Method for preparing isosorbide based on cellulose

A technology for isosorbide and cellulose, applied in the field of preparing isosorbide based on cellulose and isosorbide, can solve the problems of inevitable equipment corrosion, increase equipment investment and maintenance costs, environmental pollution, etc., and achieve high selectivity. The effect of sexual transformation, small investment and low corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Put 0.06g of 5wt% ruthenium / hydrous niobium oxide catalyst, 0.6g of cellulose (microcrystalline, Alfa Aesar) and 30mL of water into a 100mL reaction kettle, and replace the gas with hydrogen gas for 6 times, fill it with hydrogen gas to 6MPa, and raise the temperature to 220°C for reaction After 1 h, the temperature was rapidly lowered after the reaction, and the supernatant liquid after centrifugation was taken for high-performance liquid chromatography analysis.

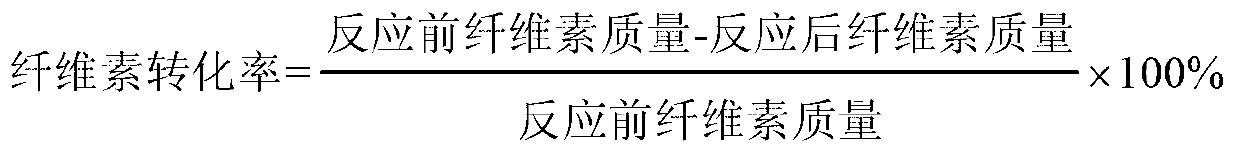

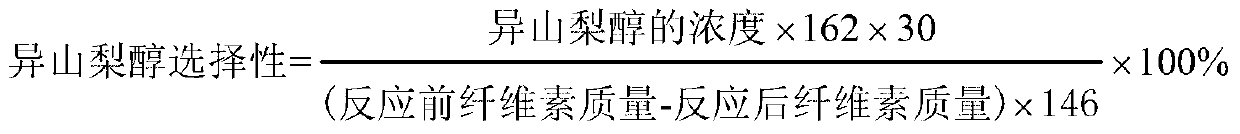

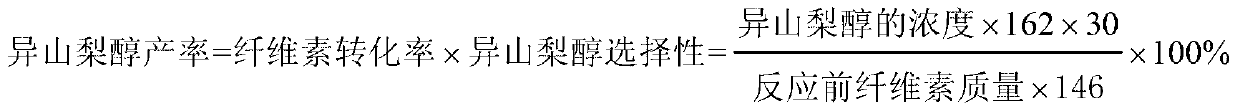

[0027] After the reaction finishes, measure the amount of isosorbide in the reaction solution according to the following method:

[0028] Quantitative analysis of the reaction products was carried out by high performance liquid chromatography (Agilent1260series HPLC, Beijing Agilent Co., Ltd.), the separation column was Alltech Prevail Carb ES, with acetonitrile and water as the mobile phase, the flow rate was 0.8mL / min, the column temperature was 30°C, and the evaporating light Scattering detector.

[0029...

Embodiment 2

[0035] Put 0.06g of 5wt% ruthenium / niobium-silicon composite oxide catalyst, 0.6g of cellulose (microcrystalline, Alfa Aesar) and 30mL of water into a 100mL reactor, and replace the gas with hydrogen gas for 6 times, fill it with hydrogen to 6MPa, and raise the temperature to 210 ℃ for 1.5 h, after the reaction was completed, the temperature was rapidly lowered, and the centrifuged supernatant liquid was taken for high-performance liquid chromatography analysis.

[0036] According to the method described in Example 1, measure and calculate the amount of isosorbide in the reaction solution.

[0037] The results showed that the conversion rate of cellulose was 98%, the selectivity of isosorbide was 32%, and the yield of isosorbide was 31.4%.

Embodiment 3

[0039] Put 0.04g of 5wt% ruthenium / niobium-molybdenum composite oxide catalyst, 0.6g of microcrystalline cellulose (microcrystalline, Alfa Aesar) and 30mL of water into a 100mL reaction kettle, replace the gas with hydrogen gas for 6 times, fill it with hydrogen gas to 6MPa, and raise the temperature React at 230°C for 0.5h. After the reaction, the temperature is rapidly lowered, and the supernatant liquid after centrifugation is taken for high-performance liquid chromatography analysis.

[0040] According to the method described in Example 1, measure and calculate the amount of isosorbide in the reaction solution.

[0041] The results showed that the conversion rate of cellulose was 99%, the selectivity of isosorbide was 33%, and the yield of isosorbide was 32.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com