Preparation method of graphene-like boron nitride loading ionic liquid catalyst and application thereof

A technology of ionic liquid and graphene, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve the difficulties of recovery and recycling, unfavorable dispersion of ionic liquids, pores Easy to clog and other problems, to achieve the effect of convenient separation, short reaction time, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

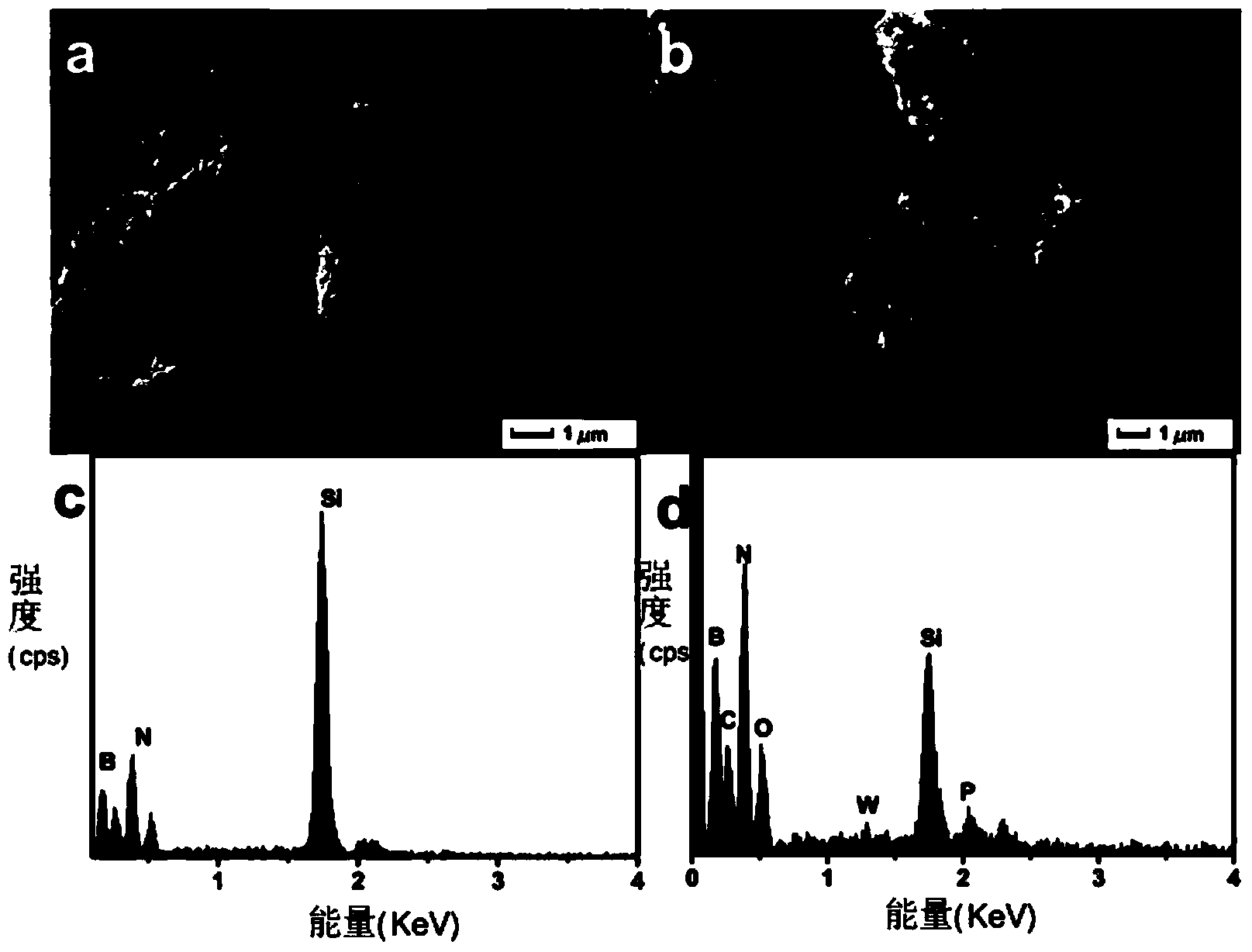

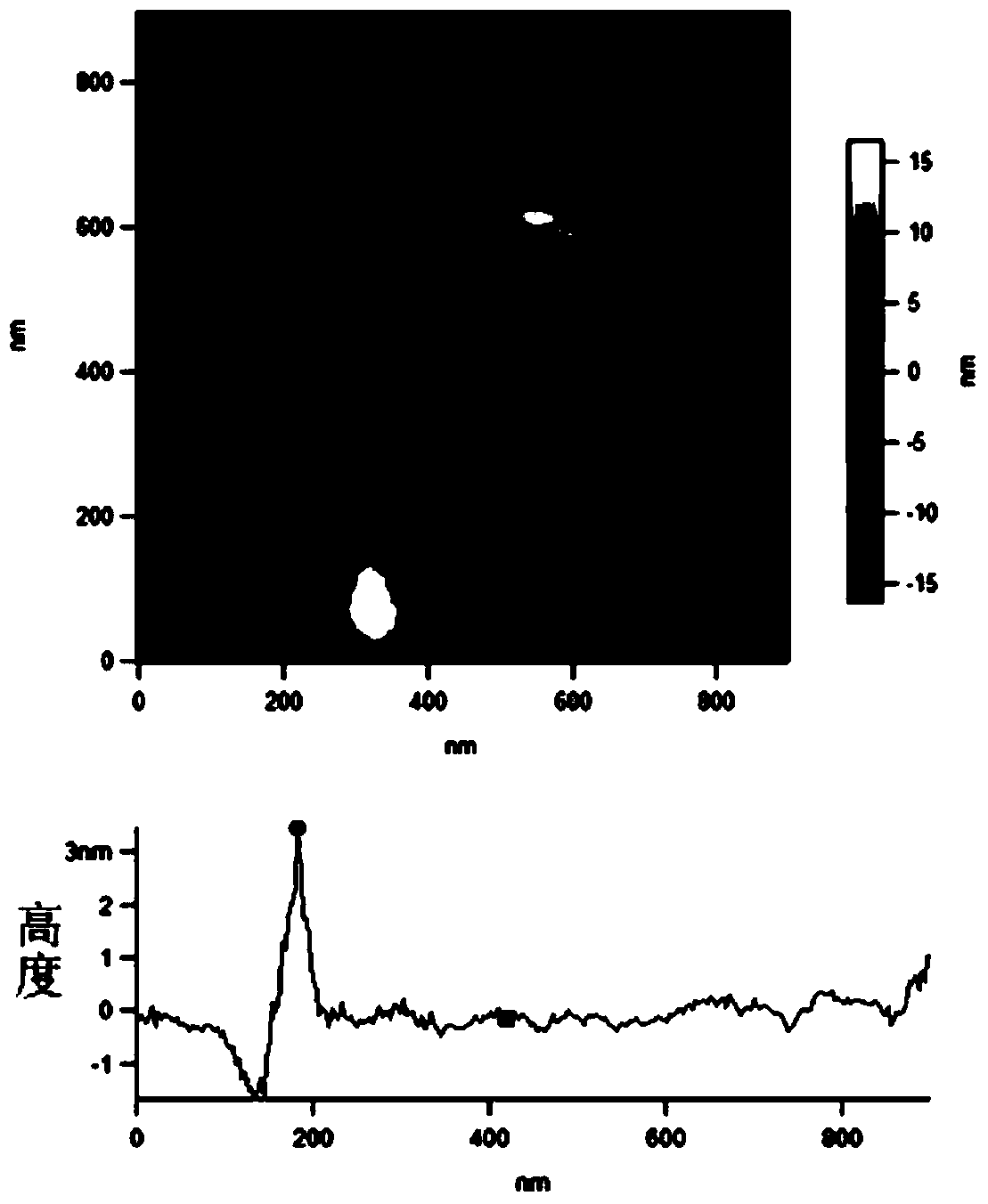

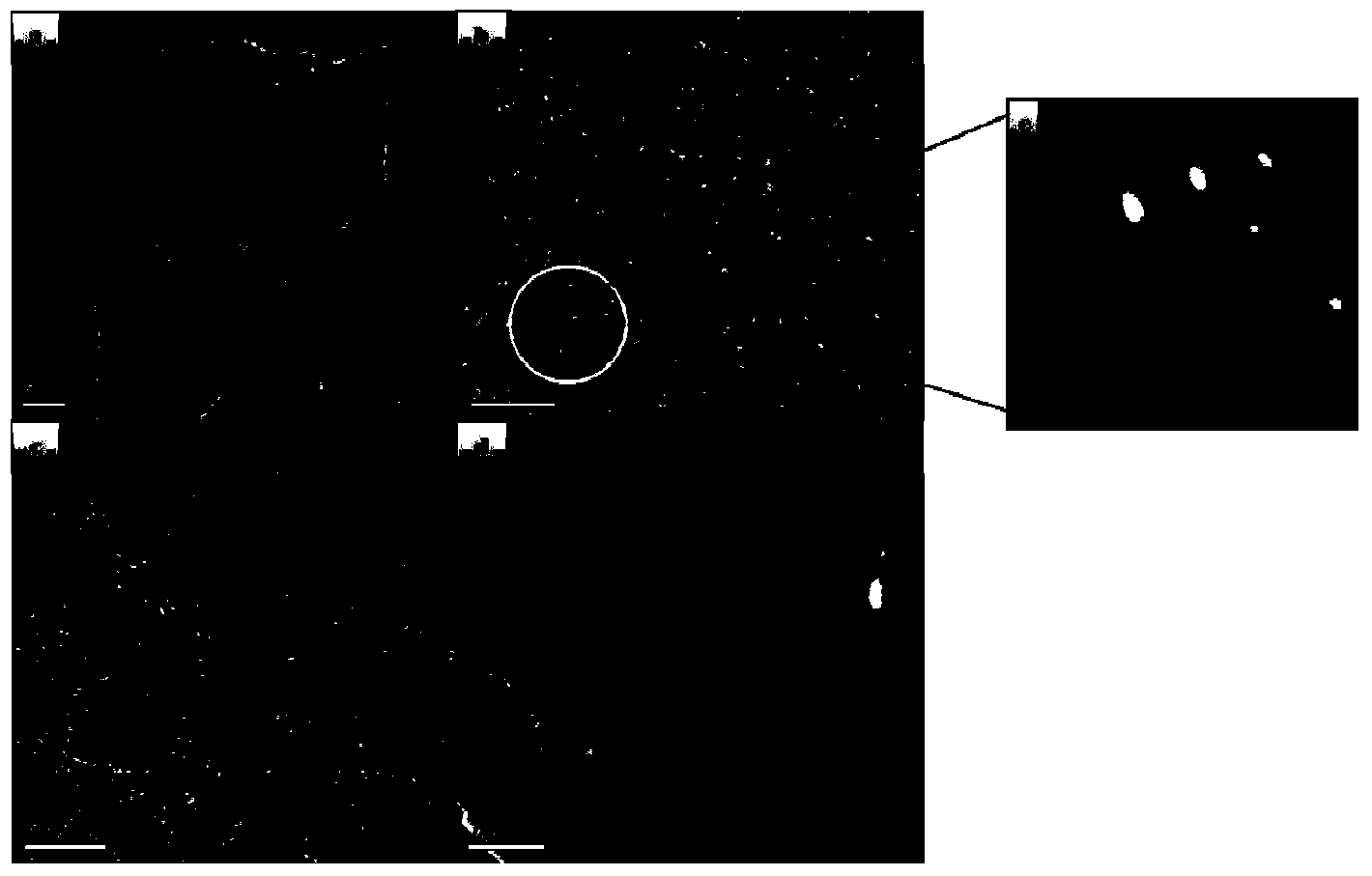

[0044] Get 0.18g graphene-like boron nitride (BN) and 0.02g [(C 6 h 13 ) 3 PC l4 h 29 ] 2 W 6 o 19 Mix and add 3mL CH 2 Cl 2 , stirred at 20°C for 3 h, dried in a vacuum oven to remove CH 2 Cl 2 , to obtain a graphene-like boron nitride-supported ionic liquid catalyst (IL / G-BN).

Embodiment 2

[0046] Get 0.19g graphene type boron nitride and 0.01g [(C 4 h 9 ) 3 PC l6 h 33 ] 2 W 6 o 19 Mix and add 3mL CH 2 Cl 2 , stirred at 30°C for 3 h, dried in a vacuum oven to remove CH 2 Cl 2 , to obtain a graphene-like boron nitride-supported ionic liquid catalyst (IL / G-BN).

Embodiment 3

[0048] Get 0.1g graphene type boron nitride and 0.05g [(C 6 h 13 ) 3 PC l4 h 29 ] 2 Mo 6 o 19 Mix and add 3mL CH 2 Cl 2 , stirred at 30°C for 3h, dried in a vacuum oven to remove C 3 h 7 Cl to obtain a graphene-like boron nitride-supported ionic liquid catalyst (IL / G-BN).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com