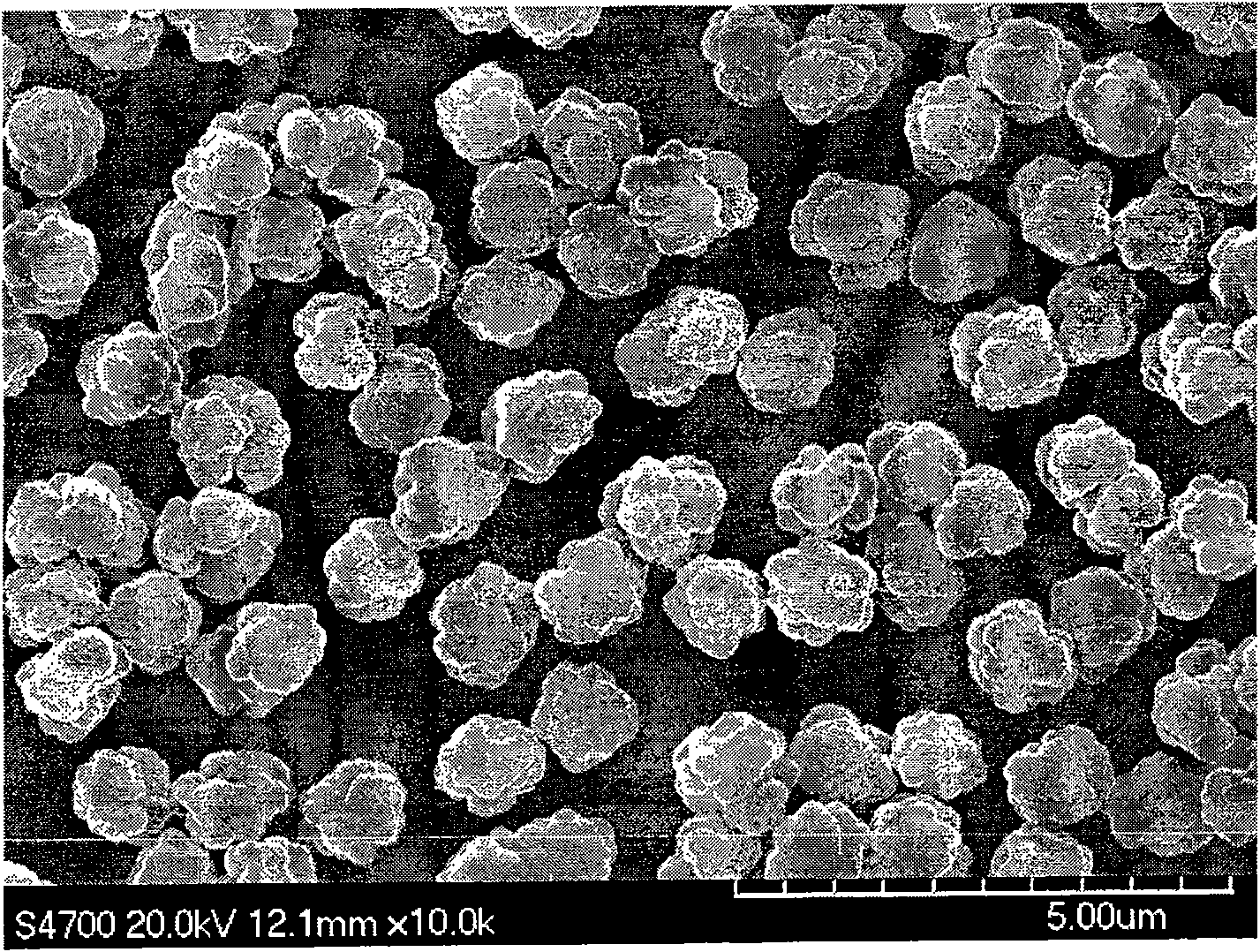

Embodiment 2

[0050] The molar ratio of MAn and St is 1:1, where MAn is 0.613g and St is 0.325g; the initiator is AIBN, 0.04g; the medium is isoamyl acetate, 45mL. Adopt water-bath heating, react 6 hours under the temperature of 70 ℃, obtain the average particle diameter (Dn) of PMS copolymer microsphere, dispersion coefficient (U) and polymerization yield (C p ), and the number average molecular weight (Mn) results of the polymer are shown in Table 1.

Embodiment 3

[0052] The molar ratio of MAn and St is 1:1, wherein MAn is 1.226g and St is 1.3g; the initiator is AIBN, 0.04g; the medium is isoamyl acetate, 45mL. Adopt water-bath heating, react 6 hours under the temperature of 70 ℃, obtain the average particle diameter (Dn) of PMS copolymer microsphere, dispersion coefficient (U) and polymerization yield (C p ), and the number average molecular weight (Mn) results of the polymer are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com